Professional Documents

Culture Documents

Uninterruptible Power Supply (UPS) : Maintenance Management Operations and Maintenance Plan For UPS

Uploaded by

Udari WickramasingheOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Uninterruptible Power Supply (UPS) : Maintenance Management Operations and Maintenance Plan For UPS

Uploaded by

Udari WickramasingheCopyright:

Available Formats

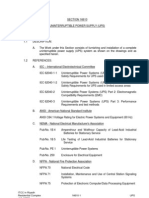

Maintenance Management Operations and Maintenance Plan for UPS

Uninterruptible Power Supply (UPS)

An uninterruptible power supply, (UPS) is an electrical apparatus that provides emergency power to a

load when the input power source, typically the main power supply, fails. A UPS differs from an

auxiliary or emergency power system or standby generator in that it will provide instantaneous or

near-instantaneous protection from input power interruptions by means of one or more attached

batteries and associated electronic circuitry for low power users.

A variety of design approaches are used to implement UPS systems, each with distinct performance

characteristics. The most common design approaches are as follows:

• Standby

• Line Interactive

• Standby-Ferro

• Double Conversion On-Line

• Delta Conversion On-Line

During the project work the observed types of UPS are Stand by and Double Conversion On-Line at

the IT Faculty building and an on line dual conversion UPS at the Department of Building Economics.

1. Stand- by UPS

The Standby UPS is the most common type used for Personal Computers. The Offline / Standby UPS

(SPS) offer only the most basic features, providing surge protection and battery backup. With this type

of UPS, a user's equipment is normally connected directly to incoming utility power with the same

voltage transient clamping devices used in a common surge protected plug strip connected across the

power line.

Advantages of Stand-by UPS

Figure 1: Stand by UPS

Department of Building Economics 1

Maintenance Management Operations and Maintenance Plan for UPS

Low cost

High efficiency

Compact

At the IT Faculty building there are mainly stand by UPS. For servers they have used stand by UPS

with a longer back up time period while having a shorter back up UPSs individually for other

computers in labs.

Below tables illustrate the specification of two observed UPSs at IT faculty building.

Table 1 : UPS of an individual computer

Model DCP 650VA/ 390W

Battery 7AH x 1

DC voltage of long backup 12 VDC

Type of load Computer, displayer

Input voltage 230/240 + 25%

Input frequency 50/60 Hz + 10%

Output voltage 230/240 + 10%

Output frequency 50/60 Hz + 0.5Hz (in battery mode)

Back up time 8 ~ 20 mints (rated computer as load)

Transfer time < 10ms

Short-circuit protection Fuse in AC mode, limited output currency in

inverter mode

Efficiency of power >80% in inverter mode

Temperature 00c – 400c

Humidity 10% - 90%

Table 2 : UPS of a server computer

Model PC 650

Capacity 650 VA

Input Voltage Range 160 – 275 V

Frequency 40 – 70 Hz

Phase Single + GND

Output Voltage range 220 VAC

Battery mode 220 VAC + 15%

Department of Building Economics 2

Maintenance Management Operations and Maintenance Plan for UPS

Frequency 50 Hz + 1Hz (battery mode)

Transfer time 2ms typical

Battery Type and number 12 V7AH – 1pc

Back up time 8 – 20 minutes depending on load

Recharge time 90% capacity after 8 hours

Protection/ Monitoring Short circuit Line mode – fuse and software protection

protection (CPU)

Battery mode – Software protection (CPU)

Surge protection Yes

Alarms Audible and Visual

Over Temperature >750C Alarm will sound

Protection >850C the system will shutdown

General Noise < 45dB

Temperature 00C-400C

Humidity 0%-95% relative humidity

Power factor Up to 0.7

Built in AVR Yes

Currently Prevailing Maintenance Activities and Drawbacks

The main ongoing maintenance activity for UPS is battery replacements. Normally when purchasing

these stand-by UPS units, one year warranty is taken from the supplier. Therefore as for normal

practise, the batteries are checked after two years of operation.

When the main power is disconnected manually and UPS is being loaded, if it is unable to provide at

least five minute back up, the remedial action is taken which means a replacement of the battery. The

time constraint is taken as 5 minutes since to on stand-by generators and to provide the generator

power to the building that much time is spent. There are specifications for replacement batteries as

given in below table.

Table 3 : Specification for UPS battery

Rated Voltage 12 V

Department of Building Economics 3

Maintenance Management Operations and Maintenance Plan for UPS

Rated Capacity 7.0 AH or 7.2 AH

Dimensions Length 5.94”

Width 2.54”

Height 3.70”

Total Height 3.94”

Terminal Type F2 (0.25” wide)

Chemical Sealed Lead Acid

At the replacement a sticker is pasted on the UPS with the replaced date and after a year the UPS back

up time is checked again. If it is more than 5 minutes the battery condition is good and it will not be

changed until a failure occurs.

In addition to that corrective maintenance is done for receiving complaints.

Drawbacks of current procedures

Do not maintain a proper record system with installed date, replacement dates, complaints

received, etc which may help to predict troubles and for easiness of reference.

Only check UPS conditions when complaints received.

2. Double conversion on line UPS

In the Double Conversion On-Line design, failure of the input AC does not cause activation of the

transfer switch, because the input AC is charging the backup battery source which provides power to

the output inverter. Therefore, during an input AC power failure, on-line operation results in no

transfer time.

Both the battery charger and the inverter convert the entire load power flow in this design, resulting in

reduced efficiency with its associated increased heat generation.

Figure 2: Double conversion on line UPS

Department of Building Economics 4

Maintenance Management Operations and Maintenance Plan for UPS

Advantages of On-line UPS

No time gap between power failure and supply

Excellent voltage conditioning

Table 4: On line dual conversion UPS

Model LP10-31T

Rating 10kVA/ 8kW

Battery 240V/ 12Ah

Typical back up time 50% load - 22 minutes

100% load – 8 minutes

Enclosure 680 x 313 x 720 mm

Net weight including battery 170kg

Input power factor 0.99

Input frequency 40 – 70 Hz

Output voltage 220/230/240V (user selectable)

Output voltage regulation +/- 1

Output frequency 50/60 Hz

Humidity 95% non condensing

Ambient operating temperature 0-400C

Audible noise 40-55 dB

Currently Prevailing Maintenance Activities

At present all the maintenance activities of the UPS system are performed by Energy Net (pvt), Ltd. A

technician from the above mentioned company comes in every four months and check for any

abnormal condition of the system while measuring Input voltage, rectifier voltage, load percentage,

power / electronic controls of cooling fans, UPS loading and etc.

He fills a check list and original copy is given to the department while keeping a copy to him. Format

of the check list is attached in annexure.

If any break down occurs, it is informed to the company through a telephone call and they will come

to check and perform the necessary remedial actions.

Draw backs

Maintenance only centred through outsourced company

Department of Building Economics 5

Maintenance Management Operations and Maintenance Plan for UPS

Since no maintenance or inspection is done by the owner of the UPS, hardly a failure will be witnessed

by them. If they record relevant operating parameters daily (eg: Main voltage, Inverter voltage, Load

percentage, supply return frequencies) then there is a possibility to identify any deviating

circumstance.

Additionally if the owner himself can visually check the panel fans monthly the risk of switching off

of the UPS due to the heat generated inside as malfunctioning of fans, can be minimized.

Proposed Preventive Maintenance Schedule for UPS

Table 5 : Proposed maintenance schedule

Duration Maintenance Activities

Monthly For stand-by UPS

- Turn off the UPS,

Check the air way for any blockage

Make sure the UPS cover is not covered by dust

Check input, output and battery connecting lines are firm or not

Check line insulation effective or not

- Turn on the UPS

- Let the UPS work in battery mode for about 5 minutes

For On line UPS

- Check the panel fans

Quarterly - Visually inspect equipment for loose connections, burnt insulation or any

other signs of wear

- Connect the UPS to AC and turn on the UPS, charge the battery for at least 10

hours, noting the load status (Only for On line UPS)

Bi - annually - Check for liquid contamination from batteries

Corrective and Preventive Maintenance activities implementation procedure

Department of Building Economics 6

Maintenance Management Operations and Maintenance Plan for UPS

Individual UPS:

Initially all the UPS units will be given with a separate code number in accordance with the

relevant lab number, in order to keep all the information relating to undergone maintenance

activities.

Since the maintenance technicians are now given the preventive maintenance schedule, all

preventive maintenance are performed in an effective manner.

They will also be given a below mentioned kind of a format to keep all the records of

preventive maintenance. (At this table the dates of the performed maintenance are required to

be written).

Table 6: Preventive Maintenance Record Sheet

Preventive Maintenance Records

Location: Lab no....................

Total UPS units: ....................

Bi-

Monthly Quarterly

UPS code annually

J F M A M J J A S O N D M J S D J D

I

f

Department of Building Economics 7

Maintenance Management Operations and Maintenance Plan for UPS

there is any abnormal condition or a failure, it will be informed to the maintenance division of

computer systems at IT faculty through phone. Mostly addressed problems are as follows.

Table 7: Troubleshooting of stand-by UPS

Problem Possible causes Solution

Normal LED does not light 1. AC power not on 1. Turn on AC power

up when UPS is turn on. 2. Power cable not properly 2. Insert power cable

Inverter LED is red and UPS inserted properly

beeping. 3. Fuse blown 3. Change the fuse

4. Faulty wall socket 4. Change to another wall

socket

UPS beeps occasionally on 1. UPS may be overloaded 1. Check that equipment

AC mode and UPS may 2. Unstable AC supply matches the specified

heated up capacity of UPS

2. Check the AC supply

and wiring

Battery backup time is short. 1. UPS may be overloaded 1. Remove any non

Long beeping sound is heard. 2. Battery not fully charged critical equipment

3. Battery may be near the 2. Charge the battery for

end of its life span at least 8 hours before

use

3. Battery is replaced

In troubleshooting if the UPS is still under warranty period, the dealer will be contacted over

the phone when a battery replacement or any sever failure occurs.

All the corrective actions will also be recorded for further reference.

The preventive maintenance activities are carried out when the labs are vacant.

Department of Building Economics 8

Maintenance Management Operations and Maintenance Plan for UPS

On Line Dual Conversion UPS:

According to the service agreement, the Energy Net company technicians will come for

quarterly service. They are bound to come for the service as to a negotiated timetable. Prior to

their visit the Department will be informed through a phone call since the necessary permission

is needed to be taken from the security.

The technicians are always accompanied with the lab assistant throughout the service.

After the completion of the service, the check list they have filled with the conditions of the

UPS will be authorized from the lab assistant.

All the records will be kept filed at the department.

Any failure of the system will be informed to the company over the phone and as for the

agreement they are bound to take remedial actions as soon as possible. Department will pay

additional payments for these kinds of requirements.

Department of Building Economics 9

Maintenance Management Operations and Maintenance Plan for UPS

Annexure

Department of Building Economics 10

You might also like

- Apc Back-Ups Rs 800va 230VDocument7 pagesApc Back-Ups Rs 800va 230VboonyongchiraNo ratings yet

- OnfinitiDocument6 pagesOnfinitiAPC UPSNo ratings yet

- Introduction to Power System ProtectionFrom EverandIntroduction to Power System ProtectionRating: 5 out of 5 stars5/5 (1)

- APC Smart-UPS 2200VA LCD RM 2U 230V: Home Products Uninterruptible Power Supply (UPS) Smart-UPSDocument4 pagesAPC Smart-UPS 2200VA LCD RM 2U 230V: Home Products Uninterruptible Power Supply (UPS) Smart-UPSAkram KareemNo ratings yet

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsFrom EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsRating: 3.5 out of 5 stars3.5/5 (3)

- APC Smart-UPS 3000VA LCD RM 2U 230V: Home Products Uninterruptible Power Supply (UPS) Smart-UPSDocument4 pagesAPC Smart-UPS 3000VA LCD RM 2U 230V: Home Products Uninterruptible Power Supply (UPS) Smart-UPSmuhamad agusNo ratings yet

- 93E 15-80 KVA Guide SpecificationDocument11 pages93E 15-80 KVA Guide SpecificationHafiz SafwanNo ratings yet

- APC SMART 2200VA SMTiDocument4 pagesAPC SMART 2200VA SMTiTanveer AhmedNo ratings yet

- PC Mate - Feature BenefitDocument1 pagePC Mate - Feature BenefitEyuNo ratings yet

- Apc Smt1500rmi2uDocument4 pagesApc Smt1500rmi2uUlya HasnaNo ratings yet

- Ups Apc 10kvaDocument8 pagesUps Apc 10kvapablomejia37No ratings yet

- Double conversion UPS for critical power protectionDocument2 pagesDouble conversion UPS for critical power protectionAnonymous KFOfMbNANo ratings yet

- APC Smart-UPS 1500VA LCD 230VDocument4 pagesAPC Smart-UPS 1500VA LCD 230VHadi BitarNo ratings yet

- Numeric Ups 1 10kvaDocument6 pagesNumeric Ups 1 10kvasandeep RajakNo ratings yet

- Apc Suvt10kf1b2s DatasheetDocument6 pagesApc Suvt10kf1b2s DatasheetJose MhNo ratings yet

- Liebert NX Ups Guide SpecsDocument16 pagesLiebert NX Ups Guide SpecstwobruinsNo ratings yet

- UPS - 1 - 3kVA - VRLA - Spec SheetDocument7 pagesUPS - 1 - 3kVA - VRLA - Spec SheetVictor JuarezNo ratings yet

- Technical-Specification_DPH-500kVA_V1Document22 pagesTechnical-Specification_DPH-500kVA_V1Pham van SangNo ratings yet

- Optimum 6-10K LCD Service ManualDocument28 pagesOptimum 6-10K LCD Service ManualAbdelwhab ElsaftyNo ratings yet

- Manual Alpha PsDocument19 pagesManual Alpha PsSalimNo ratings yet

- ONDULEUR APC Easy UPS 3S 1-10 KVADocument7 pagesONDULEUR APC Easy UPS 3S 1-10 KVAouattara yaya katiaNo ratings yet

- APC Smart-UPS: User Manual EnglishDocument17 pagesAPC Smart-UPS: User Manual EnglishNicelizabethNo ratings yet

- Symmetra PX 48kW - Guide SpecificationDocument11 pagesSymmetra PX 48kW - Guide SpecificationAugusto Francisco Diaz LaraNo ratings yet

- UPS APC SRV 1-3kva - Hoja de DatosDocument7 pagesUPS APC SRV 1-3kva - Hoja de DatosGermanYPNo ratings yet

- Types of UPS Systems ExplainedDocument10 pagesTypes of UPS Systems ExplainedRahul ItaliyaNo ratings yet

- APC Smart-UPS 2200VA USB & ...Document3 pagesAPC Smart-UPS 2200VA USB & ...pukazhendhiNo ratings yet

- UPS Spec 80 kVA HPE I 33 - IITK CSE - Tender Specs - Updated - 20180208Document2 pagesUPS Spec 80 kVA HPE I 33 - IITK CSE - Tender Specs - Updated - 20180208Dipesh BhagatNo ratings yet

- AEG - Protect 8 INV1-enDocument4 pagesAEG - Protect 8 INV1-enArfian Edy TamaNo ratings yet

- UPSDocument54 pagesUPSy m dNo ratings yet

- Liebert Npower Guide SpecificationsDocument16 pagesLiebert Npower Guide SpecificationsJOSE MIGUEL AYALA DURANNo ratings yet

- Offline UPS Reference Design Using The dsPIC DSCDocument86 pagesOffline UPS Reference Design Using The dsPIC DSCthietdaucongNo ratings yet

- ITCC in Riyadh Residential Complex J10-13300 16610-1 UPSDocument6 pagesITCC in Riyadh Residential Complex J10-13300 16610-1 UPSuddinnadeemNo ratings yet

- Vertiv Liebert gxt5 500 3000 Va Rack Tower Guide Specifications SL 71027Document13 pagesVertiv Liebert gxt5 500 3000 Va Rack Tower Guide Specifications SL 71027Dendy PurnamaNo ratings yet

- UPS Guide SpecsDocument13 pagesUPS Guide SpecsONILEDA1970100% (1)

- 1 Apc Sku-Smt1000icDocument3 pages1 Apc Sku-Smt1000icYasser Al EmadiNo ratings yet

- UPS Atlas Power Online BH - Plus Power+ 1-20KVA (Rack Mount) 2019 PDFDocument2 pagesUPS Atlas Power Online BH - Plus Power+ 1-20KVA (Rack Mount) 2019 PDFarmandonetNo ratings yet

- Powerware 9305 20-80 Kwa PDFDocument520 pagesPowerware 9305 20-80 Kwa PDFalex80% (5)

- EA900II Maintenance Manual 1 - 3KVA PDFDocument66 pagesEA900II Maintenance Manual 1 - 3KVA PDFVictor Mihai Oglinda Elivic70% (10)

- Ups Enertronic I: Excellent Technology, Efficiency and QualityDocument8 pagesUps Enertronic I: Excellent Technology, Efficiency and Qualitysanjaykhan17No ratings yet

- Apc Smart Ups 750 DatasheetDocument6 pagesApc Smart Ups 750 DatasheetFebri Cobra 郭汉亮No ratings yet

- APC Easy UPS 1 PH Online Rack Mount ModelsDocument5 pagesAPC Easy UPS 1 PH Online Rack Mount Modelsson.600No ratings yet

- 9305 - Datasheet UPSDocument2 pages9305 - Datasheet UPSsNo ratings yet

- CONVENTIONNAL UPS - 100kva To 800kva - Tender Technical SpecificationsDocument8 pagesCONVENTIONNAL UPS - 100kva To 800kva - Tender Technical SpecificationsMuhammad Qumar NazeerNo ratings yet

- ITCC in Riyadh Residential Complex J10-13300 16610-1 UPSDocument6 pagesITCC in Riyadh Residential Complex J10-13300 16610-1 UPSuddinnadeemNo ratings yet

- BENNING UPS 784370 - Enertronic - I - enDocument8 pagesBENNING UPS 784370 - Enertronic - I - enrioNo ratings yet

- Guide Specifications Symmetra 96 160kVADocument8 pagesGuide Specifications Symmetra 96 160kVAAugusto Francisco Diaz LaraNo ratings yet

- World Class Power Solutions Provides Reliable UPS ProtectionDocument8 pagesWorld Class Power Solutions Provides Reliable UPS ProtectionPizzas DelvalleNo ratings yet

- Easy UPS 1 PH Online Rack Mount Family Overview 1-10 kVADocument5 pagesEasy UPS 1 PH Online Rack Mount Family Overview 1-10 kVANguyen NinhNo ratings yet

- GXT3-10000RT230 Guide Spec PDFDocument12 pagesGXT3-10000RT230 Guide Spec PDFAlan BartlettNo ratings yet

- QUINT4-UPS/1AC/1AC/1KVA: Uninterruptible Power SupplyDocument33 pagesQUINT4-UPS/1AC/1AC/1KVA: Uninterruptible Power SupplyOmar Alfredo Del Castillo QuispeNo ratings yet

- APC by Schneider Electric: APC Symmetra PX Guide Specifications 96/160 KW Uninterruptible Power SystemDocument8 pagesAPC by Schneider Electric: APC Symmetra PX Guide Specifications 96/160 KW Uninterruptible Power SystemAugusto Francisco Diaz LaraNo ratings yet

- SMT2200RM2U: Product Data SheetDocument2 pagesSMT2200RM2U: Product Data SheetTINo ratings yet

- SEM Datasheet GB 06 2003Document2 pagesSEM Datasheet GB 06 2003Raúl LópezNo ratings yet

- Sag SwellDocument149 pagesSag Swellfurqan mahmudNo ratings yet

- AEG Protect 8 33 End UPSDocument6 pagesAEG Protect 8 33 End UPSomarNo ratings yet

- JY Series Transformer Based Industrial Online UPS Product DescriptionDocument4 pagesJY Series Transformer Based Industrial Online UPS Product DescriptionAsad IqbalNo ratings yet

- APC Smart-UPS RT 2000VA 230V: Home Products Uninterruptible Power Supply (UPS) Smart-UPS On-LineDocument4 pagesAPC Smart-UPS RT 2000VA 230V: Home Products Uninterruptible Power Supply (UPS) Smart-UPS On-LineMarius BaltariuNo ratings yet

- Eaton 9155 Ups Guide SpecDocument12 pagesEaton 9155 Ups Guide SpecFernando Joan Ramos RojasNo ratings yet

- TRADITIONAL GERMAN QUALITY FOR EVERYONEDocument70 pagesTRADITIONAL GERMAN QUALITY FOR EVERYONEpartha6789No ratings yet

- Outdoor Integrated Cabinet ICC710-HA1-C7 (01075400) Datasheet 03 - (20201031)Document2 pagesOutdoor Integrated Cabinet ICC710-HA1-C7 (01075400) Datasheet 03 - (20201031)Odai Kiwan100% (1)

- Anurag Pandey Resume - PDFDocument2 pagesAnurag Pandey Resume - PDFAnuragNo ratings yet

- SolarCity ResiBrochureDocument5 pagesSolarCity ResiBrochurepsobaniaNo ratings yet

- 38tkb 4wCARRIERDocument2 pages38tkb 4wCARRIERSyed Noman AhmedNo ratings yet

- Overcurrent Coordination StudyDocument25 pagesOvercurrent Coordination StudyMohamed TalebNo ratings yet

- Demand, Diversity & Utilization Factors for Electrical Load CalculationsDocument5 pagesDemand, Diversity & Utilization Factors for Electrical Load CalculationsJanitha HettiarachchiNo ratings yet

- High Voltage Test Data CabelDocument18 pagesHigh Voltage Test Data Cabelvery sihombingNo ratings yet

- Hybrid Power Systems Based On Renewable Energies-A Suitable and Cost-Competitive Solution For Rural Electrification PDFDocument7 pagesHybrid Power Systems Based On Renewable Energies-A Suitable and Cost-Competitive Solution For Rural Electrification PDFbdsrlNo ratings yet

- Transformers PDFDocument30 pagesTransformers PDFMichael Williams100% (1)

- Active Harmonic Filter (AHF) : AHF Wallmount AHF Cabinet MountDocument16 pagesActive Harmonic Filter (AHF) : AHF Wallmount AHF Cabinet MountPepe Eulogio OrtízNo ratings yet

- 12) Relay ReturnsDocument14 pages12) Relay Returnsveera chaitanyaNo ratings yet

- SAP MicroprojectDocument25 pagesSAP MicroprojectDurgesh M Pátíl100% (1)

- ELOSDocument14 pagesELOSMostafa MohmmedNo ratings yet

- Power Quality Improvement Using Shunt Active FilterDocument58 pagesPower Quality Improvement Using Shunt Active FilterPradheepohmmuruga100% (1)

- Electrical & Ict Need Statement: Hospital Kapar (Reka Dan Bina)Document229 pagesElectrical & Ict Need Statement: Hospital Kapar (Reka Dan Bina)james 87No ratings yet

- Merchant Power and Captive Generation Post Electricity Act 2003Document17 pagesMerchant Power and Captive Generation Post Electricity Act 2003robinNo ratings yet

- Philippine Agricultural Chipping Machine StandardDocument39 pagesPhilippine Agricultural Chipping Machine StandardManantan Ma. KatherinaNo ratings yet

- Performance of Transmission LinesDocument33 pagesPerformance of Transmission LineszvzizNo ratings yet

- Micrologic For Masterpact NW PDFDocument12 pagesMicrologic For Masterpact NW PDFazisNo ratings yet

- Technical Data For The Bhel 500 MW Steam TurbineDocument2 pagesTechnical Data For The Bhel 500 MW Steam Turbinesai ramanaNo ratings yet

- HSVC1 PP4-QA, QC Equipment Status Report - 20190830Document39 pagesHSVC1 PP4-QA, QC Equipment Status Report - 20190830nkvonNo ratings yet

- LCD - Backlight - Inverter - IC SOLUTIONS PDFDocument44 pagesLCD - Backlight - Inverter - IC SOLUTIONS PDFVictor Avendaño GrilloNo ratings yet

- Centrado Transformers Are Produce Centrado TranDocument6 pagesCentrado Transformers Are Produce Centrado Tranbagus saputraNo ratings yet

- CPG Catalog 2020Document16 pagesCPG Catalog 2020MothilalNo ratings yet

- UnionDocument1 pageUnionMallik AvijitNo ratings yet

- Price List For Switchyard EquipmentDocument6 pagesPrice List For Switchyard Equipmentdaminhvien0% (1)

- EECE370 Q2 F11 Key PostDocument7 pagesEECE370 Q2 F11 Key PosttelNo ratings yet

- Regulador Woodward 8290-184Document4 pagesRegulador Woodward 8290-184kinosi100% (1)

- 2 Imech - Energy Dome Company PresentationDocument16 pages2 Imech - Energy Dome Company PresentationRoque Alfredo Da Rosa AvilaNo ratings yet