Professional Documents

Culture Documents

For Official Use Only: U. S. Army Engineer District Corps of Engineers Fort Worth, Texas

For Official Use Only: U. S. Army Engineer District Corps of Engineers Fort Worth, Texas

Uploaded by

GanderOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

For Official Use Only: U. S. Army Engineer District Corps of Engineers Fort Worth, Texas

For Official Use Only: U. S. Army Engineer District Corps of Engineers Fort Worth, Texas

Uploaded by

GanderCopyright:

Available Formats

U. S.

ARMY ENGINEER DISTRICT

CORPS OF ENGINEERS

FORT WORTH, TEXAS

PERIODIC INSPECTION REPORT

DALLAS FLOODWAY

TRINITY RIVER

DALLAS, DALLAS COUNTY, TEXAS

REPORT NO. 9

3-5 DECEMBER 2007

FOR OFFICIAL USE ONLY

PERIODIC INSPECTION REPORT

DALLAS FLOODWAY

TRINITY RIVER

DALLAS, DALLAS COUNTY, TEXAS

REPORT NO. 9

3-5 DECEMBER 2007

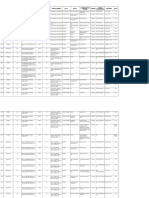

TABLE OF CONTENTS

SECTION NO. TITLE PAGE NO.

I – EXECUTIVE SUMMARY

1.1 EXECUTIVE SUMMARY 4

II – INSPECTION TEAM AND DATE OF INSPECTION

2.1 INSPECTION TEAM MEMBERS 5

2.2 DATE OF INSPECTION 6

III – SYSTEM BACKGROUND INFORMATION

3.1 PROJECT IDENTIFICATION 6

3.2 PROJECT AUTHORITY 6

IV – PRE-INSPECTION PACKET INFORMATION

4.1 PRE-INSPECTION BROCHURE 8

V – INSPECTION FINDINGS AND EVALUATIONS

5.1 GENERAL 8

5.2 RESULTS OF EXAMINATION FOR EACH FEATURE 8

5.3 DOCUMENTATION OF SIGNIFICANT GEOTECHNICAL FINDINGS 25

5.4 DESIGN CRITERIA REVIEW 51

VI – LEVEE SAFETY ISSUES AND RECOMMENDATIONS

6.1 LEVEE CREST ELEVATION 55

6.2 EMBANKMENT CRACKING 55

6.3 DART BRIDGE 58

6.4 HAMPTON BRIDGE 58

6.5 WOODALL RODGERS BRIDGE 58

6.6 I-35 BRIDGE 59

6.7 EROSION AT OTHER BRIDGE PENETRATIONS 59

6.8 CONDITION OF ACCESS ROADS 59

6.9 VEGETATION 60

6.10 REMOVAL AND REPLACEMENT OF CREEPING SLIDE REPAIRS 61

6.11 CHANNEL REPAIRS 62

6.12 SILTATION 63

6.13 DAMAGE DUE TO UNAUTHORIZED ACCESS 64

6.14 GATE CLOSURES 64

FOR OFFICIAL USE ONLY

2

SECTION NO. TITLE PAGE NO.

6.15 EMERGENCY ACTION PLAN 64

VII – REFERENCES

7.1 REFERENCES 64

VIII – ACTIONS TAKEN BY SSD SINCE PERIODIC INSPECTION

8.1 ACTIONS TAKEN 66

APPENDICES

Appendix No. Title

A PROJECT LOCATION MAP

B PRE-INSPECTION BROCHURE

C GIS MAPS

D PHOTOGRAPHS

E INSPECTION CHECKLIST (SPREADSHEETS)

F DALLAS FLOODWAY MAINTENANCE PROGRAM SUMMARY

G FLOOD 2007 GEOTECHNICAL TRIP REPORT

H LEVEE CREST SURVEYS

I CERTIFICATION LETTER

J ACTIONS TAKEN BY SSD SINCE PERIODIC INSPECTION

K AGENCY TECHNICAL REVIEW (ATR)

FOR OFFICIAL USE ONLY

3

PERIODIC INSPECTION REPORT

DALLAS FLOODWAY

TRINITY RIVER

DALLAS, DALLAS COUNTY, TEXAS

REPORT NO. 9

3-5 DECEMBER 2007

I – EXECUTIVE SUMMARY

1.1 EXECUTIVE SUMMARY. The Dallas Floodway project protects the CoD, Texas, a major

metropolitan area with a population in excess of 1.2 million people. Located along the Elm

Fork, West Fork and Trinity Rivers, the Dallas Floodway includes 22.6 miles of levees: 11.7

miles on the East levee and 10.9 miles along the West levee. The East levee protects the

Stemmons Corridor (a major transportation route through the City) and parts of Downtown

Dallas and the Central Business District from flooding on the Trinity River, while the West

levee protects a large portion of West Dallas.

These levees were originally constructed by the CoD in the early 1930s in response to

extreme flooding along the Trinity River in 1908. Originally constructed with 2.5H:1V side

slopes, a maximum height of 35 feet and a crown width of 6 feet, the levee system was

modified by USACE in the late 1950s by expanding the levee cross-section, flattening the

levee side slopes and increasing the crest width to 16 feet. Additionally, improvements to the

interior drainage system were also made at that time. Originally authorized to provide flood

protection to a level of SPF + 4 feet, major urban development and land-use changes in the

area since the project was completed in 1958 have reduced that level of protection.

Restoration of the authorized level of flood protection will require providing more height on

both the East and West Levees.

In 1999 at the direction of Congress, two additional systems were added to the Dallas

Floodway: Rochester Levee, which protects residential and commercial interests in East

Dallas; and the Central Wastewater Treatment Plant (CWWTP) Levee, which protects critical

infrastructure in South Dallas.

A periodic inspection (PI) of the Dallas Floodway project was performed on 3-5

December 2007. This inspection was the 9th PI for the East and West Levee systems, and

the 1st PI for both the Rochester and the CWWTP Levee systems. The inspection was

conducted using procedures utilized during all past PIs of the project (i.e., ‘legacy’ type

inspections), and did not incorporate the Levee Inspection Checklist distributed in June 2007.

When the report documenting the inspection and findings was being written, it was

determined that failure to use the new inspection checklist was inappropriate. Therefore,

information from the legacy inspection was transferred to the new inspection template.

During this transfer, it became apparent that the more subjective ratings from previous

inspections of the Floodway would be replaced by ratings determined in accordance with the

very specific language and rating criteria described on the checklist. As a result, significant

deficiencies were documented that resulted in unacceptable ratings for each of the 4

systems in the Floodway, and for the Dallas Floodway project overall. Items that generated

unacceptable ratings include:

• Insufficient crest height rendering the East and West Levees incapable of successfully

accommodating the Standard Project Flood without overtopping

• Significant encroachments and penetrations that impact the integrity and performance

of the levees, as well as inhibit access for O&M, surveillance, and flood-fighting

purposes

FOR OFFICIAL USE ONLY

4

• Damaged gate closures

• Unstable structures

• Severe desiccation cracking of the levees

• Erosion

• Vegetation

• Siltation

• Channel instability

In addition to numerous unacceptable ratings, it was determined that the Dallas

Floodway does not meet current USACE design criteria regarding relevant factors of safety

for embankment stability and seepage gradients.

It is noted that the results of the inspection identify negative impacts during base flood

(100-year event) conditions which would jeopardize performance of project features to

reliably function as authorized. This is a significant concern that may have a substantial

negative impact on FEMA flood mapping of the areas outside the levees and the residents

and businesses protected by those levees.

According to the Inspection Report Template, the East Levee, West Levee,

Rochester Levee, and the CWWPT Levee systems had one or more items rated as

unacceptable. Since there is a significant number of deficiencies that would prevent the

systems from performing as intended, the overall rating for the Dallas Floodway project is

unacceptable.

II – INSPECTION TEAM AND DATE OF INSPECTION

2.1 INSPECTION TEAM MEMBERS. The following were members of the inspection team:

Name Organization

David F. Garcia CoD, Street Services Department

Marie Marroquin CoD, Street Services Department

Don Lawrence CoD, Street Services Department

Frank D. Pechal CoD, Street Services Department

Mike Johnson CoD, Street Services Department

Billy Rios CoD, Street Services Department

Kelly High CoD, Director, Street Services Department

Ron Bell CESWD-RBT-W, Water Management

Les Perrin CESWF-EC-DG, Geotechnical, E&C

José Hernández (team lead) CESWF-EC-DG, Geotechnical, E&C

Anita Branch CESWF-EC-DG, Geotechnical, E&C

Steven Chen CESWF-EC-DG, Geotechnical, E&C

Kurt Ley CESWF-EC-DS, Structural, E&C

Zach Gerich CESWF-EC-DS, Structural, E&C

David Wilson CESWF-EC-HH, Hydrology & Hydraulics, E&C

Mark Sissom CESWF-OD-TM, Ops

Jeff Qunell CESWF-OD-TM, Ops

Jason Tackett CESWF-PM-ECSO, PPMD

John Wilson AZ & B

2.2 DATE OF INSPECTION. The inspection was conducted from 3 to 5 December 2007. The

weather was sunny, dry, and cool, with temperatures in the 70s and clear blue skies. The

FOR OFFICIAL USE ONLY

5

elevation of the Trinity River at Baker Pump Station was 383.75 feet NGVD on 2 December

2007 (All elevations mentioned in this report are expressed in feet, NGVD). Information,

data, and as-built drawings contained in previous inspection reports are referenced, but not

repeated.

This report contains the results of the inspection performed by representatives of the

U.S. Army Corps of Engineers (USACE), Fort Worth District (CESWF), and the CoD Street

Services Department (SSD). Authority for conducting PIs and preparing inspection reports is

contained in ER 1110-2-100, Periodic Inspection and Continuing Evaluation of Completed

Civil Works Structures, dated 15 February 1995, and Policy Guidance Letter, Periodic

Inspection Procedures for the Levee Safety Program, dated 17 December 2008.

III – SYSTEM BACKGROUND INFORMATION

3.1 PROJECT IDENTIFICATION. The Dallas Floodway, Trinity River (West Fork and Elm Fork),

Texas, is an urban flood damage reduction project consisting of the following four systems:

East Levee, West Levee, Rochester Levee, and Central Wastewater Treatment Plant

(CWWTP) Levee. The project is federally authorized and non-federally operated and

maintained.

3.2 PROJECT AUTHORITY. The authority under which the Dallas Floodway Project was

constructed was the River and Harbor Act approved 2 March 1945 (PL-79-14) (HD

403/77/1), and the River and Harbor Act approved 17 May 1980 (PL 81-516) HD 242/81/1.

The authority for the Dallas Floodway Extension construction was under Section 301, River

and Harbor Act 1965, modified by Section 351 WRDA 1996; and Section 356 of WRDA

1999. The reimbursement shown in the project cost was authorized by Section 351 WRDA

1996 for the useful portions of the Rochester and Central Wastewater Treatment Plant Levee

Systems, which were constructed by the CoD after the floods of 1989, 1990 and 1991.

Section 301 of the River and Harbor Act of 1965 (79 Stat. 1091) was modified to

provide that flood protection works constructed by the non-federal interests along the Trinity

River for Rochester Park and the Central Wastewater Treatment Plant shall be included as a

part of the project and the cost of such works shall be credited against the non-federal share

of project costs.

3.2.1 Estimated Original Cost of Federal Project. The estimated original project cost was

$23.9 million.

3.2.2 Construction Completion Date of Original Federal Project. Construction to modify

the original Dallas levees by enlarging the levee cross-section was performed between

February 1953 and April 1959.

3.2.3 Public Sponsors. The public sponsor is the SSD. The point of contact is David F.

Garcia, P.E., Senior Program Manager, at 214-671-0322.

3.2.4 Location. The project is located in the CoD, Dallas County, Texas, as shown on the

Project Location Map provided as Appendix A. The floodway alignment runs along the Elm

Fork and the West Fork of the Trinity River, Mountain Creek, and the main stem of the Trinity

River.

The East Levee system extends from river miles 497.9 to 505.5 of the Trinity River

and 3.8 miles along the Elm Fork. The West Levee system extends from river miles 498.1 to

FOR OFFICIAL USE ONLY

6

505.5 of the Trinity River and 3.6 miles along the West Fork and Mountain Creek. The

Rochester Levee system surrounds Rochester Park, and the Central Wastewater Treatment

Plant (CWWTP) Levee system surrounds the plant of the same name.

3.2.5 Potential Consequences. The potential consequences for the Dallas Floodway

project consisting of populations at risk and the estimated value of the property in the

protected areas are to be obtained from the National Levee Database (NLD), which has not

been populated at the time this report was prepared.

3.2.6 Investigations Prior to Construction. As-built construction drawings of the Dallas

Floodway are stored at the SSD Operations Office. The description of the embankment and

foundation materials, design data, basis of design, and stability analyses may be found in the

USACE publication “Review of Levee Design, Dallas Floodway,” June 1968. Soils data and

seepage investigations may be found in the USACE publication “Periodic Inspection and

Continuing Evaluation of Completed Civil Works Structures, Dallas Floodway, Trinity River,

Texas,” February 1969, Appendix C, “Seepage Investigations of West Levee Between

Stations 134+90 and 196+40,” September 1953.

3.2.7 History of Remedial Measures and Major Modifications. The Dallas Floodway

consists of approximately 22.6 miles of levees. The existing levees generally follow the

alignment of the original levees, which were constructed between 1928 and 1931. The East

Levee is approximately 11.7 miles long and the West Levee is approximately 10.9 miles long.

The original levees had a crown width of 6 feet, an average height of 26 feet, and a

maximum height of 37 feet. Side slopes were approximately 1 vertical (V) on 2.5 horizontal

(H). The original levees were constructed by dragline with no compaction or moisture

control.

The reconstructed levees have a crown width of 16 feet, an average height of 28 feet,

and a maximum height of approximately 35 feet. Landside slopes are generally 1V:3H and

riverside slopes vary from 1V:3H to 1V:4H. Side slopes of the sumps (excavations in the

landside used as borrow areas) range from 1V:1.5H to 1V:3H, with an average depth of 20

feet. The inside slopes of the sumps are generally separated from the landside toe of the

levee by a berm that varies in width from 15 to 40 feet. As mentioned earlier, levee

strengthening construction (from original levees to existing levees) was performed between

February 1953 and April 1959. The chronology of the levee strengthening and construction

of other features within the project (including contractors) is as follows:

Date Feature Contractor

Jun 1954 Able Pump Station E.E. Const. Co.

Aug 1954 East Levee Strengthening & Sump Excavation John A. Petty Co.

May Turtle Creek Pressure Sewer, Part 1 Whittle Const. Co. (WCC)

1955 Turtle Creek Pressure Sewer, Part 2 WCC & McKenzie Const. Co. (MCC)

Sep 1955 Pavaho Pump Station List and Clark Const. Co.

West Levee Strengthening & Sump Excavation Cleal T. Watts Co.

Nov 1955

Turtle Creek Pressure Sewer, Part 3 WCC & MCC

Dec 1955 Lake Cliff Pressure Sewer MCC

Mar 1956 East Levee Strengthening (I) Cleal T. Watts Co. (CWC)

Sep 1956 Turtle Creek Pressure Sewer, Part 4 WCC & MCC

FOR OFFICIAL USE ONLY

7

Jan 1957 Coombs Creek Diversion Facility WCC

West Levee Strengthening (I) CWC

Oct 1957

Turtle Creek Pressure Sewer, Part 5 E.H. Reeder Const. Co., Inc.

Dec 1957 East Levee Strengthening (II) CWC

Oct 1958 Hampton Road Pump Station WCC

West Levee Strengthening (II) & Channel

Apr 1959 Griffin & Dickson Co.

Excavation

IV – PRE-INSPECTION PACKET INFORMATION

4.1 PRE-INSPECTION BROCHURE. Each member of the inspection team was furnished a pre-

inspection brochure which contained an agenda, checklists, floodway maps, and actions

taken to previously identified problems. The Pre-Inspection Brochure is provided as

Appendix B.

V – INSPECTION FINDINGS AND EVALUATIONS

5.1 GENERAL. Most of the items rated as unacceptable and minimally acceptable are shown

in the GIS Maps provided as Appendix C (Plates 1 to 9). All photographs referenced in

Section 5.2 are provided as Appendix D (Plates D-1 to D-25). Inspection findings are

detailed by system, feature, and rated item in the inspection checklist (spreadsheets)

provided as Appendix E. Results of examination for each feature are presented in Section

5.2, Results of Examination for Each Feature, and significant findings of the geotechnical

project components are presented in Section 5.3, Documentation of Significant Geotechnical

Findings.

According to the Inspection Report Template, the East Levee, West Levee,

Rochester Levee, and the CWWPT Levee systems had one or more items rated as

unacceptable. Since there is a significant number of deficiencies that would prevent the

systems from performing as intended, the overall rating for the Dallas Floodway project is

unacceptable.

5.2 RESULTS OF EXAMINATION FOR EACH FEATURE. Results of the visual inspection for the

features and components of the systems are discussed below. Findings are for those items

that received a minimally acceptable or unacceptable rating.

It is noted that sufficient time was not allocated during the inspection to thoroughly

assess all the various components of project operation, maintenance, and response system;

so much of this information was requested after the inspection. The SSD has supplied

written responses to demonstrate its capability to manage the project effectively. The

responses are shown in the Dallas Floodway Maintenance Program Summary provided as

Appendix F and these addressed the following items: level of maintenance performed over

the previous five years; required operations and maintenance manuals; emergency supplies

and equipment; flood preparedness and training; and specific preventive maintenance,

inspections, communication, and security elements.

As noted in the inspection report template, some components were not inspected

while others were not available for review. In some cases a rating was able to be assigned.

FOR OFFICIAL USE ONLY

8

Where there was insufficient data to give a rating, a future inspection should be arranged to

assess and validate the project’s ability to function as authorized. Special attention should

be paid to ensuring permanent functioning of the closure structures and that conduit

condition surveys are conducted periodically.

5.2.1 East Levee Embankments.

The following items were rated as unacceptable (U):

• Unwanted vegetation was found at Station 147+70, where a tree is growing on the

riverside levee toe and trees were present within 50 feet of the toe near Stations

474+, 524+25, and HWY 30 (U). This vegetation should be removed to ascertain

levee integrity.

• Encroachments found along the levee consist of 18 bridges, including the DART

Bridge. Many had piers on the levee crest, slopes, or within 50 feet of the toe (U).

See Plate D-1, Photo EL 3b.

• From the DART to the I-35 Bridges (Stations 20+00 to 81+00), there are electric

power towers on the landside lower slopes (U). This was also the case at Stations

237+50, 320+ to 364+, and 612+, where electric power towers and poles are present

on the landside levee toe (U). At Station 515+70, the electric power pole was on the

riverside levee toe (U). Encroachments inhibit O&M and emergency operations, and

may negatively impact the integrity and performance of the levee.

• A construction stockpile was present on the crest of the levee at Station 147+40, and

an unauthorized encroachment from the ongoing construction of a jail annex that may

include a basement adjacent to the landside levee toe (U). The latter had damaged

the levee section and removed material from the foundation adjacent to the levee toe.

See Plate D-1, Photo EL 3c.

• Hampton Bridge at Station 292+91 had a 5-foot deep void under the landside bridge

slope paving (U). See Plate D-2, Photo EL 3d. Caving has progressed into the levee

section.

• A void was found under the pier support beam on the Highway 183 Bridge at Station

546+30 in the riverside of the levee crest (U). See Plate D-2, Photo EL 3e.

• The DART Bridge had bridge piers on the levee crest from Stations 13+50 to 22+00

(U). See Plate D-3, Photo EL 3f & 6.

• Erosion was found around each of the DART Bridge piers on the landside crest of the

levee from Stations 13+50 to 22+00 that had been created by drainage coming from

the bridge. This erosion has significantly reduced the levee crest width and height,

creating gullies and exposing the pier foundations (U). See Plate D-3, Photo EL 3f &

6.

• The crest survey performed in 2003 indicates 47% of the East Levee crest is below

the SPF elevation (U).

• No cracking of the East Levee was observed during this inspection, but a history of

severe seasonal desiccation cracking has been recorded for this system. Some

cracks measured after the PI in September 2008 were up to 4 feet in depth (U).

FOR OFFICIAL USE ONLY

9

• Some joint seals were out of the joints between the floodwall panels near the DART

railroad bridge (U) and brush was growing along parts of the north side of the

floodwall (M). See See Plate D-3, Photo EID 8 and ELF 7. Closures that are in poor

condition or are missing parts may compromise the system in a flood event.

• The “railroad” and “paved road” stop log gate structures have been compromised by

unauthorized removal of their sills (U). See Plate D-4, Photo ELF 3. The placement

location of the stop log center post beam for the railroad stop log structure was not

visible and appeared to be buried (U). Seepage under the stop logs through the

railroad ballast is predicted (U). At Station 13+50 the sand pile for sealing the stop

log was overgrown with weeds and brush. As mentioned earlier, closure structures

that are in poor condition or are missing parts may compromise the system in a flood

event. Additionally, trial erections have not been accomplished in accordance with

the O&M Manual. This has been a persistent problem due to coordination difficulties

with the railroad (U).

The following items were rated as minimally acceptable (M):

• Stations 54+95 and 260+90 had bushes growing at the base of power line towers off

the landside levee toes (M). See Plate D-4, Photo EL 1 and EL 3a.

• Johnson grass growth was observed to be widespread over the entire project. The

rapid growth of this grass can hinder inspection and make seepage harder to detect

(M). A survey of additional areas where unwanted vegetation is within 50 feet of the

levee toe is recommended. Localized bare areas were observed along the levee,

commonly near bridge abutments. This makes the embankment soils more

susceptible to cracking and erosion.

• The I-35 northbound bridge abutment at Station 81+00 had a void (10'L x 17'W x 4'D)

under the broken slope paving of the ramp on the landside of the levee. It also had a

cracked bridge beam on the south abutment ramp (M). Although this feature is

outside the Floodway’s ROW, the item was rated because it needs to be evaluated in

order to determine its impact on the performance of the Floodway. The situation has

been reported to TxDOT bridge authorities.

• Station 286+80 and 364+60 had fiber optic line crossings over the levee not

streamlined to the channel (M).

• Station 286+95 had a fiber optic line crossing over the levee (M). Station 621+10 had

a 48" abandoned water line under the levee (M).

• Station 292+90 had a 10-foot diameter concrete debris pile in the channel off of the

riverside levee toe next to the bridge piers (M).

• Station 175+70, 380+00, 473+90, and 568+70 had rutting on the levee slopes from

unauthorized recreational ATV use (M).

• Slide areas on the riverside slope at Stations 480+20 and 563+40, which had been

repaired, appeared to be bulging again (M).

• Station 54+95 had a repaired landside slide and Stations 320+00, 515+75, 520+00,

and 524+25 to 530+75 had repaired riverside slides. At Station 551+50, a repaired

FOR OFFICIAL USE ONLY

10

riverside slope slide had a 1-inch wide crack on the landside crest edge (M). At

Station 175+70, a bench on the riverside mid-slope was observed. These areas

should be repaired.

• At Station 25+00 an erosion gully (30’L x 4’W x 3’D) on the landside levee toe ditch

was observed (M). Filter fabric and 12" stone protection had been placed within the

erosion gully on the north end of each pier, but this had not been effective as an

erosion control measure and gullies have formed on the landside levee slopes.

• The TRE Railroad Bridge at Station 473+90 had two erosion gullies (20'L x 2'W x 1'D)

on the riverside slope (M). Sylvan Ave. Bridge at Station 225+00 had an erosion gully

(12'L x 3'W x 1'D) on the slope under the bridge (M). These erosion deficiencies do

not appear to threaten the levee integrity but need to be repaired.

• Highway I-30 Bridge at Station 118+30 had multiple large erosion gullies (30'L x 6'W

x 5'D each) under the bridge on the landside slope of the levee (M). Jefferson Bridge

at Station 97+50 had minor erosion on the levee slope (M). These erosion

deficiencies do not appear to threaten the levee integrity but need to be repaired.

• The drainage ditch adjacent to the landside levee toe (such as in Station 473+90) and

the sump areas is the typical project condition that would obscure seepage that may

develop during flood events (M).

• Hampton Bridge at Station 292+91 had a 2-inch displacement on the landside bridge

slope paving (M).

• Highway 183 Bridge at Station 546+30 had a 6-foot diameter caving/erosion on the

levee slope (M) and the railroad bridge at Station 147+70 had a depression on the

levee slope below the bridge (M).

• Continental Ave. Bridge at Station 163+60 had stone protection that was being

displaced down the slope (M). Homeless people appeared to be removing stone

riprap and using it to construct shelters.

5.2.2 East Levee Structures.

5.2.2.1 Belleview Pressure Conduit, Station 59+93.

The following items were rated as unacceptable (U):

• Shoaling with established vegetation on the right bank is causing the diversion of the

channel into the levee at the Belleview Pressure Conduit. The discharge channel

slopes of Belleview Pressure Conduit have been severely eroded (U). Refer to East

Levee Flood Damage Reduction Channels spreadsheet, rated item #2, page 51/53.

See Plate D-5, Photos EFD 2a and EFD 2b. This needs to be repaired before the

problem worsens and compromises the levee section and access road.

The following items were rated as minimally acceptable (M):

• Damage to the concrete around the perimeter of the outlet was observed. There was

slight rust on the upper bridge girder (M).

5.2.2.2 Able Pump Station, Station 99+45.

FOR OFFICIAL USE ONLY

11

The following items were rated as unacceptable (U):

• The left gate of the tower is either loose or out of alignment. Either the guide is

broken or the gate was raised too high and came off the guide (U). Most likely the

guide has rusted and broke. Project personnel will have to construct a cofferdam in

the outlet trench to effect repairs.

• There is a hole (12"W x 24"L) along the curb of the drive above the conduits from the

small (old) pump house, where water bubbles up at times of high water (U). See

Plate D-6, Photo APS 17.

• A concrete drainage chute at the right side of the trash racks for the small pump

house has failed due to loss of soil underneath the chute (U). See Plate D-6, Photo

EID 7a.

The following items were rated as minimally acceptable (M):

• The bearing for the service bridge at the outlet works is cracked and settlement of the

abutment at the levee has resulted in bending of the anchor bolts (M).

• There was a misaligned joint in the retaining wall at the discharge outlet and a large

concrete spall on the upstream side of control tower (M).

• There has been movement of masonry walls in the large pump house away from the

concrete columns (M).

• Trash in the sump pond area next to the trash racks was observed (M).

• The chain link fence with razor wire at the top was in good condition. Exterior brick

masonry is cracking near a corner of the pump house (M). Although needing repair,

these are minor structural defects that do not threaten the structural integrity or

stability of the structure, and should not impact pumping operations.

5.2.2.3 Woodall Rodgers Pressure Outfall, Station 160+98.

The following items were rated as minimally acceptable (M):

• Silt deposits covering 75% of the width of the channel on the right side of the

discharge channel need to be removed (M).

5.2.2.4 Baker Pump Station, Station 235+04.

The following items were rated as minimally acceptable (M):

• At the intake for the Baker Pump Station addition, the spalling and continuous vertical

crack on each side of the trash rack, noted in previous inspections, appeared to be

unchanged (M).

• The lower concrete wall panel right of the trash racks was displaced 1 inch inward,

possibly from construction. There was a major fracture in the retaining wall along a

set of stairs behind the old pump station (M).

FOR OFFICIAL USE ONLY

12

• The fracture had been sealed but either the sealant has shrunk or further separation

of the concrete has occurred, causing the sealant to fail. The other stairs have been

shifted about one foot along the upper bearing as a result of being struck by a bobcat

that was clearing trash in the area (M).

• There was a broken hand rail at the top of the stairs behind the building (M).

• There was bending of the bearing assembly for the service bridge due to settlement

of the abutment at the levee. The concrete in the corbel under the beam supports at

the control structure was showing signs of scaling (M).

• The service bridge was tilted relative to the bridge abutment and the girder was tight

against the abutment (M).

• The concrete trapezoidal channel next to the trash rack and the earthen ditch in front

of the rack had deposition that should be cleaned out. Trash in the sump pond area

next to the trash racks was observed (M).

• The pump station had erosion (4'W x 35'L) on the slope above the discharge chute,

erosion (15'W x 35'L) on the left slope, and erosion (50'W x 80'L) on the right side of

the discharge channel (M). See Plate D-7, Photo EID 7b. There was some corrosion

on the four flap gates. Although needing repair, these are minor structural defects

that do not threaten the structural integrity or stability of the structure, and should not

impact pumping operations.

5.2.2.5 Dallas Branch Pressure Conduit, Station 154+33.

The following items were rated as unacceptable (U):

• At the control structure, the bottom of two posts for the handrail at the left side of the

tower operating deck had completely rusted out. Due to the height of the tower, this

is a safety issue (U). See Plate D-7, Photo DBP 21.

The following items were rated as minimally acceptable (M):

• The replacement of rusted bolts at the base of the stem for the right gate operator

appeared to have caused cracking in the concrete deck. The cracks, unless sealed,

will allow future freeze/thaw damage (M).

• There was an erosion depression (3’L x 2’W x1’D) on the slope of the service bridge

abutment (M).

• Erosion (3’L x 1’W x 10”D) was found on the upstream side of the control structure

and another 6-inch erosion depression on the right side of the control structure (M).

• There was a 3-foot long crack in the right wing wall of the discharge chute with

seepage flowing slowly from the bottom 5 inches of this crack (M).

• Deposition was blocking 70% of the discharge channel (on the right side of the

channel) just downstream of the discharge chute. This area should be cleared (M).

FOR OFFICIAL USE ONLY

13

5.2.2.6 Turtle Creek Pressure Conduit, Station 194+13.

The following items were rated as unacceptable (U):

• The Turtle Creek Pressure Conduit had six trees growing in the upper section of a

gabion retaining wall on the left side of the channel leading to the intake, and a tree

growing next to the right side of the box culvert at the intake (U). See Plate D-8,

Photo EID 2.

• The left discharge wing wall was displaced 3 inches with an erosion hole behind it

(5'W x 4'L x 3'D). The offset between headwall and wing wall appeared to be getting

worse over time (U). See Plate D-8, Photo EID 6a.

The following items were rated as minimally acceptable (M):

• There was corrosion on the lower part of the intake trash rack at the entrance leading

to the conduit (M) and light debris in the intake. The conduit had four locations where

exposed steel reinforcement in the ceiling of conduit is corroding and two locations

where steel objects are protruding (one from the ceiling and another from the left wall

of the conduit).

• There was condensation forming on the ceiling of the conduit approximately at the

location where the water level in the floor of the conduit deepens. There was

moderate seepage at some of the joints (M).

• The service bridge abutment had settled (M) and erosion (6"W x 6'L x 6"D) was found

on the right side of the control structure (M). See Plate D-9, Photo TCP 5.

• A homeless camp was observed under the bridge at the bridge abutment. This is

considered an encroachment and should be removed (M).

• There was erosion on both the right and left slope just above the corners of the

discharge chute (M).

• A second wall joint at another location had separated by 1 to 2 inches and moved

towards the channel by 1/4 inch (M). See Plate D-9, Photo EID 6b. There was

deposition (8'L x 3'W) in the discharge channel.

5.2.2.7 New Hampton Road Pump Station, Station 309+08.

The following items were rated as unacceptable (U):

• Riprap displaced from the slopes of the discharge channel to the bottom of the

channel had exposed bedding (U) and the riprap stones accumulated at the bottom of

the channel. There was erosion (30’L x 17’W) on the right channel slope just past the

riprap slope and shallow slides on the downstream right and left slopes. See Plate D-

10, Photos EFD 10 and EID 14.

5.2.2.8 Old Hampton Road Pumping Plant, Station 312+05.

The following items were rated as minimally acceptable (M):

FOR OFFICIAL USE ONLY

14

• The concrete slabs adjacent to the structure have settled 6 inches on both sides of

the structure (M). The slab of the service bridge is uptight against the abutment (M).

The vertical joint at the corner in the left wing wall at the intake for the pump station

has a large gap between the concrete sections (M). Refer to rated item #5.

• The fiberglass dome supporting the manhole cover over the low flow for the pump

station had failed (M).

• The vertical joint at the corner in the left wing wall at the intake for the pump station

had a 2-inch separation and the left wall had tilted toward the channel by ½ inch at

the joint (M).

• An erosion gully (2'W x 10'L x 18"D) caused from run-off from the parking lot above

the left intake wing wall was observed (M).

• Metal plates at the end of the bridge deck and bridge abutment are butting up against

each other (M).

• The headwall at the outlet was showing a significant bend (M) and corrosion on the

flap gate was observed. See Plate D-11, Photo HRP 13. Although needing repair,

these are minor structural defects that do not threaten the structural integrity or

stability of the structure, and should not impact pumping operations.

5.2.2.9 Six Gravity Sluice East Levee Station 235+04.

The following items were rated as minimally acceptable (M):

• Erosion was found on the slope above the sluice discharge head wall and also on

both the right (70’L x 20’W x 6’D) and left (60’L x 17’W) slopes of the discharge

channel just beyond the wing walls.

5.2.2.10 Elm Fork Sluice East Levee Station 601+32.

The following items were rated as minimally acceptable (M):

• The Elm Fork facility was not in service. Exposed steel reinforcement at the bridge

support on the control structure and an 8-inch erosion depression on the slope side of

the service bridge abutment was observed (M). Erosion had created a 25-foot

diameter pond just upstream of the Elm Fork Sluice discharge channel.

5.2.2.11 Emergency Control Structure.

The following items were rated as minimally acceptable (M):

• The service bridge was tight against both the bridge abutment and control structure

(M). There was an 8-inch erosion depression on the slope side of the control structure

and the service bridge abutment on the levee (M).

5.2.3 West Levee Embankments.

The following items were rated as unacceptable (U):

FOR OFFICIAL USE ONLY

15

• At Eagle Ford Sluice (Station 479+72), trees were growing on the landside levee

slope (U). See Plate D-11, Photo WL 1. At Stations 350+00, 371+50, 376+50, and

near HWY 30, trees were also growing within 50 feet of the levee toe (U). This

vegetation should be removed to ascertain levee integrity.

• Encroachments found on the levee included 15 bridges. Many had piers on the levee

crest, slopes, or within 50 feet of the toe (U). See Plate D-12, Photo WL 3a.

• Walton Walker Bridge at Station 475+65 had its pier support buried in the levee (U).

The levee crest was excavated under the Houston Street Bridge and had reduced the

crest width (U).

• At Station 18+90, a power line tower was found on the landside levee toe (U). See

Plate D-12, Photo WL 3b.

• From the DART to I-35 Bridges (Stations 20+00 to 81+00), electric power towers

were found along the landside levee toe (U). See Plate D-13, Photo WL 3d.

• The previous deficiency was also the case at Stations 237+50, 320+ to 364+, and

612+ (these had either electric towers or poles and were located on the land side

levee toe) (U).

• At Station 515+70 an electric power pole was found on the riverside levee toe (U).

• A series of power line poles on the land side levee slope/toe and cabled pole vehicle

barriers on the land side levee slope was observed upstream of Station 171+40 (U).

• More power poles were found on the land side levee toe downstream of Station

267+95 (U).

• Station 500+00 had a pole on the riverside levee slope (U). Utility encroachments

crossing the levee included: a gas line crossing at Station 253+70 not streamlined to

the channel (U), a 6-inch jet fuel pipeline crossing at Station 329+70 (U), and an 8-

inch petroleum line crossing over the levee streamlined to the channel at Station

466+50 (U). See Plate D-13, Photo WL 3c.

• Stations 11+90 and 25+40 had unidentified lines crossing the levee (U).

• The crest survey in 2003 indicates 42% of the West Levee crest is below the SPF

elevation (U). The levee crown was below design elevation at Station 54+14(-1.17

feet), 70+00(-0.66 feet), 160+00 to 315+00 (max. of -2.61 feet), 340+00 (-0.33 feet),

and 380+00 to 570+00 (max. of -1.21 feet) according to the 2003 survey.

• Three-inch deep mower rutting on the riverside slope around the Pump Station Delta

service bridge was observed. No cracking of the West Levee was observed during

this inspection, but a history of severe seasonal desiccation cracking has been

recorded for this levee system. Some cracks that were measured in September of

2008 were up to 4 feet in depth (U). Tension cracks along the crest of levees or the

face of the slopes fill up with water when it rains and may cause slides to occur.

The following items were rated as minimally acceptable (M):

FOR OFFICIAL USE ONLY

16

• Johnson grass growth was observed to be widespread over the entire system. The

rapid growth of this grass can hinder inspection and make seepage harder to detect

(M). A survey of additional areas where unwanted vegetation is within 50 feet of

levee toes is recommended. Localized bare areas were observed along the levee,

especially near bridge abutments. This makes the soil more susceptible to cracking

and erosion.

• Stations 244+80 and 309+30 had a fiber optic line crossing over the levee not

streamlined to the channel (M). I-35 Bridge northbound at Station 52+50 had four

shopping carts full of removed rock protection most likely being to be used for a

homeless shelter (M). A sewer line repaired at Station 503+50 had increased the

levee section at this location.

• Repaired slide areas were observed at Stations 316+00 (2 slides), 317+60, 338+40,

350+00, 371+50 to 376+50, and 377+50 (a 420’L repaired riverside shallow slide)

(M).

• Erosion gullies were found at the I-35 Bridge northbound, Station 52+50, on the

riverside levee slope (M). A 20-foot long erosion gully was found at Station 134+20

on the riverside levee ramp (M). An erosion gully was found next to a pier at Walton

Walker Bridge, Station 475+65 (M). See Plate D-14, Photo WL 6.

• Corinth Street Bridge at Station 5+40 and Union Pacific Railroad Bridge at Station

133+20 had depressions on the riverside levee slope protection under the bridges

(M).

5.2.4 West Levee Structures.

5.2.4.1 Charlie Pump Station, Station 68+32.

The following items were rated as unacceptable (U):

• Power poles upstream and downstream of the pump station at the same elevation as

the pump station were observed leaning in the slope direction.

• An erosion void (10’L x 1.5’D) under the concrete stairs on the west side of the pump

house and a gully running down the slope from this erosion was found. It is unclear

how far back the void goes (U). See See Plate D-15, Photo CPS 5a.

The following items were rated as minimally acceptable (M):

• Debris was obstructing 10% of the inlet for the small pump house (M).

• Trash was found in the sump area next to the trash racks (M).

• The concrete on the bridge support corbel under the bridge girders was scaling at the

control structure (M).

• Erosion gullies were found on both slopes of the discharge channel. The right gully

was 20’L x 5’W x 3’D and the left was 7’L x 2’W x 1’D (M).

• There was erosion on the right toe (5'W x 10'L) of the discharge channel (M). The

FOR OFFICIAL USE ONLY

17

discharge outlet was submerged. Although needing repair, these are minor structural

defects that do not threaten the structural integrity or stability of the structure, and

should not impact pumping operations.

5.2.4.2 Delta Pump Station, Station 267+95.

The following items were rated as unacceptable (U):

• A slope slide (60'W x 70'L x5'D) has occurred just upstream and below the pump

house that should be stabilized (U).

The following items were rated as minimally acceptable (M):

• Erosion had washed out soil from under a concrete structure behind the pump house

(M). See Plate D-15, Photo DPS 5.

• Corrosion on the trash racks and trash was observed in the sump area (M). See

Plate D-16, Photo DPS 21.

• A bridge abutment bolt was found bent on the levee end of the bridge (M).

• There was erosion (50'W x 80' L x 12'D) on the right discharge channel slope next to

the discharge chute (M). Although needing repair, these are minor structural defects

that do not threaten the structural integrity or stability of the structure, and should not

impact pumping operations.

5.2.4.3 Lake Cliff Pressure Conduit, Station 75+92.

The following items were rated as minimally acceptable (M):

• A 6-inch erosion depression on the slope side of the service bridge abutment was

observed (M).

• Three minor erosion gullies (40’L x 8’W x 8”D) were found on the slope above the

discharge chute on the left side of the wing wall (M).

• Corrosion on flap gate was noted (M).

5.2.4.4 Coombs Creek Pressure Diversion Facilities, Station 93+57.

The following items were rated as unacceptable (U):

• The right wing wall had a 3-inch separated joint exposing the rebar (U). See Plate D-

16, Photo WID 6a.

The following items were rated as minimally acceptable (M):

• One of the bridges had its plate girder up against the abutment and the rocker arm

positioned back further than it should be (M).

• The non-mechanical trash racks at the inlet was bent and had corrosion (M). See

Plate D-17, Photo CCP 21.

FOR OFFICIAL USE ONLY

18

• Exposed steel reinforcement was found in the ceiling, and cracks were observed on

the floor and the wall of the conduit (M).

• A 16-foot long safety handrail on the right discharge wing wall has broken off and was

in the bottom of the discharge channel (M).

• Two erosion gullies (6’L x 1’W x 1’D - each) were found above the discharge chute on

the right slope (M). A slope slide (65’L x 15’W x 1.5’D) on the right slope just past the

right wing wall and deposition in the discharge channel were observed. The outlet

was submerged.

5.2.4.5 Little Coombs Creek Pressure Diversion Facilities, Station 97+29.

The following items were rated as unacceptable (U):

• The steel brace installed to prevent movement of the wing wall had become

disconnected from the right wing wall and had failed (U). See Plate D-17, Photo WID

6b.

The following items were rated as minimally acceptable (M):

• The service bridge abutment had moderate cracking (M).

• The bottom of the conduit had a 6" diameter hole, a scour area, and a failed patch

over a second scour area (M).

• Debris behind the flap gate was preventing it from sealing (M) and corrosion on flap

gate was noted on the flap gate (M).

• Erosion gully was found on the right channel slope (5'W x 12'L x 2'D) of the discharge

channel (M).

5.2.4.6 Pavaho Pump Station, Station 174+60.

The following items were rated as unacceptable (U):

• Erosion (20’L x 20’W x 4’D) had exposed the concrete piers supporting the driveway

on the downstream side of the pump station where the trash container is located (U).

See Plate D-18, Photo PPS 5. This is above the wing wall on the downstream side of

the trash rack and should be repaired as soon as possible.

The following items were rated as minimally acceptable (M):

• The chain link fencing was leaning on the east side of the building (M).

• The left intake wing wall has a 1-inch separation from the intake (M) and there was a

5"W x 8"L tear on the right side rail screen of the trash rack.

• The bottom of the trash rack was silted in at the small inlet for the left structure with

debris that obstructs 10% of the inlet (M).

FOR OFFICIAL USE ONLY

19

• Light debris was found in the sump area (M) and three 36" RCPs

• appeared to be abandoned at the left side of the sump (M).

• The discharge channel had a slope slide on the left bank (35'W x 150'L) and another

slide (12'W x 20'L) on the right lower slope also (M). Although needing repair, the

minor structural defects that do not threaten the structural integrity or stability of the

structure, and should not impact pumping operations.

5.2.4.7 Eagle Ford Sluice West Levee Station 479+72.

The following items were rated as unacceptable (U):

• Trees were growing around the levee toe drainage ditch (U). This vegetation should

be removed. See Plate D-18, Photo WID 1a.

• Sediments had filled in and blocked 60% of the inlet (U). See Plate D-14, Photo WID

1b.

• The sluice had sustained significant structural damage to the walls of the structure

(U). This has supposedly been corrected but should be verified.

The following items were rated as minimally acceptable (M):

• The control building located on the landside of the levee crest had an erosion gully

(6"W x 3'L x 1'D) on the upstream landside corner of the pad that was eroding toward

the building. This erosion had already undermined a corner post of the guardrail (M).

These erosion deficiencies do not appear to threaten the levee integrity but need to

be repaired.

• Debris behind the left flap gate at the outlet is preventing it from closing tightly (M).

5.2.4.8 Abandoned structures.

The following items were rated as unacceptable (U):

• According to PI Report #8 (October 2002), there is an abandoned 48-inch sewer line

that runs under the levee at the downstream end of the west levee, and there might

be another 36-inch interceptor line near Cadiz Street that has been abandoned.

Project personnel should verify that these sewer lines were properly plugged and

notify SWF. Debris had obstructed 50% of the inlet at the Ledbetter Sluice (U). See

Plate D-19, Photo WID 1c.

5.2.5 Flood Damage Reduction Channels.

The following items were rated as unacceptable (U):

• The abandoned old Santa Fe Railroad Bridge catches debris and obstructs flow and

should be removed (U). See Plate D-19, Photo EFD 1.

• Shoaling with established vegetation is causing the diversion of the channel into the

levee along Belleview Pressure Conduit at East Levee Station 59+93 (U). This

condition, if not corrected, may compromise the levee section, access, and integrity.

FOR OFFICIAL USE ONLY

20

The following items were rated as minimally acceptable (M):

• Trees and other vegetative types growing in the flood plain and channel slopes on

both abutments of the Santa Fe Railroad Bridge should be removed (M).

• Debris caught in the Continental Bridge piers was observed (M). The Sylvan Ave

Lake Development Park was seen in the flood plain just downstream of Sylvan Ave

(observation).

• Construction equipment was in the flood plain at East Levee Station 157+50 (or West

Levee Station 141+80) (M).

• A concrete debris pile 10 feet in diameter was found in the channel next to Hampton

Road Bridge at Station 292+91 (M).

• A 700-foot long area of standing water in the flood plain at East Levee Station 380+00

has attracted recreational vehicles (ATVs), leaving rutting (M).

• A 100-foot diameter area of standing water in the flood plain at East Levee Station

568+70 had rutting caused by ATVs (M).

• A sludge lagoon was in the flood plain near East levee Sta. 621+00.

• The right side of river bank at Station 161+00 had failed and fallen into the river

channel (M).

5.2.6 Rochester Levee.

The following items were rated as unacceptable (U):

• Station 51+00 had a sanitary sewer control valve on the levee crest (U) and a sewer

crossing under the levee (U).

• A 24-inch diameter, 12-inch deep moist depression was found on the levee crest near

this crossing (U).

• Large trees were observed within 50 feet of the landside levee toe (U). This

vegetation should be removed.

• The mechanically stabilized earth (MSE) retaining wall on the riverside levee slope

approximately between Stations 114+00 and 120+00 had separation in its concrete

panels of up to 2 inches wide at the corner, indicating lateral movement of the wall

(U). See Plate D-20, Photo RL 5a. Project personnel have reportedly been

monitoring the gap sizes in the wall and have reported no additional movement over

the last 15 years.

• The guardrail on top of the MSE wall was leaning towards the riverside approximately

from Stations 114+00 to 120+00. See Plate D-20, Photo RL 5b.

• Power poles and their anchorages on the levee crest between Stations 121+55 to

130+00 were leaning toward the riverside of the levee (U). See Plate D-21, Photo RL

FOR OFFICIAL USE ONLY

21

3. The power poles encroaching on the levees should be removed off the levee to at

least 50 feet from the toe.

• Three active closures were inspected and no records of trial erections have been

verified (U).

• The first closure inspected was the "Railroad Street Closure" that was tied into berms

on both sides. At the Railroad Street closure, the ladder was bent on one of the

swinging gates and the turnbuckle was jammed between the steel attachments, thus

not being able to create a tight closure for the gate (U). See Plate D-21, Photo RFW

3a.

• The second closure inspected, the "levee closure" structure for the railroad track was

tied into berms on both sides. This closure did not have a concrete sill (U). Closure

structures that are in poor condition or are missing parts may compromise the system

in a flood event.

• The sheet pile floodwall design needs to be reviewed. Seepage along the side of the

sheet pile floodwall is a known weakness on this type of floodwall design. A

geotechnical investigation will be required (U).

• The right side of the intake gravity flow structure had a 2-foot deep gully next to the

wing wall (exposed/washing out bedding) and the left side had a 18’L x 10’W area

depression on the gabion slope next to the wing wall (U). See Plate D-22, Photo RID

15.

The following items were rated as minimally acceptable (M):

• Recent elevation survey records are needed to verify if the current levee elevation is

adequate (M). No cracks were found along the levee during the inspection.

However, seasonal desiccation cracking is common in this area.

• The third closure was the "floodwall stop log closure” structure for the railroad track

tied into a flood wall on one side and a berm on the other. The bottom seals on the

stop logs of this closure are deformed near the ends due to the stop logs being stored

with a section of the bottom seals resting on concrete stands (M). See Plate D-22,

Photo RFW 3b.

• When the seals are replaced, it is recommended that the concrete stands be adapted

to hold the stop logs without the rubber seals resting on the concrete by cutting a

groove in the concrete for the seals. Minor spalls on the corner of this closure

structure were observed. Light vegetation up to 6 feet high was growing against the

west side of the floodwall at several locations (M).

• An area of erosion gullies (60’L x 10’W x 18”D) on the slope was found on the right

side of the pump station inlet at Station 87+00 (M).

• A second area of erosion (6’L x 2'W x 10"D) behind the right wing wall of the intake

was observed also (M).

• Corrosion was noted on the pump station flap gates and walkway platform (M).

FOR OFFICIAL USE ONLY

22

• The intake gravity flow structure at Station 89+00 had a 4-foot long crack over the left

box culvert (M) and had depressions on the gabion slopes on both sides of the intake

caused by erosion of soil under the gabions next to the wing walls.

5.2.7 CWWPT Levee.

The following items were rated as unacceptable (U):

• The levee elevation had been verified and the current levee elevation is adequate.

Encroachments found on the levee included: odor control fan poles on the river side

levee slope of the north and west side of the levee system (U). See Plate D-23,

Photo CWWTP 3a.

• A chain link fence that had a 12-inch concrete strip foundation was running along the

riverside levee crest edge along the north, east, and south side of the levee system

(U). Desiccation cracking was noted along the concrete (observation). See Plate D-

23, Photo CWWTP 3d.

• Electric towers were observed on the landside slope and crest of the north side of the

levee system (U). See Plate D-24, Photo CWWTP 3b.

• An 84-inch emergency outfall control valve on the crest was at the east corner of the

levee system and two control valves were on the crest at the south corner area of the

levee system (U).

• Penetrations crossing through and/or under the levee include: two 60-inch diameter

force main lines (U), 84-inch emergency outfall, 66-inch diameter plant outfall

(emergency use), 10’x10’ main double box culvert outlet, 84” diameter waste water

gravity main line, 60-inch diameter waste water gravity line, and an abandoned

outfall. Numerous utilities crossing under the levee are yet to be identified (U). See

Plate D-24, Photo CWWTP 3e, and Plate D-25, Photo WL 3c.

The following items were rated as minimally acceptable (M):

• Brush was growing between the landside north levee toe and a retention pond (M).

This retention pond may obscure any seepage that develops during a flood event (M).

• Cracks (2”W x 6”D) along the crest in the area of the fence were observed (M).

Seasonal desiccation cracking is common in this area. Records of slides, if any,

should be investigated.

• An odd 24-inch diameter depression was noted 30 feet off the riverside toe of the

north levee.

• Only a few discharges were inspected. Therefore, follow-up inspections are needed

(M).

• Riprap at one discharge had grass growing in it (M), erosion around another

discharge chute was observed (M), and vines in the riprap was found above a

discharge chute (M).

• The bottom of a 24-inch round flap gate was silted in at the sewer plant (M) and a

FOR OFFICIAL USE ONLY

23

second flap gate was noted as being under water.

• Pipe interiors have not been inspected. Additionally, the pump station in the center of

the facility has not been inspected.

5.2.8 Emergency Action Plan (EAP). The CoD stated that they have a general EAP and an

evacuation plan. The SSD has a written system-specific flood response plan and maintains

that it can effectively respond to emergency situations. SSD should provide a copy of the

EAP to SFW (Operations, E&C, and Levee Safety Program Manager) for review. Recent

flood activities in 2007 attest to the quick response generated by the Sponsor to protect

project features.

5.3 DOCUMENTATION OF SIGNIFICANT GEOTECHNICAL FINDINGS.

5.3.1 East and West Embankments.

5.3.1.1 Surface Cracks. None noted during the inspection, but no cracking is

actually unusual for the project. See Part VI of this report for additional discussion.

5.3.1.2 Sliding and Sloughing of Levee Slopes. Four shallow slides that had

occurred during the summer of 2007 had been repaired. See trip report provided as

FOR OFFICIAL USE ONLY

24

Appendix G for details. However, these repairs appeared to be creeping. No other

significant sliding or sloughing of the levee slopes was noted.

PHOTO 1 - 3 December 2007. Slide #286 occurred during the summer of 2007. Although it had

been repaired using plastic clays blended with lime, the repair appeared to be creeping.

5.3.1.3 Vertical and Horizontal Alignment of Crest. Significant vertical or

horizontal misalignment of the crest was not observed. However, a survey of the crest

indicates that the crests of both the East and West levees are low over significant reaches.

See Part VI, Levee Safety Issues and Recommendations for additional discussion.

5.3.1.4 Cracking or Movement at Toe. None noted.

5.3.1.5 Seepage. None noted, but the presence of drainage ditches and sumps

located along most of the dry side levee toe would make it very difficult to observe seepage

under most cases since these features are generally filled with water.

FOR OFFICIAL USE ONLY

25

PHOTO 2 - 3 December 2007, East Levee. View of the East Levee looking upstream. Water in the

sump areas adjacent to the levee, under both normal and flood conditions, would obscure seeps that

could develop in the dry side toe area.

5.3.1.6 Erosion. Erosion was observed at several locations along the Floodway, primarily in

the vicinity of bridges, adjacent to the channel, and in the vicinity of discharges. See Section

5.3.2, Channels (Mainstem Trinity, Inlets and Outlets). Erosion of the levee slopes was

relatively minor. However, a loss of material at the levee toe adjacent to the outlet for the

Old Baker Pump Station is a concern, as was erosion beneath the I-30 and DART Bridges

(see Photos 3 and 5a).

FOR OFFICIAL USE ONLY

26

PHOTO 3 - 3 December 2007, East Levee Toe at Old Baker Outlet. Erosion behind the outlet

headwall for Old Baker has resulted in a slight loss of cross-section adjacent to the wet side levee toe.

PHOTO 4 - 3 December 2007, Hampton Pump

Station, East Levee. An erosion gully resulting from

concentrated flows coming through gaps in the curbing

was noted. Erosion damage was also evident behind

both the upstream and downstream wing walls at Old

Hampton.

FOR OFFICIAL USE ONLY

27

PHOTO 5a - 3 December 2007, I-30 Bridge, East PHOTOS 5b (top) and 5c (bottom) - 3

Levee. Substantial erosion under the I-30 Bridge December 2007, DART Bridge, East

at the dry side levee toe would likely have a Levee. The erosion under the DART Bridge

negative impact on the levee during high water is a serious levee safety concern. Repairs

events since the interior drainage would exceed need to be made as soon as possible.

the capacity of the channel visible near the top of

the photo, resulting in inundation of the levee toe.

Interior drainage capacity behind the East Levee is

less than required to accommodate a 100-year

event.

5.3.1.7 Condition of Access Roads. In general, the condition of the access roads

throughout the project was good (see Photos 6a and 6b). Numerous bridge crossings on the

East and West Levees, however, prevent continuous access and restrict the ability to

maintain and repair the levees in the area of the crossings. In several places, the bridges

are at or below the levee crest. In these areas, access has been routed down the levee

slopes to the wet and/or dry side levee toes.

FOR OFFICIAL USE ONLY

28

PHOTO 6a - 3 December 2007, Access Road at PHOTO 6b - 3 December 2007, Access Road

Levee Crest, East Levee. The access roads at at Wet Side Levee Toe, East Levee. The

the levee crest are graveled to allow access under access road at the toe of the levee had been

most conditions. Note bridge in background that recently graded and was in acceptable

prevents continuous access along the crest. condition. Note rutting near center of photo.

5.3.2 Channels (Mainstem Trinity, Inlets and Outlets).

5.3.2.1 Mainstem Trinity Channel. Inspection of the mainstem river channel

indicates a few areas of instability, with some debris and siltation occurring. The most

serious non-compliance with CESWF vegetation policy is generally located along the

channels, where trees are found in abundance (see Photos 7a and 7b). All vegetation,

except for short grass cover, on the channel side slopes or is within 50’ of the top of the river

bank needs to be removed.

PHOTO 7a - 3 December 2007, Typical PHOTO 7b - 3 December 2007, Channel at

Channel Looking DS from Continental Bridge. Continental Bridge, Looking US. Debris from

The left bank was in generally good condition. flooding in the summer of 2007 was lodged

However, instability is evident on the right bank. against the piers of the bridge, partially blocking

Trees along the channel do not meet vegetation the channel. Similar blockages were noted at

policy and need to be removed. bridges throughout the Floodway.

FOR OFFICIAL USE ONLY

29

5.3.2.2 Pump Station Sump Areas. Silt had been recently removed from behind the

Baker and Hampton Pump Stations.

PHOTO 8a - 3 December 2007, Baker Pump PHOTO 8b - 3 December 2007, Hampton

Stations, East Levee. The sump area behind Pump Stations, East Levee. The sump had

the pump stations had been cleaned of silt and been de-silted in the September-October 2007

debris and was in good condition. time frame and was in good condition.

5.3.2.3 Inlet and Outlet Channels. Inspection of the various inlet and outlet

channels for the project indicates local areas of instability and some siltation are occurring.

PHOTO 9a - 3 December 2007, Baker Pump PHOTO 9b - 3 December 2007, Old Baker

Station, East Levee. The side slopes of the inlet Pump Station Outlet Channel, East Levee.

channel nearest Old Baker are over-steepened. The discharge channel was in minimally

However, no signs of instability were noted. acceptable condition, with some back of bank

erosion observed (see Photo 3 for another view).

FOR OFFICIAL USE ONLY

30

PHOTO 10a - 3 December 2007, New Hampton PHOTO 10b - 3 December 2007, Outlet for

Pump Station Outlet, East Levee. The Belleview Pressure Sewer, East Levee.

discharge channel was in minimally acceptable Erosion at outlet of Belleview Pressure Sewer.

condition, with some back of bank erosion Repairs are necessary to protect the access road

associated with surface drainage into the channel along the wet side the levee toe, visible in the

observed. The slides need to be repaired. lower left foreground.

PHOTO 11a - 3 December 2007, Dallas Branch PHOTO 11b - 4 December 2007, Lake Cliff

Outfall, East Levee. Some siltation of the outfall Outlet, West Levee. The channel for this pump

channel is occurring. De-siltation is required to station is partially silted in. De-siltation is

restore capacity. required to restore capacity.

5.3.3 Encroachments and Penetrations. Hundreds of encroachments and penetrations of

the levee were noted during the inspection. Most of these penetrations are not new and

include electrical transmission towers, wooden power poles, fences, bridges and

miscellaneous structures.

5.3.3.1 Dallas County Jail Expansion, East Levee. Located upstream of the

Commerce Street Bridge, construction of an expansion to the Dallas County Jail was

ongoing. In addition to excavations adjacent to the levee toe, the contractor’s field office and

staging area were located on the crest of the levee and dry side levee slope. A chain link

fence had been installed along the levee crest to secure the staging area (see Photo 12).

FOR OFFICIAL USE ONLY

31

Discussions with the contractor revealed that during excavation of the basement, the

contractor encountered fill consisting of steel, concrete, iron, and paper. Concrete tickets

found in the excavated materials indicate that the waste fill has been in place since at least

1972.

PHOTO 12 - 3 December 2007, Dallas County Jail Expansion, East Levee. This unauthorized

encroachment is located US of the Commerce Street Bridge and includes a basement immediately

adjacent to the dry side levee toe.

This expansion worsens the unauthorized encroachment associated with construction

of the original Dallas County Jail (see Figure 1), and further impedes access for O&M. It

restricts the ability to make repairs due to reduced space at the toe of the levee, and the

basement excavation may contribute to seepage and stability problems.

FOR OFFICIAL USE ONLY

32

Figure 1 - Footprint of the Dallas County Jail Facility with Respect to the East Levee. This

facility presents a significant risk to the levee’s integrity. The large rectangular building south of the

bridge is the state jail facility, another unauthorized encroachment that may also impact the

performance of the levee. (Google Earth Photo)

5.3.3.2 Electricity Transmission Towers. Foundations and anchorages for

transmission towers penetrate the levees throughout the Floodway and are considered to be

unacceptable with respect to levee safety. These encroachments impact access for O&M,

restrict the ability to make repairs due to restricted clearance, and provide pathways for water

that can contribute to seepage and stability problems. Typical transmission tower

penetrations are shown in Photo 13.

FOR OFFICIAL USE ONLY

33

PHOTO 13 - 3 December 2007, Encroachments, East Levee. View of transmission towers at the

dry side toe of the east levee. Foundations for these towers are typically concrete piers, 6’ to 8’ in

diameter.

5.3.3.3 Bridges. Foundations elements for at least 23 bridges penetrate the East

and West Levees (see Figure 2). Many of these bridges pre-date the levee expansion

implemented when the Dallas Floodway became a USACE flood damage reduction project in

the 1950s. One of the bridges, the Houston Street Bridge, was constructed in 1918 and pre-

dates the original levee project constructed by the SSD in the 1920s.

Typical bridge penetrations are shown in Photos 14 through 16. Observations and

findings at bridges that are of particular interest or concern are discussed below.

FOR OFFICIAL USE ONLY

34

Figure 2. At least 23 bridges cross the Dallas Floodway. All of these encroachments have an impact on the East and West levees in the form of

penetrations and /or restrictions to access for operations and maintenance, surveillance, and flood fighting. (Google Earth Photo)

PHOTO 14a - 4 December 2007, I-35 Bridge, PHOTO 14b - 4 December 2007, Continental

West Levee. Bridge, West Levee.

PHOTO 15a - 4 December 2007, Walton PHOTO 15b - 4 December 2007, Walton

Walker Bridge, West Levee. Walker Bridge, West Levee.

PHOTO 16a - 4 December 2007, Sylvan PHOTO 16b - 4 December 2007, Highway 183

Avenue Bridge, East Levee. Bridge, East Levee.

FOR OFFICIAL USE ONLY

36

5.3.3.3.1 DART Bridge. Substantial erosion damage was noted on the levee at the

DART Bridge. The erosion is caused by discharge from downspouts that drain the bridge

deck. The condition of the levee in this area of the project is unacceptable, and it will not

perform as designed at the SPF level. Performance at the 100-year flood level is

questionable due to the impact of the piers on the seepage paths under and through the

levee. It is noted that this encroachment was approved by USACE more than 20 years ago.

PHOTO 17a - 3 December 2007, DART Bridge, PHOTO 17b - 3 December 2007, DART Bridge,

East Levee. This photo illustrates the serious East Levee. Approximately 1,400 feet of levee

erosion that is typical at the pier penetrations has been degraded as a result of the construction

along this section of the levee. of the DART Bridge.

5.3.3.3.2 I-35 Bridge. Adjacent to the dry side levee toe, the concrete slope

protection beneath the bridge has failed due to loss of support. The mechanism for the loss

of material is unknown, but it is possibly related to drainage from the bridge abutment. The

void under the broken slab extends under the adjacent slabs and the east abutment’s pier

cap, exposing piles used to support the abutment (see Photos 18a and 18b). This item

needs to be evaluated to determine its impact on the performance of the Floodway.

Of more critical concern for public safety is the condition of the bridge’s pier caps and

abutment, where large, structurally significant cracks were noted. This is not a SSD issue

per se, but it is noted for record as a serious public safety concern. Mr. Zach Gerich,

CESWF’s structural engineer, notified TxDOT on 7 December 2007 as to the condition of the

bridge seats.

FOR OFFICIAL USE ONLY

37

PHOTO 18a - 3 December 2007, I-35 Bridge, PHOTO 18b - 3 December 2007, I-35 Bridge,

East Levee. The concrete slope paving under East Levee. Piles exposed by the failure of the

this bridge has failed and needs to be replaced. concrete slab indicate significant loss of soil.

5.3.3.3.3 Hampton-Inwood Replacement Bridge. Construction of this bridge was

approved by CESWF in February 2006, prior to issuance of Section 408 policy guidance in

October 2006. This bridge replaces the old Hampton-Inwood Bridge. Pier spacing for the

new bridge is greater than that of the old bridge, resulting in reduced hydraulic conveyance

impacts (see Photo 19). Additionally, the grade of the new bridge is approximately 5 feet

higher than the old bridge, an improvement that allows access for SSD passenger vehicles

(see Photos 20 and 21). Although this bridge is considered to be an improvement to the

Floodway when compared to the structure it replaced, mitigation measures now need to be

incorporated into its design to address impacts of the penetrations on the levee and its

foundation.

PHOTO 19 - 25 July 2008, Hampton Bridge, East Levee. View of new bridge from the East Levee

crest, looking south across the Floodway. Spacing between the pier bents varies from 100’ to 120’.

FOR OFFICIAL USE ONLY

38

Construction of the 6-lane replacement bridge began in late 2006 with demolition of

the easternmost lanes of the old bridge. Pier construction began in May 2007. However,

several months of near record precipitation during the summer of 2007 resulted in substantial

construction delays. CESWF personnel were onsite the entire time that the pier construction

within the levee template was ongoing. On the east levee, Bents 30, 31 and 32 penetrate

the levee cross-section (see Figure 3); while the west levee was penetrated by Bents 4 and 5

(see Figure 4). Each bent consisted of eight 42-inch diameter piers socketed into the

underlying unweathered clay shale. CESWF required that all levee piers be drilled using

slurry to minimize the potential for hole collapse.

Figure 3 - Hampton Bridge, East Levee. Construction drawing showing location of Pier Bents 30,

31 and 32 with respect to the east levee cross-section. Pier Bent 30 is at the wet side levee toe, Bent

31 is through the crest, and Bent 32 is at the dry side toe of the levee.

FOR OFFICIAL USE ONLY

39

Figure 4 - Hampton Bridge, West Levee. Construction drawing showing location of Pier Bents 4

and 5 with respect to the west levee cross-section. Pier Bent 5 is at the wet side levee toe.

PHOTO 20a - 27 June 2008, Hampton Bridge, PHOTO 20b - 27 June 2008, Hampton Bridge,

East Levee. View of new bridge with respect to East Levee. Close-up view of new bridge

levee crest looking downstream (east). The showing that the clearance over the levee is

levee and levee crest are wider in this area due sufficient for passenger vehicles to travel across

to the access road at the dry side levee toe. the crest. Large SSD equipment must still utilize

access along the dry side levee toe (left).

FOR OFFICIAL USE ONLY

40

PHOTO 21a - 3 December 2007, Hampton PHOTO 21b - 3 December 2007, Hampton

Bridge, East Levee. View of new bridge Bridge, East Levee. Close-up view of new

substructure (left) compared to existing bridge bridge (foreground) with respect to the levee

substructure (right)). The bottom chord of the crest. Note the increased clearance compared

new bridge is approximately 5 feet higher than to the old structure (background).

the old bridge.

During the PI, a void was noted at the down gradient limit of the abutment paving on

the East Levee (see Photo 22a). This void was first observed in May 2007 during the

inspection of the construction for the Hampton Bridge replacement. In May 2007, the

maximum depth was greater than 18 inches. However, at the time of the PI, the void was

probed and found to be at least 4 feet deep. The lateral extent of the void was unknown but

it appeared to extend across at least 70% of the width of the slab.

PHOTO 22a - 3 December 2007, Hampton PHOTO 22b - 27 June 2008, Hampton Bridge,

Bridge, East Levee. Concrete paving at the East Levee. Reconstruction of the levee crest

levee crest had been undermined. At the time of was ongoing. The slab in Photo 22a had been

the PI, the depth of the void was more than 48” partially removed and the void backfilled.

deep.

FOR OFFICIAL USE ONLY

41

5.3.3.3.4 Woodall-Rodgers Bridge. Also known as the Margaret Hunt Hill Bridge, this