Professional Documents

Culture Documents

Organizing Engineering Research Papers

Uploaded by

柯泰德 (Ted Knoy)Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Organizing Engineering Research Papers

Uploaded by

柯泰德 (Ted Knoy)Copyright:

Available Formats

Organizing Engineering

Research Papers (39)

http://www.chineseowl.idv.tw

(:)

Setting of research (): ?

?

Research problem () :

?

Quantitative specification of problem () :

Importance of problem () :

, ?

(:)

Research objective ()

Methodology to achieve objective

()

Anticipated results ()

Contribution to field ()

(:)

LCD panels use an analog input signal as a data source that

is compatible with a CRT monitor.

However, the conventionally adopted interface can not

enhance display quality or comply with high resolution

requirements. The signal of the analog interface must be encoded to

compose the RGB signal and be generated by a digital-to-analog

converter (DAC). The IC with an analog interface requires an

additional ADC to convert the analog input into a digitalized format and

decode the composite signal to each RGB datum. Therefore, DAC and

ADC distort the source datum, subsequently lowering display

quality. Moreover, video decoder circuits increase interference noise in

the data. Alternatively, a digital interface for the panel can reduce the

number of ADCs, DACs, video encoders and decoders to achieve a

higher display quality and resolution than the analog one. Furthermore,

discrete IC components cost less than analog ones.

(:)

Importantly, a digital interface can

decrease the design schedule by 50% when adopting the

HDL-based scheme. For mass production, analog IC has a

yield loss exceeding 20% and is sensitive to process

variation.

The above predicament will increase IC

testing costs and complexity, making it extremely difficult to

achieve time to market delivery. Moreover, the

conventionally adopted analog interface can not satisfy

market requirements of high performance, high resolution,

and low retail cost.

(:)

Based on the above, we should develop a digital

interface, in which both the data source and panel are

modified for integration to decrease the design schedule and

IC testing costs.

To do so, a digital video interface, e.g.,

CCR, and a digital RGB interface can be developed. The

digital signal processing can then be simulated using MatLab

software. Next, logic circuits can be described by program

editing. Additionally, the physical circuits can be generated

using CAD software.

(:)

As anticipated, in addition to

automatically generating production procedures via

software, the proposed digital interface can

enhance the performance, e.g., display quality and

high resolution.

Furthermore, the proposed interface for

the panel can reduce the number of ADCs, DACs,

video encoders and decoders, ultimately decreasing

power consumption and production costs.

(:)

Charging flash-light-capacitance circuits are

integrated into a single chip for digital cameras.

However, conventional circuits contain discrete

components,

not only increasing the overhead costs of

components by approximately 20%, but also increasing

production size by 10%.

The inability to integrate these circuits into

a single chip makes it impossible not only to satisfy

consumer demand for miniaturized, light and slim products,

but also to reduce time constraints in a design schedule

and production costs.

(:)

Based on the above, we should develop

an integrated circuit to simplify conventional

circuits and easily support miniaturized products

To do so, conventional circuits

can be analyzed. Circuits can then be combined

to reduce the chip area. Next, in terms of the chip

layout, adding a substrate ring can restrain the

noise and the coupling effect.

(:)

As anticipated, the proposed

integrated circuit can reduce overhead costs and

increase market competitiveness.

Importantly, in the market of digital still

cameras, the proposed integrated circuit can

simplify product design and miniaturize product

size.

Further details can be found at

http://www.chineseowl.idv.tw

You might also like

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Vietnam 2.41:Tổ chức lớp viết báo khoa học thương mại đăng trên tạp chí quốc tếDocument24 pagesVietnam 2.41:Tổ chức lớp viết báo khoa học thương mại đăng trên tạp chí quốc tế柯泰德 (Ted Knoy)No ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Writing Engineering AbstractsDocument8 pagesWriting Engineering Abstracts柯泰德 (Ted Knoy)No ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Writing Engineering AbstractsDocument9 pagesWriting Engineering Abstracts柯泰德 (Ted Knoy)No ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Vietnam 1.5:Tránh sử dụng quá nhiều "It" và "There" ở đầu câu (Đào tạo chỉnh sửa trong viết văn bản tiếng anh)Document32 pagesVietnam 1.5:Tránh sử dụng quá nhiều "It" và "There" ở đầu câu (Đào tạo chỉnh sửa trong viết văn bản tiếng anh)柯泰德 (Ted Knoy)No ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Writing Engineering AbstractsDocument7 pagesWriting Engineering Abstracts柯泰德 (Ted Knoy)No ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Writing Engineering AbstractsDocument7 pagesWriting Engineering Abstracts柯泰德 (Ted Knoy)No ratings yet

- Writing Engineering AbstractsDocument7 pagesWriting Engineering Abstracts柯泰德 (Ted Knoy)No ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Writing Engineering AbstractsDocument8 pagesWriting Engineering Abstracts柯泰德 (Ted Knoy)No ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Writing Engineering AbstractsDocument7 pagesWriting Engineering Abstracts柯泰德 (Ted Knoy)No ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Writing Engineering AbstractsDocument7 pagesWriting Engineering Abstracts柯泰德 (Ted Knoy)No ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Writing Engineering AbstractsDocument7 pagesWriting Engineering Abstracts柯泰德 (Ted Knoy)No ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Writing Engineering AbstractsDocument7 pagesWriting Engineering Abstracts柯泰德 (Ted Knoy)No ratings yet

- Writing Engineering AbstractsDocument7 pagesWriting Engineering Abstracts柯泰德 (Ted Knoy)No ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Writing Engineering AbstractsDocument9 pagesWriting Engineering Abstracts柯泰德 (Ted Knoy)No ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Writing Engineering AbstractsDocument7 pagesWriting Engineering Abstracts柯泰德 (Ted Knoy)No ratings yet

- Writing Problem and Hypothesis Statements For Engineering ResearchDocument13 pagesWriting Problem and Hypothesis Statements For Engineering Research柯泰德 (Ted Knoy)No ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Writing Business AbstractsDocument7 pagesWriting Business Abstracts柯泰德 (Ted Knoy)No ratings yet

- Writing Medical AbstractsDocument7 pagesWriting Medical Abstracts柯泰德 (Ted Knoy)No ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Writing Business AbstractsDocument7 pagesWriting Business Abstracts柯泰德 (Ted Knoy)No ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Writing Medical AbstractsDocument8 pagesWriting Medical Abstracts柯泰德 (Ted Knoy)No ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Writing Science AbstractsDocument7 pagesWriting Science Abstracts柯泰德 (Ted Knoy)No ratings yet

- Writing Medical AbstractsDocument7 pagesWriting Medical Abstracts柯泰德 (Ted Knoy)No ratings yet

- Writing Problem and Hypothesis Statements For Engineering ResearchDocument9 pagesWriting Problem and Hypothesis Statements For Engineering Research柯泰德 (Ted Knoy)No ratings yet

- Writing Problem and Hypothesis Statements For Engineering ResearchDocument9 pagesWriting Problem and Hypothesis Statements For Engineering Research柯泰德 (Ted Knoy)No ratings yet

- Writing Problem and Hypothesis Statements For Engineering ResearchDocument10 pagesWriting Problem and Hypothesis Statements For Engineering Research柯泰德 (Ted Knoy)No ratings yet

- Writing Problem and Hypothesis Statements For Engineering ResearchDocument12 pagesWriting Problem and Hypothesis Statements For Engineering Research柯泰德 (Ted Knoy)No ratings yet

- Writing Problem and Hypothesis Statements For Engineering ResearchDocument8 pagesWriting Problem and Hypothesis Statements For Engineering Research柯泰德 (Ted Knoy)No ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Writing Problem and Hypothesis Statements For Engineering ResearchDocument10 pagesWriting Problem and Hypothesis Statements For Engineering Research柯泰德 (Ted Knoy)No ratings yet

- Writing Problem and Hypothesis Statements For Engineering ResearchDocument9 pagesWriting Problem and Hypothesis Statements For Engineering Research柯泰德 (Ted Knoy)No ratings yet

- Writing Problem and Hypothesis Statements For Engineering ResearchDocument9 pagesWriting Problem and Hypothesis Statements For Engineering Research柯泰德 (Ted Knoy)No ratings yet

- Navori How To Position On-Screen ElementsDocument5 pagesNavori How To Position On-Screen Elementshewhc85No ratings yet

- Variable Frequency DriveDocument11 pagesVariable Frequency DriveNAYEEM100% (4)

- SLS11Document27 pagesSLS11maneeshNo ratings yet

- PLCDocument87 pagesPLCAnoop RaviNo ratings yet

- Verify The Gain Setting Through The SV Command Before Continuing!Document1 pageVerify The Gain Setting Through The SV Command Before Continuing!LUISNo ratings yet

- Chapter 3 - Input and OutputDocument61 pagesChapter 3 - Input and Outputannie69007No ratings yet

- Lesson 2Document41 pagesLesson 2Chito A. Florenosos100% (1)

- Control Remoto 1Document52 pagesControl Remoto 1jose100% (6)

- BTS Power ConsumptionDocument3 pagesBTS Power ConsumptionSavolyukDmitry50% (2)

- LTE ParametersDocument388 pagesLTE ParametersAamir Riaz MalikNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Rectifiers: Alternating Current (AC) To Direct Current (DC)Document20 pagesRectifiers: Alternating Current (AC) To Direct Current (DC)Golu SinghNo ratings yet

- B3LT1018Document1 pageB3LT1018ErnaNo ratings yet

- Features and Benefits of Zuken PCB Design SoftwareDocument8 pagesFeatures and Benefits of Zuken PCB Design SoftwarejackNo ratings yet

- ISP Technologies DAAT Power Amplifier Technology White Paper PDFDocument9 pagesISP Technologies DAAT Power Amplifier Technology White Paper PDFHumberto D PertuzNo ratings yet

- Mobile Communications Handbook: Stuber, G.L. "Modulation Methods" Ed. Suthan S. Suthersan Boca Raton: CRC Press LLC, 1999Document16 pagesMobile Communications Handbook: Stuber, G.L. "Modulation Methods" Ed. Suthan S. Suthersan Boca Raton: CRC Press LLC, 1999Sai RamNo ratings yet

- Service Tool: Manual 26250 L-Series Integrated Speed ControlDocument2 pagesService Tool: Manual 26250 L-Series Integrated Speed ControlAnonymous V9fdC6No ratings yet

- Full-Wave Center-Tapped Rectifier: ObjectivesDocument3 pagesFull-Wave Center-Tapped Rectifier: ObjectivesShannen Joyce FloresNo ratings yet

- Long Term Evolution: Author: Badal MishraDocument19 pagesLong Term Evolution: Author: Badal Mishrabadal mishraNo ratings yet

- Rajkumar Seminar ReportDocument22 pagesRajkumar Seminar ReportRaj KumarNo ratings yet

- Comparators & Code ConverterDocument22 pagesComparators & Code ConverternandhakumarmeNo ratings yet

- May 2002 Q BrochureDocument31 pagesMay 2002 Q Brochurenabilo20No ratings yet

- Project Proposal: Wireless Mobile ChargerDocument13 pagesProject Proposal: Wireless Mobile ChargerJerin TasnimNo ratings yet

- Pushing and PullingDocument5 pagesPushing and PullingAsutosh AcharyaNo ratings yet

- PK Ups 2014 Us8000tr - 1-10kvaDocument2 pagesPK Ups 2014 Us8000tr - 1-10kvaBOsy Ying LoNo ratings yet

- Pulse-Based Analog VLSI Velocity Sensors: J Org Kramer, Rahul Sarpeshkar, and Christof KochDocument16 pagesPulse-Based Analog VLSI Velocity Sensors: J Org Kramer, Rahul Sarpeshkar, and Christof KochsudhiprabhuNo ratings yet

- The Design of Small Slot ArraysDocument6 pagesThe Design of Small Slot ArraysRoberto B. Di RennaNo ratings yet

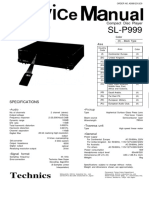

- Technics SL p999Document58 pagesTechnics SL p999garberer1100% (1)

- Embedded SystemDocument15 pagesEmbedded Systemd_dharaNo ratings yet

- A 500Μw 2.4Ghz Cmos Subthreshold Mixer For Ultra Low Power ApplicationsDocument4 pagesA 500Μw 2.4Ghz Cmos Subthreshold Mixer For Ultra Low Power ApplicationsRF_RAJANo ratings yet

- Manual Kronnus Mih61m-DDocument19 pagesManual Kronnus Mih61m-DVitor DantasNo ratings yet