Professional Documents

Culture Documents

More About Plastics: (Continued On Following Page)

Uploaded by

Daniel LiawOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

More About Plastics: (Continued On Following Page)

Uploaded by

Daniel LiawCopyright:

Available Formats

More About Plastics

Tensile StrengthThe amount of stretching a material can withstand before breaking. It is usually measured in pounds per square inch (psi). A larger number indicates a stronger material.

Impact StrengthThe ability to withstand shock loading. Determined by the notched Izod test, which measures the effect on a material when it is struck by a swinging pendulum. A larger number

signifies greater impact resistance. No Break means the material was not broken during testing.

Coefficient of FrictionThe ratio of the frictional force between two surfaces and the force that keeps those surfaces in contact. A lower value indicates a material that moves more easily, or with

less friction, than a material with a higher value.

Short-Term Dielectric StrengthThe maximum voltage a material can withstand without rupture, measured as volts per mil of thickness. This is an indication of how effective the material is as

an electrical insulator. A higher value signifies a better insulator.

Coefficient of Thermal ExpansionThe amount a material increases in volume as the temperature rises. A smaller coefficient is an indicator of less thermal expansion.

Machine WithHigh-Speed Steel Tooling (HSS); Tungsten Carbide Tooling (Carbide).

Warning: Physical and mechanical properties are not guaranteed and are intended only as a basis for comparison. Data is not for design purposes.

It is given without obligation or liability. No warranty of fitness for a particular purpose or application is made.

Tensile

Strength, psi

Rockwell

Hardness

Impact

Strength,

ft.-lbs./in.

Coefficient of

Friction

Dielectric

Strength,

volts/0.001!

Water

Absorption, %

Density,

lbs./in.3

Thermal Expansion,

in./in./ F

Machine

With

5,100-6,100

R102-109

5.2-7.7

Not Rated

450-1,220

0.3-1.0

0.032-0.038

5.2 ! 105

HSS

4,500

R87

Not Rated

Not Rated

Not Rated

0.04

4.6 to 5.5!105

Carbide

Acetal

Delrin Acetal Resin

Glass-Filled

Delrin Acetal Resin

PTFE-Filled

Delrin Acetal Resin

Turcite Acetal

6,400-9,500

9,000-11,000

M51-M88

M89-M94

1-1.8

1-2.4

0.11-0.35

0.2

420-500

435-500

0.2-0.8

0.2-0.4

0.048-0.051

0.051

5.4 to 12 !105

4.7 to 12.2 ! 105

HSS

HSS

8,700

M81

0.8

Not Rated

450

Not Rated

0.054

3.33 ! 105

Carbide

6,800-12,490

M77-M78

0.7-1.2

0.07-0.14

400-500

0.25

0.054

5.1 ! 105

HSS

5,900-7,600

M63-M81

0.54-0.57

0.22-0.3

Not Rated

0.2

0.053

5.0 !105

HSS

Acrylic

Cast Acrylic

Extruded Acrylic

8,000-11,250

8,100-11,030

M94-M103

M68-M95

0.04-0.5

0.3-0.7

Not Rated

Not Rated

400-430

430-760

0.2-0.8

0.2-0.4

0.043

0.043

3.5 to 4.2 !105

3.0 to 4.0!105

Carbide

Carbide

Acrylic/

PVC

Kydex Acrylic/PVC

6,100

R94

15

Not Rated

Not Rated

0.05

0.049

3.8 !105

HSS

Acetate

4,500-8,000

R78-R120

2.0-8.5

Not Rated

250-600

2.0-7.0

0.048

5.6 to 8.3!105

Butyrate

4,800

R78

4.5

Not Rated

300-475

1.4

0.027

6.0 to 9.0! 105

Cut with

knife

HSS

Material

ABS

Product

ABS

Conductive

ABS/PVC Electrically

ABS/PVC

Acetal

Cellulose

CPVC

CPVC

7,100-7,300

R116-119

8-9

Not Rated

1,250

0.03

0.053-0.056

3.9 ! 105

Carbide

CTFE

CTFE

4,860-5,710

Shore D85D95

2.5-3.5

0.08

500

0.034-0.08

3.9 to 5.1 ! 105

HSS

3,000

R25

No Break

0.25

1,800

<0.01

0.078

4.6 to 5.8 ! 105

Carbide

FEP

FEP

HDPE

HDPE Polyethylene

4,000-4,100

Shore D60D68

1.1

0.22-0.62

450-1,800

0.034

5.3 to 10 ! 105

HSS

LDPE

LDPE Polyethylene

3,100-6,100

Shore D42D56

Not Rated

Not Rated

Not Rated

Not Rated

0.033

Not Rated

HSS

(Continued on following page)

Copyright 2015 McMaster-Carr Supply Company. All rights reserved.

Page 1 of 3

Document 8574KAC; 8747KAC; 8539KAC

8657KAC; 8545KAC

More About Plastics

Warning: Physical and mechanical properties are not guaranteed and are intended only as a basis for comparison. Data is not for design purposes.

It is given without obligation or liability. No warranty of fitness for a particular purpose or application is made.

Tensile

Strength, psi

Rockwell

Hardness

Impact

Strength,

ft.-lbs./in.

Coefficient of

Friction

Dielectric

Strength,

volts/.001!

Water

Absorption, %

Density,

lbs./in.3

Thermal Expansion,

in./in./ F

Machine

With

Cast Nylon

Glass-Filled Nylon

Kevlar-Filled Nylon

MDS-Filled

Cast Nylon

MDS-Filled

Nylon 6/6

Nylon 6/6

Nylon 6/12

Oil-Filled Cast Nylon

10,000-13,500

13,000

17,200

R100-R125

M88

R121

0.4-1.8

1.8

2.7

0.22

Not Rated

0.32

500-600

530

350

0.6

0.30

0.8

0.042

0.048

0.042

5! 105

2.7! 105

1.6 ! 105

HSS

Carbide

HSS

10,000-13,500

R115-R125

0.7-0.9

0.22

500-600

0.5-0.6

0.042

5.0 ! 105

HSS

Material

Nylon

Product

0.08-1.2

0.2-0.28

R108-R121

R114

R100-R120

0.6-1.4

0.9

1.2-1.8

0.25-0.28

0.31

0.12-0.15

300-400

Not Rated

500-600

1.2-1.5

0.25

0.5-2.0

0.041

0.038

0.042

15,000-20,000

E70-E87

0.08-2.0

0.35

Not Rated

0.4

0.052

1.4 to 1.7 ! 105

Carbide

PEEK

Carbon-Filled PEEK

14,000-17,400

11,000

R126

M85

0.8-1.57

0.7

0.18-0.40

0.21

190-500

Not Rated

0.1-0.5

0.05

0.047

0.052

1.2 to 2.6 !105

1.7 !105

Carbide

Carbide

Ultem PEI

14,200-17,000

M109-M112

0.05-1.0

0.17-0.42

830

0.25

0.046

3.1 !105

Carbide

PETG

7,100-10,250

R106-R115

1.8

Not Rated

410

0.13-0.2

0.046

3.8 !105

HSS

PFA

3,600-4,000

Shore D60

No Break

0.21

2,000

0.03

0.077

5.5 to 7.6 !105

Cut with

Scissors

Polycarbonate

8,000-16,000

Glass-Filled

16,000

Polycarbonate Polycarbonate

Thermally Conductive

6,235

Polycarbonate

R118-R126

1.5-18

Not Rated

380-490

0.15-0.34

0.043-0.048

1.5 to 3.8 !105

Carbide

Not Rated

2.06

Not Rated

490

0.16

0.048

1.5 !105

Carbide

Not Rated

Not Rated

Not Rated

Not Rated

0.046

Not Rated

Not Rated

400

Sheet/Rod 0.070.1; Film Not

Rated

0.038

Sheet/Rod 3.9 !105;

Film 1.7 !105

HSS

PAI

PEEK

PEI

PETG

PFA

11,000-12,400

R108-R120

11,200-12,400

8,000

9,500-11,000

Torlon PAI

Sheet 0.7;

Sheet 0.11Rod/Film Not 0.45; Rod/Film

Rated

Not Rated

300-350

1.2-2.5

0.041

4! 10

5.5 !105

4 to

5 ! 105

5! 105

HSS

HSS

HSS

HSS

Polyester

Polyester

6,100-28,000

Not Rated

Polyimide

Kapton Polyimide

Vespel Polyimide

16,000-33,000

12,500

Not Rated

E45-E60

0.58

0.8

0.63

0.29

2,000

560

3.0

0.24

Not Rated

0.048

Not Rated

3 ! 105

HSS

Carbide

2,500-5,400

R55-R102

0.9-10.1

Not Rated

500-660

0.01-1.0

0.033-0.050

4.3 to 8.1 !105

Carbide

Polystyrene

2,560-3,700

R97

2.2-3.3

Not Rated

550

0.05

0.038

3.7 to 5 !105

HSS

Rexolite Polystyrene

8,000-10,500

R130

1.2

Not Rated

2,000

0.08

0.038

3.8 !105

HSS

10,200

R120

1.3

0.37

425

0.3

0.045

3.1 !105

HSS

Polypropylene Polypropylene

Polystyrene

Polysulfone

Polysulfone

(Continued on following page)

Copyright 2015 McMaster-Carr Supply Company. All rights reserved.

Page 2 of 3

Document 8574KAC; 8747KAC; 8539KAC

8657KAC; 8545KAC

More About Plastics

Warning: Physical and mechanical properties are not guaranteed and are intended only as a basis for comparison. Data is not for design purposes.

It is given without obligation or liability. No warranty of fitness for a particular purpose or application is made.

Material

Product

Tensile

Strength, psi

Rockwell

Hardness

Impact

Strength,

ft.-lbs./in.

Coefficient of

Friction

Dielectric

Strength,

volts/.001!

Water

Absorption, %

Density,

lbs./in.3

Thermal Expansion,

in./in./ F

Machine

With

PPO

Noryl PPO

9,200

R119

3.5

0.39

500

0.07

0.038

3.3 !105

HSS

PPS

PPS

13,500

R125

0.6

0.4

540

0.01

0.049

2.8 !105

Carbide

PPSU

Radel PPSU

10,100

R122

13.0

0.4

380

0.37

Not Rated

3.1 ! 105

HSS

1,500-4,500

Shore D50D65

2.3-3.5

0.05-0.1

600-2,000

0.01

0.08

5.5 to 10 !105

HSS

2.0-3.49

0.05-0.08

600-2,000

0.01

0.013-0.079

5.5 to 7 !105

HSS

PTFE

PTFE

Shapes Made with

Teflon PTFE

Antistatic PTFE

Glass-Filled PTFE

Reprocessed PTFE

4,500

R58

4,500

2,100-4,500

1,500-1,885

2.0

2.0-2.3

Not Rated

0.05-0.08

0.05-0.15

0.05-0.08

Not Rated

330-600

Not Rated

0.01

0.02

0.01

Not Rated

0.011-0.083

0.08

7 !105

7 !105

7 !105

HSS

Carbide

HSS

Rulon PTFE

1,500-4,500

R58

R58

R58

Shore D60D65

Shore D52

2.0-6.0

0.01-0.15

100-1,100

0.02

Not Rated

4.9 to 7 !105

Carbide

2.9

0.05-0.08

Not Rated

0.01

0.078

5.5 !105

HSS

Shore D80

0.65-1.0

Not Rated

985-1,410

0.05-0.2

0.044-0.053

2.9 to 3.7 !105

Carbide

0.32-0.54

Not Rated

280

0.5-0.8

0.020-0.022

3.7! 105

HSS

10-17

Not Rated

335-690

0.056-0.2

0.05

3.2 to 3.7 !105

Carbide

Weldable PTFE

PVC

PVC

PVDF

UHMW

VHMW

4,000

6,000-10,300;

Film 1,9003,750

Foam PVC

1,600-2,300

Strengthened PVC

5,600-6,200

Shore D79D85

R111

PVDF

7,550-7,800

R100

2.5-3.0

0.2-0.4

280

0.02-1.0

0.064-1.78

7.1 !105

HSS

UHMW Polyethylene

2,470-7,740

Shore D61D77

16.8-No

Break

0.12-0.25

450-2,300

0.01

0.034

0.83 to 2 !104

HSS

Abrasion-Resistant

UHMW

Electrically

Conductive UHMW

High-Temperature

UHMW

5,600

Shore D69

No Break

0.12

2,300

0.01

0.034

1 ! 104

HSS

2,600-3,200

Shore D63D68

No Break

0.1-0.2

Not Rated

<0.01

0.034

Not Rated

HSS

5,800

Shore D68

No Break

0.12

2,300

0.01

0.034

1.1 !104

HSS

VHMW Polyethylene

>3,800

Shore D65

No Break

Not Rated

Not Rated

0.034

6 ! 105

HSS

Copyright 2015 McMaster-Carr Supply Company. All rights reserved.

Page 3 of 3

Document 8574KAC; 8747KAC; 8539KAC

8657KAC; 8545KAC

You might also like

- Sulfur-Vanadium Binary Phase Diagram (1990 Smith J.F.) ImageDocument4 pagesSulfur-Vanadium Binary Phase Diagram (1990 Smith J.F.) ImageFernando TorresNo ratings yet

- McMaster - About Plastics Doc 8574KACDocument3 pagesMcMaster - About Plastics Doc 8574KACkristechnikNo ratings yet

- INEOS Engineering Properties of PPDocument2 pagesINEOS Engineering Properties of PPsimonorr17No ratings yet

- Bolt GradeDocument2 pagesBolt GradeguthaleNo ratings yet

- O Ring BrochureDocument36 pagesO Ring BrochureJesus N RodriguezNo ratings yet

- PPT-Q A For Steel and ConcreteDocument146 pagesPPT-Q A For Steel and ConcreteDr.SRINIVAS RAO PASUPULETI50% (2)

- Hydra Ulic Hose: UroflexDocument4 pagesHydra Ulic Hose: UroflexAsima Jaya TamaNo ratings yet

- 17-4 PHDocument4 pages17-4 PHfahimshah1301No ratings yet

- RASCHIG-Ring DataDocument23 pagesRASCHIG-Ring Datalhphong021191No ratings yet

- Aalco Metals LTD Stainless Steel 14462 Sheet and Plate 102Document3 pagesAalco Metals LTD Stainless Steel 14462 Sheet and Plate 102HoangNo ratings yet

- 175-80 InstructionsDocument11 pages175-80 Instructionssajad gohariNo ratings yet

- 304 Stainless Steel: Metal Ferrous Metal Heat Resisting Stainless Steel T 300 Series Stainless SteelDocument2 pages304 Stainless Steel: Metal Ferrous Metal Heat Resisting Stainless Steel T 300 Series Stainless SteelTomy GeorgeNo ratings yet

- Loctite Innovations: Loctite Primers Properties ChartDocument1 pageLoctite Innovations: Loctite Primers Properties Chartzombiehunter247No ratings yet

- Smith Fibercast Green Thread Performance Plus Fiberglass Pipe Piping BrochureDocument8 pagesSmith Fibercast Green Thread Performance Plus Fiberglass Pipe Piping BrochureWong Chung MengNo ratings yet

- Aspen Aerogel Pyrogel XT-DSDocument2 pagesAspen Aerogel Pyrogel XT-DSkflimNo ratings yet

- Zeron 100 Data SheetDocument2 pagesZeron 100 Data SheetMorgan PalmaNo ratings yet

- TD BrazeTec s15 EDocument1 pageTD BrazeTec s15 EIonutCiobanuNo ratings yet

- Wear Guides: Quality Value ServiceDocument4 pagesWear Guides: Quality Value ServicepaulNo ratings yet

- Ace Mersen Armylor - 2 Ptfe Pfa Lined Pipes Fittings AnsiDocument32 pagesAce Mersen Armylor - 2 Ptfe Pfa Lined Pipes Fittings AnsiClaire GrecoNo ratings yet

- Stelex ZR PDFDocument4 pagesStelex ZR PDFRafael TellezNo ratings yet

- Titeflex Transportation CatalogDocument4 pagesTiteflex Transportation Catalogkrzys10No ratings yet

- Ace Mersen Armylor 2 Ptfe Pfa Lined Pipes DinDocument32 pagesAce Mersen Armylor 2 Ptfe Pfa Lined Pipes DinClaire GrecoNo ratings yet

- Fe 500 D Brochure 2018Document4 pagesFe 500 D Brochure 2018Sanjit DasNo ratings yet

- Quality Assurance in Reinforcement Steel PDFDocument52 pagesQuality Assurance in Reinforcement Steel PDFRajha RajeswaranNo ratings yet

- GasketDocument45 pagesGasketSathish RajanNo ratings yet

- Loctite 243Document4 pagesLoctite 243ablemathew173974No ratings yet

- Panduit Superheavy TiesDocument2 pagesPanduit Superheavy TiesHerman [BSI]No ratings yet

- PEER Seals CatalogDocument64 pagesPEER Seals CatalogRodatecnia Javier100% (1)

- Insulation Material SpecificationDocument1 pageInsulation Material SpecificationSandra FerrellNo ratings yet

- BM Europe Expansion Joints Technical CalculationDocument9 pagesBM Europe Expansion Joints Technical CalculationsahirprojectsNo ratings yet

- Nylaflow Nylatron 2006Document4 pagesNylaflow Nylatron 2006Miguel GradeNo ratings yet

- Everything Is About To Change.: Introducing The Change GasketDocument35 pagesEverything Is About To Change.: Introducing The Change GasketSandra MArrugoNo ratings yet

- Stelex ProDocument4 pagesStelex ProRafael TellezNo ratings yet

- Stellite 1 DS01-22008 (S R0808)Document2 pagesStellite 1 DS01-22008 (S R0808)Kunal PandeyNo ratings yet

- MaterialData - 14076 HDS H13Document2 pagesMaterialData - 14076 HDS H13Amol KulkarniNo ratings yet

- Gehr Kynar HalarDocument2 pagesGehr Kynar HalarElambarithi KalyanakumarNo ratings yet

- Platinum Resistance Pt100Document9 pagesPlatinum Resistance Pt100Denis BohushNo ratings yet

- Shrinkage TableDocument6 pagesShrinkage TableMahesh Deivasiga Mani DNo ratings yet

- Socket Head Cap Screws Alloy SteelDocument5 pagesSocket Head Cap Screws Alloy SteelChris MedeirosNo ratings yet

- Socket Head Cap Screws Alloy SteelDocument5 pagesSocket Head Cap Screws Alloy SteelChris MedeirosNo ratings yet

- Rubberexp ConnectallDocument6 pagesRubberexp ConnectallThaiminh VoNo ratings yet

- L3341 HeatSeal Insulated PEX Pipe Brochure 2009-07-28Document2 pagesL3341 HeatSeal Insulated PEX Pipe Brochure 2009-07-28Tanveer Alam AnsariNo ratings yet

- Corod SWR High Strength 29feb12Document3 pagesCorod SWR High Strength 29feb12Ronald LlerenaNo ratings yet

- Material Properties of UHMW Polyethylene - ThermoplasticDocument4 pagesMaterial Properties of UHMW Polyethylene - ThermoplasticS.Mohana sundaramNo ratings yet

- 4X Flexiable Dual Wall Heat Shrink TubingDocument2 pages4X Flexiable Dual Wall Heat Shrink Tubingsales3167No ratings yet

- PTFE DatasheetDocument2 pagesPTFE DatasheetthodatisampathNo ratings yet

- (PTFE) Polytetrafluoroethylene: Physical Properties Metric English CommentsDocument2 pages(PTFE) Polytetrafluoroethylene: Physical Properties Metric English CommentsMakhdum Muhardiana PutraNo ratings yet

- Lead Free Solder Reliability Issues Test MethodsDocument7 pagesLead Free Solder Reliability Issues Test MethodsAntonio Vieira MScNo ratings yet

- Section 18 Design of Plastic Gears PDFDocument15 pagesSection 18 Design of Plastic Gears PDFSergio CandiottiNo ratings yet

- CT R14ptfe TDSDocument3 pagesCT R14ptfe TDSIan HoraNo ratings yet

- EvolutionTekDatasheet PDFDocument1 pageEvolutionTekDatasheet PDFRobNo ratings yet

- Ertalyte TXDataDocument5 pagesErtalyte TXDatavizcensoNo ratings yet

- 2017 Kynar Wire and Cable SolutionsDocument8 pages2017 Kynar Wire and Cable SolutionsKaarthicNatarajanNo ratings yet

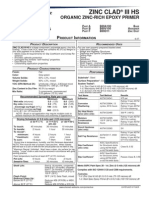

- Zinc Clad IIIDocument4 pagesZinc Clad IIIScott Van PeltNo ratings yet

- Anti-Surge Thick Film Chip Re Sis Tors 0603, 0805, 1206, 1210 ERJ P03, P06, P08, P14Document5 pagesAnti-Surge Thick Film Chip Re Sis Tors 0603, 0805, 1206, 1210 ERJ P03, P06, P08, P14Francisco Lopez MoyaNo ratings yet

- HDPE Brochure (Lamson)Document6 pagesHDPE Brochure (Lamson)arkadjyothiprakashNo ratings yet

- Aisi 305Document3 pagesAisi 305Aditya PratapNo ratings yet

- Soldering Electronic Components 2nd EditionFrom EverandSoldering Electronic Components 2nd EditionRating: 3 out of 5 stars3/5 (2)

- Farm and Workshop Welding: Everything You Need to Know to Weld, Cut, and Shape MetalFrom EverandFarm and Workshop Welding: Everything You Need to Know to Weld, Cut, and Shape MetalRating: 4.5 out of 5 stars4.5/5 (3)

- More About Plastics: (Continued On Following Page)Document3 pagesMore About Plastics: (Continued On Following Page)Daniel LiawNo ratings yet

- Physics 2016 Curriculum Data BookletDocument15 pagesPhysics 2016 Curriculum Data Bookletrayban262No ratings yet

- Test Plan and CalibrationDocument8 pagesTest Plan and CalibrationDaniel LiawNo ratings yet

- Smoothly Does It: Case StudyDocument2 pagesSmoothly Does It: Case StudyDaniel LiawNo ratings yet

- AppendixC 2012Document6 pagesAppendixC 2012Daniel LiawNo ratings yet

- Conservation of Mechanical Energy, Linear MomentumDocument6 pagesConservation of Mechanical Energy, Linear MomentumDaniel LiawNo ratings yet

- Appendix D 2008Document14 pagesAppendix D 2008Daniel LiawNo ratings yet

- Iso 281:2007Document6 pagesIso 281:2007Daniel LiawNo ratings yet

- Mech Compared To EngphysDocument4 pagesMech Compared To EngphysDaniel LiawNo ratings yet

- Design Basis: CE 315-Design of Concrete Structure - I Instructor: Dr. E. R. LatifeeDocument2 pagesDesign Basis: CE 315-Design of Concrete Structure - I Instructor: Dr. E. R. LatifeeShafiqul HasanNo ratings yet

- ElasticityDocument8 pagesElasticityGuru GuroNo ratings yet

- Friday, May 10, 2019: Fatigue Failure Resulting From Variable LoadingDocument117 pagesFriday, May 10, 2019: Fatigue Failure Resulting From Variable LoadingarulmuruguNo ratings yet

- Unit IV (B) - Theories of FailureDocument51 pagesUnit IV (B) - Theories of FailureSupritha K100% (1)

- Charactristcs of FKM and HNBR BlendsDocument9 pagesCharactristcs of FKM and HNBR Blendsadriano_rodsNo ratings yet

- Hanwha Total PP RJ770Document2 pagesHanwha Total PP RJ770Nguyễn Hồng Nam0% (1)

- 3D and Circuit Integration of MEMS by Masayoshi EsashiDocument502 pages3D and Circuit Integration of MEMS by Masayoshi EsashiAleyna ArslanNo ratings yet

- Rheological Behaviour MR GreaseDocument9 pagesRheological Behaviour MR GreaseChiranjit SarkarNo ratings yet

- Simplified Modified Compression Field Theory For Calculating Shear Strength of Reinforced Concrete ElementsDocument11 pagesSimplified Modified Compression Field Theory For Calculating Shear Strength of Reinforced Concrete ElementsTooma David100% (1)

- Zdeněk Bittnar - Jiří Šejnoha-Numerical Methods in Structural Mechanics-Amer Society of Civil Engineers (1996)Document429 pagesZdeněk Bittnar - Jiří Šejnoha-Numerical Methods in Structural Mechanics-Amer Society of Civil Engineers (1996)ErickSimon100% (2)

- Design of Steel BeamsDocument108 pagesDesign of Steel BeamsNajif IsmailNo ratings yet

- Heat and Internal Energy SeatworkDocument1 pageHeat and Internal Energy SeatworkJonel RuleNo ratings yet

- Analysis of The Catastrophic Rupture of A Pressure VesselDocument3 pagesAnalysis of The Catastrophic Rupture of A Pressure VesselQamar AbbasNo ratings yet

- 15me742 Dec18-Jan19 PDFDocument2 pages15me742 Dec18-Jan19 PDFPunith JayramNo ratings yet

- As 4600 Rel NoteDocument14 pagesAs 4600 Rel NoteDiana Ho WyNo ratings yet

- Tutorial 1 QuestionsDocument4 pagesTutorial 1 QuestionsSaeed MishalNo ratings yet

- Buckling Test PresentationDocument11 pagesBuckling Test Presentationarmando nolasco rodriguezNo ratings yet

- Rheological Properties of The Polymer Modified Bitumen With Emphasis On SBS Polymer and Its MicrostructureDocument8 pagesRheological Properties of The Polymer Modified Bitumen With Emphasis On SBS Polymer and Its MicrostructureMEHDI FARROKHINo ratings yet

- STP 619-1977Document74 pagesSTP 619-1977Anonymous pSozzNFc100% (1)

- Development of High-Tensile-Strength Stainless Steel WireDocument6 pagesDevelopment of High-Tensile-Strength Stainless Steel WireAmaliaFikry AssegafNo ratings yet

- Effects of Microporosity On Tensile Properties of A356 Aluminum AlloyDocument6 pagesEffects of Microporosity On Tensile Properties of A356 Aluminum AlloyMohamed RamadanNo ratings yet

- Mechanical and Wear Behavior of AA7075 Aluminum Matrix Composites Reinforced by Al 2 O 3 NanoparticlesDocument9 pagesMechanical and Wear Behavior of AA7075 Aluminum Matrix Composites Reinforced by Al 2 O 3 NanoparticlesARULKUMARSUBRAMANIANNo ratings yet

- Design of BearingDocument56 pagesDesign of BearingPawan BhattaraiNo ratings yet

- Hdi0653u1 Enus AstmDocument1 pageHdi0653u1 Enus AstmJonathan GuadarramaNo ratings yet

- Study of DelaminationDocument8 pagesStudy of Delaminationjunjie yiNo ratings yet

- Dimensionless Group of Heat TransferDocument1 pageDimensionless Group of Heat TransferSalwanNo ratings yet

- Energy BalanceDocument31 pagesEnergy BalanceShubham AgrawalNo ratings yet

- Design and Assessment of Multi Leaf Spring: Ashish V. Amrute, Edward Nikhil Karlus, R.K.RathoreDocument10 pagesDesign and Assessment of Multi Leaf Spring: Ashish V. Amrute, Edward Nikhil Karlus, R.K.RathoreVenkatesh NanneboinaNo ratings yet

- Single Site Catalysts and Dual Reactor Technology Create More Freedom in Pe Rotomolding Resin and Product DesignsDocument5 pagesSingle Site Catalysts and Dual Reactor Technology Create More Freedom in Pe Rotomolding Resin and Product Designsjsk789No ratings yet