Professional Documents

Culture Documents

9.underground Mining With Backfill

9.underground Mining With Backfill

Uploaded by

Anonymous EyAgVDtAiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

9.underground Mining With Backfill

9.underground Mining With Backfill

Uploaded by

Anonymous EyAgVDtAiCopyright:

Available Formats

Underground Mining with Backfill

by

Tony Grice

Senior Mining Engineer

Australian Mining Consultants

L19/114 William Street, Melbourne, VIC 3000

tgrice@ausmin.com.au

Tel: +61 3 9670 8455

Fax: +61 3 9670 8311

The 2nd Annual Summit Mine Tailings Disposal Systems, Brisbane

24-25 November 1998

UNDERGROUND MINING WITH BACKFILL

INTRODUCTION

Backfill is an increasingly important component of underground mining operations around

the world. This paper will give a brief overview of the current application of mining with

backfill technology, focusing on Australian operations. In the context of this summit, the

disposal of mine tailings underground not only reduces the environmental impact but

provides the base of an engineering material which can be used to improve both the

ground conditions and the economics of mining. Carefully engineered and efficiently run

backfill systems can significantly enhance a mining operation. By contrast, badly

engineered and poorly run backfill can be a serious impediment to the mine and, worst of

all, compromise safety.

This paper will briefly describe how backfill contributes to a mining operation, the types

available and some mining methods that use it. It will cover the method of selecting the

appropriate backfill system and some of the challenges and opportunities that arise from

the selection process.

The paper will discuss each of the backfill types in turn, commencing with hydraulic fills.

The concept of mine tailings disposal will be expanded to include waste rock in order to

cover the important rock backfill systems, which are used in the biggest underground

mines. The paper will then cover pastefill, which has been newly reintroduced into

Australia.

The following terms will be used throughout:

Hydraulic backfill

Deslimed mill tailings slurries, with densities raised to

over 70%Cw (solids by weight). The coarser fractions are

placed underground as hydraulic backfill and the slimes

rejected to the surface dam.

Paste backfill

Total mill tailings filtered or thickened to around 80%Cw

to which cement and water is then added to achieve the

required rheological and strength characteristics. Any

rejects to the dam are at the full tailings sizing range.

Rock backfill

Waste rock from surface or underground and crushed to

a typical top size of around 40mm. This can be placed as

is or with cemented hydraulic backfill slurry or cement

water slurry.

WHAT IS BACKFILL?

Backfill refers to any waste material that is placed into voids mined underground for the

purposes of either disposal or to perform some engineering function. Waste materials used

include waste development rock, deslimed and whole mill tailings, quarried and crushed

UNDERGROUND MINING WITH BACKFILL

aggregate, and alluvial or aeolian sand. Other exotic backfill types used overseas include

ice and salt.

The waste materials are often placed with very lean cement or other pozzolanic binders to

improve the strength properties.

Gravity based delivery methods are utilised for slurry based systems with the dense

tailings slurry being delivered by pipeline to the disposal point in the stope. These

pipelines can range from low pressure (less than 1MPa) turbulent flow systems for

deslimed slurries to high pressure (greater than 5MPa) laminar flow systems for pastefill.

Sometimes backfill only acts as a void filler and needs only sufficient strength to prevent

any form of remobilisation. Where backfill is used as an engineering material it requires

sufficient strength be exposed by ore pillar mining in tall vertical faces or undercuts. Lean

cement addition is used to generate unconfined compressive strengths ranging from 0.5 to

4 MPa.

The other essential requirement is that backfill must be of low cost. Typical costs of

backfill range from $2 to $20 per cubic metre, depending on the duty required. These

costs can be a significant contribution to the operating costs of the mine. Where cemented

backfills are used, these costs tend to be between 10 and 20% of the total operating cost

of the mine and cement represents up to 75% of that cost.

3

WHY BACKFILL?

Backfill has a typical low modulus of elasticity of around 500MPa and is typically one to

two orders of magnitude less stiff than the surrounding rock. The purpose of the backfill is

not to transmit the rock stresses, but to reduce the relaxation of the rock mass so the rock

itself will retain a load carrying capacity and will improve load shedding to crown pillars

and abutments (Barrett et al, 19781). This leads to less deterioration in ground conditions

in the mine, improving operations and safety.

Adding low percentages of ordinary Portland Cement (OPC) of between 3% and 6% by

weight, permits the development of cohesive strength and the ability for the backfill mass

to be self supporting when exposed in vertical faces by adjacent pillar mining. The self

supporting nature of the backfill permits higher recovery of pillar ore, which in turn

improves the utilisation of the mining reserve and the economics of the mining operation.

Increased ore recovery results in longer mine lives.

In some mining methods the backfill forms a working platform for people and equipment

and therefore must be capable of supporting the traffic. Generally, cement is not required

in this application.

UNDERGROUND MINING WITH BACKFILL

The placement of backfill underground directly reduces the quantity to be disposed on

surface. This has direct operating and capital cost benefits and reductions in future

rehabilitation costs.

Nantel (19982) raised the emerging trend in Canada where future environmental

permitting for underground mines will require the return of the maximum quantity of mine

wastes to the underground workings. This trend has reached the logical limit in the recent

Federal Government recommendation approving an option for the proposed Jabiluka

Mine (JMA alternative) where ALL milling wastes may be required to be placed

underground.

4

MINING METHODS USING BACKFILL

Early mining methods either left open voids after the ore had been removed or permitted

the caving of the surrounding waste rock. Caving methods often resulted in surface

subsidence. Temporary and permanent timber supports enabled larger sized workings and

there is a rich history of mining in the 18th and 19th centuries using timber alone. One of

the earliest records of backfilling in Australia as a discrete technique was the placement of

aggregate from lead jig wastes at Mount Isa in 1933 tipped directly from the mill by

conveyor to square set timber stopes. This was done both for disposal purposes and for

stabilising the working areas by providing an improved platform.

Cut and fill mining methods evolved to use hydraulic fill as a bulk filling material. The

tailings slurries were deslimed and densified to achieve a reasonable permeability and to

minimise the water that would drain out. The fill would provide an effective surface to

walk on after a few hours and for equipment to be moved on it within a day or so. The fill

would provide a mucking horizon and confinement to the exposed rock below. In some

mines, cement was routinely added to improve cohesion but at significant additional cost.

Rock and other mine wastes were routinely disposed in cut and fill stopes.

At the Black Swan nickel mine in WA, a marker bed of finely graded and compacted sand

is placed on the top of the placed rockfill to act as a digging horizon and to prevent the

loss of high grade nickel ore into the fill (McGurk & Lock, 19983). At Henty Gold Mine

in Tasmania, paste backfill is being placed in the cut and fill stopes (Henderson et al,

19984).

The benching method evolved from experience with sub level open stoping and applying

the long hole drilling methods to the cut and fill mining areas. At Mount Isa, the cut and

fill stopes (MICAF) were initially mechanised to use trackless development equipment

(MECAF) and then long hole drilling rigs were introduced to mine several lifts in one go,

over short strike lengths. Hydraulic backfill, dry aggregate and mine development waste

are used when available (Villaescusa & Kuganathan, 19985). The controlling factors on

backfill placement are the need to maintain stable bench sizes and the need for working

platforms for the heavy mobile equipment.

UNDERGROUND MINING WITH BACKFILL

Long hole open stoping methods with post backfill have become a major low cost mining

method around the world. By designing integrated mining and backfill systems, very high

ore extraction ratios are possible. Using combinations of cemented and uncemented

backfill optimises costs. At Mount Isa, crushed rock was added at high ratios to cemented

hydraulic fill to create very lean cement masses. Early experience quickly showed that

exposures 40 metres wide and virtually unlimited in height could be created with little risk

of fill failure (Leahy & Cowling, 19786). A large number of stopes were filled with

cemented hydraulic fill alone where geometry precluded the addition of rock. All stopes

not requiring future re-exposure were filled with uncemented hydraulic fill. These stopes

were an important part of the backfill operations since these stopes often formed low

priority sand dumps where deslimed tailings could be placed whenever other sources

were not available. Considerable quantities of deslimed tailings have been placed

underground at Mount Isa through the life of the mining operation. Bloss (19967) records

that 64 million tonnes of backfill has been placed into the 1100 Orebody since 1973, over

half of which has been deslimed tailings.

Coal mining in Australia has not traditionally used backfill, relying instead on caving of the

overlying sediments with surface subsidence occurring in shallower operations. By

contrast, Polish coal operations have widely used hydraulic backfill to both minimise

surface subsidence and to enable thick seam extraction methods (Palarski, 19938). An

Australian desktop study (ACARP, 19979) has identified the use of washery tailings to

improve the extraction potential of punch mining in highwall coal operations.

More recently, Wambo Mining Corporation placed cemented backfill into a series of

headings in the path of the Longwall No. 9 at Homestead Colliery near Singleton. The

sand, flyash and cement mix was designed to 4MPa strength. This permitted the

uninterrupted mining through the heading area without the need for several weeks of

shutdown. No ground stability problems were encountered and Wambo concluded that

the cost of the backfill project was revenue positive. This technique has a wide range of

applications to underground coal mining problems.

Lane10 will be discussing details of disposal of tailings into open pits later in this summit.

Other uses of backfill in open pits include the early extraction of ore in the crown between

the pit and the underground workings and replacing it with a stiff and impermeable

backfill pillar.

5

FRAMEWORK FOR BACKFILL SELECTION

The selection of a backfill system for a mine is increasingly a part of the overall plan for

the mining of the orebody. This plan takes into account the full life cycle of the operation,

including shutdown and rehabilitation of the site. Clearly, the use of backfill in the mine

will reduce these end of life costs and the overall environmental impact. Discounted

cashflow techniques are the appropriate technique to provide the economic analysis. This

UNDERGROUND MINING WITH BACKFILL

permits assessment of the full operating and capital costs of the project and takes into full

account the impact of expenditure on backfill now compared to rehabilitation later.

The assessment of the use of backfill in a mine is an iterative process. During the

feasibility stage, a number of mining methods may be identified for a particular orebody.

Factors such as mining rate, resource recovery and dilution levels are considered. These

will provide a base set of options from which improved alternatives can be compared. The

mining methods can then be considered from the view of the backfill systems. Questions

arise that need to be addressed;

What improvements to ground conditions can be expected?

What is the increase in resource recovery rate?

What is the impact on ventilation?

Do the dilution rates increase or decrease?

Will cement from fill dilution affect metallurgical recoveries?

Is cyanide an issue?

The answers to some of these questions can have a significant impact on the mining

method selection and this cycle of mining method and backfill type design can iterate a

number of times to determine possible options.

The primary source of backfill materials will be local to the mine. As this summit attests,

the tailings from the processing of ore are the most readily available source of backfill

materials. Placement as backfill will directly offset disposal costs and will have

environmental credits that are frequently intangible within our current costing and

accounting systems. Understanding the characteristics of the tailings material such as

sizing, mineralogical composition, rheology and reactivity are important numbers of which

we will hear much discussion during this summit.

Open cut operations move considerable quantities of waste rock. Will that rock be

suitable for use as an aggregate in backfill? The Australian experience would be that much

of the weathered surface rock in this country is unsuitable, but fresh or marginally

weathered material is frequently acceptable. The underground development operations, by

contrast, produce large volumes of fresh broken rock, much of which is suitable for

backfill use.

Surface sand is a valuable resource for backfill use. Prestripping operations to prepare for

surface infrastructure, the pit, waste dumps and even the tailings dams themselves can

yield useful quantities of material. This can be used directly as backfill material such as the

proposed use at NFMs Callie Mine where the initial sand will be sourced ahead of the

UNDERGROUND MINING WITH BACKFILL

waste rock dumps. In Canada, the use of alluvial and glacial sands is common in pastefill

systems to improve both the economics and the performance.

The primary external component of backfill will be the cement binder. The uncompetitive

cost of domestic cement supplies and the transport distances involved result in cement

costs representing over one half of the total cost of backfill systems. There has been

continual research into alternative binders such as pozzolans to minimise this cost. Mount

Isa has used ground copper furnace slag since the early seventies and Olympic Dam uses

fly ash. In Canada, iron blast furnace slags are widely used.

For each of the backfill materials, various process and transport methods are available.

Each of these should be considered in turn. For example, Olympic Dam deslimes the

neutralised mill tailings, raises the density of the slurry, adds binder and crushed aggregate

in a pugmill. The resultant mix is then transported in 30 tonne end tipper trucks and

dropped into vertical boreholes drilled from surface to each stope below at 400 metres

depth. Scuddles Mine in WA deslimes the tailings and then delivers the high density slurry

by gravity pipeline to the underground workings. When the backfill system is running the

slimes fraction is sent to the tailings dam and during down times, the full mill tailings go to

the dam.

The range of mining methods, backfill types, supply and processing options are then put

together to determine a short list of two or three technically feasible systems. Only those

systems that meet all of the operating and geotechnical needs of the mine are included in

this list. The systems are then assessed economically using discounted cash flow

techniques and using long term or life of mine time scales. Tangible environmental factors

are readily included at this phase of the analysis.

The mining systems with backfill are then ranked in terms of technical feasibility and

economic desirability. These are compared to the base case and the change in project net

present value can be used as the major economic indicator. In a recent study conducted by

the author an older mine, which was considering backfill to improve ground conditions,

demonstrated an increased value by the introduction of backfill. This was despite the

increased operating cost since backfill permitted sill pillar recovery and extended the life

of the mine and cashflow by an additional 6 to 9 months.

6

BULK AND EXPOSABLE BACKFILLS

There are several ways of classifying backfills, both by type and by function. An essential

distinction from the design point of view is whether the backfill is to be used essentially as

void filler or will it be exposed by future mining of ore pillars. Prior to the advent of paste

backfill systems this classification could be described as cemented or uncemented.

However, paste needs small quantities of cement in all backfill placed to eliminate the risk

of liquefaction, therefore this classification is no longer appropriate. A preferred

classification is given below:

UNDERGROUND MINING WITH BACKFILL

Bulk Backfill

Waste materials placed into a stope for the purpose of

disposal and or to provide confinement to surrounding rock

walls. The upper surface can be used as a working platform.

Resistance to rock wall closure effected by intergranular

friction of the backfill.

Exposable Backfill

Engineered materials with cement and or other binder added

which has sufficient cohesion to support its self weight when

exposed either as a vertical face or in an overhang by the

blasting of adjacent pillar ore.

CEMENT AND OTHER BINDERS

The strength of particulate materials is generated by intergranular friction with little or no

cohesion present. Sometimes, water tension in unsaturated conditions can generate an

apparent cohesion. Thats why wet sand works better for sandcastles than dry sand. Since

we cant control water content to such a fine degree then other binders must be added to

provide the cohesion and increase the strength of the material.

By far the commonest binder that is added to backfill is OPC GP Grade. Typical

addition rates up to 6% by weight are added into hydraulic fill and 4.5 to 5% by weight

into paste fill and rock fills. The cemented rock fills which utilise hydraulic fill as the

source of fines are the most efficient consumers of cement and total addition rates as low

as 2% can be used.

These addition rates generate cohesion values of around 250 to 500kPa and unconfined

compressive strengths from 0.75 to 4MPa. These strengths are sufficient to enable the

backfill to be exposed in vertical walls up to 40 metres wide and virtually unlimited in

height.

The cost of cement can represent more than half of the operating cost of the backfill

system. There has been continuous research around the world into alternative binders and

the most common solution has been the use of pozzolans such as fly ash and blast furnace

slags.

OPC is a hydraulic cement, which means that it reacts with water alone to form the

cement binding alumino-silicate products. Pozzolans, by contrast, require the presence of

lime in addition to the water for the cementing reaction to proceed. The lime is usually

generated as a by-product of the initial hydraulic cement reaction.

Mount Isa uses ground copper furnace slag to replace half of the cement in backfill and

has saved over 25,000 tonnes of cement annually as a result. Olympic Dam utilises flyash

from Port Augusta.

UNDERGROUND MINING WITH BACKFILL

More recently, synthesised hydrophilic alumino-silicates have been developed in China11.

These complex binders are capable of taking up 32 molecules of water per binder

molecule and have been demonstrated to solidify tailings slurries of around 50%Cw with

only low addition rates. These binders are currently not commercially viable.

Gypsum has been tested as an alternate binder with limited success (Petrolito et al,

199812). Gypsum is being used for pillar replacement in small gold mine applications.

8

BACKFILL TYPES AND MATERIALS

The three backfill types that will be discussed are:

Hydraulic backfill

Deslimed mill tailings slurries, with densities raised to

over 70%Cw (solids by weight). The coarser fractions are

placed underground as hydraulic backfill and the slimes

rejected to the surface dam.

Paste backfill

Total mill tailings filtered or thickened to around 80%Cw

to which cement and water is then added to achieve the

required rheological and strength characteristics. Any

rejects to the dam are at the full tailings sizing range.

Rock backfill

Waste rock from surface or underground and crushed to

a typical top size of around 40mm. This can be placed as

is or with cemented hydraulic backfill slurry or cement

water slurry.

HYDRAULIC BACKFILL

Hydraulic backfill is produced by cycloning of mill tailings slurries to produce a coarse

dense underflow. Typical specifications of hydraulic backfill are:

Not more than 10% by weight of size fraction less than 10 (micrometres) in

size. This ensures that acceptable permeability of the placed fill is achieved.

Slurry density is greater than 70%Cw (solids by weight). The high density

minimises the drainage of transport water. The target density is a function of

particle specific gravity and the controlling parameter is %Cv (solids by volume)

which balances the requirement to transport the slurry without plugging the line

and excess drainage water. The practical range is between 45%Cv and 50%Cv.

Hydraulic backfill slurries are transported by gravity through boreholes and pipelines to

the stopes. The slurry enters the stope and the solid particles consolidate rapidly. The

excess transport water in the slurry will initially pond above the current solids layer, but

under the influence of gravity will commence on a generally vertical drainage path

UNDERGROUND MINING WITH BACKFILL

downwards. The rate of drainage is a function of the permeability of the backfill and the

driving head. The quantity of water that will drain is a function of the initial slurry density

and the residual moisture content of the backfill. The quantity of drainage resulting from

slurry densities of around 70%Cw is as little as a quarter of the drainage resulting from

55%Cw slurries.

Free draining hydraulic backfill has a typical porosity of around 50%, can be walked on in

a few hours and is trafficable within 24 hours.

Where the hydraulic fill is to be exposed, cement addition rates of around 6% are typically

required and this will result in unconfined compressive strengths of greater than 750kPa

within 28 days. Higher strengths and faster curing can be achieved by adding extra

cement.

At Mount Isa cemented hydraulic backfill consisting of 3% OPC, 6% ground furnace slag

(to produce 6% equivalent cement) and 91% deslimed tails are routinely exposed over

widths of 40 metres and over 100 metres high.

The primary advantage of hydraulic backfill is the simplicity and low cost of production

and delivery. Uncemented hydraulic backfill can be placed for less than $2 per cubic

metre. Increasing strength is a simple matter of adding cement.

There are two significant disadvantages to hydraulic backfill. The first is that permeable

barricades must be designed and constructed to retain the backfill and permit the free

drainage of excess transport water. Barricades are commonly built with porous concrete

bricks and take a two man crew between 2 to 3 shifts to complete. This occurs as a

critical path activity between the completion of production in a stope and the

commencement of filling.

The second disadvantage is the management of water in the fill and the requirement to

pump this water out of the mine. When controls on slurry density are lax, excessive water

can result in ponding of water in the stopes, which can lead to the development of erosion

pipes and cause barricade failure. In calendar 1997, there were nine such incidents; in

1998 there have been none reported. The risk of barricade failure and the consequences of

a backfill inrush are a serious safety issue that requires management focus to ensure that

the risk factors are managed. The guidelines of fines removal and placement at high slurry

densities eliminate those risk factors.

10

CEMENTED ROCK BACKFILL - WITH HYDRAULIC BACKFILL

The performance of cemented hydraulic backfill can be improved by the addition of

crushed rock at high proportions. The cemented rock backfill used in the Mount Isa

copper orebody includes quarried siltstone crushed to minus 75mm size to the hydraulic

fill at the rate of two parts of rock to one part of hydraulic fill. The resultant mix is 1%

OPC, 2% CRFS, 30% hydraulic fill and 66% rockfill. This mixture develops strengths of

10

UNDERGROUND MINING WITH BACKFILL

around 1.5MPa in 28 days and can be exposed in large exposures and on several sides in

succession.

The advantage of the rock addition is that it trebles the tonnage rate of filling (doubling

the volumetric rate), increases the strength and performance and reduces equivalent

cement consumption to below 2% by weight. Instantaneous backfill rate at Mount Isa is

around 350m3 per hour.

Olympic Dam uses higher cement and flyash proportions and delivers at a higher slurry

density than Mount Isa. Strengths in excess of 4MPa are routinely achieved. The new

expanded backfill system to meet the needs of the larger mining operation is designed to

place cemented rock backfill at the rate of 300m3 per hour.

Bronzewing in WA is just commissioning a cemented rock backfill system with a rate

capability of around 100m3 per hour.

11

CEMENTED ROCK BACKFILL - PC SLURRY

A variation on cemented rock backfill, widely used in Canada, utilises crushed waste rock

and Portland cement slurry added at rates of around 5% by weight. No mill tailings are

used and consequently the overall sizing curve is short on fines content. This reduces the

workability of the placed backfill and necessitates the higher cement addition rates for

equivalent strength performance. This technique has been used at the Williams Mine in

Ontario and the initial temporary filling at Bronzewing has employed a surface batching

plant to produce this type of backfill.

12

TOTAL TAILS - PASTE BACKFILL

Total tailings paste backfills were developed originally by Preussag in Germany and

utilised at the Bad Grund Mine in the late seventies. Development in South Africa and

more intensively by INCO in Canada substantially refined the system. The first paste

backfill system in Australia was installed at Elura mine in NSW in the mid 1980s but this

was not successful. More recently, Henty Mine in Tasmania commissioned a 10 to 15m3

per hour paste system and Cannington in Queensland is now running a 100m3 per hour

system. Mount Isa is constructing a 300m3 per hour hybrid plant for the Enterprise

Copper Mine capable of delivering a high density uncemented hydraulic fill or cemented

paste backfill.

Paste backfill consists of the full size fraction of the tailings stream prepared at a high

slurry density. The slurry behaves as a non-Newtonian fluid, which means that it requires

an applied force to commence flowing. An example of a Non-Newtonian fluid that is in

common use is toothpaste and the applied force (yield stress) explains why you have to

squeeze the toothpaste out of the tube. The paste has a higher viscosity than hydraulic

backfill and exhibits plug flow when transported in a pipe. The outer portions of the slurry

shear against the sidewall of the pipe and the central core travels as a plug.

11

UNDERGROUND MINING WITH BACKFILL

The friction factors generated require that high pressure pipelines are used to transport

pastefill. Pressures typically exceed 5MPa. Early systems used high pressure reciprocating

pumps but experience has shown that paste fill can be readily by transported by gravity

alone, provided that the reticulation geometry is favourable.

The higher slurry densities improve the water to cement ratios and for a given tonnage of

pastefill, lesser quantities of cement are required to achieve comparable strengths to

hydraulic backfill. This has obvious operating cost benefits.

The higher density and reduced permeability due to the inclusion of fines also results in

negligible water drainage from the paste fill. The need for engineered barricades is

removed and the nuisance of drainage water and impact on ventilation is eliminated.

Typically, backfill systems have utilisation rates of between 66% and 75% which results in

paste being deposited into the surface dams during down periods. The material placed in

the dams from a pastefill system has improved particle sized distribution over the slimes

generated by hydraulic backfill systems and improved geotechnical properties.

There are a number of disadvantages to paste backfill systems and these relate to the

higher capital cost primarily attributable to the expensive filter dewatering systems and the

complexity of operations and supervision required to ensure that line plugging does not

occur.

Because of the inclusion of the slimes fraction and the non draining nature of the backfill,

cement must be added to all pastefill placed underground including the fill that will not be

exposed by subsequent mining. Adding cement at around 1.5% by weight will eliminate

the risk of liquefaction. This aspect places a significant operating cost penalty to the use of

paste fill compared to hydraulic fill which due to its free draining nature can be readily be

placed in uncemented forms. In mines, which have high proportions of cemented backfill

such as open stoping, the disadvantage is minimal. In mining methods such as cut and fill

where the use of exposed fill is minimal, the penalty is large.

Another problem with paste backfill is the incorrect perception that ALL tailings can be

returned underground. Pastefill tends to have a lower porosity ranging from between 35%

and 50%Cw compared to between 40% and 55%Cw for hydraulic backfill. This means that

slightly more pastefill can be returned underground than hydraulic fill but the difference is

marginal. As the porosity values show it is unlikely that there will be sufficient ore

removal or void underground to place all of the fill back underground.

A recent exercise was conducted to compare the options of placing all pastefill back

underground compared to surface storage. It was shown that for this operation there was

an excess mine volume of 46% which would have to be created to store the paste. The

cost of mining this additional volume far outweighed the cost of surface disposal and

subsequent rehabilitation.

12

UNDERGROUND MINING WITH BACKFILL

13

CONCLUSIONS

Backfill is an increasingly important component of underground mining operations. As

mines get deeper, the need for improved ground control and maximised resource recovery

is essential to their safe and economic operation. The total management of waste materials

at the mine site needs to be engineered into the design of the mine. Increasingly,

environmental considerations are showing that improved waste management procedures

have benefits to the mining operations. Regulators are increasingly requiring the prior

planning of final site restoration as part of the initial mine plan.

Mining with backfill technology helps mining companies achieve many of these goals.

Backfill minimises the total quantities of materials to be managed on surface. The waste

materials can be engineered to give support and strength properties that improve the

safety of the mining operations and the economics of the enterprise.

The technology of backfilling enables a wide range of engineering solutions to particular

mine sites and their unique sets of problems and opportunities. There is not one universal

solution to backfill or mine tailings disposal systems.

AMC predicts that there will be many more developments yet to be seen in this rapidly

emerging area of technology.

14

REFERENCES

Barrett, JR, Coulthard, MA and Dight, P.M. (1978) Determination of Fill Stability, Mining with

Backfill, 12th Canadian Rock Mechanics Symposium, CIM Special Volume 19, Sudbury, Ontario May 2325, 1978

2

Nantel, J (1998) Recent Developments and Trends in Backfill Practices in Canada, Minefill 98,

AusIMM, April 14-16 1998, Brisbane

3

McGurk, TJ and Lock PR (1998) Maximising Recovery at Silver Swan Nickel Mine using Cement

Stabilisation, Minefill 98, AusIMM, April 14-16 1998, Brisbane

4

Henderson A, Jardine G & Woodall C (1998) The Implementation of Paste Fill at the Henty Gold Mine,

Minefill 98, AusIMM, April 14-16 1998, Brisbane

5

Villaescusa, E and Kuganathan, K (1998) Backfill for Bench Stoping Operations, Minefill 98, AusIMM,

April 14-16 1998, Brisbane

6

Leahy, F & Cowling R (1978) Stope Fill Development at Mount Isa, Mining with Backfill, 12th

Canadian Rock Mechanics Symposium, CIM Special Volume 19, Sudbury, Ontario May 23-25, 1978

7

Bloss, ML (1996) Evolution of Cemented Rock Fill at Mount Isa Mines Limited, Mineral Resources

Engineering, Vol. 5, No. 1 (1996), 23-43, Imperial College Press

13

UNDERGROUND MINING WITH BACKFILL

Palarski, J (1993) The Use of Fly-ash, Tailings, Rock and Binding agents as Consolidated Backfill for

Coal Mines, Minefill 93, SAIMM, Johannesburg 1993

9

BFP (1997) Improved Recovery in Highwall Mining Using Backfill, ACARP Project C3052, Australian

Coal Research Limited.

10

Lane C (1998) Reducing Capital and Operating Costs by Using Inpit Tailings Disposal: Marymia Gold

Operations Case History, 2nd Annual Summit Mine Tailings Disposal Systems, AIC Worldwide,

Brisbane 24-25 Nov 1998.

11

Sun Henghu, Liu Wenyong, Huang Yucheng & Yang Baogui (1998) The Use of High-Water Rapid

Solidifying Material as Backfill Binder and its Application in Metal Mines, , Minefill 98, AusIMM, April

14-16 1998, Brisbane

12

Petrolito J, Anderson RM & Pigdon SP (1998) The Strength of Backfills Stabilised with Calcined

Gypsum, Minefill 98, AusIMM, April 14-16 1998, Brisbane

14

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5813)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Simp Kin Radiation ShieldingDocument22 pagesSimp Kin Radiation ShieldingZoran MirkovNo ratings yet

- THW1.soft Drinks vCOMPLETEDocument2 pagesTHW1.soft Drinks vCOMPLETEjunho yoonNo ratings yet

- Mental Health: Self GrowthDocument2 pagesMental Health: Self GrowthMariennel Bontogon LacsinaNo ratings yet

- Timeline of Research No. Date Time Description of The ActivitiesDocument2 pagesTimeline of Research No. Date Time Description of The ActivitiesZikri alwiNo ratings yet

- Plasma TV: Service ManualDocument50 pagesPlasma TV: Service Manualdann222No ratings yet

- DBC - Company ProfileDocument22 pagesDBC - Company Profilesivakumar100% (1)

- Submucousal MyomaDocument55 pagesSubmucousal MyomaAngelie SanchezNo ratings yet

- Laser Tooth Preparation For Pit and Fissure Sealing: Environmental Research and Public HealthDocument11 pagesLaser Tooth Preparation For Pit and Fissure Sealing: Environmental Research and Public HealthFikrisalsabilahmahmudNo ratings yet

- Cofferdams & CaissonsDocument17 pagesCofferdams & CaissonsAja Esma100% (2)

- YogaDocument6 pagesYogashaivam123No ratings yet

- Audiotech PDFDocument116 pagesAudiotech PDFDharmeshNo ratings yet

- Assignment of Statistics Gangajal Water PurifierDocument11 pagesAssignment of Statistics Gangajal Water PurifierSiddhartha TiwariNo ratings yet

- Physical Geography A Landscape Appreciation 9th Edition Mcknight Test BankDocument36 pagesPhysical Geography A Landscape Appreciation 9th Edition Mcknight Test Bankdominichaimre100% (28)

- If There Are Images IDocument4 pagesIf There Are Images ISaurav BansalNo ratings yet

- PDF FileDocument44 pagesPDF FileAnant MishraNo ratings yet

- Parents Policy Father PDFDocument1 pageParents Policy Father PDFshamsehrNo ratings yet

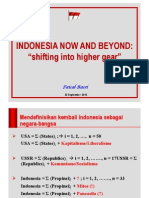

- Faisal Basri - Indonesia Now and Beyond PDFDocument20 pagesFaisal Basri - Indonesia Now and Beyond PDFAmalia AyuningtyasNo ratings yet

- Professional Services, Inc. vs. AganaDocument13 pagesProfessional Services, Inc. vs. AganajNo ratings yet

- Effect of Blanching On Enzyme Activity, Color Changes PDFDocument8 pagesEffect of Blanching On Enzyme Activity, Color Changes PDFmahsazdNo ratings yet

- 742210V01Document2 pages742210V01hakim_zadehNo ratings yet

- FGE Engine ControlDocument56 pagesFGE Engine ControlHai DuyNo ratings yet

- Multiple Choice Quiz For Groover BookDocument36 pagesMultiple Choice Quiz For Groover BooktitanfallkillofweekNo ratings yet

- State-Wide Equipment Program Continence Catalogue For NDIS Clients OnlyDocument46 pagesState-Wide Equipment Program Continence Catalogue For NDIS Clients OnlyАлина ВладиславовнаNo ratings yet

- Q1 Earth and Life Science 11 - Module 18Document19 pagesQ1 Earth and Life Science 11 - Module 18maricar relatorNo ratings yet

- 147 Amity Avenue Nampa, ID 81937 (999) 999-9999 William at Email - ComDocument4 pages147 Amity Avenue Nampa, ID 81937 (999) 999-9999 William at Email - ComjeyesbelmenNo ratings yet

- Pemberian Therapy Pemberian Madu Untuk Mengatasi Diare Di Wilayah Kerja Puskesmas Tanjung Uncang Kota BatamDocument9 pagesPemberian Therapy Pemberian Madu Untuk Mengatasi Diare Di Wilayah Kerja Puskesmas Tanjung Uncang Kota Batammadeina FamaniNo ratings yet

- Playbook Launchpackage Cassida Chain Oil XteDocument11 pagesPlaybook Launchpackage Cassida Chain Oil XteKiệt NgôNo ratings yet

- Jessica Payne Resume - Apr 2024Document3 pagesJessica Payne Resume - Apr 2024api-726672148No ratings yet

- Sieve Plate ColumnDocument14 pagesSieve Plate ColumnShamini Sathivel0% (1)

- Drug Dependency Examination (DDE)Document38 pagesDrug Dependency Examination (DDE)Ace VisualsNo ratings yet