Professional Documents

Culture Documents

Mak Hydrol 12-460

Mak Hydrol 12-460

Uploaded by

annamalailubesOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mak Hydrol 12-460

Mak Hydrol 12-460

Uploaded by

annamalailubesCopyright:

Available Formats

Product Data Sheet

MAK HYDROL

ISO VG: 15, 22, 32, 46, 68, 100, 150, 220, 320 & 460 Non ISO VG: 12, 37, 57, 81, 121 & 176

DESCRIPTION PERFORMANCE BENEFITS

These are specially designed oils for hydraulic • Exhibits good oxidation, anti-rust, anti-wear

transmission and circulating systems. and anti-foam properties

• Have excellent compatibility with the seals

PERFORMANCE LEVEL

APPLICATIONS

• IS 3098 : 1983 [Reaffirmed Nov., 1998]

These are recommended for hydraulic • IPSS : 1-09-022

systems and a wide variety of circulation • IS 10522 : 1983 [Reaffirmed Nov., 1998]

systems of industrial and automotive

• Vickers V-104C Vane pump test

equipments.

• DIN 51 524 Part 1 HL Type

Our grades meet above specification for the

respective viscosity grades.

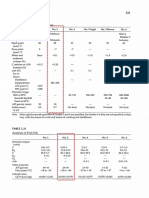

IS Typical Figures

Characteristics 1448 12 15 22 32

Appearance -- Clear fluid Clear fluid Clear fluid Clear fluid

Density at 15° C P:16 0.849 0.849 0.850 0.852

K.V at 40° C, cSt P:25 12.8 15.3 22.6 32.6

Viscosity Index P:56 103 103 102 101

Pour Point, °C P:10 -15 -12 -12 -12

Flash Point, (COC), °C P:69 180 186 200 220

Copper Strip Corrosion Test at P:15 1 1 1 1

100°C for 3 hrs.

Foaming Characteristics/Stability

a) Sequence I P:67 Nil Nil Nil Nil

b) Sequence II Nil Nil Nil Nil

c) Sequence III Nil Nil Nil Nil

IS Typical Figures

Characteristics 1448 37 46 57 68

Appearance -- Clear fluid Clear fluid Clear fluid Clear fluid

Density at 15° C P:16 0.852 0.855 0.857 0.860

K.V at 40° C, cSt P:25 37.3 46.7 57.2 68.1

Viscosity Index P:56 100 100 100 99

Pour Point, °C P:10 -12 -12 -12 -12

Flash Point, (COC), °C P:69 224 226 234 238

Copper Strip Corrosion Test at P:15 1 1 1 1

100°C for 3 hrs.

Foaming Characteristics/Stability

a) Sequence I Nil Nil

P:67 Nil Nil

b) Sequence II Nil Nil Nil Nil

c) Sequence III

Nil Nil Nil Nil

MAK® makes it possible

Product Data Sheet

IS Typical Figures

Characteristics 1448 81 100 121 150

Appearance -- Clear fluid Clear fluid Clear fluid Clear fluid

Density at 15° C P:16 0.862 0.865 0.868 0.874

K.V at 40° C, cSt P:25 81.4 100.2 121.2 150.5

Viscosity Index P:56 98 96 96 95

Pour Point, °C P:10 -12 -12 -9 -9

Flash Point, (COC), °C P:69 246 248 252 256

Copper Strip Corrosion Test at P:15 1 1 1 1

100°C for 3 hrs.

Foaming Characteristics/Stability

a) Sequence I P:67 Nil Nil Nil Nil

b) Sequence II Nil Nil Nil Nil

c) Sequence III Nil Nil Nil Nil

IS Typical Figures

Characteristics 1448 176 220 320 460

Appearance -- Clear fluid Clear fluid Clear fluid Clear fluid

Density at 15° C P:16 0.880 0.886 0.895 0.904

K.V at 40° C, cSt P:25 176.5 220.1 320.4 460.6

Viscosity Index P:56 94 94 92 92

Pour Point, °C P:10 -9 -6 -6 -6

Flash Point, (COC), °C P:69 258 262 268 272

Copper Strip Corrosion Test at P:15 1 1 1 1

100°C for 3 hrs.

Foaming Characteristics/Stability

a) Sequence I P:67 Nil Nil Nil Nil

b) Sequence II Nil Nil Nil Nil

c) Sequence III Nil Nil Nil Nil

Health and Safety

These oils are not hazardous under normal conditions of use. For further guidance appropriate Material Safety Data Sheet may

be referred.

Bharat Petroleum Corporation Ltd. Edition: R&D / Indl / 035 / Issue 1 / Oct, 2008

Technical Services

A’ Installation, Sewree (East), Mumbai – 400 015

Phone: 022-24176354, Fax: 022-24182511 / 24166512

email: z_techservices@bharatpetroleum.in

MAK® makes it possible

You might also like

- Activated Carbon Filter CalculationDocument2 pagesActivated Carbon Filter CalculationSiavash74% (27)

- Topc 2 HYDROSTATIC PRESSURE - StudentDocument36 pagesTopc 2 HYDROSTATIC PRESSURE - StudentMuhammad AzarulNo ratings yet

- Sigma Fluid PDFDocument2 pagesSigma Fluid PDFHubertt Chacon AntonioNo ratings yet

- Cutback Asphalt (Rapid-Curing Type) : AashloDocument3 pagesCutback Asphalt (Rapid-Curing Type) : AashloNacer KisyNo ratings yet

- Pump & PrimerDocument16 pagesPump & Primerrmaffireschool100% (12)

- Mak Hydrol: Product Data SheetDocument2 pagesMak Hydrol: Product Data SheetSajib Chandra RoyNo ratings yet

- Mak Hydrol HLP Extra Heavy Duty Anti Wear TypeDocument2 pagesMak Hydrol HLP Extra Heavy Duty Anti Wear TypeM/S-S S Black Stone WorksNo ratings yet

- Mak Hydrol HLPDocument2 pagesMak Hydrol HLPAbhimanyaNo ratings yet

- MAK Hydrol AWDocument2 pagesMAK Hydrol AWannamalailubesNo ratings yet

- Mak Turbol EP Data SheetDocument2 pagesMak Turbol EP Data Sheet邢焕震No ratings yet

- PDS Hydrotur RDocument1 pagePDS Hydrotur RBenny Bryle SagunNo ratings yet

- Product Information Fuchs Renolin SC MC SeriesDocument1 pageProduct Information Fuchs Renolin SC MC Seriesandy habibiNo ratings yet

- Green Marine Oks StabDocument1 pageGreen Marine Oks StabTifal MeqrizhaNo ratings yet

- Abb-02-Ics-Das-Enf-000-00001-00 Z-03Document2 pagesAbb-02-Ics-Das-Enf-000-00001-00 Z-03mvdeole7056No ratings yet

- NIC Component Series NTIDocument4 pagesNIC Component Series NTINICCompNo ratings yet

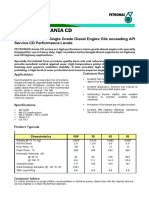

- Petronas Urania CD: High-Performance Single Grade Diesel Engine Oils Exceeding API Service CD Performance LevelsDocument1 pagePetronas Urania CD: High-Performance Single Grade Diesel Engine Oils Exceeding API Service CD Performance LevelsAMAN ULLAHNo ratings yet

- Field Rotameters: Lightweight, Rugged, PortableDocument2 pagesField Rotameters: Lightweight, Rugged, Portablesshosac HigieneNo ratings yet

- Transformer Oil PDFDocument2 pagesTransformer Oil PDFBhanu ChanderNo ratings yet

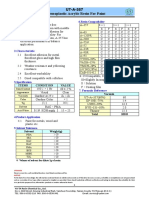

- Thermoplastic Acrylic Resin: UT-A-357NDocument2 pagesThermoplastic Acrylic Resin: UT-A-357NSi PhamNo ratings yet

- 42 Mab 191Document5 pages42 Mab 191false mailNo ratings yet

- Petronas Urania CF: High-Performance Single Grade Diesel Engine Oils Exceeding API Service CF Performance LevelsDocument1 pagePetronas Urania CF: High-Performance Single Grade Diesel Engine Oils Exceeding API Service CF Performance Levelsbarrysmith77No ratings yet

- Petronas Urania CD: High-Performance Single Grade Diesel Engine Oils Exceeding API Service CD Performance LevelsDocument1 pagePetronas Urania CD: High-Performance Single Grade Diesel Engine Oils Exceeding API Service CD Performance LevelsEko SurantoNo ratings yet

- NIC Components NTL SeriesDocument4 pagesNIC Components NTL SeriesNICCompNo ratings yet

- Zic Supervis AwDocument2 pagesZic Supervis AwMohammed Abdul GhafoorNo ratings yet

- Oando Transformer OilDocument3 pagesOando Transformer OilGeorgina SuleNo ratings yet

- Cofran Mecanep 220 enDocument2 pagesCofran Mecanep 220 enMATHEW JOSENo ratings yet

- Dokumen - Tips - Waterborne CNSL Curing Agent For Grout and Adhesive Curing Agent Dry ConcreteDocument16 pagesDokumen - Tips - Waterborne CNSL Curing Agent For Grout and Adhesive Curing Agent Dry Concretem_shahbaghiNo ratings yet

- 989 TDSDocument2 pages989 TDSAchilles NizamopoulosNo ratings yet

- Velvex - 296 Ut: Transformer Oil Product Data SheetDocument9 pagesVelvex - 296 Ut: Transformer Oil Product Data SheetVaradrajan jothiNo ratings yet

- ICHIRO GENBU (ICR-6122 6131) : Product DescriptionDocument2 pagesICHIRO GENBU (ICR-6122 6131) : Product DescriptiondnoaisapsNo ratings yet

- Item - 2 - 80. SN - 3499-03-388Document1 pageItem - 2 - 80. SN - 3499-03-388Jhonatan GonzalezNo ratings yet

- A357Document1 pageA357AceVũNo ratings yet

- EQ2615 Epoxy Adhesive PDFDocument12 pagesEQ2615 Epoxy Adhesive PDFPedro RosaNo ratings yet

- ULTRA DIVERSITY-21 - Oct - 2022 - 06 - 03 - 14-100009554Document15 pagesULTRA DIVERSITY-21 - Oct - 2022 - 06 - 03 - 14-100009554Lee Quan DeNo ratings yet

- shinEtsuRubber PDFDocument12 pagesshinEtsuRubber PDFAmier FaudziNo ratings yet

- 2N6178 RcaDocument8 pages2N6178 RcaJohnnysNo ratings yet

- Condensate Water Tank Data Sheet (1000 m3)Document13 pagesCondensate Water Tank Data Sheet (1000 m3)GunturMudaAliAkbarNo ratings yet

- Bartran HV: Product DescriptionDocument2 pagesBartran HV: Product DescriptionUmberti Boff KolingNo ratings yet

- Motiva Group II Base OilDocument1 pageMotiva Group II Base Oiliescobar0702No ratings yet

- 15B35H, 15B35RHDocument3 pages15B35H, 15B35RHGil CabreraNo ratings yet

- M-1454-22The Executive Engineer EHV (O&M) Div. MSETCL JalnaTr-1, 132 KV Rajur-KT-25000-20-Bottom-14!06!2022mailDocument1 pageM-1454-22The Executive Engineer EHV (O&M) Div. MSETCL JalnaTr-1, 132 KV Rajur-KT-25000-20-Bottom-14!06!2022mailoholkar32No ratings yet

- Polyurathane Resin HardnerDocument32 pagesPolyurathane Resin HardnerPritpal SinghNo ratings yet

- Typical Properties Comparison Supercool HVAC 3G & 4G To Capella WF 32 & 68Document1 pageTypical Properties Comparison Supercool HVAC 3G & 4G To Capella WF 32 & 68Arlex Ricardo Guillen PetitNo ratings yet

- Material Test Report: (Established 1918)Document1 pageMaterial Test Report: (Established 1918)Adrian GalvisNo ratings yet

- Q8 Goya DDocument3 pagesQ8 Goya DMoutaz IsmailNo ratings yet

- Datasheet - Oil PDFDocument1 pageDatasheet - Oil PDFVijay KumarNo ratings yet

- Distribución de CombustibleDocument34 pagesDistribución de CombustibleServicios de Energía EléctricaNo ratings yet

- Principle: King Cloud & Pour Point BathDocument2 pagesPrinciple: King Cloud & Pour Point BathLizaNo ratings yet

- Reunião - 8 - 11 - Powerflow - Pressure Drop EquationsDocument18 pagesReunião - 8 - 11 - Powerflow - Pressure Drop EquationsJoão PedroNo ratings yet

- ASTM Fuel Oil ChartDocument1 pageASTM Fuel Oil ChartsizmaruNo ratings yet

- ASTM Fuel Oil Chart PDFDocument1 pageASTM Fuel Oil Chart PDFsizmaru100% (1)

- Israel Flores Valvula 2Document2 pagesIsrael Flores Valvula 2Israel Flores MamaniNo ratings yet

- Ie 101Document14 pagesIe 101raiNo ratings yet

- RP MOTO TOWN 4T 20W50 EN tcm14-56018Document1 pageRP MOTO TOWN 4T 20W50 EN tcm14-56018TakNo ratings yet

- Adobe Scan 09 Dec 2021Document2 pagesAdobe Scan 09 Dec 2021RAJKUMAR CHATTERJEE. (RAJA.)No ratings yet

- Fluorinert: Electronic Liquid FC-77Document4 pagesFluorinert: Electronic Liquid FC-77asdNo ratings yet

- Apar Transformer Oil PDS - To 1020 60 U PDFDocument1 pageApar Transformer Oil PDS - To 1020 60 U PDFmaa vaishnavi ventureNo ratings yet

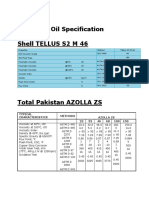

- Specifications For Hydraulic OilDocument3 pagesSpecifications For Hydraulic OilAliya NaseemNo ratings yet

- JCB HP HYDRAULIC FLUID 46 - enDocument2 pagesJCB HP HYDRAULIC FLUID 46 - enMiguel MacedoNo ratings yet

- Certificates-50l O2 CylinderDocument6 pagesCertificates-50l O2 CylinderClaudia TiradoNo ratings yet

- 2-Part Room Temperature Cure Silicone Pottant: Preliminary Data SheetDocument3 pages2-Part Room Temperature Cure Silicone Pottant: Preliminary Data SheetUday TembeNo ratings yet

- 9A01404 Fluid Mechanics & Hydraulic MachineryDocument4 pages9A01404 Fluid Mechanics & Hydraulic MachinerysivabharathamurthyNo ratings yet

- Presentation On Water Issues in PakistanDocument15 pagesPresentation On Water Issues in PakistanEnviro_Pak0% (4)

- 7ed ch09 SolnsDocument232 pages7ed ch09 SolnschaibabyNo ratings yet

- Api Oil Separator: (Fresh Water)Document6 pagesApi Oil Separator: (Fresh Water)Meena Munim100% (1)

- M07 - Separation EquipmentDocument48 pagesM07 - Separation Equipmenthoghost123100% (2)

- Coffee Machine Machine A Cafe Cafetera Eléctrica: Owner's Instructions Mode D'emploi Instrucciones para El UsoDocument19 pagesCoffee Machine Machine A Cafe Cafetera Eléctrica: Owner's Instructions Mode D'emploi Instrucciones para El Usomesk17No ratings yet

- Sedimentation CE4305Document117 pagesSedimentation CE4305Jeezan AzikNo ratings yet

- Ch.4 Plumbing Fixtures and Fixture FittingsDocument6 pagesCh.4 Plumbing Fixtures and Fixture FittingsMac ShaikNo ratings yet

- III-8.1-3GC-three-screw-pump-catalogueSILI-PUMP (Standby Pump)Document13 pagesIII-8.1-3GC-three-screw-pump-catalogueSILI-PUMP (Standby Pump)Jaya BayuNo ratings yet

- 5.4. Falling Film Heat Transfer: 5.4.1. Vertical In-Tube VaporizerDocument2 pages5.4. Falling Film Heat Transfer: 5.4.1. Vertical In-Tube VaporizerRishokNo ratings yet

- Back Pressure Regulator : SRGBPDocument2 pagesBack Pressure Regulator : SRGBPHUNGNo ratings yet

- Chapter 3: ViscoelasticityDocument11 pagesChapter 3: ViscoelasticityHARIMETLYNo ratings yet

- Mesolayer in Turbulent Pipe and Channel FlowsDocument7 pagesMesolayer in Turbulent Pipe and Channel Flowsnoorafzal786No ratings yet

- Chapter One Fluid MechanicsDocument29 pagesChapter One Fluid MechanicsAlexander MugabeNo ratings yet

- Mass Transfer Assignment - 02, 2020Document1 pageMass Transfer Assignment - 02, 2020taha zafarNo ratings yet

- Subcooling Superheating and Liquid Suction Heat ExchangerDocument4 pagesSubcooling Superheating and Liquid Suction Heat ExchangerDeniell Joyce MarquezNo ratings yet

- SL-726 - Rev-00 - EngDocument5 pagesSL-726 - Rev-00 - EngDamirRichterNo ratings yet

- Ex 9 GDocument3 pagesEx 9 GStanleyNo ratings yet

- Saturation and Capillary Pressure in Reservoir RocksDocument30 pagesSaturation and Capillary Pressure in Reservoir Rocksmhdstat100% (1)

- Displacement Thickness and Momentum ThicknessDocument11 pagesDisplacement Thickness and Momentum ThicknessHaroon RasheedNo ratings yet

- Legend: Hydraulic/Hydrostatic Schematic 319 (S/N 563311001 AND ABOVE)Document2 pagesLegend: Hydraulic/Hydrostatic Schematic 319 (S/N 563311001 AND ABOVE)Леонид ЮртаевNo ratings yet

- Fluid Mechanics, ASU QRO Summer 2022, Course MaterialDocument256 pagesFluid Mechanics, ASU QRO Summer 2022, Course MaterialxREDCivicCometxNo ratings yet

- High Power HPC Series Datasheet PDFDocument44 pagesHigh Power HPC Series Datasheet PDFUsama PopatiaNo ratings yet

- Non Mandatory: NotesDocument1 pageNon Mandatory: NotesMarko's Brazon'No ratings yet

- Save Water Speech 2Document2 pagesSave Water Speech 2Harsh HarshNo ratings yet

- Flow and Heat Transfer of A Power-Law Fluid Over A Permeable Shrinking SheetDocument6 pagesFlow and Heat Transfer of A Power-Law Fluid Over A Permeable Shrinking SheetHendarNo ratings yet

- Low Pressure SewersDocument23 pagesLow Pressure SewersUlil A JaNo ratings yet