Professional Documents

Culture Documents

Quality, Reliability & Maintenance Warwick Manufacturing Group

Uploaded by

Ibrahim YucedagOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Quality, Reliability & Maintenance Warwick Manufacturing Group

Uploaded by

Ibrahim YucedagCopyright:

Available Formats

Quality, Reliability & Maintenance Warwick Manufacturing Group

SixSigma

QFD

Lean

Kano

Benchmarking

EFQM Excellence

ISO 9000 Quality Model

SPC

Circle

Quality, Reliability & Maintenance Warwick Manufacturing Group

Quality, Reliability & Maintenance Warwick Manufacturing Group

William Edwards Deming

• The father of the third Industrial

revolution

•Considered one of the co-founders of

the TQM philosophy

•In 1947, Deming was involved in early

planning for the 1951 Japanese Census

and asked to assist the Census by US

Army

•He is regarded as having had more

impact upon Japanese manufacturing

and business than any other individual

not of Japanese heritage.

Quality, Reliability & Maintenance Warwick Manufacturing Group

Quality, Reliability & Maintenance Warwick Manufacturing Group

Quality, Reliability & Maintenance Warwick Manufacturing Group

Quality, Reliability & Maintenance Warwick Manufacturing Group

Quality, Reliability & Maintenance Warwick Manufacturing Group

Quality, Reliability & Maintenance Warwick Manufacturing Group

Quality, Reliability & Maintenance Warwick Manufacturing Group

Quality, Reliability & Maintenance Warwick Manufacturing Group

Quality, Reliability & Maintenance Warwick Manufacturing Group

Quality, Reliability & Maintenance Warwick Manufacturing Group

Quality, Reliability & Maintenance Warwick Manufacturing Group

Joseph M. Juran

•Books on Quality Planning,

Quality control and Quality

Improvement.

• “Juran`s Triology”.

•Human dimension to quality

management.

• Education and training of

managers.

• Human relations problems were

the ones to isolate

Quality, Reliability & Maintenance Warwick Manufacturing Group

Quality, Reliability & Maintenance Warwick Manufacturing Group

Quality, Reliability & Maintenance Warwick Manufacturing Group

Quality, Reliability & Maintenance Warwick Manufacturing Group

Quality, Reliability & Maintenance Warwick Manufacturing Group

PHILIP B. CROSBY

[ June 18, 1926 – August 18, 2001]

QUALITY GURU

“meet requirements on time,

first time, and every time”

• Born in June 18th, 1926 in Wheeling, West Virginia. A graduate from

Western Reserve University.

• He began his career in 1952, as a quality professional.

• Vice President for ITT (International Telephone Telegraph).

•In 1979, founder of PCA, Inc. (Philip Crosby Associates) – To help organization

and corporations avoid problems rather than to fix them through quality

processes.

• In 1991, retired from PCA and continued by training executives at Career IV.

• Also known as “ The Evangelist”

• Creator of the concept of ‘Zero Defects’ - Quality Management.

• 14 Steps for quality improvement.

• Suggested five characteristics of a success of Total Quality organization.

Quality, Reliability & Maintenance Warwick Manufacturing Group

1. Quality is defined as conformance to requirements, not as

‘goodness’.

2. The system for causing quality is prevention, not appraisal.

3. The performance standard must be ZERO DEFECTS, not that’s

close enough.

4. The measurement of quality is the Price of Non-Conformance, not

indices.

Quality, Reliability & Maintenance Warwick Manufacturing Group

1. Management Commitment 14. Do it all over again

2. Quality improvement teams 13. Quality councils

3. Measurement

12. Recognition

4. Cost of quality

11. Obstacles

5. Quality Awareness 9. Zero defects day

6. Corrective action 10. Improvement goals

7. Monitor progress 8. Train Supervisor

Quality, Reliability & Maintenance Warwick Manufacturing Group

Quality, Reliability & Maintenance Warwick Manufacturing Group

Quality, Reliability & Maintenance Warwick Manufacturing Group

Quality, Reliability & Maintenance Warwick Manufacturing Group

Quality, Reliability & Maintenance Warwick Manufacturing Group

Quality, Reliability & Maintenance Warwick Manufacturing Group

As a Quality Guru:

TAGUCHI

Quality, Reliability & Maintenance Warwick Manufacturing Group

Quality, Reliability & Maintenance Warwick Manufacturing Group

Taguchi came up with a new idea which pushes quality control back to the design

process. Up to that time, quality control is considered in manufacturing process.

Consequently, he developed a strategy for quality engineering that can be used in

both cases.

In this manner, product can easily be changed or modified according to the lack of

quality or customer satisfaction.

Taguchi’s methodology (which is divided into three phases: System design,

Parameter design, Tolerance design) allow the designer through experiments to

determine which factors most affect product performance and which factors are

unimportant.

Quality, Reliability & Maintenance Warwick Manufacturing Group

Loss function has implication to quality costs.

Traditionally, if a product characteristic falls outside specification limits, it

will increase the cost of poor quality. However, if that characteristic is closer to

specifications and not to intended target, the quality of that product is poorer,

even if it stills satisfy the requirements. This may lead to lower customer

satisfaction.

Taguchi proposed that as conformance values moves away from the

target, loss increases as a quadratic function. This means that smaller

differences from the target result in smaller costs.

Quality, Reliability & Maintenance Warwick Manufacturing Group

Quality, Reliability & Maintenance Warwick Manufacturing Group

Quality, Reliability & Maintenance Warwick Manufacturing Group

Quality, Reliability & Maintenance Warwick Manufacturing Group

Dr. Kaoru Ishikawa

• Ishikawa introduced the

concept of Quality Circle in 1962

in conjunction with JUSE

• The innovator of Ishikawa or

Cause and Effect diagram, well

known in North America and use

in analysis of industrial process

•He promoted the Annual

Quality Control Conference for

Top management in 1963

•Chairman of FQC journal

editorial board

1915 - 1989

Quality, Reliability & Maintenance Warwick Manufacturing Group

Quality, Reliability & Maintenance Warwick Manufacturing Group

Quality, Reliability & Maintenance Warwick Manufacturing Group

TQM Six sigma ISO 9000 EFQM

Continual improvement (Kaizen)

Improve the process

Team Team and People

-

involvement ownership Development

Supplier Partnership

- -

relationship development

Customer Customer

focus value Customer focus Customer focus

creation

Quality, Reliability & Maintenance Warwick Manufacturing Group

You might also like

- Branded Jewellery Market Research QuestionnaireDocument3 pagesBranded Jewellery Market Research QuestionnairePratima Nair70% (10)

- Key Account Management PDFDocument54 pagesKey Account Management PDFRavi Parmar100% (2)

- Kone Case StudyDocument10 pagesKone Case StudyRajib Hasan100% (4)

- Aizyl PueblosDocument2 pagesAizyl PueblosMarvin TalahibanNo ratings yet

- Quality Control - IntroductionDocument55 pagesQuality Control - IntroductionHariharan PNo ratings yet

- Unit 1Document25 pagesUnit 1Siva MaxNo ratings yet

- OM Unit 5Document85 pagesOM Unit 5Dharaneesh VKNo ratings yet

- Lecture IQM Week 11-12Document24 pagesLecture IQM Week 11-12Sahar Batool QaziNo ratings yet

- Estelle Joyce L. CantonaDocument18 pagesEstelle Joyce L. CantonaEcyoj EllesteNo ratings yet

- What Is Quality?Document16 pagesWhat Is Quality?Yash BhandariNo ratings yet

- BSM 522 LatestDocument13 pagesBSM 522 LatestAhmed YusufNo ratings yet

- Chapter 9 QualityDocument20 pagesChapter 9 QualityAina SyafiahNo ratings yet

- Quality: Fundamentals of Management (MGT 162)Document17 pagesQuality: Fundamentals of Management (MGT 162)izzahkjNo ratings yet

- Final HandoutDocument3 pagesFinal HandoutCrisanta EstebanNo ratings yet

- Introduction To Quality Week 1Document57 pagesIntroduction To Quality Week 1Hafiz Amirul100% (1)

- Management of QualityDocument31 pagesManagement of QualityDboyJuabanNo ratings yet

- TQMDocument23 pagesTQMpradeepNo ratings yet

- Orca Share Media1541593176918Document23 pagesOrca Share Media1541593176918jessa rodene franciscoNo ratings yet

- Chapter 1 SlidesDocument22 pagesChapter 1 SlidesSheena Doria de VeraNo ratings yet

- OM - Mod 2.6 - Total Quality ManagementDocument33 pagesOM - Mod 2.6 - Total Quality ManagementAyush KaushalNo ratings yet

- Total Quality Management: Anusuya Charan Ashma Katiyar Kritika Gupta Rajesh Yadav Sakshi Mohan Shaweta Goyal Vikash JoshiDocument29 pagesTotal Quality Management: Anusuya Charan Ashma Katiyar Kritika Gupta Rajesh Yadav Sakshi Mohan Shaweta Goyal Vikash JoshisudarshitaNo ratings yet

- NUL1 - Operations ManagementDocument24 pagesNUL1 - Operations ManagementMarria FrancezcaNo ratings yet

- MBA18GE37-Total Quality ManagementDocument228 pagesMBA18GE37-Total Quality ManagementRajkumar PNo ratings yet

- Quality Management - Ch.9 2Document15 pagesQuality Management - Ch.9 2manarNo ratings yet

- Unit 1 TQM NotesDocument26 pagesUnit 1 TQM NotesHarishNo ratings yet

- Quality, Quality Control and Quality ManagementDocument91 pagesQuality, Quality Control and Quality Managementsaurabh das100% (1)

- Chapter 1 Total Quality ManagementDocument5 pagesChapter 1 Total Quality ManagementZaylee CassidyNo ratings yet

- 4 CBME 1 Quality UpdatedDocument136 pages4 CBME 1 Quality UpdatedArnel OlsimNo ratings yet

- Course Unit 1 Quality Management Jan 2024Document25 pagesCourse Unit 1 Quality Management Jan 2024anshu.kumari.civ20No ratings yet

- CBM 112 LESSON 7pptDocument57 pagesCBM 112 LESSON 7pptRJ 1No ratings yet

- Total Quality Management: BY-Abhishek K. Ajisha D. Anand Mohan AmalDocument70 pagesTotal Quality Management: BY-Abhishek K. Ajisha D. Anand Mohan AmalAnjali GirishNo ratings yet

- Quality AssuranceDocument16 pagesQuality AssuranceDario SusicNo ratings yet

- Ge8077 LNDocument61 pagesGe8077 LNNilambari BhaviniNo ratings yet

- T5.Principles of Quality Engineering in Design and Manufacturing - Part IDocument33 pagesT5.Principles of Quality Engineering in Design and Manufacturing - Part IAl Aiden100% (1)

- Group 1 TQMDocument49 pagesGroup 1 TQMDonabell RapiNo ratings yet

- Ch1 TQM DR Hesham For OaklandDocument20 pagesCh1 TQM DR Hesham For OaklandAnum Nadeem GillNo ratings yet

- 1 Introduction PDFDocument42 pages1 Introduction PDFMarah Abu ShakraNo ratings yet

- Importance of QualityDocument31 pagesImportance of QualityEr Rizwana Qureshi100% (1)

- Value Creation Strategies: Quality Concepts and ToolsDocument87 pagesValue Creation Strategies: Quality Concepts and ToolsAjay PadhiNo ratings yet

- Iso 9001 Benefits of Iso 9001 CertificationDocument2 pagesIso 9001 Benefits of Iso 9001 CertificationSandeep KumarNo ratings yet

- Operations Management MidtermDocument5 pagesOperations Management MidtermMara CalambaNo ratings yet

- Quality: 5. ManufacturingDocument4 pagesQuality: 5. ManufacturingJhanna RoseNo ratings yet

- BA 160 Unit I StudentDocument51 pagesBA 160 Unit I StudentRoselyn Balio-anNo ratings yet

- CH 03 QualityDocument56 pagesCH 03 QualityDejene DeribaNo ratings yet

- Module 4, Lesson 12Document67 pagesModule 4, Lesson 12Larwa KenithNo ratings yet

- QMS Lesson 3 Part 1Document15 pagesQMS Lesson 3 Part 1Reniella Jane Delacruz SajolNo ratings yet

- Appendix: About The Importanceof Quality in ProductsDocument4 pagesAppendix: About The Importanceof Quality in ProductsRajashree KiniNo ratings yet

- GE6757 Unit-1Document92 pagesGE6757 Unit-1Dhamotharan SNo ratings yet

- Cbme Chap 9 FinallllDocument28 pagesCbme Chap 9 FinallllKirk Rumar ClavelNo ratings yet

- TQM (Atul Presentation)Document72 pagesTQM (Atul Presentation)atulnatuNo ratings yet

- TQM - IntroductionDocument25 pagesTQM - IntroductionimadNo ratings yet

- Ge8077 - Total Quality Management Unit I - IntroductionDocument12 pagesGe8077 - Total Quality Management Unit I - Introductionsafina rahmanNo ratings yet

- Total Quality Management (8515) : - MBA Semester VII - Notes by Awais Javed SattiDocument22 pagesTotal Quality Management (8515) : - MBA Semester VII - Notes by Awais Javed SattiHaleema HafeezNo ratings yet

- Webinar: Supplier Management - A Risk-Based Approach: Qse LTD Frank ReynoldsDocument42 pagesWebinar: Supplier Management - A Risk-Based Approach: Qse LTD Frank Reynoldsrony_lesbtNo ratings yet

- Unit - IDocument86 pagesUnit - IArivanandanNo ratings yet

- 3.cqap - QMS (NS 16.09.18) PDFDocument27 pages3.cqap - QMS (NS 16.09.18) PDFsaifullah629No ratings yet

- 2 Total Quality ManagementDocument33 pages2 Total Quality Managementzenia thea dulayNo ratings yet

- Quality and InnovationDocument61 pagesQuality and InnovationahyaniluthfianasariNo ratings yet

- TQM - IntroDocument25 pagesTQM - Introanon_919415No ratings yet

- The ISO 9001:2015 Implementation Handbook:: Using the Process Approach to Build a Quality Management SystemFrom EverandThe ISO 9001:2015 Implementation Handbook:: Using the Process Approach to Build a Quality Management SystemNo ratings yet

- Implementing ISO 9001:2015 – A practical guide to busting myths surrounding quality management systemsFrom EverandImplementing ISO 9001:2015 – A practical guide to busting myths surrounding quality management systemsNo ratings yet

- Project Feasibility Study For The Establishment of Footwear and Other AccessoriesDocument12 pagesProject Feasibility Study For The Establishment of Footwear and Other Accessoriesregata4No ratings yet

- IE 659-851 - Supply Chain EngineeringDocument7 pagesIE 659-851 - Supply Chain EngineeringboonlueNo ratings yet

- Chi Do - CV-Eng-Viet - Project CoordinatorDocument2 pagesChi Do - CV-Eng-Viet - Project CoordinatorSai NoFearzNo ratings yet

- Full Project ReportDocument46 pagesFull Project ReportRakeshNo ratings yet

- PRIA FAR - 014 Income Taxes (PAS 12) Notes and SolutionDocument7 pagesPRIA FAR - 014 Income Taxes (PAS 12) Notes and SolutionEnrique Hills RiveraNo ratings yet

- Company Profile ShineWing Indonesia 2020Document19 pagesCompany Profile ShineWing Indonesia 2020cindy wiriaatmadjaNo ratings yet

- LK-mengelola-buku-jurnal - B. IndoDocument11 pagesLK-mengelola-buku-jurnal - B. IndohussenNo ratings yet

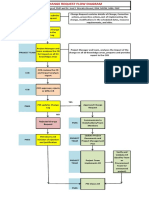

- Change Request Flow DiagramDocument2 pagesChange Request Flow DiagramSwapnil0% (1)

- Fedex Label - PL2303002 S&S MartechDocument6 pagesFedex Label - PL2303002 S&S MartechAnh HuynhNo ratings yet

- BCHDE5311 - Regular MORNINGDocument10 pagesBCHDE5311 - Regular MORNINGDhruv ShahNo ratings yet

- Planning and Operational Variances F5Document14 pagesPlanning and Operational Variances F5Mazni HanisahNo ratings yet

- Revised MGT 210-NOVARTIS Final ReportDocument21 pagesRevised MGT 210-NOVARTIS Final Reportkazi saadNo ratings yet

- Chapter 02 - CONCEPTUAL FRAMEWORK: Objective of Financial ReportingDocument6 pagesChapter 02 - CONCEPTUAL FRAMEWORK: Objective of Financial ReportingKimberly Claire AtienzaNo ratings yet

- Aakash Sharma: Career ObjectiveDocument3 pagesAakash Sharma: Career ObjectiveAAKASH SHARMANo ratings yet

- Application - of - 8d - Methodology - An - Effective - ProblDocument8 pagesApplication - of - 8d - Methodology - An - Effective - ProblHemant ChavanNo ratings yet

- Potential Multibagger 2.0Document4 pagesPotential Multibagger 2.0telegenicsNo ratings yet

- Accenture Total Enterprise ReinventionDocument62 pagesAccenture Total Enterprise ReinventionValeria TorresNo ratings yet

- Legal Register - Federal Law No. 32Document7 pagesLegal Register - Federal Law No. 32Priyanka JNo ratings yet

- استخدام نمذجة المعادلات الهيكلية بالمربعات الصغرى الجزئيةDocument19 pagesاستخدام نمذجة المعادلات الهيكلية بالمربعات الصغرى الجزئيةEsmail Al SabriNo ratings yet

- UntitledDocument63 pagesUntitledCesaret EhmedovNo ratings yet

- Sample DissertationDocument32 pagesSample DissertationAnamika VatsaNo ratings yet

- Career Paths Accounting SB-17Document1 pageCareer Paths Accounting SB-17YanetNo ratings yet

- Market Gap Analysis TemplateDocument2 pagesMarket Gap Analysis TemplateZeshanNo ratings yet

- Solution Manual For Managerial Accounting For Managers 4th Edition Noreen Brewer Garrison 1259578542 9781259578540Document36 pagesSolution Manual For Managerial Accounting For Managers 4th Edition Noreen Brewer Garrison 1259578542 9781259578540richardwilsonmgftzpsjxq100% (27)

- Design Thinking AssignmentDocument3 pagesDesign Thinking AssignmentOpeyemi OyewoleNo ratings yet

- L'Oréal Brandstorm 2021 - The Mission PDFDocument7 pagesL'Oréal Brandstorm 2021 - The Mission PDFAbhijithNo ratings yet