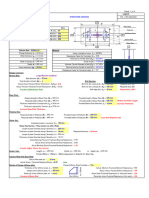

AISC 360-10

01. COLUMN BASE CONNECTION, CBA

H-SHAPE STEEL COLUMN

Calculation of Allowable Axial Force

1) Axial Capacity due to Steel Member, P1

Rn

= 1.67

P2 = Rn/

F cr 0 . 658

Pn = FcrAg

Fe

2E

KL

Fy

Fe

=0.90

Fy

AISC (E3-2)

Fcr=Fy

60% of P1 was applied.

AISC (E3-4)

2) Axial Capacity due to Concrete Bearing Pressure, P2

Rn

= 2.5

P1 = Rn/

Rn = 0.85 x fc' x A1 x

=0.6

A2 / A1 1.7 x fc' x A1

AISC (J8-2)

where : A1 = area of base plate = A x B

A2 = area of pedestal = a1 x b1

a1, b1 = minimum pedestal size

P1 < P2

3) DETERMINE VALUES OF m, n, n', X , and

m = 0.5 (N - 0.95 d)

n = 0.5 (B - 0.8 bf )

AISC DG-1

n' = 0.25 (d bf ) 0.5

4db f P

u ,1

X MIN

2

d b f c Pp

2 X

MIN

,1

1 1 X

4) DETERMINE REQUIRED THICKNESS OF BASE PLATE

t min l

Where,

AISC DG-1

2 Pu

0.9 Fy BN

l MAX ( m, n, n' )

5) Tensile Capacity

a) Tensile Capacity of Anchor Bolts , T1

T1 = Rn/ or Rn

where :

= 2

=0.75

n = number of anchor bolt

Fnt = nominal tensile stress of A307 anchor bolt

Ab = nominal unthread body area of anchor bolt

Rn = n x Fnt x Ab

40% of T1 was applied.

AISC (J3-1)

�b) Tensile Capacity due to Base Plate Bending

AISC DG-1

Requried Moment Strength of the base plate

Mu = T1/n * (G/2 - tw/2)

Ma = T1/n * (G/2 - tw/2)

beff = (G/2-tw/2) * (n/2)

beff t 2

4

t req 'd

Mu 4

beff Fy

t req 'd

M a 4

beff Fy

4) Shear Capacity

a) Shear Strength of Anchor Bolt , V1

V1 = Rn/ or Rn

where :

AISC (J3-1)

= 2

=0.75

n = number of anchor bolt

Fnv = nominal shear stress of A307 anchor bolt

Ab = nominal unthread body area of anchor bolt

Rn = n x Fnv x Ab

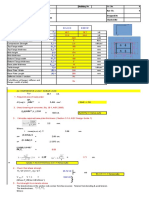

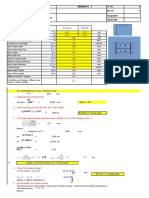

�COLUMN BASE CBA ( H-SHAPE )

MEMBER

MARK

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

42

44

45

46

47

48

BOLT

SIZE

H - 200 x 100 x 5.5 x 8

H - 250 x 125 x 6 x 9

H - 300 x 150 x 6.5 x 9

H - 350 x 175 x 7 x 11

H - 400 x 200 x 8 x 13

H - 450 x 200 x 9 x 14

H - 500 x 200 x 10 x 16

H - 600 x 200 x 11 x 17

H - 194 x 150 x 6 x 9

H - 244 x 175 x 7 x 11

H - 294 x 200 x 8 x 12

H - 340 x 250 x 9 x 14

H - 390 x 300 x 10 x 16

H - 440 x 300 x 11 x 18

H - 488 x 300 x 11 x 18

H - 588 x 300 x 12 x 20

H - 700 x 300 x 13 x 24

H - 800 x 300 x 14 x 26

H - 900 x 300 x 16 x 28

H - 150 x 150 x 7 x 10

H - 200 x 200 x 8 x 12

H - 250 x 250 x 7 x 14

H - 300 x 300 x 10 x 15

H - 350 x 350 x 12 x 19

H - 400 x 400 x 13 x 21

MEMBER

MARK

SIZE

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

42

44

45

46

47

48

H - 200 x 100 x 5.5 x 8

H - 250 x 125 x 6 x 9

H - 300 x 150 x 6.5 x 9

H - 350 x 175 x 7 x 11

H - 400 x 200 x 8 x 13

H - 450 x 200 x 9 x 14

H - 500 x 200 x 10 x 16

H - 600 x 200 x 11 x 1

17

H - 194 x 150 x 6 x 9

H - 244 x 175 x 7 x 11

H - 294 x 200 x 8 x 12

H - 340 x 250 x 9 x 14

H - 390 x 300 x 10 x 16

H - 440 x 300 x 11 x 18

H - 488 x 300 x 11 x 18

H - 588 x 300 x 12 x 20

H - 700 x 300 x 13 x 24

H - 800 x 300 x 14 x 26

H - 900 x 300 x 16 x 28

H - 150 x 150 x 7 x 10

H - 200 x 200 x 8 x 12

H - 250 x 250 x 7 x 14

H - 300 x 300 x 10 x 15

H - 350 x 350 x 12 x 19

H - 400 x 400 x 13 x 21

BASE PLATE

d

(cm)

bf

(cm)

tw

(cm)

tf

(cm)

Ax

(cm2)

Qty

n(pcs)

db

(mm)

dh

(mm)

20.00

25.00

30.00

35.00

40.00

45.00

50.00

60.00

19.40

24.40

29.40

34.00

39.00

44.00

48.80

58.80

70.00

80.00

90.00

15.00

20.00

25.00

30.00

35.00

40.00

10.00

12.50

15.00

17.50

20.00

20.00

20.00

20.00

15.00

17.50

20.00

25.00

30.00

30.00

30.00

30.00

30.00

30.00

30.00

15.00

20.00

25.00

30.00

35.00

40.00

0.60

0.60

0.65

0.70

0.80

0.90

1.00

1.10

0.60

0.70

0.80

0.90

1.00

1.10

1.10

1.20

1.30

1.40

1.60

0.70

0.80

0.90

1.00

1.20

1.30

0.80

0.90

0.90

1.10

1.30

1.40

1.60

1.70

0.90

1.10

1.20

1.40

1.60

1.80

1.80

2.00

2.40

2.60

2.80

1.00

1.20

1.40

1.50

1.90

2.10

27.2

37.7

46.8

63.1

84.1

96.8

114.2

134.4

39.0

56.2

72.4

101.5

136.0

157.4

163.5

192.5

235.5

267.4

305.8

40.0

64.0

92.2

119.8

173.9

218.7

2

4

4

4

4

4

6

6

2

4

4

4

4

4

6

6

6

6

6

2

2

4

4

4

4

20

20

24

24

24

24

24

24

20

20

24

24

30

30

30

30

30

30

36

20

20

24

24

30

30

24

24

30

30

30

30

30

30

24

24

30

30

36

36

36

36

36

36

42

24

24

30

30

36

36

beff

Required Base Plate Thickness

Requried

Tensile

moment

Strength of

strength

Anchor Rod

(Mu, Ma)

(T1)

ASD LRFD ASD LRFD

(kN)

(kN) (kN-m) (kN)

39

58

0.62

0.93

78

117

1.11

1.67

112

168

1.59

2.39

112

168

2.01

3.01

112

168

1.99

2.99

112

168

1.98

2.97

168

252

1.96

2.95

168

2 2

252

19

1.95

2 92

2.92

39

58

0.92

1.37

78

117

1.10

1.65

112

168

1.99

2.99

112

168

2.40

3.60

175

263

4.16

6.25

175

263

4.14

6.21

263

394

4.58

6.87

263

394

4.56

6.84

263

394

4.54

6.80

263

394

4.51

6.77

379

568

6.44

9.66

39

58

0.91

1.36

39

58

1.29

1.93

112

168

1.89

2.84

112

168

2.38

3.58

175

263

4.34

6.51

175

263

4.54

6.80

(mm)

32.0

114.0

113.5

143.0

142.0

141.0

210.0

208

208.5

47.0

113.0

142.0

171.0

190.0

189.0

313.5

312.0

310.5

309.0

306.0

46.5

66.0

135.0

170.0

198.0

207.0

5000

11400

11350

14300

14200

22031

32813

32 8

32578

7344

11300

14200

26719

29688

42525

70538

70200

95091

94631

93713

7266

10313

21094

26563

44550

63394

ASD

(mm)

22.8

16.1

19.4

19.4

19.4

19.4

15.8

1 8

15.8

22.8

16.1

19.4

19.4

24.2

24.2

19.8

19.8

19.8

19.8

23.7

22.8

22.8

19.4

19.4

24.2

24.2

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

E,F

(mm)

120

120

150

150

150

330

400

120

150

180

200

200

320

390

470

530

600

125

180

210

220

LFRD

(mm)

22.8

16.1

19.3

19.3

19.3

19.3

15.8

1 8

15.8

22.8

16.1

19.3

19.3

24.2

24.2

19.7

19.7

19.7

19.7

23.7

22.8

22.8

19.3

19.3

24.2

24.2

G

(mm)

A

(mm)

B

(mm)

tb

(mm)

70

120

120

150

150

150

150

150

100

120

150

180

200

200

220

220

220

220

220

100

140

144

180

210

220

140

190

210

240

240

240

240

240

190

220

240

290

340

340

340

340

340

340

340

190

240

290

340

390

440

240

290

340

390

440

490

540

640

234

284

334

380

430

480

528

628

740

840

940

190

240

290

340

390

440

25

20

20

20

20

25

25

25

25

20

20

25

25

30

30

30

35

35

35

25

25

25

25

30

35

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

RIB PLATE

td

(mm)

Hd

(mm)

10

10

10

10

10

10

10

200

200

200

200

200

200

200

10

10

10

10

12

12

12

12

12

12

200

200

200

200

200

200

200

200

200

200

10

10

12

20

200

200

200

200

PEDESTAL

P1

Concrete Bearing Capa (P2)

h

(mm)

b

(mm)

ASD

(kN)

LRFD

(kN)

Rn1

(kN)

Rn2

(kN)

Min(Rn1&2)

(kN)

350

400

450

490

540

590

640

740

400

420

440

480

540

580

630

730

840

940

1040

400

440

480

520

640

700

350

350

400

420

440

440

440

440

400

420

440

480

540

540

540

540

540

540

570

400

440

480

520

640

700

244

338

420

567

756

869

1026

1207

350

505

650

912

1222

1414

1469

1729

2115

2402

2747

359

575

828

1076

1562

1964

367

508

632

852

1136

1306

1542

1814

527

759

977

1370

1836

2125

2207

2599

3179

3610

4128

540

864

1244

1617

2348

2952

1745

2389

3084

3775

4308

4753

5196

6083

2294

2856

3388

4334

5616

6150

6722

7891

9189

10356

11839

2067

2872

3786

4809

6789

8378

1828

2997

3884

5092

5745

6397

7050

8356

2419

3399

4361

5995

7953

8878

9766

11615

13687

15537

17386

1964

3133

4575

6289

8274

10532

1745

2389

3084

3775

4308

4753

5196

6083

2294

2856

3388

4334

5616

6150

6722

7891

9189

10356

11839

1964

2872

3786

4809

6789

8378

Required Base Plate Thickness

ASD

(kN)

LRFD

(kN)

698

956

1233

1510

1723

1901

2078

2433

918

1142

1355

1734

2246

2460

2689

3157

3676

4143

4736

786

1149

1514

1924

2716

3351

1047

1433

1850

2265

2585

2852

3118

3650

1376

1713

2033

2600

3370

3690

4033

4735

5513

6214

7104

1178

1723

2272

2885

4073

5027

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

m

(mm)

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

25

26

28

29

30

31

33

35

25

26

27

29

30

31

32

35

38

40

43

24

25

26

28

29

30

Shear Strength

of Anchor Rod

(V1)

ASD LRFD

(kN)

(kN)

52

78

104

156

149

224

149

224

149

224

149

224

224

336

224

336

52

78

104

156

149

224

149

224

233

350

233

350

350

525

350

525

350

525

350

525

504

756

52

78

52

78

149

224

149

224

233

350

233

350

P1 = Axial Capacity

T1 = Tension Capacity

V1= Shear Capacity of Anchor Rod

Ratio

Ratio

0.6

0.4

H-shape, A36:

Fy = 250 Mpa

Fu = 400 Mpa

E = 2E+05 Mpa

W ld M

Weld

Metall :

Ft = 480

ASTM (A307) Anchor Bolt :

Fnt = 310

Fnv = 165

Concrete :

fc' =

32

Pedestal:

Cside =

50

Fyreinf = 420

Plate:

Fy = 250

Fu = 400

Mpa

Mpa

Mpa

Mpa

mm

MPa

MPa

MPa

(Clear cover to stirrup)

n

(mm)

n'

(mm)

ASD

LRFD

30

45

45

50

40

40

40

40

35

40

40

45

50

50

50

50

50

50

50

35

40

45

50

55

60

35

44

53

62

71

75

79

87

43

52

61

73

86

91

96

105

115

122

130

38

50

63

75

88

100

0.31

0.31

0.30

0.33

0.39

0.39

0.40

0.37

0.38

0.43

0.46

0.51

0.53

0.55

0.52

0.49

0.48

0.46

0.43

0.46

0.50

0.55

0.56

0.58

0.59

0.31

0.32

0.30

0.33

0.39

0.39

0.40

0.37

0.38

0.43

0.46

0.51

0.54

0.56

0.52

0.49

0.48

0.46

0.44

0.46

0.50

0.55

0.56

0.58

0.59

ramda

ASD LRFD

0.61

0.61

0.60

0.64

0.70

0.70

0.72

0.68

0.68

0.75

0.78

0.84

0.87

0.89

0.85

0.82

0.81

0.78

0.75

0.78

0.83

0.88

0.90

0.92

0.93

0.61

0.61

0.60

0.64

0.70

0.70

0.72

0.68

0.69

0.75

0.79

0.85

0.87

0.89

0.85

0.82

0.81

0.78

0.75

0.78

0.83

0.89

0.90

0.92

0.93

tmin

ASD

LRFD

30.0

45.0

45.0

50.0

49.6

52.6

56.6

58.9

35.0

40.0

47.6

61.5

74.3

81.1

80.9

85.8

92.7

95.8

97.8

35.0

41.4

55.2

67.4

80.3

93.2

30.0

45.0

45.0

50.0

49.6

52.6

56.7

59.0

35.0

40.0

47.6

61.6

74.4

81.2

81.1

85.9

92.8

95.9

98.0

35.0

41.5

55.3

67.5

80.5

93.3

ASD

9.34

12.89

12.62

14.23

15.32

16.51

18.41

19.10

11.36

13.15

15.66

20.46

24.83

27.59

26.76

28.21

31.06

32.10

33.15

12.76

15.13

20.03

23.78

29.76

34.31

LRFD

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

9.3

12.9

12.6

14.2

15.3

16.5

18.4

19.1

11.4

13.1

15.7

20.5

24.9

27.6

26.8

28.3

31.1

32.1

33.2

12.8

15.2

20.1

23.8

29.8

34.4

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK