Professional Documents

Culture Documents

SAP MRP Procedure Parameter PDF

Uploaded by

anilOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SAP MRP Procedure Parameter PDF

Uploaded by

anilCopyright:

Available Formats

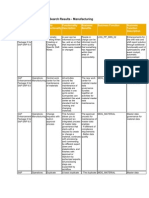

Configuration of the SAP MRP Procedure Parameter

Conduction of disposition (MRP procedure, MRP policy)

Material not critical and no demand (during last x months)

OR: Minimal planning effort requested (planning with BOM-successor through BOM explosion): C-item

NO

YES

Demand-driven (MRP, plan-based, deterministic) vs consumption-based disposition

LT + LT of BOM-successors < acc. LT

Production smoothing and strategic stocking are not primary goals of material planning

YES

NO

Consumptionbased

No disposition

Saisonal product?

Planning according

to BOM explosion

Demand-driven

(MRP)

VS

Saisonal planning

Supplier manages

stock more efciently?

YES

NO

MRP with Master Schedule items (critical items)

Material has signicant inuence on production performance

OR production technology highly inuences the production process

OR high share on overall turnover (A-item) AND top level BOM item

Replenishment policy

Material planning conducted for customer

SMI demand-driven

SM

NO

Replenishment

policy

BOM explosion

No disposition

X0, X1

ND

Consumption-based

(normal)

YES

Internal or external

customer

NO

Plan-driven + periodic review

Continuous review applicable

technical and organizational

Delivery at any date possible, no xed intervals?

A or B items only, if high control costs

YES

Plan-driven and

continuous review

Planning with fixing horizon:

high planning nervousness over BOM

Planning with fixing horizon:

high planning nervousness over BOM

YES

NO

R1 with PD

YES

P1

(periodic)

YES

PD

NO

YES

NO

P3

(periodic)

P2

(periodic)

Continuous review applicable

technical and organizational

Delivery at any date possible, no xed intervals?

A or B items only, if high control costs

Use of VMI-module

NO

P4

(periodic)

YES

P1

(continuous)

YES

NO

Set and fix order proposal

autmatically without manual control

NO

P2

(continuous)

YES

P3

(continuous)

NO

Set and fix order proposal

autmatically without manual control

NO

YES

M1

P3: (M3 with MPS items)

not automatic xing of order proposals

necessary proposals are shifted to the end of

the fixing horizon

RE

NO

YES

Continuous review

Periodic review

Continuous review

(reorder point policy)

Dynamic target stock

level (A or Y,Z item)

Dynamic target stock

level (A- or Y,Z item)

Consider external

requirements

(Reservations etc.

not adequately

considered in forecast and safety stock)

M3

NO

YES

M2

M4

YES

RR

NO

RS

NO

YES

RF

RP

Periodic review

Consider external

requirements

P2 (M2 with MPS items)

Order proposals are xed withing xing horizon

No automatic setting of new order proposals

A shortage situation in xing horizon is not

balanced automatically

constant demand

(X-item)

B-/C-items

Order cost relatively

high

var. demand

(Y, Z item)

A-items

ordering costs

relative low

No consideration

of ext. requirem.

periodic reorder point

policy (T,s,S), R2

periodic stochastic

policy (s, S), VV

NO

Set reorder point

automatically

good forecast quality

P4 (M4 with MPS items)

Order proposals are not generated automaticaly

A shortage situation is not balanced

YES

V1

Taken from 'Automatic Parameter Conguration for Inventory Management in SAP ERP/APO' by David Bucher and Joern Meissner, available at: http://www.meiss.com

delivery schedule in

place

relatively stable average daily demand

(X-item)

use dynamic ss (R1)

NO

YES

P1 (M1 with MPS items):

Order proposals within the xing horizon get xed

(but no new proposals)

Continuous review applicable

technical and organizational

Delivery at any date possible, no xed intervals?

A or B items only, if high control costs

NO

Set and fix order proposal

autmatically without manual control

P4

(continuous)

NO

YES

Generate order proposals automatically? (good

forecast quality)

YES

Set and fix order proposal

autmatically without manual control

NO

YES

VI

NO

M0: No automatic fixing of order proposals

Generate order proposals automatically? (good

forecast quality)

YES

Set and fix order proposal Set and fix order

proposal manual control

YES

External customer

Planning with fixing horizon:

high planning nervousness over BOM

NO

Generate order proposals automatically? (good

forecast quality)

Set and fix order proposal Set and fix order

proposal manual control

Internal customer

MRP with Master

Schedule items

Demand-driven

(MRP)

NO

V2

Set reorder point

automatically

good forecast quality

YES

VB

NO

VM

Periodic policy

width range of

coverage profile

Delivery rhythm depends on day of order

YES

Periodic with

delivery rhythm

You might also like

- Retail Pricing Worklist GuideDocument15 pagesRetail Pricing Worklist GuideKarunGaurNo ratings yet

- S4H VC Data ModelsDocument68 pagesS4H VC Data ModelsShailesh Mahajan100% (1)

- CRM Overview & Master Data - Day1Document239 pagesCRM Overview & Master Data - Day1anilNo ratings yet

- QMDocument17 pagesQMbishwa198No ratings yet

- SAP REM Full Cycle Scenario With Basic StepDocument12 pagesSAP REM Full Cycle Scenario With Basic StepAjay KumarNo ratings yet

- LSMW Data Migration MethodsDocument8 pagesLSMW Data Migration Methodssouvik karmakarNo ratings yet

- Create Classic BADI with Single UseDocument25 pagesCreate Classic BADI with Single UseanilNo ratings yet

- Can MRP Be Carried Out For One Particular Level of A BomDocument10 pagesCan MRP Be Carried Out For One Particular Level of A BomVipul ShuklaNo ratings yet

- MRPDocument27 pagesMRPRAMAKRISHNA.GNo ratings yet

- SAP Documentary BatchDocument3 pagesSAP Documentary BatchvrkattulaNo ratings yet

- SAP Master Data - OvewviewDocument38 pagesSAP Master Data - OvewviewMilind ShirolkarNo ratings yet

- EHP5 Enhancements in PP ModuleDocument8 pagesEHP5 Enhancements in PP ModulekiranmagarNo ratings yet

- Organizational Structure in SAPDocument9 pagesOrganizational Structure in SAPHardik SharmaNo ratings yet

- Master Data and Enterprise Structure Configuration:: Organizational Units in AccountingDocument9 pagesMaster Data and Enterprise Structure Configuration:: Organizational Units in AccountingmayurNo ratings yet

- P25 Img Consumption Based PlanningDocument23 pagesP25 Img Consumption Based PlanninglymacsauokNo ratings yet

- Sap Master Data in Materials ManagementDocument13 pagesSap Master Data in Materials Managementedmondo77No ratings yet

- Simplification of MRP Functionality Is DoneDocument6 pagesSimplification of MRP Functionality Is DoneraaghuNo ratings yet

- SAP WM SyllabusDocument7 pagesSAP WM Syllabuskurrysuchit50% (2)

- SAP Note BookDocument8 pagesSAP Note Bookమనోహర్ రెడ్డిNo ratings yet

- PP Basics UnderstandingDocument7 pagesPP Basics UnderstandingprashantsdpikiNo ratings yet

- LO935 Flexible Planning: Release 640 04/06/2006Document220 pagesLO935 Flexible Planning: Release 640 04/06/2006KRISHNANo ratings yet

- Anubandh - SAP MM - 4.6 Yrs of ExperienceDocument5 pagesAnubandh - SAP MM - 4.6 Yrs of ExperienceMallu LoharNo ratings yet

- BBP - PP - V1.0 DraftDocument145 pagesBBP - PP - V1.0 Draftnp71727No ratings yet

- Scoping Workshop SAP PPDocument21 pagesScoping Workshop SAP PPMohd FadzilNo ratings yet

- SAP customer project billing guideDocument36 pagesSAP customer project billing guideDanielpremassis100% (1)

- SAP PO ConfirmationsDocument18 pagesSAP PO Confirmationsarrowxen8396100% (1)

- SAP PP Material Planning PDFDocument39 pagesSAP PP Material Planning PDFzramuk3No ratings yet

- What is SAP? Introduction to ERP Software ModulesDocument4 pagesWhat is SAP? Introduction to ERP Software ModulesharibabuNo ratings yet

- Sap Apo DP NutsellDocument53 pagesSap Apo DP NutsellSundaran NairNo ratings yet

- Idea /asset Name: LSMW To Upload SAP Master Data MaterialsDocument19 pagesIdea /asset Name: LSMW To Upload SAP Master Data Materialssksk1911No ratings yet

- Configuration Rationale Document - Personnel StructureDocument11 pagesConfiguration Rationale Document - Personnel Structurepkank09100% (1)

- Steps To Create A Simple LSMW Using Batch Input RecordingDocument18 pagesSteps To Create A Simple LSMW Using Batch Input RecordingSharad TiwariNo ratings yet

- Period Closing in Sap Ecc6Document14 pagesPeriod Closing in Sap Ecc6Roohi AjmeraNo ratings yet

- End-To-End SAP Fiori Extensibility Use CaseDocument72 pagesEnd-To-End SAP Fiori Extensibility Use CasePallaviNo ratings yet

- MM Scope Document by Mansoor Ali SeelroDocument10 pagesMM Scope Document by Mansoor Ali SeelroAL-HAMD GROUP100% (5)

- Determine Order Priority in PP/DSDocument2 pagesDetermine Order Priority in PP/DSvikashdhimanNo ratings yet

- Sap SD TopicsDocument6 pagesSap SD Topicssoorya6969No ratings yet

- Forms Functional SpecificationDocument3 pagesForms Functional SpecificationSAP_2006No ratings yet

- SAP PP ProcessDocument51 pagesSAP PP Processkannanraj666No ratings yet

- Resume SAPDocument3 pagesResume SAPdeebhaNo ratings yet

- SAP MM ContentDocument5 pagesSAP MM ContentSiva ChalicheemalaNo ratings yet

- SAP MRP What Is SAP MRP - Material Requirement PlanningDocument2 pagesSAP MRP What Is SAP MRP - Material Requirement Planningswayam100% (1)

- PP-Master Data To BeDocument13 pagesPP-Master Data To Bekoushik goswamy100% (1)

- Discrete Vs REMDocument4 pagesDiscrete Vs REMShashank Mani TripathiNo ratings yet

- SAP PP - Demand ManagementDocument2 pagesSAP PP - Demand ManagementAr CahyadiNo ratings yet

- 4+ Years SAP MM / WM ConsultantDocument4 pages4+ Years SAP MM / WM ConsultantSurya VijayakumarNo ratings yet

- Third Party Process 1627475186Document23 pagesThird Party Process 1627475186Vardhan SDNo ratings yet

- Expertise in Configuration of Sap Materials Management (MM) - Material Master, Pos, AgreementsDocument6 pagesExpertise in Configuration of Sap Materials Management (MM) - Material Master, Pos, AgreementsArun PadhiNo ratings yet

- Sap PP AbbreviationsDocument2 pagesSap PP Abbreviationsatul82950% (1)

- Group of StrategyDocument12 pagesGroup of StrategyMangeshNo ratings yet

- ERP PP Configuration Expert RamenDocument2 pagesERP PP Configuration Expert RamenRamen HaldarNo ratings yet

- Sap PP Master DataDocument1 pageSap PP Master DatadkpdharmNo ratings yet

- SAP SD Training Table of ContentsDocument12 pagesSAP SD Training Table of ContentsBharathk KldNo ratings yet

- Cbs Successstory Roche Sam-Sap-Migration en PDFDocument8 pagesCbs Successstory Roche Sam-Sap-Migration en PDFSascha LoefflerNo ratings yet

- SAP Live Project PDFDocument8 pagesSAP Live Project PDFsaurabhbectorNo ratings yet

- SAP Project System 2008: Managing Your SAP ProjectsDocument3 pagesSAP Project System 2008: Managing Your SAP Projectssrk kattiNo ratings yet

- SAP - PP-PI Training 09 Aug'02 To 15 Aug'02 Gaurav RastogiDocument58 pagesSAP - PP-PI Training 09 Aug'02 To 15 Aug'02 Gaurav RastogiDHL123No ratings yet

- Aa Alternative Items in BOMDocument14 pagesAa Alternative Items in BOMAhmed TalaatNo ratings yet

- BPML PMDocument6 pagesBPML PMDINESH SINGH BHATINo ratings yet

- Create Optimal Orders in S4hanaDocument8 pagesCreate Optimal Orders in S4hanaSonaNo ratings yet

- Implementing Integrated Business Planning: A Guide Exemplified With Process Context and SAP IBP Use CasesFrom EverandImplementing Integrated Business Planning: A Guide Exemplified With Process Context and SAP IBP Use CasesNo ratings yet

- Classical ReportsDocument2 pagesClassical ReportsanilNo ratings yet

- Differences Between LSMW and BDCDocument6 pagesDifferences Between LSMW and BDCanilNo ratings yet

- Table Operations Supply ChainDocument13 pagesTable Operations Supply ChainanilNo ratings yet

- Transfer Table Records Between SAP Clients Using ALE IDOCDocument139 pagesTransfer Table Records Between SAP Clients Using ALE IDOCanilNo ratings yet

- SAP Transactions Interview QuestionsDocument18 pagesSAP Transactions Interview QuestionsHarish MaheshwariNo ratings yet

- BapiDocument1 pageBapianilNo ratings yet

- Materials Valuation And: Account Assignment For MMDocument22 pagesMaterials Valuation And: Account Assignment For MMDhrubajyoti PanigrahiNo ratings yet

- ALE IDOC With Segment FilteringDocument38 pagesALE IDOC With Segment Filteringanil100% (1)

- Sap Ap User Training Tutorial PDFDocument58 pagesSap Ap User Training Tutorial PDFDeepak ChandraNo ratings yet

- Saving The Custom ViewDocument20 pagesSaving The Custom ViewanilNo ratings yet

- Create Tab Strip in Module Pool ProgramDocument49 pagesCreate Tab Strip in Module Pool Programanil100% (1)

- Bapi Material ExtensionDocument3 pagesBapi Material ExtensionanilNo ratings yet

- Difference Between Non Dialog & Dialog BAPIDocument22 pagesDifference Between Non Dialog & Dialog BAPIanilNo ratings yet

- Bapi Material ExtensionDocument3 pagesBapi Material ExtensionanilNo ratings yet

- Reading Data From SAP Application Server (Tx-AL11)Document20 pagesReading Data From SAP Application Server (Tx-AL11)anilNo ratings yet

- Sales Alv HierarchialDocument6 pagesSales Alv HierarchialanilNo ratings yet

- ABAPPROGRAM1Document6 pagesABAPPROGRAM1anilNo ratings yet

- Requirment POP UPDocument14 pagesRequirment POP UPanilNo ratings yet

- Week 1 Day 2 CRM TransactionDocument30 pagesWeek 1 Day 2 CRM TransactionanilNo ratings yet

- Requirment POP UPDocument14 pagesRequirment POP UPanilNo ratings yet

- Create Smartforms and Call Function ModulesDocument17 pagesCreate Smartforms and Call Function ModulesanilNo ratings yet

- 2) Goto SE80 - Object Navigator and Provide The Package Name in The List BoxDocument11 pages2) Goto SE80 - Object Navigator and Provide The Package Name in The List BoxanilNo ratings yet

- Oops DocDocument1 pageOops DocanilNo ratings yet

- Search Help F4Document20 pagesSearch Help F4anilNo ratings yet