Professional Documents

Culture Documents

RTD Settings

Uploaded by

GeorgeckangOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

RTD Settings

Uploaded by

GeorgeckangCopyright:

Available Formats

RECOMMENDED Initial Temperature RTD Settings

ALARM TRIP

Stator RTD's (based on F insulation

system) 155 deg.C 165 deg. C

Stator RTD's (based on H insulation

system) 165 deg.C 175 deg. C

Bearing RTD's (Sleeve Bearings) 95 deg. C 100 deg. C

Bearing RTD's ( Anti Friction) - 5811 &

smaller 100 deg. C 110 deg.C

Bearing Anti-friction API designed / & 5812 larger 95 deg. C 100 deg. C

Alternate method of setting relay - if data from actual load & ambient is known:

This is for motors being specified as B rise by resistance and Class F insulation

For motors specified B rise by Detector, the settings listed above can be reduced by 10 degree C

ALARM TRIP

Final Stator

Settings 10 deg. + T MAX 20 deg. + T MAX

Final Bearing Settings 10 deg. + T MAX 15 deg. + T MAX

T MAX = Worse case ambient and load conditions, usually trend value during 1 year of operation

RECOMMENDED Vibration Settings

Initial settings ALARM TRIP

Frame Vibrations (NEMA standard 0.15

in/s) 0.22 in/s (5.5 mm/s) 0.35 in/s (8.9 mm/s)

Shaft Vibrations Displacement - NEMA 90 um

specification 5.4 mil (137 um) 7.2 mil (183 um)

For API design motor, shaft vibration limits can be lowered by 20 um from above settings (70 um specification)

Note after initial start up the settings should be lowered to reflect actual installation :

Shaft vibration alarm setting shall be lowered to 1.8 x loaded vibration settings

Shaft vibration trip setting shall be lowered to 2.8 x loaded vibration settings

For example: Motor running at 0.08 in/s = alarm set 0.14 in/s and trip 0.22 in/s

Revision 1 - Dated September 3, 2008 - Additional explanation of Vibration Settings in Field

Revision 2 - Dated October 16, 2008 - Increase setting for A/F bearing - Non API motor

13131 W. Little York Road

Houston, TX. 77041

Phone # 1-713-466-0277

Fax # 1-713-896-5252

LVM Applications 10/16/2008

You might also like

- Ogden Etr-900 Temperature Controller Manual PDFDocument4 pagesOgden Etr-900 Temperature Controller Manual PDFAlejandroCoilaNo ratings yet

- Tp65H150Lsg: 650V Gan Fet PQFN Series PreliminaryDocument9 pagesTp65H150Lsg: 650V Gan Fet PQFN Series PreliminaryWepa BizNo ratings yet

- EnerVista 469 Setup Active ScreDocument5 pagesEnerVista 469 Setup Active ScreJosue CardosoNo ratings yet

- AUIRFR6215: DSS DS (On) DDocument10 pagesAUIRFR6215: DSS DS (On) DFrancisco FilhoNo ratings yet

- KP-9P (YD380D) Generating Set Technical Data SheetDocument5 pagesKP-9P (YD380D) Generating Set Technical Data SheetKEYPOWER GENERATOR & LOAD BANKNo ratings yet

- Cummins 175 DSGAD - QSB7Document4 pagesCummins 175 DSGAD - QSB7pank4r4No ratings yet

- KP-9P-1 (KM385BD) Generating Set Technical Data Sheet: Fuzhou GFF Keypower Equipment Co., LTDDocument5 pagesKP-9P-1 (KM385BD) Generating Set Technical Data Sheet: Fuzhou GFF Keypower Equipment Co., LTDKEYPOWER GENERATOR & LOAD BANKNo ratings yet

- KPX K12PDocument5 pagesKPX K12PDerek ChenNo ratings yet

- XoxoxoxoDocument7 pagesXoxoxoxoAdmin BisnisNo ratings yet

- CT365 CT400S (QSG12 50Hz)Document3 pagesCT365 CT400S (QSG12 50Hz)Md ShNo ratings yet

- KP D39SDocument5 pagesKP D39SDerek ChenNo ratings yet

- KP D120PDocument5 pagesKP D120PDerek ChenNo ratings yet

- EL-QT-CTB-S - 20180420B-ESTRUAGUA LATAM-SOPLADORES TURBO-Floculación-Ficha Tecnica Jul1018Document2 pagesEL-QT-CTB-S - 20180420B-ESTRUAGUA LATAM-SOPLADORES TURBO-Floculación-Ficha Tecnica Jul1018mafevalle4201No ratings yet

- MCS350-1 (NTA855-G2A) Generating Set Technical Data Sheet: Millennium Power Manufacturing CorpDocument5 pagesMCS350-1 (NTA855-G2A) Generating Set Technical Data Sheet: Millennium Power Manufacturing CorpRianNo ratings yet

- DT100-DT110S (50 HZ)Document3 pagesDT100-DT110S (50 HZ)Md ShNo ratings yet

- KP-10P-1 (LL480D) Generating Set Technical Data SheetDocument5 pagesKP-10P-1 (LL480D) Generating Set Technical Data SheetKEYPOWER GENERATOR & LOAD BANKNo ratings yet

- DatasheetDocument13 pagesDatasheetJNo ratings yet

- KP D30SDocument5 pagesKP D30SDerek ChenNo ratings yet

- KP D100PDocument5 pagesKP D100PDerek ChenNo ratings yet

- KP D28PDocument5 pagesKP D28PDerek ChenNo ratings yet

- CT500 CT570S (KTA19 50Hz)Document3 pagesCT500 CT570S (KTA19 50Hz)Md ShNo ratings yet

- GB C350KVA1.doc 1Document4 pagesGB C350KVA1.doc 1Amr KhaledNo ratings yet

- CT150 CT165S (50Hz)Document3 pagesCT150 CT165S (50Hz)M. ShaatNo ratings yet

- CT1000-CT1100S (50 HZ)Document3 pagesCT1000-CT1100S (50 HZ)tarekNo ratings yet

- KP D50PDocument5 pagesKP D50PDerek ChenNo ratings yet

- Dyna 129 NewDocument4 pagesDyna 129 NewAndry PriyantoNo ratings yet

- TSTM-DC / TSTMH-DC: Torque Test StandDocument3 pagesTSTM-DC / TSTMH-DC: Torque Test StandmuaadhNo ratings yet

- Eurl Tassili Motors: FeaturesDocument4 pagesEurl Tassili Motors: Featuresbachir zouizaiNo ratings yet

- CT575 CT635S (KTA19 60Hz)Document3 pagesCT575 CT635S (KTA19 60Hz)M. ShaatNo ratings yet

- FQP8P10 1009587Document11 pagesFQP8P10 1009587Hdhm TdhNo ratings yet

- KP-C500P (KTA19-G3A) Generating Set Technical Data SheetDocument5 pagesKP-C500P (KTA19-G3A) Generating Set Technical Data SheetMario CastroNo ratings yet

- C400N5C - A042j404 Cummins Gta38Document5 pagesC400N5C - A042j404 Cummins Gta38Maximiliano SanchezNo ratings yet

- Aceleoromometru330450 40Document9 pagesAceleoromometru330450 40AlexandraAndreeaNo ratings yet

- Low Voltage Alternators - 4 Pole: Tal A46 - Tal A47 - Tal A49Document15 pagesLow Voltage Alternators - 4 Pole: Tal A46 - Tal A47 - Tal A49Duc Thao VuNo ratings yet

- SS15 CPGKDocument4 pagesSS15 CPGKDenzo RyugaNo ratings yet

- KP-C275P 6LT TalDocument5 pagesKP-C275P 6LT Talczz6723No ratings yet

- PRD64Document2 pagesPRD64Dewi Aura KasihNo ratings yet

- 12 Genset Sizing and Load Types (Compatibility Mode)Document20 pages12 Genset Sizing and Load Types (Compatibility Mode)lilya mohNo ratings yet

- Model ETR-9200 Automatic Tuning Smarter Logic ControllerDocument26 pagesModel ETR-9200 Automatic Tuning Smarter Logic ControllervhelectronicaNo ratings yet

- Chip Ferrite Bead PDFDocument4 pagesChip Ferrite Bead PDFMRousstiaNo ratings yet

- Thyristor tn1605h-8tDocument10 pagesThyristor tn1605h-8tsateeshNo ratings yet

- Yff-Hc: SeriesDocument5 pagesYff-Hc: SeriesDhaval PatelNo ratings yet

- FQPF13N06L 1306265 PDFDocument11 pagesFQPF13N06L 1306265 PDFCristianNo ratings yet

- KP D313PDocument5 pagesKP D313PDerek ChenNo ratings yet

- PRD45Document2 pagesPRD45Dewi Aura KasihNo ratings yet

- Cummins Data Sheet C550D5Document3 pagesCummins Data Sheet C550D5fahad pirzadaNo ratings yet

- DT-5TP - Manual (03.2020)Document8 pagesDT-5TP - Manual (03.2020)Matheus AndreoNo ratings yet

- KP-11P (KM385BD) Generating Set Technical Data Sheet: Fuzhou GFF Keypower Equipment Co., LTDDocument5 pagesKP-11P (KM385BD) Generating Set Technical Data Sheet: Fuzhou GFF Keypower Equipment Co., LTDKEYPOWER GENERATOR & LOAD BANKNo ratings yet

- Diesel Generator Sets For The Ag Market: Specification SheetDocument4 pagesDiesel Generator Sets For The Ag Market: Specification SheetTheronNo ratings yet

- RDDA Es Metric A4Document1 pageRDDA Es Metric A4Daniel GómezNo ratings yet

- AUIRLR2905 AUIRLU2905: Automotive GradeDocument11 pagesAUIRLR2905 AUIRLU2905: Automotive GradeDany toboysNo ratings yet

- ETR 9090 Instruction Manual PDFDocument22 pagesETR 9090 Instruction Manual PDFAlejandroCoilaNo ratings yet

- DT40-DT45S (50 HZ)Document3 pagesDT40-DT45S (50 HZ)Md ShNo ratings yet

- C800D6Document4 pagesC800D6Gestión del Talento Humano GEMRANo ratings yet

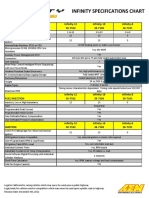

- Infinity Specifications ChartDocument4 pagesInfinity Specifications ChartGopalakrishnan RajuNo ratings yet

- Bat Rat-M: Ratemeter & Totalizer With Alarm OutputDocument35 pagesBat Rat-M: Ratemeter & Totalizer With Alarm OutputYuri PalomarNo ratings yet

- Diesel Generator Set NT Series Engine: 360 Kwe - 400 Kwe 60 HZDocument5 pagesDiesel Generator Set NT Series Engine: 360 Kwe - 400 Kwe 60 HZLuis MejiaNo ratings yet

- Diesel Generator Set QST30 Series Engine: 680 KW - 1000 KW 60 HZ Data Center ContinuousDocument5 pagesDiesel Generator Set QST30 Series Engine: 680 KW - 1000 KW 60 HZ Data Center ContinuousmnezamiNo ratings yet