Professional Documents

Culture Documents

Green Marine Oks Stab

Uploaded by

Tifal Meqrizha0 ratings0% found this document useful (0 votes)

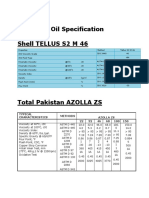

13 views1 pageThis document provides typical specifications for three types of hydraulic fluids (ISO 32, 46, 68) including viscosity measurements at various temperatures, specific gravity, flash point, pour point, oxidation stability, corrosion resistance, foam tendency, demulsibility, filterability, and biodegradability classification. ISO 32 fluid has the lowest viscosity, pour point, and flash point while ISO 68 has the highest. All three fluids pass tests for rust prevention, copper corrosion, and wear protection.

Original Description:

ISO VG 32,46,82

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides typical specifications for three types of hydraulic fluids (ISO 32, 46, 68) including viscosity measurements at various temperatures, specific gravity, flash point, pour point, oxidation stability, corrosion resistance, foam tendency, demulsibility, filterability, and biodegradability classification. ISO 32 fluid has the lowest viscosity, pour point, and flash point while ISO 68 has the highest. All three fluids pass tests for rust prevention, copper corrosion, and wear protection.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

13 views1 pageGreen Marine Oks Stab

Uploaded by

Tifal MeqrizhaThis document provides typical specifications for three types of hydraulic fluids (ISO 32, 46, 68) including viscosity measurements at various temperatures, specific gravity, flash point, pour point, oxidation stability, corrosion resistance, foam tendency, demulsibility, filterability, and biodegradability classification. ISO 32 fluid has the lowest viscosity, pour point, and flash point while ISO 68 has the highest. All three fluids pass tests for rust prevention, copper corrosion, and wear protection.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

Typical Specifications for Hydraulic fluids (ISO 32,46,68)

Performance Data

ISO 32

Specific Gravity @ 15.6C

API Gravity @ 15.6C

Viscosity @ 40C

Viscosity @ 100C

Viscosity @ 15C, Brookfield

Viscosity @ 25C, Brookfield

Viscosity @ 30C MRV TP1

0.874

30.4

30.87

6.9

Not complete

1,200 cP

4,500 cP

0.876

30.0

43.8

9.67

1100 cP

3,000 cP

8,000 cP

0.886

28.2

64.1

12.5

7,500 cP

Viscosity @ 35C MRV TP1

Viscosity Index

ISO 46 ISO 68

184

216

198

Pour Point

Flash Point (COC)

40C

236C

36C

243C

30C

251C

Fire Point (COC)

Hydrolytic Stability,

Copper Wt. Loss (mg)

Copper Appearance

Water Layer

260C

268C

274C

0.0208

1B

0.3

0.0208

1A

0.9

0 Foam

0 Foam

Foam Sequence I, II, III (10 min)

Rust Prevention

Distilled Water

Syn. Sea Water

Copper Corrosion Strip 3hr@100C

Rotary Bomb Oxidation (minutes)

Oxidation Stability

Neutralization Number mg KOH/g

Swell of Synthetic NBR1 Rubber, % (Avg.)

Volume Change (%)

Shore A Hardness Change (%)

Filterability

ANo Water (s)

(Avg.)

B2% Water (s)

(Avg.)

0.0139

1B

0

0 Foam

Pass

Pass

Pass

Pass

Pass

Pass

1B

250

1B

250

1B

250

47.0 C

47.0C

45.0C

< 0.4

< 0.4

< 0.4

6.0

6.0

6.0

113

187

268

271

335

449

40/ 40/ 0

40/ 40/ 0

39/ 40/ 1

0.3 0.4

0.3 0.4

0.3 0.4

12

12

12

Ultimate

Ultimate

Ultimate

Pw1

Pw1

Pw1

Demulsibility,

ML Oil/Water/Emulsion

4Ball Wear

1h, 167F, 1200 RPM, 40 kg

FZG Test

Biodegradation Classification

Notes:

1. Viscosity Sufficient for Application

2. Not required

You might also like

- Retirement SpeechDocument11 pagesRetirement SpeechRayan Castro100% (1)

- NZAA ChartsDocument69 pagesNZAA ChartsA340_600100% (5)

- Consolidation Physical Fitness Test FormDocument5 pagesConsolidation Physical Fitness Test Formvenus velonza100% (1)

- Gas Condensate PVTDocument14 pagesGas Condensate PVTMaisam Abbas100% (1)

- Kubera-Petroleum Product PassportDocument2 pagesKubera-Petroleum Product Passportptintimaritimsekawan100% (1)

- Product Specifications Octane 95Document3 pagesProduct Specifications Octane 95Vishnu PillaiNo ratings yet

- Presentation Transformer OilDocument44 pagesPresentation Transformer Oilravi_bagga2000100% (3)

- EN590 10ppm SPECIFICATIONS PEGASUS OILDocument1 pageEN590 10ppm SPECIFICATIONS PEGASUS OILSephiwe Mafilika100% (1)

- Miri Crude Assay RPTDocument14 pagesMiri Crude Assay RPTapiskai100% (1)

- Icpo NG En590 2704231111Document3 pagesIcpo NG En590 2704231111Nikita NovikovNo ratings yet

- Crude Oil SpecificationsDocument8 pagesCrude Oil SpecificationsLeslie BoyerNo ratings yet

- Unit 02 NHT Operator Training Material - 20210626 REV1Document72 pagesUnit 02 NHT Operator Training Material - 20210626 REV1ضياء محمدNo ratings yet

- Al Shaheen AssayDocument23 pagesAl Shaheen Assaydassi99No ratings yet

- Project ManagementDocument37 pagesProject ManagementAlfakri WaleedNo ratings yet

- General Characteristic of Crude OilDocument20 pagesGeneral Characteristic of Crude Oildassi99No ratings yet

- GM Performance DataDocument1 pageGM Performance Dataprasanna2210No ratings yet

- Envirotemp 360 Fluid FINALDocument2 pagesEnvirotemp 360 Fluid FINALandresdlatmNo ratings yet

- Mak Hydrol: Product Data SheetDocument2 pagesMak Hydrol: Product Data SheetSajib Chandra RoyNo ratings yet

- Aliquat 336: Technical Information Global Mining SolutionsDocument3 pagesAliquat 336: Technical Information Global Mining SolutionsEduardo OetikerNo ratings yet

- Mak Hydrol 12-460Document2 pagesMak Hydrol 12-460annamalailubesNo ratings yet

- Bulk Chemical SpecificationsDocument1 pageBulk Chemical SpecificationsSahil ShahNo ratings yet

- Ten Blend 2019Document4 pagesTen Blend 2019Para DiseNo ratings yet

- Cofran Mecanep 220 enDocument2 pagesCofran Mecanep 220 enMATHEW JOSENo ratings yet

- Envirotempfr3 FluidDocument8 pagesEnvirotempfr3 FluidSM KNo ratings yet

- Swelling/Extraction Test of A Small Sample Size For Phase Behavior StudyDocument20 pagesSwelling/Extraction Test of A Small Sample Size For Phase Behavior StudyJuan BettinNo ratings yet

- 09 AppendixDocument7 pages09 AppendixbojkrvickyNo ratings yet

- Crudo 2 Alba United KingdomDocument2 pagesCrudo 2 Alba United KingdomFlorencia GonzalezNo ratings yet

- Therminol - 66 Synthetic Heat Trasnfer Fluid. Aceite Termico Therminol Venezuela.Document8 pagesTherminol - 66 Synthetic Heat Trasnfer Fluid. Aceite Termico Therminol Venezuela.Renso PiovesanNo ratings yet

- Specifications For Hydraulic OilDocument3 pagesSpecifications For Hydraulic OilAliya NaseemNo ratings yet

- Fo Analysis Reports Prabhu YuvikaDocument17 pagesFo Analysis Reports Prabhu YuvikaSumit ChandwaniNo ratings yet

- Specification For Light Diesel Oil (Ldo) : SL - No. Parameter Specification STD - Method Typical QualityDocument1 pageSpecification For Light Diesel Oil (Ldo) : SL - No. Parameter Specification STD - Method Typical Qualitysudhakarrajam2002No ratings yet

- QALCO Syntholube GX 220Document1 pageQALCO Syntholube GX 220Deepak JoyNo ratings yet

- Mak Hydrol HLP Extra Heavy Duty Anti Wear TypeDocument2 pagesMak Hydrol HLP Extra Heavy Duty Anti Wear TypeM/S-S S Black Stone WorksNo ratings yet

- Aviation Turbine Fuel (ATF) IS: 1571: 2008: Sl. No. Characteristics Unit Method No. Requirement Minimum MaximumDocument2 pagesAviation Turbine Fuel (ATF) IS: 1571: 2008: Sl. No. Characteristics Unit Method No. Requirement Minimum MaximumRajesh KumarNo ratings yet

- Total Seriola 32 - Product Data SheetDocument3 pagesTotal Seriola 32 - Product Data Sheetjihad jamarei100% (1)

- Specifications & Typical Properties For Motiva Base OilsDocument1 pageSpecifications & Typical Properties For Motiva Base OilsMassimiliano VolaNo ratings yet

- Lub TR Oil TDocument1 pageLub TR Oil TJorge CondoriNo ratings yet

- MODEL: KP603-45-B-NW: Maximum System Voltage (V) Temperature Coefficients of Voc (%)Document4 pagesMODEL: KP603-45-B-NW: Maximum System Voltage (V) Temperature Coefficients of Voc (%)Paulo MercadoNo ratings yet

- Crude Summary Report: Crude: OSEBERG 2016 04 Reference: OSEBERG201604Document3 pagesCrude Summary Report: Crude: OSEBERG 2016 04 Reference: OSEBERG201604Jorge Rodriguez HerreraNo ratings yet

- 7 Tds Unioleo Fa c0818h f0818 01 - tcm1359 493815 - enDocument2 pages7 Tds Unioleo Fa c0818h f0818 01 - tcm1359 493815 - enSuryaNo ratings yet

- Alvheim Blend 2013 09Document5 pagesAlvheim Blend 2013 09Tree SilviaNo ratings yet

- Crudo 3 Alvheim NorwayDocument2 pagesCrudo 3 Alvheim NorwayFlorencia GonzalezNo ratings yet

- RC 101Document15 pagesRC 101VaanNo ratings yet

- Scotch-Weld: Structural Adhesive FilmDocument14 pagesScotch-Weld: Structural Adhesive FilmTommy JonceNo ratings yet

- PDS Hydrotur RDocument1 pagePDS Hydrotur RBenny Bryle SagunNo ratings yet

- Technical Data Sheet ML90FB 220-240V 50Hz 1 R404A: Compressor Model Voltage RefrigerantDocument4 pagesTechnical Data Sheet ML90FB 220-240V 50Hz 1 R404A: Compressor Model Voltage Refrigerantoscar rene rodriguez rojasNo ratings yet

- Methacrylate Monomers: Typical Properties - Methacrylate EstersDocument2 pagesMethacrylate Monomers: Typical Properties - Methacrylate EstersPau ZalazarNo ratings yet

- M.Novriyanto M1B118028 - UTS SIMKOMDocument10 pagesM.Novriyanto M1B118028 - UTS SIMKOMDave N7RNo ratings yet

- Technological Institute of The Philippines: (Aq) 2 (L) 2 3(s) 3(s)Document17 pagesTechnological Institute of The Philippines: (Aq) 2 (L) 2 3(s) 3(s)VaanNo ratings yet

- Synopsis: Waste Lube Oil Re-Refining Using Vacuum DistillationDocument4 pagesSynopsis: Waste Lube Oil Re-Refining Using Vacuum DistillationFarah SaadNo ratings yet

- Zic Supervis AwDocument2 pagesZic Supervis AwMohammed Abdul GhafoorNo ratings yet

- Solar Panel - Perc MONO (385w 400w)Document3 pagesSolar Panel - Perc MONO (385w 400w)nairsangeet9No ratings yet

- Technical Data Sheet Mpt16La 220-240V 50Hz 1 R404A: Compressor Model Voltage RefrigerantDocument4 pagesTechnical Data Sheet Mpt16La 220-240V 50Hz 1 R404A: Compressor Model Voltage RefrigerantmustafaNo ratings yet

- 08 - Analisis Del Lugar Geometrico de La RaicesDocument1 page08 - Analisis Del Lugar Geometrico de La RaicesNorbert HernándezNo ratings yet

- Lutensol atDocument10 pagesLutensol atVilas DhakappaNo ratings yet

- Camisea Planos de InstrumentaciònDocument19 pagesCamisea Planos de InstrumentaciònNavarro Zavala AntonyNo ratings yet

- Texaco Meropa 320 Eng M0010Document2 pagesTexaco Meropa 320 Eng M0010Ady MihailaNo ratings yet

- Technical Data Sheet R 417a Gas ServeiDocument3 pagesTechnical Data Sheet R 417a Gas Serveialiakbar tavafiNo ratings yet

- Panel Led 60x60Document4 pagesPanel Led 60x60Ignacio CáceresNo ratings yet

- Airforce 4000 Compressor Oils ISO VG 32, 46, 68, 100: Product InformationDocument1 pageAirforce 4000 Compressor Oils ISO VG 32, 46, 68, 100: Product Informationbiomed systechNo ratings yet

- MS HSD Bs-Vi SpecsDocument3 pagesMS HSD Bs-Vi SpecsKusunuru SandeepNo ratings yet

- Rigid 10k DatasheetDocument2 pagesRigid 10k DatasheetAna Maria RodrigoNo ratings yet

- Danfoss - GLY12NRb - R134a - 115 - 60Document5 pagesDanfoss - GLY12NRb - R134a - 115 - 60Cristian GarciaNo ratings yet

- Biomedical Electron Microscopy: Illustrated Methods and InterpretationsFrom EverandBiomedical Electron Microscopy: Illustrated Methods and InterpretationsNo ratings yet

- Narendra Budiman: Professional StatementDocument1 pageNarendra Budiman: Professional StatementPratika SariputriNo ratings yet

- Test Bank For We The People 10th Essentials Edition Benjamin Ginsberg Theodore J Lowi Margaret Weir Caroline J Tolbert Robert J SpitzerDocument15 pagesTest Bank For We The People 10th Essentials Edition Benjamin Ginsberg Theodore J Lowi Margaret Weir Caroline J Tolbert Robert J Spitzeramberleemakegnwjbd100% (14)

- Core Values Behavioral Statements Quarter 1 2 3 4Document1 pageCore Values Behavioral Statements Quarter 1 2 3 4Michael Fernandez ArevaloNo ratings yet

- 05 Vision IAS CSP21 Test 5Q HIS AM ACDocument17 pages05 Vision IAS CSP21 Test 5Q HIS AM ACAvanishNo ratings yet

- UAS English For Acc - Ira MisrawatiDocument3 pagesUAS English For Acc - Ira MisrawatiIra MisraNo ratings yet

- Correctional Case StudyDocument36 pagesCorrectional Case StudyRaachel Anne CastroNo ratings yet

- (BDMR) (DIY) (Building) (Green) (Eng) Munton - Straw Bale Family HomeDocument5 pages(BDMR) (DIY) (Building) (Green) (Eng) Munton - Straw Bale Family HomeMiklós GrécziNo ratings yet

- Daniel Salazar - PERSUASIVE ESSAYDocument2 pagesDaniel Salazar - PERSUASIVE ESSAYDaniel SalazarNo ratings yet

- Upcoming Book of Hotel LeelaDocument295 pagesUpcoming Book of Hotel LeelaAshok Kr MurmuNo ratings yet

- MC Script For StorytellingDocument1 pageMC Script For StorytellingPPD LUBOK ANTU-CM15 KPMNo ratings yet

- .. Anadolu Teknik, Teknik Lise Ve Endüstri Meslek LisesiDocument3 pages.. Anadolu Teknik, Teknik Lise Ve Endüstri Meslek LisesiLisleNo ratings yet

- Revision of Future TensesDocument11 pagesRevision of Future TensesStefan StefanovicNo ratings yet

- Medieval Societies The Central Islamic LDocument2 pagesMedieval Societies The Central Islamic LSk sahidulNo ratings yet

- Tail Lamp Left PDFDocument1 pageTail Lamp Left PDFFrancis RodrigueNo ratings yet

- 14CFR, ICAO, EASA, PCAR, ATA Parts (Summary)Document11 pages14CFR, ICAO, EASA, PCAR, ATA Parts (Summary)therosefatherNo ratings yet

- Febi Dwirahmadi - PPT Disaster Management and COVID19Document34 pagesFebi Dwirahmadi - PPT Disaster Management and COVID19Fenny RahmadianitaNo ratings yet

- Challenges in Leadership Development 2023Document26 pagesChallenges in Leadership Development 2023Girma KusaNo ratings yet

- Beowulf Essay 1Document6 pagesBeowulf Essay 1api-496952332No ratings yet

- Jurisdiction and Kinds of JurisdictionDocument3 pagesJurisdiction and Kinds of JurisdictionANUKULNo ratings yet

- Module Letter 1Document2 pagesModule Letter 1eeroleNo ratings yet

- GHMC Results, 2009Document149 pagesGHMC Results, 2009UrsTruly kotiNo ratings yet

- SMART Train ScheduleDocument1 pageSMART Train ScheduleDave AllenNo ratings yet

- Testamentary Succession CasesDocument69 pagesTestamentary Succession CasesGjenerrick Carlo MateoNo ratings yet

- WT WIAB Reworked CH 3 FullDocument5 pagesWT WIAB Reworked CH 3 Fulljack3314sonyNo ratings yet

- Pre-Qualification Document - Addendum 04Document4 pagesPre-Qualification Document - Addendum 04REHAZNo ratings yet