100%(4)100% found this document useful (4 votes)

1K views49 pagesProject Quality Plan

Prosedur ini menetapkan persyaratan yang harus dipenuhi oleh Peserta Lelang dalam Perencanaan, Penjadwalan, Monitoring dan Evaluasi proyek yang dikelola oleh Peserta Lelang sesuai dengan lingkup pekerjaan.

Tujuan dari prosedur ini adalah untuk meletakkan pedoman untuk pelaksanaan proyek konstruksi secara efisien dari tahap kontrak hingga penyelesaian proyek sesuai dengan kewajiban kontrak sesuai biaya dan waktu yang ditetapkan

Uploaded by

osmondmanurungCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF or read online on Scribd

100%(4)100% found this document useful (4 votes)

1K views49 pagesProject Quality Plan

Prosedur ini menetapkan persyaratan yang harus dipenuhi oleh Peserta Lelang dalam Perencanaan, Penjadwalan, Monitoring dan Evaluasi proyek yang dikelola oleh Peserta Lelang sesuai dengan lingkup pekerjaan.

Tujuan dari prosedur ini adalah untuk meletakkan pedoman untuk pelaksanaan proyek konstruksi secara efisien dari tahap kontrak hingga penyelesaian proyek sesuai dengan kewajiban kontrak sesuai biaya dan waktu yang ditetapkan

Uploaded by

osmondmanurungCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF or read online on Scribd

- Purpose: Explains the goals of the Project Quality Plan and defines its application to quality control and quality assurance.

- Scope: Outlines the extent and boundaries of the project, including the responsibilities and procedures involved.

- Quality Policy: Describes the commitment to client satisfaction, quality standards, and continual improvement.

- Terms & Definitions: Provides a list of essential terms and their definitions as used in the quality management system.

- Management Responsibility: Identifies the roles, responsibilities, and authorities in quality management within the project structure.

- Abbreviation: Lists the abbreviations used in the document for ease of understanding.

- Resources: Details the human and material resources allocated for the project tasks and responsibilities.

- Quality Documentation: Enumerates the various documents that uphold and ensure quality throughout the project.

- Project Management General: Describes general management guidelines and office arrangements for project operations.

- Contract Changes / Amendments: Discusses the procedures for implementing and documenting any changes or amendments to contracts.

- Document and Data Control: Defines the control and storage methodologies for documents and records related to the project.

- Purchasing: Outlines procedures for purchasing, including vendor evaluations and approval processes.

- Control of Customer Supplied Product: Sets procedures for handling customer-supplied items during the project.

- Inspection and Test Status: Covers the methods for assessing and recording inspection and testing results.

- Control of Inspection, Measuring and Test Equipment: Ensures that equipment is calibrated and maintained for project use.

- Inspection and Test Status: Explains the status markers used after products have been inspected or tested.

- Control of Non-Conforming Product & Corrective Action: Specifies procedures for managing and correcting non-conforming products.

- Control of Project Records: Details the measures for maintaining and accessing project records, including security and archiving.

- Internal Quality Audit: Describes audit procedures to ensure the adherence to quality management standards.

- Training: Emphasizes the necessity of training to achieve quality standards and competence.

- Control of Construction Work: Provides guidelines for managing and supervising construction activities for quality assurance.

- Sub Contractor Control: Covers the evaluation and management of subcontractors in accordance with quality expectations.

- List of Applicable Documents: Lists all documents relevant to management, safety, and project control.

- Annexures: Supplementary materials and charts that support the main document.

SOUTH SUMATRA WEST JAVA GAS PIPELINE PROJECT

PHASE II Fa conmens, Woe ocee

[] teneccamrente, Werkmay proceed,

LT meas tenon.

[7] rater commen wert may nat raced

the eso ni acumen.

tee

PROJECT QUALITY PLAN

DESCRIPTION rev | avrv | rev. [ ape.

PLL-PTPLI

consortium | PPTU/Par

STATUS CODE: 1 = Approved -2 = Approved except as noted - 3 = Not Approved (Resubmit) 4 = For Information Only

‘TOTAL OR PARTIAL REPRODUCTION ANDIOR UTILIZATION OF THIS DOCUMENT ARE FORBIDDEN

WITHOUT PRIOR WRITTEN AUTHORIZATION OF PT. PUNJ LLOYD INDONESIA

a8.

CONSULTANT: PENSPEN LIMITED ~ PT. PETRO TECHINDO UTAMA

a cuX

CONTRACTOR:

PUNJ LLOYD LIMITED - PT. PUNJ LLOYD INDONESIA CONSORTIUM

‘ SOUTH SUMATRA WEST JAVA GAS TANSMISSION PIPELINE PHASE II

P— Jeorsuar:psnaren uinea-revnoreomoouramn B®.

ae Nagare | CONTRACTOR: PUNJ LLOYDLIMITED. PT PUN LLOYD INDONESIA CONSORTIN EEE

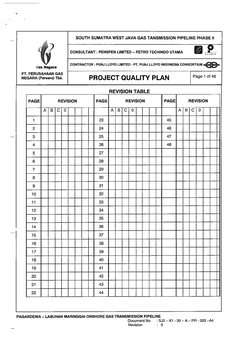

NEGARA erer) TOK, PROJECT QUALITY PLAN Page 1 of 8

REVISION TABLE SESE

PAGE| REVISION, PAGE REVISION PAGE| REVISION

“[ayB{cyo 7 A]B]Cyo AlB/C{o

7 Z 6

2 2 «6

3 2 7

4 26 #8

5 a

6 2

7 29

8 30

9 31

10 2

W EJ

2 38

8 3

14 36

5 7

16 38

17 3

18 40

19 at

2 2

24 43

2 a

PAGARDEWA — LABUHAN MARINGGAI ONSHORE GAS TRANSMISSION PIPELINE

Document No: SJ2~K1-30-A—PR- 003 —Aa

Revision 0

‘SOUTH SUMATRA WEST JAVA GAS TANSMISSION PIPELINE PHASE II

>| consucrantvensrenvuren esto recmnourann BD,

Bee ‘CONTRACTOR : PUNJ LLOYD LIMITED PT. PUNY LLOYD INDONESIA CONSORTIUM ZFS

PT, PERUSAHAAN GAS

NEGARA (Persero) Tok PROJECT QUALITY PLAN Page 2 of 48

—____|

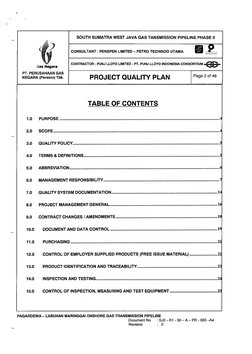

TABLE OF CONTENTS

10

2.0

3.0

4,0 TERMS & DEFINITIONS snnnnmnnnamnnenianamn

5.0 ABBREVIATION...

6.0 MANAGEMENT RESPONSIBILITY.

7.0 QUALITY SYSTEM DOCUMENTATION .wnrnsenmn

8.0 PROJECT MANAGEMENT GENERAL everceoneurnnnnamnene

9.0 CONTRACT CHANGES / AMENDMENTS,

10.0 DOCUMENT AND DATA CONTROL wmrenounanenmen

11.0 PURCHASING...

12.0 CONTROL OF EMPLOYER SUPPLIED PRODUCTS (FREE ISSUE MATERIAL) overaneonenenen23)

13.0 PRODUCT IDENTIFICATION AND TRACEABILITY.

14,0 INSPECTION AND TESTING serminenssnnn

15,0 CONTROL OF INSPECTION, MEASURING AND TEST EQUIPMENT.

PAGARDEWA~ LABUHAN MARINGGAI ONSHORE GAS TRANSMISSION PIPELINE

Document No: SJ2—K1-30-A~PR- 003-Aa

Revision 0

SOUTH SUMATRA WEST JAVA GAS TANSMISSION PIPELINE PHASE II

SoS rT a aa Le

i a

i CONTRACTOR PUNY LLOYDLIMTED- PT. PUN LLOYD NDONESIA CONSORTIUM BES

PT. PERUSAHAAN GAS:

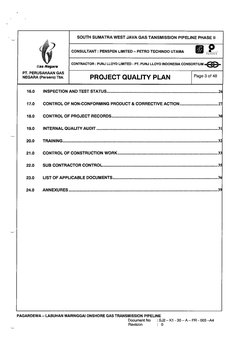

NEGARA (Perera) Tok PROJECT QUALITY PLAN Page 3 ota

16.0 INSPECTION AND TEST STATUS cov 29

17.0 CONTROL OF NON-CONFORMING PRODUCT & CORRECTIVE ACTION wninsnunnnnnnnn 2

18.0 CONTROL OF PROJECT RECORDS...

19.0 INTERNAL QUALITY AUDIT.

20.0 TRAINING...

21.0 CONTROL OF CONSTRUCTION WORK...

22.0 SUB CONTRACTOR CONTROL...

23.0 LIST OF APPLICABLE DOCUMENTS.

2A.0 ANNEXURES swnnsrnnnn

PAGARDEWA— LABUHAN MARINGGAI ONSHORE GAS TRANSMISSION PIPELINE

Document No : SJ2—K1-30-A—PR- 003 Aa

Revision 0

SOUTH SUMATRA WEST JAVA GAS TANSMISSION PIPELINE PHASE II

PT covsucanr:renerauiurea-reroresincouraun OB

‘CONTRACTOR : PUNJ LLC Pr eS a

feeds ,0YD LIMITED - PT. PUNJ LLOYD INDONESIA CONSORTIUM —ZES=

PT. PERUSAHAAN GAS

NEGARA rover) Tok PROJECT QUALITY PLAN Page 4 ot

1.0 PURPOSE

The purpose of this document is to describe the Quality Control and Quality

Assurance Program which shall be implemented by Punj Lloyd - PT. Punj Loyd

Indonesia Consortium for SOUTH SUMATRA WEST JAVA GAS PIPELINE

PROJECT PHASE II.

The document describes the Quality Control and Quality Assurance

organization, which includes a description of implementation procedures for

Quality Control and Quality Assurance for PAGARDEWA — LABUHAN

MARINGGAI ONSHORE GAS TRANSMISSION PIPELINE and roles and

responsibilities of personnel and management.

PUNJ LLOYD LIMITED - PT. PUNJ LLOYD INDONESIA CONSORTIUM is

committed to ensure QA/QC functions during all phases of the CONTRACT and

also to ensure that work performed meets the various standard specifications

consistent with the Client's Engineering and design requirements as well as

complying with the Quality Control requirements.

2.0 SCOPE

This PROJECT QUALITY PLAN (PQP) is applicable for construction of the

SOUTH SUMATRA WEST JAVA GAS PIPELINE PROJECT PHASE Il. POP provides

evidence of PUNJ LLOYD LIMITED - PT. PUNJ LLOYD INDONESIA

CONSORTIUM Management's commitment and responsibilities for Quality

Control and Quality Assurance.

PAGARDEWA — LABUHAN MARINGGAI ONSHORE GAS TRANSMISSION PIPELINE

Document No: SJ2—K1-30—A—PR - 003 -Ad

Revision 10

NEGAAA (rae) TOR PROJECT QUALITY PLAN eee

SOUTH SUMATRA WEST JAVA GAS TANSMISSION PIPELINE PHASE I

CONSULTANT : PENSPEN LIMITED ~ PETRO TECHINDO UTAMA

contracron: er.

a : PUNY LLOYD LIMITED -PT. PUNY LLOYD INDONESIA CONSORTIUM ZS

30

4.0

at

42

QUALITY POLICY

We are committed to Client Satisfaction and loyalty. Our endeavor is to reduce

cost and cycle times through effective and efficient use of resources.

Organisational capabilities will be continually improved to retain competitive

advantange by aligning our process, to build strong business relationships with

clients and suppliers. We endeavor to be the customer's preferred choice in

everything we do. Our clients will experience professional competence and a

high level of service in our deliveries.

‘A copy of the quality policy signed by the authorized signatory is attached in

annexure-1.

TERMS & DEFINITIONS

Quality

The totality of features and characteristics of a product or service that bears on

its ability to satisfy stated or implied needs.

Quality Policy

The overall Quality intentions and direction of an organization as regards

Quality as formally expressed by top management.

PAGARDEWA — LABUHAN MARINGGAI ONSHORE GAS TRANSMISSION PIPELINE

Document No: $J2~K1-30-A-PR-003—A4

Revision 0

SOUTH SUMATRA WEST JAVA GAS TANSMISSION PIPELINE PHASE It

ge

as ‘CONTRACTOR : PUNY LLOYD LIMITED- PT, PUNY LLOYD INDONESIA CONSORTIUM -€ZE>=

PT, PERUSAHAAN GAS

NEGARA Pros) Toe PROJECT QUALITY PLAN Page 6of48

43 Quality Management

The aspect of the overall management function that determines and implements

the Quality Policy.

4.4 Quality System

The organizational structure, responsibilities, procedures, processes and

resources for implementing Quality Management.

4.5 Quality Assurance (QA)

All the activities implemented within the Quality System and demonstrated as

needed, to provide adequate confidence that an entity will fulfil requirements for

Quality.

48 Quality Control (@)

The operational techniques and activities that are used to fulfill requirements for

Quality.

5.0 ABBREVIATION

EMPLOYER PT. PERUSAHAAN GAS NEGARA (Persero) Tbk

PROJECT South Sumatra West Java Gas Pipeline Project Phase II

THE PROJECT MANAGER - SOUTH SUMATRA WEST JAVA GAS

ENGINEER piPELINE PROJECT PHASE Il

CONSULTANT — Penspen Limited — PT. Petrotechindo Utama

CONTRACTOR = Punj Lloyd Limited - PT. Punj Lloyd Indonesia Consortium

oT Destructive Testing

NOT Non Destructive Testing

HSE Health, Safety and Environment

QHSE Quality, Health, Safety and Environment

ac Quality Control

QsM Quality System Manual

sP Standard Procedure

Pap Project Quality Plan

FIM Free Issue Material

PAGARDEWA - LABUHAN MARINGGAI ONSHORE GAS TRANSMISSION PIPELINE

No :$J2—K1-30—A~PR-003-Ad

Revision 0

‘SOUTH SUMATRA WEST JAVA GAS TANSMISSION PIPELINE PHASE Il

yy?

consuLTaT:Paxspen uuTeD-eemnoTecunco urn — OD

cas Negara | SONTRACTOR LUNI LLOYD LMTED-PT. PUNY LLOYD INDONESIA CONSORTIUM MS

NEGARA (Perse) TO PROJECT QUALITY PLAN | Pras

6.0 MANAGEMENT RESPONSIBILITY

61 Scope

This section defines the Contractor's management responsibility, functional

organization and individual's responsibility for implementation of Quality

Procedure of various activities to achieve the Quality Policy.

62 Organisation

The PROJECT MANAGER shall have the overall responsibility and authority for

control, direction and management for the implementation of the project,

although the project activities and responsibilities are directly delegated to

discipline manager and key persons for carrying out the task as defined in the

project organization chart (Refer to Annexure — 2):

Annexure 2a: Project Organization Chart.

juality Assurance and Quality Control Organization Chart.

Annexure 2b:

6.3 Function and Responsibility

6.3.1, Project Director Responsible for the operation and

performance of the whole organization and

overall management. Responsible for

formulation of the establishment and

distribution of authority. Responsible to

ensure that the detailed requirements of the

Project Quality, Health, Safety &

Environmental Plan are implemented across

the Project.

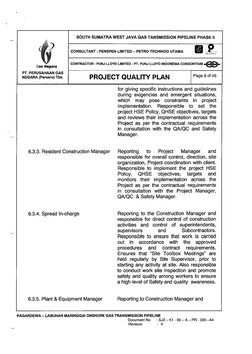

6.3.2, Project Manager Reporting to Project Director. Responsible

PAGARDEWA ~ LABUHAN MARINGGAI ONSHORE GAS TRANSMISSION PIPELINE

Document No: SJ2~K1-30—A~PR -003 Ad

Revision Po

SOUTH SUMATRA WEST JAVA GAS TANSMISSION PIPELINE PHASE I

P — [consucsrivarsrenunren-emorecmco umn ©

i CONTRACTOR :PUNI LLOYD LIMITED PT, PUNJ LLOYD INDONESIA CONSORTIUM mEEED=

NEGARA ferser) TOK PROJECT QUALITY PLAN Page Bo 48

for giving specific instructions and guidelines

during exigencies and emergent situations,

which may pose constraints in project

implementation. Responsible to set the

project HSE Policy, QHSE objectives, targets

and reviews their implementation across the

Project as per the contractual requirements

in consultation with the QA/QC and Safety

Manager.

6.3.3, Resident Construction Manager Reporting to Project Manager and

responsible for overall control, direction, site

organization, Project coordination with client.

Responsible to implement the project HSE

Policy, QHSE objectives, targets and

monitors their implementation across the

Project as per the contractual requirements

in consultation with the Project Manager,

QA/QC & Safety Manager.

6.3.4. Spread In-charge Reporting to the Construction Manager and

responsible for direct control of construction

activities and control of superintendents,

‘supervisors and ‘Subcontractors.

Responsible to ensure that work is carried

out in accordance with the approved

Procedures and contract requirements.

Ensures that “Site Toolbox Meetings” are

held regularly by Site Supervisor, prior to

starting any activity at site. Also responsible

to conduct work site inspection and promote

safety and quality among workers to ensure

ahigh level of Safety and quality awareness.

6.3.5. Plant & Equipment Manager Reporting to Construction Manager and

PAGARDEWA - LABUHAN MARINGGAl ONSHORE GAS TRANSMISSION PIPELINE

Document No: $J2—K1-30-A-—PR-003-A4

Revision Po

i ‘SOUTH SUMATRA WEST JAVA GAS TANSMISSION PIPELINE PHASE I

‘CONTRACTOR: PUNJ LLOYD LIMITED PT. PUNY LLOYD INDONESIA CONSORTIUM mEE>=

Gas Negara

PT. PERUSAHAAN GAS.

NEGARA (Persero) Tok. PROJECT QUALITY PLAN Page 9 of 48

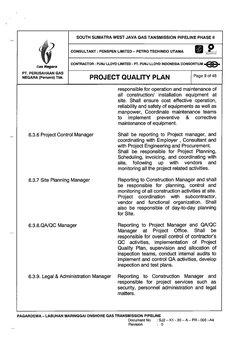

responsible for operation and maintenance of

all construction’ installation equipment at

site. Shall ensure cost effective operation,

reliability and safety of equipments as well as

manpower, Coordinate maintenance teams

to. implement preventive & corrective

maintenance of equipment.

6.3.6 Project Control Manager Shall be reporting to Project manager, and

coordinating with Employer , Consultant and

with Project Engineering and Procurement.

Shall be responsible for Project Planning,

Scheduling, invoicing, and coordinating with

site, following up with vendors and

monitoring all the project related activities.

6.3.7 Site Planning Manager Reporting to Construction Manager and shall

be responsible for planning, control and

monitoring of all construction activities at site.

Project coordination with subcontractor,

vendor and functional organization. Shall

also be responsible of day-to-day planning

for Site.

6.3.8.QA/QC Manager Reporting to Project Manager and QA/QC

Manager at Project Office. Shall be

responsible for overall control of contractor's

QC activities, implementation of Project

Quality Plan, supervision and allocation of

inspection teams, conduct intemal audits to

implement and control QA activities, develop

inspection and test plans.

6.3.9. Legal & Administration Manager Reporting to Construction Manager and

responsible for project services such as

security, personnel administration and legal

matters.

PAGARDEWA ~ LABUHAN MARINGGAI ONSHORE GAS TRANSMISSION PIPELINE

Document No : $J2—K1-30-A~PR -003-A4

Revision 0

Pl

SOUTH SUMATRA WEST JAVA GAS TANSMISSION PIPELINE PHASE It

Gas Negara

‘CONTRACTOR PUNS LLOYD LIMTED PT. PUN LLOYD INDONESIA CONSORTIUM EES

PT. PERUSAHAAN GAS

NEGARA (Perser) Tok PROJECT QUALITY PLAN Page 10 of 48

6.3.10. HSE Manager

6.3.11. HSE Coordinator (SITE)

Shall support and encourage his manpower

to maintain safe working practice in all the

activities. Shall also enforce appropriate

disciplinary action towards any breach of the

Project Rules and Procedures.

Reporting to Project Manager and

responsible to monitor the implementation of

the HSE plan and appraise the Project

Manager on all Safety matters related to the

project.

Responsible to review safety systems and

work procedures to ensure that it confirms

with Safety system & prepare the risk

assessment for review and approval.

Shall Co-ordinate for planned Safety training

and awareness programs.

Shall act as the Safety auditor and shall

liaise with EMPLOYER / ENGINEER.

Shall compile, monitor and report Safety

statistics and identify trends and areas

required more attention, risk reduction or

systems improvement.

Shall report administratively to Spread in-

charges and functionally to HSE Manager.

Responsible to monitor the implementation of

the HSE and shall review & monitor the

“Safety systems” and work procedures to

ensure that it confirms with CONTRACTOR

and Project Safety system,

Shall ensure that all persons receive

induction training, prior to the issue of their

PAGARDEWA— LABUHAN MARINGGAI ONSHORE GAS TRANSMISSION PIPELINE

Document No: SJ2—K1-30—A—PR - 003 -A4

Revision 0

SOUTH SUMATRA WEST JAVA GAS TANSMISSION PIPELINE PHASE II

) lexmasanr rearaisms-rcroccwcomin OP

CONTRACTOR: PUNJ LLO | consuranrrensrevunren-rersovecmoo umn @_®

{CONTRACTOR : PUN LLOV LIMITED -PT.PUNI LLOYD INDONESIA CONSORTIUM ~ZE>=

66

7.0

7A

standards, statutory requirements, Project specifications and the Project Quality

Plan.

The Project QA/(QC Manager shall be the representative for Quality at site and

where appropriate, liaise with PROJECT MANAGER on matters related to the

operation of the Project Quality Plan and procedures. Project QA/QC Manager

shall review Corrective Action Requests, audit reports and Non conformance

reports and monitor the performance of the Quality management system.

Management Review

The project team shall highlight any problems, difficulties or proposed

amendments to Project Quality Plan at internal meetings. Monthly once the

PROJECT MANAGER in conjunction with the Project QA/QC Manager shall

review the continuing suitability and effectiveness of the Project Quality Plan

and update it where necessary to reflect changes to practices, audit findings,

issues resolved at internal meetings and feedback.

QUALITY SYSTEM DOCUMENTATION

Basis of Project Quality Plan

The CONTRACT requires contractor to provide Engineering, Procurement,

Construction, installation and testing services with required equipment,

manpower, material and services to carry out their part of Scope of Work with

the Contract Specifications, Scope of work and Project Procedures and as

working defined hereunder:

+ Survey of the Pipeline routes and preparation of survey.

PAGARDEWA— LABUHAN MARINGGAI ONSHORE GAS TRANSMISSION PIPELINE

Document No : $J2—K1-30-A~PR- 003 -A4

Revision 0

SOUTH SUMATRA WEST JAVA GAS TANSMISSION PIPELINE PHASE I

2 [eomenraer paneoruamen reno remcovran OB ©

CONTRACTOR : PUNJ LLOYD LIMITED - PT. PUN a>

a LLOYD INDONESIA CONSORTIUM —EZES—

NEGARA (Perse) TOK PROJECT QUALITY PLAN Page 15 of 48

* Construction and installation engineering.

+ Procurement and supply of consumables and equipment necessary for the

execution of work,

+ Prefabrication of Plant Components in yard.

+ CONSTRUCTION on SITE.

‘+ Interfacing with INDONESIAN Certifying Authority. (MIGAS)

+ Mobilization / demobilization of Construction Equipment.

+ Temporary protection of existing facilities.

* Crossing and Site preparation work.

+ Reinstatement.

+ Provision of Final Documentation.

The Project Quality Plan is based on the following documents:

1. CONTRACT Documents.

2. Quality System Manual — PLI.QS04.01

3. ISO 9001 - 2000 — Quality Management System Requirements

7.2 Project Quality Plan Attachments

The attachments to this document are current at the date of issue of the Project

Quality Plan. Revision of attachments may be undertaken in a contractual

manner without re-issue of the Project Quality Plan and in this instance holders

of controlled copies of the Project Quality Plan will be provided with

revised/modified attachments.

7.3 Revision and Distribution

Where revision is necessary, the Project QA /QC Manager shall revise the

Project Quality Plan .

PAGARDEWA - LABUHAN MARINGGAI ONSHORE GAS TRANSMISSION PIPELINE

Document No: SJ2—K1 -30~—A~ PR - 093 -Aé

Revision PO

‘SOUTH SUMATRA WEST JAVA GAS TANSMISSION PIPELINE PHASE I

cou roereumco seve women van OO?

i Pr.

aa ‘CONTRACTOR: PUN LLOYD LIMITED PT PUNY LLOYD INDONESIA CONSORTIUM ZS

NEQAHA poroe) TOR PROJECT QUALITY PLAN Page 16 of 48

Each revision of the Project Quality Plan shall be distributed by Document

Controller and the distribution shall be updated by the Project Planning

Manager.

7.4 Procedures and Controls

All important functions for the execution of the project are controlled by

Employer approved documented procedures, the Contract Specifications ,

International Standards and Project Specification.

8.0 PROJECT MANAGEMENT GENERAL

8.1 General

The project shall be controlled in accordance with:

4) Quality System Manual.

2) Project Coordination Procedure

3) Approved Construction procedures.

4) Contract Documents

8.2 Project Offices and Contacts

The offices and contact details of the main parties involved in the project are:

a) EMPLOYER

Pt. PERUSAHAAN GAS NEGARA (PERSERO) Tbk.

dl. K. H. Zainul Arifin No. 20

Jakarta 11140, INDONESIA. PO Box 1119 Jkt

Phone + 62 (021) 633 4838, 633 4848, 633 4861 Ext. 1512

Fax : 62 (021) 633 6308, 633 3080

Contact: Mr. M, Napitupulu (Project Manager)

b) CONSULTANT

Penspen Limited — PT. Petrotechindo Utama

Jl. Batu Ceper No. 28,

PAGARDEWA - LABUHAN MARINGGAI ONSHORE GAS TRANSMISSION PIPELINE

Document No: SJ2—K1-30—A—PR-003-A¢

Revision 0

SOUTH SUMATRA WEST JAVA GAS TANSMISSION PIPELINE PHASE I

CONSULTANT : PENSPEN LIMITE!

ETRO TECHINDO UTAMA

az Negara | SONTRACTOR:PUNI LLOYD LINTED- FT. PUN LLOYD INDONESIA CONSORTIUM EES=

NESARA arr) TO PROJECT QUALITY PLAN Page 17048

Jakarta 10120,

INDONESIA

Phone: (021) 381 2054

Telefax: (021) 381 4039

Contact: Mr. Peter Harling (Project Manager)

©) CONTRACTOR OFFICE (CORPORATE):

PT. Punj Lloyd Indonesia, Project Office

Ventura Building, 4th Floor, Suite 401 B

Jl. R.A. Kartini Kav. 26

Jakarta — 12430, INDONESIA.

Phone: (021) 7591 4766

Telefax: (021) 7591 4241

Contact: Mr. Praveen K. Chand (Project Manager)

d) CONTRACTOR OFFICE (SITE):

PT. PUNJ LLOYD INDONESIA

~ SOUTH SUMATRA WEST JAVA GAS TRANSMISSION PIPELINE PROJECT

Marika, Bukit Sezatera, Block BT — 06,

RT 15 RW4, PALEMBANG

Phone: (0711) 443168

Telefax: (0711) 443168

Contact: Mr. R. M. Shukla (Resident Construction Manager)

8.3 Project Correspondance and Filing System

Correspondence shall be controlled in accordance with Employer approved

Project Coordination Procedure — SJ2-K1-30-A-PR-001-A4

PAGARDEWA - LABUHAN MARINGGAI ONSHORE GAS TRANSMISSION PIPELINE

Document No: SJ2~K1-30-A-PR-003-A4

Revision 0

‘SOUTH SUMATRA WEST JAVA GAS TANSMISSION PIPELINE PHASE It

yy

CONSULTANT: pensPeN iwTeD-psrno Tecuwoo urawa —

CONTRACTOR: PURI LLOYD LIMITED FT. PUN LLOYD INDONESIA CONSORTIUM #ZE>=

Gas Negara

PT, PERUSAHAAN GAS

NEGARA (Persero) Tbk. PROJECT QUALITY PLAN | pee ian Ae

9.0 CONTRACT CHANGES / AMENDMENTS

9.1 Scope

This section defines the necessary measures to ensure that adequate control is

in place for contract changes/amendments in the tender and contract

performance in order to meet the contractual requirements and obligations set

forth in the contract review document.

9.2 Applicable References

The CONTRACT changes / amendments shall be registered, controlled and

resolved with EMPLOYER / ENGINEER in accordance with the CONTRACT

AGREEMENT and Employer approved Change Order Procedure — SU2-K1 —

30 -A-—PR -006~ Aa.

9.3 Review

‘The CONTRACT Review is carried out jointly by responsible individuals in the

Business/Technical and Design/Engineering Dept. and coordinated with other

functional organization in the execution phase. Consequently the review is

pursued further with EMPLOYER / ENGINEER representative to resolve

contractual issues both commercial and technical requirement of the

CONTRACT for formal CONTRACT AGREEMENT.

9.4 Changes / Amendements / Deviations

All Contract changes, which affect Contract Schedule price either initiated by

functional organizations or EMPLOYER / ENGINEER shall be formalized in

writing and brought to the attention of responsible individuals affected by such

PAGARDEWA — LABUHAN MARINGGAI ONSHORE GAS TRANSMISSION PIPELINE

‘Dooumé

jentNo : SJ2—K1-30-A~PR-003-A4

Revision Po

SOUTH SUMATRA WEST JAVA GAS TANSMISSION PIPELINE PHASE It

Py

CONSULTANT : PENSPEN LIMITED ~ PETRO TECHINDO UTAMA

az Nagare | CONTRACTOR: PUNY LLOYD LITED-PT. PUNJ LLOYD NDONESIA CONSORTIUM mEZES=

PT. PERUSAHAAN GAS.

NEGARA Perse) Thi PROJECT QUALITY PLAN Page 19048

changes for review and approval of the PROJECT MANAGER and EMPLOYER

J ENGINEER REPRESENTATIVES.

For the purpose of this document and CONTRACT review the CHANGE

ORDER request/ deviation reports has been essentially divided into three main

contractual areas of control viz.,

1. During Procurement Activity: supplier clarification and exceptions

2. During Project Execution: request for site variations or relaxation

3, During all Phases: where formal change to the scope of wor

EMPLOYER / ENGINEER.

issued by

95 Records

All records of transactions generated from “Contract Review" which is part of

the Contract, shall be classified and controlled for safekeeping.

10.0 DOCUMENT AND DATA CONTROL

10.1 Scope

This section defines the necessary measures to ensure that adequate control is

in place during document and data preparation, numbering, review, approval,

verification, revisions, distribution/issuance, removal of superseded or invalid

documents, and hand-over documents both technical and commercial

generated by functional organizations as per the Contract Agreement and

Employer approved Project Coordination Procedure, document No. SJ2-Ki —

30 A— PR — 001 — A4 and Change Order Procedure — SJ2-K1 — 30 - A - PR —

006 ~ Aa

PAGARDEWA - LABUHAN MARINGGAI ONSHORE GAS TRANSMISSION PIPELINE

Document No. :$J2~K1-30—A~PR - 003 -A¢

Revision Po

SOUTH SUMATRA WEST JAVA GAS TANSMISSION PIPELINE PHASE I

2 eowurr:emermunres-renoreomoouran OB 2.

‘CONTRACTOR : PUNJ LLOYD LIMITED - PT.

oy PT. PUNJ LLOYD NDONESIA CONSORTIUM MZ

NEGARA frersera) TOK PROJECT QUALITY PLAN [Page 2018

10.2 Types of Documents

All documents containing information & data that require necessary sections

such as for review, approval, distribution, issuance or received and as defined

in scope of this section shall be recorded and controlled.

The following is the list of documents to which documents control shail be applied.

Drawings and Specifications

Quality Records (Inspection and Test Records procedures & ITP ‘s)

Subcontract Documents.

Vendor's Appraisals

Codes and Standards

Work Procedures

Non conformities

NOORON A

10.3 Document Approval & Issuance

‘All documents/data generated by functional organizations or received from

SUBCONTRACTOR and VENDORS which require appropriate action will be

carried out by responsible individuals in accordance with documented

procedures prior to use. Such documents are identified with the current revision

status and made available to individuals in order to preclude use of obsolete

documents.

The issuance and distribution of latest documents is recorded and transmitted

by the Document Controller.

10.4 Document Changes

PAGARDEWA - LABUHAN MARINGGAI ONSHORE GAS TRANSMISSION PIPELINE

Document No: SJ2—K1-30-A~PR - 003-84

Revision 0

‘SOUTH SUMATRA WEST JAVA GAS TANSMISSION PIPELINE PHASE I

“P| consuravrsvensroruure-rernorcomoo uraun 2

(CONTRACTOR : PUNJ LLOYD LIMITED - PT, PUNY LLOYD INDONESIA CONSORTIUM EE

Gas Negara

NEGARA raera) To PROJECT QUALITY PLAN emer

Any changes or modifications made in the document are reviewed and

APPROVED in similar manner by Employer / Engineer as was done for original

document unless otherwise designated.

The identification of any revisions within the body of the agreement shall be

reflected clearly in the document and re-issued to concerned organizations for

subsequent action.

11.0 PURCHASING

11.1 General

All purchased materials, components and assemblies, which directly affect the

quality of construction or product, shall be identified in the Pipe book. All such

procurement activities are planned and controlled by Employer approved

documented procedures.

The Contractor maintains a close working relationship and feedback system

with each Employer approved VENDOR/SUBCONTRACTOR for continued

quality improvement.

11.2 Applicable References

1. Employer Approved Procurement and Material Control Procedure

2, The Contract Agreement

8. Employer Approved Change order Procedure

11.3. Evaluation of Contractor's Subcontractor/Vendors

Each Employer Approved SUBCONTRACTOR / VENDORS is assessed for

capability to supply the specified product. The assessment takes into account

their technical and financial resources so as to ensure that the product is

delivered on time and meets the quality requirement fully.

PAGARDEWA — LABUHAN MARINGGAI ONSHORE GAS TRANSMISSION PIPELINE

Document No: SJ2~K1-30~A~PR-003—A4

Revision 0

114

115

12.4

‘SOUTH SUMATRA WEST JAVA GAS TANSMISSION PIPELINE PHASE II

P| consuasrsvescren ere ecmoouran OD,

cas ‘CONTRACTOR : PUNJ LLOYD LIMITED PT. PUN LLOYD INDONESIA CONSORTIUM =ZS3=

PT. PERUSAHAAN GAS

NEGARA (Persere) Tok PROJECT QUALITY PLAN eee

List of Employer approved SUBCONTRACTORS / VENDORS with relevant

records of previously demonstrated capability and performance is maintained.

Periodic review of the performance of each Employer APPROVED

SUBCONTRACTOR shall be carried out based on which his APPROVED

status is extended or withdrawn.

Purchases are made only from Employer APPROVED SUBCONTRACTORS /

VENDORS. In case of suitable SUBCONTRACTOR / VENDORS is not in the

APPROVED SUBCONTRACTORS / VENDORS list, Employer approval must

be obtained prior to placing any trial order .

Purchasing Data

All purchasing documents contain data clearly describing the technical

specifications(as per $J2-K1-30-A-PR-005) for the product, applicable drawings

and standards, process and inspection requirements and delivery schedule for

the product. All purchase documents are reviewed and approved for adequacy

by the Employer / Engineer prior to release.

Verification of Purchased Product

‘The nature of verifications by which conformance to requirements will be met is

‘specified in the purchase order. All such verifications are carried out to fulfill the

‘specified requirements. All verification reports are recorded.

12 CONTROL OF EMPLOYER SUPPLIED PRODUCTS (FREE ISSUE MATERIAL)

Scope

This section defines the necessary measures to ensure that all COMPANY

supplied products “Free Issue Material” (FIM) are identified and controlled,

during project execution,

PAGARDEWA — LABUHAN MARINGGAI ONSHORE GAS TRANSMISSION PIPELINE.

Docume

went No: SJ2~K1 -30—A—PR-003-A4

Revision PO

‘SOUTH SUMATRA WEST JAVA GAS TANSMISSION PIPELINE PHASE II

p)

consutranr:penseen uwreo pero recunwourann — 2

‘CONTRACTOR : PUNS LLOYD LIMITED - PT, PUNJ LLOYD INDONESIA CONSORTIUM €Z5=

ove Regare

NEGARA Perse) To. PROJECT QUALITY PLAN Page 28 of

12.2 Applicable References

12.3

The following procedures shall be used to control Employer-supplied products

(Free Issue Material):

4. Employer Approved Procedure for Coated Line Pipe Receiving, Handling,

Transportation, Storage And Inspection SJ2-K1-30-C-PR-001

2. Employer approved Material traceability report Su2-K1-30-Q-PR-001

3. Employer approved Procurement and Material Control Procedure SJ2-K1-

30-A-PR-005 .

Receiving Inspection

COMPANY supplied items shall be inspected before taking delivery for

damage, completeness and compliance with the Contract Specifications.

Any product that is damaged or unsuitable for use shall be recorded and

reported as per Employer approved Procedure for Coated Line Pipe Receiving,

Handling, Transportation, Storage and Inspection. SU2-K1-30-C-PR-001

43 PRODUCT IDENTIFICATION AND TRACEABILITY

13.4

13.2

Scope

This section specifies the requirements of proper identification of the products

for trace ability before installation as per the applicable procedures.

Applicable Reference

The following procedure shall be used to control traceability of materials:

1. Employer approved Inspection and Traceability Procedure SJ2-K1-30-Q-PR-001]

PAGARDEWA — LABUHAN MARINGGAI ONSHORE GAS TRANSMISSION PIPELINE

Document No : $J2—K1-30-—A—PA- 003 -Aa

Revision 10

SOUTH SUMATRA WEST JAVA GAS TANSMISSION PIPELINE PHASE I

?

CONSULTANT: PENSPEN LiMTED-perRO TecunoouTaun —

ie CONTRACTOR : PUN LLOYD LIMITED. PT PUN LLOYD INDONESIA CONSORTIUM mE

PT. PERUSAHAAN GAS.

NEGARA (Poser) To PROJECT QUALITY PLAN Page 24 of 48

2. Employer approved Procurement and Material Control Procedure SJ2-K1-

30-A-PR-005

13.3. Identification and Traceability

All materials shall be traceable from source through to installation. All items

shall be identifiable by the marking done during receipt and storage as per

Employer approved procedure. SJ2-K1-30-Q-PR-001

14 INSPECTION AND TESTING

14.1 Scope

This section defines the necessary measures to ensure that adequate

procedures are in place for the inspection and testing, and monitoring activities

during construction phase.

14.2 Applicable References

The Inspection and Test Plans to be submitted with each construction

procedure, with applicable reference shall be used to control inspection and

testing.

14.3. Characteristics of Inspection

The inspection activities shall be performed at the required, identified stages to

permit all required inspection such as dimensional, NDT/DT and visual

performance test, as specified in the Contract Specification, Project

Specifications, International Standards and MIGAS requirements.

PAGARDEWA— LABUHAN MARINGGAI ONSHORE GAS TRANSMISSION PIPELINE.

Document No: SJ2—K1 -30—A—PR-003 Aa

Revision 0

SOUTH SUMATRA WEST JAVA GAS TANSMISSION PIPELINE PHASE II

HL | eet ecient tanta te nae

(CONTRACTOR : PUNJ LLOYD LIMITED. PT. PUNJ LLOYD INDONESIA CONSORTIUM <€—=

Gas Negara

PT. PERUSAHAAN GAS

NEGARA (Persero) Tok PROJECT QUALITY PLAN Page 25 of 48

14.4 Inspection and Test Records

All inspection and test records shall be securely kept, maintained and provided

with appropriate identification for traceability and future reference.

15 CONTROL OF INSPECTION, MEASURING AND TEST EQUIPMENT

15.4

15.2

Scope

This section defines the inspection , test and calibration requirements of

measuring instrument and equipment, which are used for demonstrating the

conformance of product or process to be utilized during installation.

The measuring and test equipment used for conformance testing shall be

controlled as per list of measuring and test equipments - identified, calibrated

and controlled by the Site @A/QC Manager.

Control Procedure

The equipmentiinstruments required for inspection, measuring and testing are

selected on the basis of measurement parameters and accuracy level required

for controlling the process and product characteristics. The instruments are

caliberated at prescribed intervals against certified equipment having

traceability to internationally or Indonesian recognized standards.

instrument calibration reports include type of equipment, unique identification,

location, frequency of checks and acceptance criteria, calibration dates and

recalibration dates.

Al instruments issued to site are marked with identification number, date of

calibration, due date of calibration and accuracy level. These are handled and

stored in such a way that the accuracy and fitness for use is maintained, where

PAGARDEWA— LABUHAN MARINGGAI ONSHORE GAS TRANSMISSION PIPELINE

Document No: SJ2—K1-30-A—PR-003-A4

Revision 0

Gas Negara

NEGARA (rersore) TOK PROJECT QUALITY PLAN Page 26 of 3

‘SOUTH SUMATRA WEST JAVA GAS TANSMISSION PIPELINE PHASE II

2

CONTRACTOR: PUNS LLOYD LIMITED PT. PUNS LLOYD INDONESIA CONSORTIUM

‘CONSULTANT : PENSPEN LIMITED — PETRO TECHINDO UTAMA

‘CONTRACTOR: PUNJ LLOYD LIMITED - PT, PUNY LLOYD INDONESIA CONSORTIUM EEE

Manpower requirement and mobilization schedule shall be maintained as per

approved project schedule and updated as required by planning department in

consultation with Construction Manager and THE PROJECT MANAGER.

Requirement of Plant & Equipment

Requirement of Plant & Equipment, its mobilization schedule and its shifting

shall be maintained as per approved project schedule and updated by Planning

Dept. in consultation with Construction Manager and THE PROJECT

MANAGER as well as Maintenance Manager.

Requirement of Measuring & Test Equipment

Project QA / QC Manager shall maintain and record Type and number of

equipments ,their requirement,the calibration and status of all the Measuring &

Test Equipments, which are required for the project. PROJECT MANAGER

shall provide the required “Measuring & Test Equipments” to the Project QA /

QC Manager.

Consumable Requirement and Mobilization Schedule

Planning Dept. shall ensure that adequate supplies of consumables required,

their mobilization and status during the execution phase in coordination with

Stores Officer shall be such that no delays will be incurred due to lack of

adequate consumable supplies.

Field Document Control

The control of documents shall be carried out for receiving, recording and

distribution of project materials, Construction drawings, Specifications,

PAGARDEWA— LABUHAN MARINGGAI ONSHORE GAS TRANSMISSION PIPELINE

Document No: $J2—K1 -30-A~PR.- 003 -A4

Revision ro

SOUTH SUMATRA WEST JAVA GAS TANSMISSION PIPELINE PHASE II

2

‘CONSULTANT : PENSPEN LIMITED — PETRO TECHINDO UTAMA

‘cas Megara | CONTRACTOR: PUNSLLOYD LIMITED. PT. PUNY LLOYD INDONESIA CONSORTIUM EES

NEGARA Perera) Tok PROJECT QUALITY PLAN Page 35 of 48

Technical query, Non conformance, inspection reports and other related

documents in accordance with the Project requirements.

22.8 Health Safety & Environment Management (HSE)

Implementation of HSE measures will be by Project Safety Manager,

Construction Manager, the respective Spread supervisors & HSE Supervisors

and overall responsibility shall be borne by PROJECT MANAGER for

implementation as per Employer approved Project HSE Plan. SJ2- K1- 30-N-

PR-001

The Project Safety Manager and Safety Engineers shall advise construction /

installation teams on safety practices to be implemented at site to reduce risk to

manpower, equipment and facilities.

HSE Plan shall be read along with Emergency Response Plan and Risk

Assessment . SJ2- K1- 30-NPR-002-.

23 SUB CONTRACTOR CONTROL

23.1 Scope

This section defines the necessary measures to ensure that adequate control is

in place for performance of subcontracted work in order to meet the specified

technical requirement.

23.2 Applicable References

The following procedure shall be used to implement Sub Contractor Control :

Procedure QUALITY PLAN / INSPECTION PLAN of SUB CONTRACTOR SJ2-

K1-30-A-PR-13-A4,

PAGARDEWA — LABUHAN MARINGGAI ONSHORE GAS TRANSMISSION PIPELINE

DooumentNo :$J2-K1-30-A~PR-003 Ad

Revision oO

SOUTH SUMATRA WEST JAVA GAS TANSMISSION PIPELINE PHASE Il

2 ‘CONSULTANT : PENSPEN LIMITED ~ PETRO TECHINDO UTAMA. $

= ‘CONTRACTOR: PUM LLOYD LIMITED PT PUNY LLOYD INDONESIA CONSORTIUM MZES—

PT. PERUSAHAAN GAS

NEGARA (Persero) Tok. PROJECT QUALITY PLAN Page 26 of 48

23.3 Assessment by CONTRACTOR

All SUBCONTRACTORS will be qualified and assessed based on their

capability to meet the technical requirements, experiences of similar work

projects, organization structure and Quality standards among others in

accordance with Procedure for Project Planning and Control and will be

approved by Employer / Engineer.

23.4 Subcontract Control

Subcontract activities will not be allowed to commence until all Engineering

requirements such as Construction drawings; procedures, Quality assurance

and necessary submittals have been reviewed and Approved by EMPLOYER/

ENGINEER /CONTRACTOR.

24 LIST OF APPLICABLE DOCUMENTS

Project Document Register SJ2-K1-30-A-PR-002 shall be issued regularly

24.1 Project Specific Documents :

SNO. | DOCUMENT DESCRIPTION

PROJECT MANAGEMENT DOCUMENTS,

QUALITY CONTROL DOCUMENTS

QUALITY ASSURANCE DOCUMENTS

SAFETY DOCUMENTS:

GENERAL PROCEDURES

SPECIFIC CONSTRUCTION PROCEDURES:

@lalalojrm|—

PAGARDEWA — LABUHAN MARINGGAI ONSHORE GAS TRANSMISSION PIPELINE

Document No :SJ2~Ki-30~-A~PR-003 Ad

Rovsion =: 0

SOUTH SUMATRA WEST JAVA GAS TANSMISSION PIPELINE PHASE I

2

consuLravr:penspen iureD-perno tecunoo ran —

casAegara | CONTRACTOR: PUN/ LLOYD LMITED- PT PUNY LLOYD NDONESIA CONSORTIUM | cencaa:sasronancrewercomcoumn 2. |

Gas Negara

CONTRACTOR : PUNJ LLOYD LIMITED - PT. PUNS LLOYD INDONESIA CONSORTIUM mZES=

NEGARA (person) THE PROJECT QUALITY PLAN

Page 39 of 48,

Manual of Contractor.

24.3 EMPLOYER Contractual Documents

24.4 INSPECTION AND TEST PLANS

per the Annexure - 4,

25 ANNEXURES

ANNEXURE-1 QUALITY POLICY

ANNEXURE-2 ORGANIZATION CHARTS

a) Project Organization Chart

ANNEXURE—3 List of Internal Auditors.

ANNEXURE—4 List of Inspection Test Plan.

ANNEXURE-—5 _List of Formats.

ANNEXURE-6 = Audit Schedule.

All above department procedures will be a part of Corporate Quality System

Documents which is issued by EMPLOYER / ENGINEER to CONTRACTOR and

contractually agreed between both parties (CONTRACTOR & EMPLOYER).

Inspection and Test Plans for various activities shall be developed for the project.ag

b) Quality Assurance and Control Organization Chart.

PAGARDEWA — LABUHAN MARINGGAI ONSHORE GAS TRANSMISSION PIPELINE

Document No|

Revision

sell

We are an engineering construction company —

delivering projects and services in global markets _

of the Dyrecapor and les sectors

QUALITY POLICY

_ We are committed to client satisfaction

- and loyalty. Our endeavour is to | reduce cost and cycle times _

through’ effective and efficient use of resources. Or

capabilities will be continually improved to retain

advantage by aligning our processes, to build stron: business

relationships with clients and : suppliers. We endeavour: to

_ be the customer's preferred choice i in everything wedo. —

Our Clients will experience professional competence and ‘i

a high level of service in 1 UE deliveries.

gy

‘Chairran & Managng Director

dine 27 2008

( SOUTH SUI TRA WEST JAVA GAS PIPELINE PRC CT PHASE II

PAGARDEWA TO LABUHAN MARINGGAI ONSHORE GAS TRANSMISSION PIPELINE

PUNJ LLOYD LIMITED - PT. PUNJ LLOYD INDONESIA CONSORTIUM.

ee ORGANIZATION CHART - PROJECT MANAGEMENT AND SUPPORT

Date 4-Jan-2006

Ponjene scoop] Me er Doc. No. $32-30-A-OC-001-A4, Rey 1

I

I

i Franc rena

L__| maven onene

away

‘oe

Tapers ORE Taree

Treason Se

Fad taster

wesudhakar = | Rowena!

——

Taaesrg Fear corer i

fe somayar peo a0 |

= Faar I i

ton f—]tnineer “Coratvacton Toa Rater = i aes a

sie Karon raokired BRETT] | | er

Train $22.30: 06-0024 sasonseoa |i aos

Coordinating ‘Document Controlier _ {

{| sena i i

— I i Environmental

7 i bo] tagicer™

i Ceara

i |_|

i

i i

i

i

i

i

mi i

ssuntontarcor al

risrowom

LEGEND :

=== cammuneaton Line

orig tine

+ Construction site baredin South Sumatera

Br 30 1k 29N,

SOUTH SUI “RA WEST JAVA GAS PIPELINE PROJE

PAGARDEWA TO LABUHAN MARINGGAI ONSHORE GAS TRANSMISSION PIPELINE

PUNJ LLOYD LIMITED - PT. PUNJ LLOYD INDONESIA CONSORTIUM

ORGANIZATION CHART - CONSTRUCTION MANAGEMENT AND SUPPORT

PHASE II

Date 28-Nov-2005

Doc. No. $12-30-A-OC-002-A4, Rev 0

FTE sopatnnaaone

Kero

ar singh

Josh}

B/E Spariniendon

ep. Singh

Foreman

Topariident

10. Suk

Superior

‘Seniay

Foremen

TE peritonde

Se Tepe

Fyaeng

‘Eraning

A. Upscrayey

L_siaiaaa ar}

Carano

TB7E supertancent

postin

“nen

same

‘Sprintendent

Ure cheata

Coo

‘periianenr

‘Upadhyay

“Tie

Satie works

Superintendent

fi

Br 40 ty 290d

‘SOUTH SUMATRA WEST JAVA PIPELINE PROJECT

(CLIENT :PI-PERUSAGAN GAS NEGERA. a

‘CONSULTANT : BENSPEN LINITED - PT. PETROTECHINDO UTAMA

PUNJ LLOYD LIMITED - PT. PUNJ LLOYD INDONESIA GAIGC ORGANIZATION CHART- PROJECT MANAGENENT AND CONSTRUCTION =

Er 30 ce aged

Jene 44 of 48

SOUTH SUMATRA WEST JAVA GAS TANSMISSION PIPELINE PHASE I!

>

CONSULTANT: PENSPENLIMTED PETRO TECHNO UTANA

CONTRACTOR: PUNJ LLOYD LIMITED - PT. PUNY LLOVD INDONESIA CONSORTIUM ZED

as Negara

PT. PERUSAHAAN GAS

NEGARA (Persero) Tok. PROJECT QUALITY PLAN

ANNEXURE —3

List Of Internal Auditors:

‘SLNo. Name ‘Auditor For |” Positioned at

i MK. VENKATAPATHY OHSAS &1SO_|H.0.

2 Mr.M.D.ACHARYA “[iSO SITE

3 MiSUSHIL SINGH BHIST 1s0 HO

4 Mr.SATHISH RAJAKUMAR ISO STE

5 MirS.SRAO 1S0 SITE

PAGARDEWA ~ LABUHAN MARINGGAI ONSHORE GAS TRANSMISSION PIPELINE

Document No: SJ2—K1-30—A—PR-003-A4

Revision re

PGE 4S oF 4B

SOUTH SUMATRA WEST JAVA GAS TANSMISSION PIPELINE PHASE II

2

‘CONSULTANT : PENSPEN LIMITED - PETRO TECHINDO UTAMA

9: PUN LLOYD LIMITED Pr,

i conracroy 0 PUNI LLOYD MDONESIA CONSORTIUM EES

PT. PERUSAHAAN GAS.

NEGARA (Persero) Tbk. PROJECT QUALITY PLAN

ANNEXURE — 4

LIST OF INSPECTION AND TEST PLANS:

1. Procedure for coated line pipe Receiving, $J2-K1-30-C-PR-001 ITP.

Handling, Transportation,Storage and Inspection.

2. Procedure for Pipeline Survey $J2-K1-30-C-PR-003 ITP

3._Procedure for Pipeline ROW Grading SJ2-K1-30-C-PR-004 ITP

4. Procedure for Pipe Hauling and Stringing S$J2-K1-30-C-PR-006 ITP.

5. Procedure for Trenching ‘$J2-K1-30-C-PR-007 ITP

6, Procedure for Cold Field Bending ‘$J2-K1-30-C-PR-008 ITP.

7. Procedure for mainline Welding ___$J2-K1-30-C-PR-009 ITP.

8. Thrust Boring Procedure SJ2-K1-30-C-PR-015 ITP.

9. Procedure for pre Hydrostatic testing S$J2-K1-30-C-PR-O19ITP_

410. Field Joint coating Procedure $J2-K1-30-C-PR-020 ITP

11. Pipeline lowering Procedure $J2-K1-30-C-PR-021 ITP

42. Tie in Procedure SJ2-K1-30-C-PR-023 ITP

1 13, Backfilling Procedure SJ2-K1,

14. Pipeline Reinstatement & Restoration SJ2-K1

15. Prefabrication and installation of Piping $J2-K1-30-C-PR-026 ITP

And valves.

16. Surface preparation and painting $J2-K1-30-C-PR-027 ITP

17. Hydrostatic testing SJ2-K1-30-C-PR-028 ITP

PAGARDEWA — LABUHAN MARINGGAI ONSHORE GAS TRANSMISSION PIPELINE

Document No: SJ2~K1-30—A~PR-003-A4

Revision re

Pree 4b oF ya

‘SOUTH SUMATRA WEST JAVA GAS TANSMISSION PIPELINE PHASE lI

CONSULTANT: PENSPeWLMITED-perROTecHNDO uTawa —

: LIMITED - PT. PUN,

ae CONTRACTOR : PUNJ LLOYD | \J LLOYD INDONESIA CONSORTIUM EE

PT. PERUSAHAAN GAS

EGARA pure) tok PROJECT QUALITY PLAN |

ANNEXURE — 5

List of Formats

Line pipe receipt inspection report + $J2-K1-30-C-PR-001-A4-AF-01

Material reject /damage report = $J2-K1-30-C-PR-001-A4-RF-02

$J2-K1-30-C-PR-005-A4-RF-01

‘$J2-K1-30-C-PR-003-A4-RF-01

Engineering Survey Inspection report

Pipeline Construction survey inspection report

Field Change Notice = SJ2-K1-30-C-PR-003-A4-RF-02

Daily Right of way inspection report > $J2-K1-80-C-PR-004-A4-RF-01

Hauling and stringing inspection report = $J2-K1-30-C-PR-006-A4-RF-01

Pipe Despatch report = SU2-K1-30-C-PR-036-A4-RF-01

Trench excavation inspection report > SJ2-K1-30-C-PR-007-A4-RF-01

Bending inspection reports - SJ2-K1-30-C-PR-008-A4-RF-01

Line up weld visual inspection report > 8J2-K1-30-C-PR-009-A4-RF-01

RT Formats - — $U2-K1-30-C-PR-011-A4-RF-01

Repair weld visual inspection report - SU2-K1-0-C-PR-009-A4-RF-02

‘Arc Burn inspection Report - SJ2-K1-30-C-PR-009-A4-RF-03

~] _ Inspection report for crossing by Thrust boring - - SJ2-K1-30-C-PR-015-A4-RF-01

Inspection report for open cut crossings = 8J2-K1-30-C-PR-016-A4-RF-01

Pre hydrostatic test record = SU2-K1-80-C-PR-019-A4-RF-01

Field joint coating report - 8U2-K1-30-C-PR-020-A4-RF-O1

Lowering in report - SJ2-K1-30-C-PR-021-A4-RF-02

Pipe line cover inspection report = SU2-K1-80-C-PR-021-A4-RF-01

Tie in weld inspection report - $J2-K1-30-C-PR-023-A4-RF-01

Backfilling report = SU2-K1-30-C-PR-024-A4-RF-01

PAGARDEWA— LABUHAN MARINGGAI ONSHORE GAS TRANSMISSION PIPELINE

Document No: SJ2—K1~30—A~PR- 003 -As

Revision c

POCE AT oF 4g

‘SOUTH SUMATRA WEST JAVA GAS TANSMISSION PIPELINE PHASE I

)

ae!

‘CONTRACTOR : PUNY LLOYD LIMITED -P. PUNJ LLOYD INDONESIA CONSORTIUM MEE =

Gas Negara

PERUSAHAAN GAS

NEGARA (Persero) Tok. PROJECT QUALITY PLAN

Hydro Testing report - SJ2-K1-30-C-PR-028-A4-(RFO1-

RF 011)

Restoration report - $J2-K1-30-C-PR-025-A4-RF-01

NON CONFORMANCE REPORT > $J24K1-30-C-PR-009-A4-RF-01

CONCESSION REPORT. - $J24K1-80-C-PR-025-A4-RF-02

REGISTER NON CONFORMANCE. = SJ2-K1-30-C-PR-025-A4-RF-03

PAGARDEWA - LABUHAN MARINGGAI ONSHORE GAS TRANSMISSION PIPELINE

Document No: $J2~K1 -30—A-PR-003-Aa

Revision Pe

DEDRTWENT AREA TO BE AUOETED

ANENEERING

meocuRCAENT

‘PROECT PLANNING & CONTROL

cosstruction

ane

conmeacts

06a

nse

Lama cQUIMENT

‘PURCHASES STORES

‘Sa TEAL

ontat

open oa

PRCT

SUT Sumac Wes JAVA.

Plaine Poel

vay

CONTIACTOR?UNy LOYD UNaTED

-mipunj Lieve npowesa conor (EET

<——

wT

om

-

Bb 9 Br aved

You might also like

- 220802DBQA50001 - EXCO04 - 56 Project Quality Plan100% (5)220802DBQA50001 - EXCO04 - 56 Project Quality Plan56 pages

- PRO-PQP-QA-0001 Project Quality Plan - Rev.0ANo ratings yetPRO-PQP-QA-0001 Project Quality Plan - Rev.0A15 pages

- EPC Quality Plan for Gasoil and LPG TanksNo ratings yetEPC Quality Plan for Gasoil and LPG Tanks37 pages

- Project Quality Plan for BOGT InstallationNo ratings yetProject Quality Plan for BOGT Installation14 pages

- Quality Plan - Geotechnical Investigation Work For MSSA 1No ratings yetQuality Plan - Geotechnical Investigation Work For MSSA 139 pages

- AP1202-QS-C-002-Quality Plan-01-100-KEL-10-PLN-0001Rev0100% (2)AP1202-QS-C-002-Quality Plan-01-100-KEL-10-PLN-0001Rev034 pages

- IST-04 Instrument and Control System Architecture (R0) Update 29042025No ratings yetIST-04 Instrument and Control System Architecture (R0) Update 290420253 pages

- Low Power Autonomous Controller Fcn-Rtu: Network-Based Control SystemNo ratings yetLow Power Autonomous Controller Fcn-Rtu: Network-Based Control System4 pages

- BU53U01A01-01E - 012 Yokogawa LNG Supply ChainNo ratings yetBU53U01A01-01E - 012 Yokogawa LNG Supply Chain9 pages