Professional Documents

Culture Documents

RE24799valvulas Direccionales

Uploaded by

AliramosOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

RE24799valvulas Direccionales

Uploaded by

AliramosCopyright:

Available Formats

REXROTH

Size 62

up to 350 bar

up to 3000 I/min

Issue: 6.81

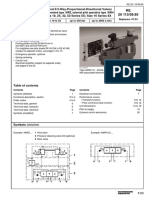

4/3 and 4/2 Directional Control Valves Type WEH 62/WH 62 Series 50

RE 24799

( HYDRONORMA")

- indirect (WEH) and direct operated (WH) directional spool valves

- subplate mounting

- flange connections

- DC or AC oil immersed or air gap solenoids, optional

- with or without hand emergency

- individual or central electrical connection

- spring centering or spring return, or pressure centering or hydraulic return of the main control spool to starting position

- pilot choke adjustment

"~

- stroke limiting and/or end position control of main ~

control spool

- with and without limit switch at solenoid

- 17 standard symbols

Type H4 WEH 62 H .. 50 F/ .. 10 ... S ..

Type H4 WEH 62 .. 50/ .. S ..

Tvpe H4 WH 62 .. 5O/ .. S ..

RE 24799/6.81

REXROTH 1

Description .of Function, Section

Directional Control Valves type WEH

Directional valves type WEH are directional spool valves with a solenoid operated pilot valve. They control starting, stopping and the direction of a flow.

These directional control valves comprise the main valve with housing (1), the control spool (2), one or two return springs .(3), and the pilot valve (4) with one or two solenoids (5).

The control spool (2) of the main valve is held in zero or starting position by means of springs or pressure.

The control spool (2) is operated hydraulically by means of the pilot valve, fitted with DC or AC oil immersed or air gap solenoids (5).

A hand emergency device (8) can be fitted, which allows the control spool to be moved without energising the solenoid.

The fluid can be supplied and drained internally or externally.

Directional Control Valves type WH

The function of this valve is basically identical to that of valve type WEH.

However the control spool (2) is operated directly by means of pressure via the cover plate.

A

R X

Type H-4 WEH 62 .. 50/.. T

BY

p

4/3 Directional Control Valve with Spring Centering of the Main Control Spool

The main control spool (2) is held in zero position by two return springs (3-). Both spring chambers are connected to tank without pressure by means of the pilot valve, (type WEH) or cover plate (Type WH).

With type WEH fluid is supplied to the pilot valve (4), externally via the control line (7). When the pilot valve is actuated, control pressure affects one of the two ends of

the control spool (2) and pushes this into the switching position. This opens the switching position required.

When the solenoid is de-energised, the pilot valve returns to the starting position (with the exception of impulse spool valves). The spring chamber (6) is unloaded to tank.

The control fluid is pushed from the spring chamber into the Y line (external) via the pilot valve.

2AEXAOTH

RE 24 799/6.81

Description .of Function, Section

\l \7 L T

W\l B Y

A p

V A

VA. R X

Type H-4 WEH 62 H .. 50/ ..

4/3 Directional Control Valve with Pressure Centering of the Main Control Spool

Control pressure affects the two ends of the main control spool (2) and holds it in zero position. The spool position is fixed by a centering bush in the housing.

The main spool (2) is moved to switched position by unloading pressure from one spool end.

The unloaded spool surface pushes the control oil into the Y line via the pilot valve (external).

4/2 Directional Control Valve, WEH Four different designs are available.

1. Type 4 WEH .. ./ ...

Pilot valve and main valve each have one return spring to fix the spool end position (guaranteed switching even if power fails).

2. Type 4 WEH .. H . ./ ..

The pilot valve has one return spring, which holds the spool in end position.

The main control spool must be held in end position by pressure.

3. Type 4 WEH .. H . ./O ..

The pilot valve has 2. solenoids. There are no return springs in the pilot valve or in the main valve. The spool positions are fixed by means of solenoid energisation and pressure.

One solenoid must therefore always remain energised.

4_ Type 4 WEH .. H . ./OF ..

The pilot valve has two solenoids, the spool has detents in switching position (impulse spool valve).

The main valve spool has no detents and moves into position when pressurised.

With types 2, 3 and 4 the switching positions are guaranteed only when pilot pressure is available.

Throttle I nsert

It is necessary to use a throttle insert if the pilot supply in the P line of the pilot valve is to be limited.

It is fitted in the P line of the pilot valve.

Pilot choke adjustment

Main valve

Type H-4 WEH 62 .. 50/ ... B ..

~E 24 799/6.81

REXROTH 3

Ordering Code

Hydraulically operated Electro-hydraulically operated

Spool centering by springs (*)

= no desig. =H

I return at main valve)

Symbols with Spool Types Symbols with Spool Types

crossover pos.

(subplate mounting) (flange connections) (flange connections)

WTitni~ ~ IZiHi! 11

=c =c

IOTi//J~ m =0 I~li ii! II =0

~W'\:T\\I m =K l~iHjll =K

~tTim~ m =Z IXiHif II =Z

:~: : = (H)C = (H)C

~ll:I\·I:;3:1~~: l~~ ~ = (H)D I ~ i~ i!~ iii it! II = (H)D

vtT!UnTl:I\\~T\\l ~ = (H)K IZi~!S!~ nil = (H)K

vtr:tT\!bWA: A~ = (H)Z ! i : = (H)Z

~Ii/T~::ir\\:~~ ItJII~r~1 I ~i~ iii iii m II ~Ii il' II

= E =E

~I:!.\l r;JM:I~~ ~llmr~~ =F I ~H!5!'H]! ;1 ZI81111 =F

~LI;~g!t\i~ ~!rI~IJ\~ =G I ZH!g!4i! II zlgl! II =G

~I:~:~:M:I~ ~rl~IJ\~ =H ~!H!EiH!! II ZIGI!ll =H

~l~lAi ~~ :i!~I~1 ~ll~l;i~ =J ~i~!S!i Ii! II ZIEIlll =J

~lIii/!! lZirl~l:ri~ ~III,~IJi~1 =L ~!~!~ii m II ~I~IIII =L

~lIi/l~$~tlr~ W~I'~IIA~ =M ZiZ!B!! ~:! II Ililal!!1 =M

~l~l/ll ~ :/1~ J\~ 1"rltJl J\~ =Q I ZiXiE!i mil 1~lal!11 =Q

~Z;;\\llZ:lT~iI~~ ~I!iZlr~ =R I ~i~~igiii!HI I~I~~IHI =R

IllT1J\~~~1~ ~II~~lrV~ =s I ~!ii!g:HiHI 1~lglHI =s

~l~/Tl~gl//~r\~1 WII~I:r~ =T l~ig!g!gl!11 ~lgl!11 =T

~l~//~~iAI:J\~1 ~IZ~II~ =U I~!iiiiliilil II ~I~ W.I =U

~~/'\!~/'\iJ\~ IlfrIQI~1 =V 1~!Bi8iH!11 ~tal! II =V

~l~b\! M:A~:I~~ ImtJlr~ =W I ~!;liS!i m II ~Iel!il =W Subplate mounting Flange connections

= no desig. =F

Fixing of switching position (pilot valve) for 2 switching positions and 2 solenoids only.

Only the pilot valve has a detent.

In both cases, hydraulic spool return "H" should be stated (possible with WEH only).

spring return

Without spring return with detent

=0 =OF

Ordering example: (*) Spool return by springs Type H-4 WEH 62 C 50/ .

(**) Hydraulic spool return Type H-4 WEH 62 HC 50/ .

• REXRO'IH

RE 24799/6.81

110 1 1 1 1 1 1 1 r I 1*

I Further details to be stated in text

no desig. = HLP mineral oils to DIN 51525

V = phosphate ester

no desig. = without throttle insert

808 = throttle dia. 0.8 mm

810 = throttle dia. 1.0 mm

811 = throttle dia. 1.1 mm

812 = throttle dia. 1.2 mm

815 = throttle dia. 1.5 mm

(possible with WEH only)

Accessory number (see page 18)

I Electrical connection, for type letter, see page 16 + 17) I

I

no desig. = without pilot choke adjustment

S = pilot choke adjustment as meter-in control

S2 = pilot choke adjustment as meter-out control

8

no desig. = without limit switch at solenoid

y = with limit switch at solenoid (possible only with

pilot valve with DC solenoid, type L)

no desig. = without hand emergency

y = with hand emergency

G24 = 24V DC

W220-50 = 220 V AC,

50 Hz

W 110 R = DC solenoids with built-in rectifier

for 110 V AC, independent of frequency

* (possible only with plug "Z5" (e.g ... R .. Z5 .. )

for further voltages and frequencies, see page 10

A= pressure tight solenoid (oil immersed)

L= dry solenoid (air-gap) RE 24799/6.81

AEXAOTH5

Symbols

Detailed and simplified symbols for 3 position valves

Valve type WEH with spring centered zero position

A B

I-·----r+--l

I a.X r a 10 I b -,b.Y I A B

,~ Jil : 1 aai2~ To1~Pb

i .~~ I ,ru;tf.-yJ

YI- ----1-l- - _J

R P X Y T

x = external I Y = external

Valve type WH with spring centered zero position

A B

a.x ........ ~b,Y RPT

Valve type WH with pressure centered zero position

A R

a, y_'~ a I: ~:I b r-t-b. X

L RPT

.....

Valves for subplate mounting have 5 service ports: A, S, P, T, R

Valves for flange connections have 4 service ports: A, S, P, T; port R omitted

~._M_o_de_l_c_od_e_s_p_ri_ng_Ce_n_te_r_ed-+_M_o_d_e_1 c_o_d_e_p_re_ss_u_re_c_e_n_te_re_d-+-_M_o_d_e_1 c_o_d_e_sp_r_i n_g_c_en_t_er_e_d-+-M_o_de_l_c_od_e_' p_r_es_su_r_e_c_en_t_er_e-ld

"': zero position (WEH) zero position (WEH) zero position (WH) zero position (WH)

..

H-4 WEHM: .. E .. ./ .

H-4 WEH62 F ... / .

H-4 WEH62 G . ../. ..

H-4 WEH 62 H .. ./ .

H-4 WEH 62 J .. ./ .

H-4 WEH 62 L.../. ..

H-4 WEH 62 M .. ./ .

H-4 WEH 62 0 .. ./ .

H-4 WEH 62 R .. ./ .

H-4 WEH 62 S .. ./ .

H-4 WEH62 T ... / .

H-4 WEH 62 U .. ./ .

H-4'WEH 62 V .. ./ .

H-4 WEH 62 .. .w ... / .

H-4 WEH 62 HE .. ./ .

H-4 WEH 62 HF .. ./ .

H-4 WEH 62 HG .. ./ .

H-4 WEH 62 HH .. ./ .

H-4 WEH 62 HJ .. ./ .

H-4 WEH 62 H L. . ./ .

H-4 WEH 62 HM .. ./ .

H-4 WEH 62 HO .. ./ .

H-4 WEH 62 H R. . ./ .

H-4 WEH 62 HS .. ./ .

H-4 WEH 62 HT .. ./ .

H4- WEH 62 HU .. ./ .

H-4 WEH 62 HV .. ./ .

H-4 WEH 62 HW .. .I .

Designation Symbol Symbol

letter (subplate mounting) (flange connections

Vlrl//J ~~ Xli iIf II

E

F V!rlblJ T\1J XISI!lI

G VlIMlr'~ X181! II

H VlTltrlJ ;\\I XIRI!II

J VIr I(T\I r\~ IXlEn ~I

L VlTI//f!r';\J IXI~II~I

M VlrlmA~ IXl8lf II H-4 WH 62 E .. .I ...

H-4.WH 62 F . ../. ..

H-4 WH 62 G . ../. ..

H-4 WH 62 H . ../. ..

H-4 WH 62 J . ..!. ..

H-4 WH 62 L. . ./ .

H-4 WH 62 M .. ./ .

H-4 WH 62 0 .. ./ .

H-4 WH 62 R .. ./ .

H-4 WH 62 S ... / .

H-4 WH 62 T .. ./ .

H-4 WH 62 U .. ./ .

H-4 WH 62 V .. ./ .

H-4 WH 62 W .. ./ .

H-4 WH 62 HE .. ./ ...

H-4 WH 62 HF . ..!. ..

H-4 WH 62 HG .. ./ ...

H-4 WH 62 HH . ..!. ..

H-4 WH 62 HJ .. .I .

H-4 WH 62 HL. . ./ .

H-4 WH 62 HM .. ./ .

H-4 WH 62 HO .. ./ .

H-4 WH 62 H R . ..!. ..

H-4 WH 62 HS .. ./ .

H-4 WH 62 HT .. ./ .

H-4 WH62 HU .. ./ .

H-4 WH 62 HV .. ./ .

H-4 WH 62 HW .. ./ .

Designation Symbol Symbol

letter (subplate mounting) (flange connections

1lI,IMI J\'J I X[}flf .1

0 *

R VlrhVTIM IXI~~IRI

S VITIA;I r\lJ IXI21HI

T VITIMIA'J IX~lf.1

U WT~\~T~ IX~ t!tll

V VlTItT\JT\\I Ixsn .1 *

W VfrIMIT~ I>cRlnl * 6REXAOTH

The centre position is throttled to 14% of nominal flow with symbols 0 and V I and to 3% with symbol W.

RE 24 799/6.81

Symbols

Detailed and simplified symbols for 2 position valve (to DI

Type H-4 WEH62 .. .I... Type H-4 WEH 62 H . ../. ..

A B

-b~

-I

I

I

I I

R P--X~ T

'§b

X RPTV

x = external; Y = external

X

RPTV

24300)

Type H-4 WEH 62.H .. .I0 ... A B

~

" I

I

Type H-4 WEH 62.H .. .I0F ...

Valve type WH, spring offset

A B a,x-+$+-b,V RPT

Valve type WH, hydraulic return

A B

a,X __._ $ -+- b,V RPT

Designation letter

Symbol (subplate mounting)

Symbol (flange connections)

C (HC) D (HD) K (HK) Z (HZ)

RE 24 799/6.81

REXROTH 7

Technical Data

hydraulic

Max. operating pressure, P,A,B (bar) 350

Max. tank pressure T (R) (bar) 250

solenoid type A ... 60

Port Y pilot drain

Y = external (WEH) (bar)

solenoid type L ... 150

Min. pilot pressure

pilot supply X = external

12 3 pos. valve, spring centered

(bar) 15

12

3 pos. valve, pressure centered 2 pos. valve, spring offset

12 2 pos. valve, hydraulic return

Max. pilot pressure

(bar) 250

Hydraulic medium

HLP mineral oil to DIN 51 525 phosphate ester

Fluid temperature range (OC)

- 30 ... + 70

Viscosity range (mm2/s)

2,8 ... 380

Control Flow for Switching Sequence

3 pos. valve, spring centered (cm3)

115

2 pos. valve, hydraulic return (cm3)

330

2 pos. valve, spring offset (cm3)

115

3 pos. valve, pressure centered from zero pos. to pos. "a" (solenoid "a" switched)

57,5

from zero pos. to pos. "b" (solenoid "b" switched)

(cm3) 115

from switching pos. "a" to zero position

(cm3) 54,3

from switching pos. "b"

to zero position (cm3) 57,5

* Total Switching Time of Valve from Zero Position to Switching Position (AC current)

At pilot pressure (bar) 50 150

250

100

180

100

"a" I "~btl

90 1 100 (rns)

3 pos. valve, spring centered

150

120

(rnsl

2 pos. valve, hydraulic return

250

210

(rnsl

2 pos. valve, spring offset

150

120

3 pos. valve, "a" I "b" "a" "b"

pressure centered (ms) 120 I 150 100 120

* Total Switching Time of Valve from Switching Position to Zero Position

3 pos. valve, spring centered (rns] 130

2 pos. valve, hydraulic return (rns) 250 210 180

2 pos. valve, spring offset (rns) 150 120 100

3 pos. valve, "a" l "b'l "a" "b" "a" 1 "b"

pressure centered (rns) 120 I 150 100 100 90 I 90

Control flow for shortest switching

time "Ox" O/min) 50

Weight: subplate mounting WH WEH

valve without pilot valve {kg) ca. 107

valve with 1 solenoid (kg) ca. 111,5

valve with 2 solenoids (kg) ca. 110

flange connections

valve without pilot valve (kg) ca. 90

valve with 1 solenoid (kg) ca. 93

valve with 2 solenoids (kg) ca. 94,5 For application to other specifications, please consult us.

* Switching time = contact at pilot valve until control lands in main valve start to open ** With DC current, the switching times from zero position to switching position

are increased by 30 ms.

8REXROTH

RE 24799/6.81

Performance Curves (measured at v = 41 mm2/s and t = 50 oC)

2

Switching position

Symbol P-A P-B A-T B-T PoT B-A

C 1 2 2 2 - -

D 1 2 2 2 - -

K 1 2 2 2 - -

Z 1 2 2 2 - -

E 1 2 2 2 - -

F 1 2 2 2 - -

G+T 3 3 3 3 4 -

H 1 2 2 2 - -

J 1 2 2 2 - -

L 1 2 2 2 - -

M 1 2 2 2 - -

Q 1 2 2 2 - -

R 5 5 5 - - 6

S 5 5 5 - 7 8

U 1 2 2 2 - -

V 1 2 2 2 - -

W 1 2 2 2 - - ~ 10~--~----~~~~--~~~--~

~ 2

-c 8t-----+-----~~iL_f_----t+--_+_:7I'_~

e

~ 6 t-----+-----~~-+_____:7I'_t___7"y..o~__1 (I)

ct 4t-----+---::~F__--~'----""7I"Eoo_""::..--_+_--__1

2~--~~--::~~~----r---~--~

16

14

~

co

.0 12

0- 10

0

~

-c 8

(I)

~

::l 6

II)

II)

(I)

~ 4

c...

2

0 18

16

14

~

co 12

.0

~ 10

~

-c 8

(I)

~

::l 6

II)

II)

(I)

~ 4

c,

2

0 18

16

~ 14

co

.0 12

~ 10

~

-c 8

(I)

~

::l 6

II)

II)

(I)

~ 4

c...

2

0

18

16

14

~

co 12

.0 Valves for subplate mounting 18

6

4

3

5

6 4

Switching position

Symbol P-A P-B A-T B-T poT B-A

C 1 1 2 3 - -

D 1 1 2 3 - -

K 1 1 2 3 - -

Z 1 1 2 3 - -

E 1 1 2 3 - -

F 1 1 2 3 - -

G+T 4 4 4 5 5 -

H 1 1 2 3 - -

J 1 1 2 3 - -

L 1 1 2 3 - -

M 1 1 2 3 - -

Q 1 1 2 3 - -

R 6 6 6 - - 7

S 6 6 6 - 8 9

U 1 1 2 3 - -

V 1 1 2 3 - -

W 1 1 2 3 - - II V'

I

/ / /

I / /

/ ./ ./

V/ // V

/ VL rL"':

// ~

~ ~

~ .,... 500 1000 1500 2000 2500 3000

Flow (I/min)

7 8

/ /

I V

II

I /

/ V ,/

// V ......

/ V V" .... V

_// " V,......... V

~ """ -- ..... :..-- 500 1000 1500 2000 2500 3000

Flow (I/min)

Valves for flange connections

7 5

/ I

j_ 1

I / ./

/ J /'

/ L / L

/ /.., /_/

/ ./ ~ ..... /'

/" ~ /'

.,..". ~ ~ 500 1000 1500 2000 2500 3000

Flow (I/min)

8 9

o 500 1000 1500 2000 2500 3000

Flow (I/min)

RE 24 799/6_81

REXROTH 9

Performance Limitations

Because of silting, the switching function of the valves is tion with 2 flow directions (e.g. from P to A and simul-

dependent on the filtration. In order to obtain the maxi- taneously return flow from B to T). (See table). If only

mum flow values shown, a full flow filtration of 25 mic- one direction of flow is required, as for example when a

ron is recommended. The forces acting within the valves 4 way valve with port A or B plugged is used as a 3 way

also influence the flow performance. On the 4 way valves, valve, then in critical cases the maximum flow can be

the flow data shown therefore apply for normal applica- considerably lower.

The performance limitation was measured with solenoids at operating temperature and 10% low tension voltage

NB: 3 position valve, spring centered I

At minimum control pressure of 15 bar, the performance Flow (I/min) at pressure (bar) or

limit for all spool types of the 4/3 way valve with hy- for symbols 70 140 210 280 350

draulic centering of the main valve is as shown in the

column marked (*) in the table opposite. Higher pilot (*) E,J,L,M,Q,R, 3000 2600 2130 1850 1650

pressure is necessary for applications in excess of the

performance limit stated. U,V,W

When operating pressure p = 350 bar and F,G,H,S,T 3000 2200 1800 1570 1370 Ii

flow Q = 3000 I/min, control pressure of 25 bar is there- 2) 2 position valve, spring offset

fore required.

The maximum flow for these valves is therefore depen- 2 position valve, hydro return

dent only on the.6.p value for the unit. C,D,K,Z 3000 2600 2130 1850 1650

1) The flow rates specified can be reached if there is a HC,HD,HK,HZ 3000 3000 3000 3000 3000

minimum pilot pressure of 11 bar. 2 position valve,spring offset

2) The flow rates specified are maximum rates, which 1 ) Flow (I/min)

can be controlled by release of the operating pressure for symbols 70 I 140 I 210 I 280 I 350

from the return spring. C,D,K,Z 3000 3000 3000 3000 3000

~ Pilot Valve (WEH only)

A 4 way directional control valve size 10 (connection For the various models of the main valve, the following

dimensions to DIN 24340) is used as a pilot valve. models and spool types of the pilot valve are used.

The valve spool is held in zero position by springs, and

in switching position by solenoid force or detent.

Operation of the control spool is by means of oil immer-

sed or air gap DC or AC solenoids. Main valve Pilot Valve

Hand emergency allows operation of the spool without 3 position valve, 3 position valve,

solenoid energisation. spring centered spring centered

The air gap solenoid is of simple design and is fu lIy spool type J = IZIEIf II

encapsulated and tropicalised.

The oil immersed solenoid has a long working life, and 3 position valve 3 position valve,

is fully encapsulated and tropicalised. The armature pressure centered spring centered

runs in oil, thus giving low wear, good heat dissipation 1~181nl

and cushioned stop. spool type M =

The AC solenoid has short switching times. Simple ope- 2 position valve 2 position valve,

ration and no special contact protection are its main

features. spring offset

The DC solenoid is extremely reliable, gives smooth ope- Spool types: without spring return

ration and is suitable for high switching frequencies. It is C,D,K, and Z with detent

not affected by voltage fluctuations in either direction. HC,HD,HK and HZ

spool type 0 = rm

Electrical Data

Voltages DC AC

Solenoid type Dry Wet Dry Wet

Data sheet RD 23330 RD 23310 RD 23332 RD 23312

Voltages available (V) 12,24,42,60,96,110,180, 42,110,127, 220 with 50 Hz

195,220 110, 120, 220 with 60 Hz

Power requirement (W) 43 35 - -

Holding current (VA) - - 64 130

I n-rush current (VA) - - 430 530

Duty cycle DB

Ambient temperature (OC) ... + 50

Max. coil temperature (OC) ... + 150

Insulation to DIN 40050 IP 65

For applications to other specifications, please consult us. 1OAEXAOTH

RE 24 799/6.81

Sandwich plate for pilot choke adjustment type Z 2 FS 10

Pilot Choke Adjustment

The pilot choke adjustment, designed as a sandwich plate, can be fitted between the pilot valve and the main valve. This a double throttle check valve (1). .

The pilot supply or drain is throttled, depending on the mounting position of the pilot choke adjustment.

Clockwise rotation of the adjustment screw increases the switching time of the valve, anti-clockwise rotation decreases the switching time.

Type H-4 WH 62 .. 501 ... S .or S2

Conversion from Meter-In to Meter-Out Control

Remove pilot valve, the plate for the seal rings remains; then turn the pilot choke adjustment round the horizontal axis and replace; replace pilot valve.

Type H-4 WEH 62 ... 501 .. S or S2

1 Sandwich plate for pilot choke adjustment type Z 2 FS 10

8 Meter-out control

5 Adjustment screw AIF 8

9 Meter-in control

2 Main valve

6 S.H.C.S. M6 x 85 DIN 912-10.9

7 S.H.C.S. M6 x 60 DIN 912-10.9

10 Cover

3 Pilot valve

4 Plate for seal rings

Connection Flange (for valve with flange connections only)

(dimensions in rnm)

· .

· .

· .

· .

........

........ ........ :.: · . .. ..

· . . . . · . .. :.:.

~lJm

seal ring

Fixing screws

Seal ring

Part no. seal material

Perbunan Viton

Pressure Size

rating DA DS DI

160 bar 62 76,1 66 63,5

320 bar 62 76,1 58 56,1

RE 24 799/6.81 303943

303903 59,7 x 5,33 f------+------i 303923

4 off S.H.C.S. M20 x 100 DIN 912-8.8

tightening torque 410 Nm

303963

REXROTH 11

Unit Dimensions: Valve Type WEH for Subplate Mounting

(dimensions in mm)

~--------------------------245--------~----------------~

~---------------------204----------------~

370

1 3 position valve with pressure 4 DC or AC oil immersed solenoid 13 Nameplate for pilot valve

centered zero position 5 DC air gap solenoid 14 7 valve fixing screws

2 3 position valve with spring 6 AC air gap solenoid M24 x 110 (for steel)

centered zero position 7 DC air gap solenoid with M24 x 120 (for cast iron)

2 position valve with built-in limit switch DIN 912-10.9

hydro return 8 Hand emergency tightening torque: 981 Nm

2 position valve, 9 Valve with 2 switching 15 Position of pilot

spring offset positions and 1 solenoid valve ports

3 Valve with 2 switching 10 Main valve 16 Nameplate for

positions and 2 solenoids 11 Plate for o-rings complete valve

Valve with 3 switching 12 Pilot choke adjustment

positions and 2 solenoids 12AEXAOTH

RE 24799/6.81

Unit Dimensions: Valve Type WH, Subplate Mounting

(dimensions in mrn)

1 3 position valve with pressure 10 Main valve

centered zero position 11 Plate for o-rings

2 3 position valve with spring

centered zero position 12 Pilot choke adjustment

2 position valve with

hydraulic return 13 Nameplate

2 pos. valve spring offset 14 7 valve fixing screws M24 x 110 (for steel) M24 x 120 (for cast iron) DIN 912-10.9

tightening torque: 981 Nm

15 Position of pilot choke adjustment ports

Main Valve Porting Pattern (Subplate Mounting)

(dimensions in mm)

17 Main valve porting pattern

18 Machined valve mounting surface

19 Leakage port L on valves with pressure centered zero position only

Required surface quality of the mating piece when fitting valve without subplate

O.01/100mm

RE24 799/6.81

REXROTH 13

Unit Dimensions: Valve Type WEH for Flange Connections

(dimensions in rnm)

~-------------------------245--------------------------~

~-------------------204-----------------'~

9

~---------------------355----------------------~ ~---------292-----------.~

1 3 position valve with pressure centered zero position

2 3 position valve with spring centered zero position

2 position valve,

hydraulic return

2 position valve,

spring offset

3 Valve with 2 switching positions and 2 solenoids Valve with 3 switching positions and 2 solenoids

4 DC or AC oil

immersed solenoid

5 DC air gap solenoid 6 AC air gap solenoid 7 DC air gap solenoid

with built-in limit switch

8 Hand emergency

9 Valve with 2 switching positions and 1 solenoid

10 Main valve

11 Plate for o-rings

12 Pilot choke adjustment 13 Nameplate for pilot valve 14 Valve fixing screws

M16 x 90 DIN 912-10.9 for steel M16 x 100 DIN 912-10.9 for cast iron tightening torque: 319 Nm

15 Position of pilot valve ports 16 Nameplate for complete valve

14REXROTH

RE 24799/6.81

Unit Dimensions: Valve Type WH for Flange Connections

(dimensions in rnm)

~---------------562--------------------~

~-------------- -+ 590 ~

\ cb

1 3 position valve with pressure centered zero position

13 Nameplate

14 Valve fixing screws

M16 x 90 DIN 912-10.9 for steel M16 x 100 DIN 912-10.9 for cast iron tightening torque: 319 Nm

2 3 position valve with spring centered zero position

2 position valve with hydraulic return

2 position valve:

spring offset

15 Position of pilot choke adjustment ports

10 Main valve

20 Model for pressure centered zero position Cover with line ports X and Y

11 Plate for o-rings

12 Pilot choke adjustment

21 Port Y

oil drain on H-4 WH 62 H .. ; port X closed

RE 24799/6.81

Electrical. Connection as Central Connection

no desig. Central connection on tank port side of valve

Cable connection PG 16

,.,Ir -~~ - "'" (~t-- - ~-~ t- -lit-T

-ltL - -LL _ _jj- - _jJ1-

Z

Central connection on tank port side of valve with plug-in connector

can be turned 300 about the plug axis

-liti0 16r-c _J

f/;3:~ . g

~{U)11i ~1 ~

L'_f~ t

OZ

Central connection on cover with plug-in connector 16.50 I

OK

ZL KL

Central connection on tank port side of valve with plug-in connector, cover with control lights

Socket only -: 50

\1/ \11

o

Central connection on cover

OL Central connection and control lights on cover

K

Socket only

OKL

L

Cover with control lights

Central connection on tank port side of valve

Electrical Connection as Individual Connection

Z2 *

Single connection

blQ. 79 ~ 9 r . with terminal box

!~~+_~I PG11

C; Lf) r s: i iA-~-· d).

-. CD ----l!1--- - ' L- -ll!-

l l_I;; . . I ;;1.)

, '"lL. - --U _ _jj- - __jJ"

Z4 Colour of plug grey Colour of plug black

!,;ft,+~.

-- (.. ~. ~~ ... )

- '" ---41--- - ._' ~ i- -1Jt--

I I lJI; ';11_)

, , '"lL~---U_jj- -__jJ'"

PG 11

Single connection with plug-in connector to

DIN 43 650

~,r~-l

--II - '1> - Ilt- N

a (.. ~. -0(7/ R . . ) ~

~ - -<jl-. -- -- . -t 1--- --1Jt- i.

, l.ll; ',II.)

-u__ --U _ u--- -__jJ" t

PG 11

OZL Central connection on cover with plug-in connector

--16r 48 plug-in connector, cover with control lights

I

PG 11 I

r i Socket

I en with light

(--11- ~~- i -Ilt- M _,

I ~-;-

a a

~ T4!--- -' t ~ ,~ [

t -ltL---U _ t _Jil) , , 0~t~

~li1. <~!' ttA<B.fi

1 _ -u_ - --iJ _ ___jJ- - ...lr

Z1L *

Single connection with terminal box, plug-in connector and light

* Available only with pilot valves with air gap solenoids

RE 24799/6.81

AEXROTH18

Electrical Connections (Solenoid with built-in limit switch)

no desig. Central connection of solenoid with cable connector on tank port side of valve

Limit switch connection on solenoid

K Socket only

Connection side

optional PG 11

L Cap with terminal box can be rotated 900

D Central connection on cover Cable connection PG 16

Limit switch connection on solenoid

D K Socket only

L

Cover with control lights, Cable connection PG 16

Limit switch connection on solenoid

Connection on tank port side

Z

Central connection on tank port side with plug-in connector

Limit switch connection on solenoid

PG 11

Connection side optional

Can be turned 300 on plug axis

L K Socket only

ZL

Central connection on tank port side with plug-in connector

Cover with control lights

Limit switch connection on solenoid

Can be turned 300 on plug axis

D L Central connection on cover, Cover with control lights, Cable connection PG 16

Limit switch connection on solenoid

DKLSocket connection only

384 -----~

Terminallay-out with limit switch

Terminallay-out with central connection

with 2 solenoids:

solenoid a at terminals 1 and 2 solenoid b at terminals 3 and 4 protective conductor at terminal SL

with 1 solenoid:

solenoid always at terminals 1 and 2 protective conductor at terminal SL

With plug connection, the socket can be turned 300 by means of a ring gear

In order to increase the service life of

the control lights to 60V, we recommend protective wiring for the solenoid.

3~

s~

contact loading 250 V -5Amp. 30 V -2 Amp.

RE 24 799/6.81

REXROTH 17

Stroke Limiter, mounting possibilities

Adjustment range: 25 mm, 1 turn = 1.5 mm adjustment stroke

Spool Position Indicator, mounting possibilities

The stroke limiter limits the stroke of the main spool (1). By loosening the lock nut (2) and clockwise rotation of the adjustment spindle (3) the spool stroke

is decreased.

The control chamber (4) must not be under pressure.

By loosening the fixing screws (3) the sleeve (1) with visual indicator can be adjusted through 3600• The control chamber must not

be under pressure.

~r----------------------766-------------- __ ~

Note.: With pressure centering only combination 11 or 14 is possible

~ __ -172

~

;---!:::::=:::..____,_..,

3 pos. valve, spring centered 3 pos. valve, pressure centered (11 only possible) 2 pos. valve, hydro return

--_'~------.--~---.-----.--~--

stroke limiter on A and B sides of main valve

= additional feature 10

stroke limiter on A side = 11

stroke limiter on B side = 12

~~--------------706---------------- __ ~

353~_

,.~~.~

3 pos, valve, spring centered 3 pOS. valve, pressure centered

. (14 only possible) 2 pOS. valve, hydro return

spool position indicator on A and B side

= additional feature 13

spool position indicator onAside= 14

spool position indicator on B side = 15

~~--------------664

383 ~_~

_ ___L_rm:n

c-, '-'~

I I \ / _

~ i _. _ ~

2 position valve, spring offset I

(spool types C-D-K-Z)

. .

stroke limiter on B side of main valve = addition feature 12

stroke limiter on B side of main valve and spool position indicator on A side

additional feature 17

G. L Rexroth GmbH JahnstraBe 3-5

0-8770 Lohr am Main Telefon: 09352/181 Telex: 0689418

G_LRexroth Ltd. Cromwell Road St. Neots/Hunt. Cambs.PE192ES Tel. 0480/7 60 41 Tlx.32161

_1------ 634

A

A

r-f----- 281----_~

I ..._

REXROTH - HYDRAULICS WORLDWIDE ~

~--------------------------------------------------------------------------------------------~~

18AEXAOTH

rr

______ UL~ .+-~=== "

A B

2 position valve, spring offset (spool types C-D-K-Z)

spool position indicator on B side of main valve = additional feature 15

A B

I \ I \

.... . L-.

! 3 pos. valves, spring centered 2 pos. valve

stroke limiter on A side of main valve and spool position indicator on B side

additional feature 16

Replaces: RE 24798

All rights reserved - Subject to revision

RE 24799/6.81

You might also like

- Fiesta ElectricaDocument30 pagesFiesta ElectricaCristi Gogu83% (6)

- Manual: Original InstructionsDocument71 pagesManual: Original InstructionsMelanie GerdesNo ratings yet

- Service Training 2005Document76 pagesService Training 2005Heidi Cuevas Venegas100% (1)

- Re24751 2008-08 PDFDocument40 pagesRe24751 2008-08 PDFakv_bhelNo ratings yet

- Re29061 4WREEDocument18 pagesRe29061 4WREEManuel VizcarraNo ratings yet

- Re 22049Document16 pagesRe 22049ShortcutterNo ratings yet

- SD 16 eDocument20 pagesSD 16 eseaqu3stNo ratings yet

- WK 420 970 Directional Spool Valve Electrically Operated Type WE6 Series 32Document22 pagesWK 420 970 Directional Spool Valve Electrically Operated Type WE6 Series 32Рома БлошенкоNo ratings yet

- WK 420 970 Directional Spool Valve Electrically Operated Type WE6 Series 32Document26 pagesWK 420 970 Directional Spool Valve Electrically Operated Type WE6 Series 32Teddy MatthewNo ratings yet

- Proportional Electro-Hydraulic ControlsDocument31 pagesProportional Electro-Hydraulic ControlshassanHyro43100% (3)

- Hydraulics: Vincke Industrial Hydraulic ValvesDocument7 pagesHydraulics: Vincke Industrial Hydraulic Valvesshahriar kazemiNo ratings yet

- WK 499 482 Directional Spool Valve Type WEH16 Electro-Hydraulically OperatedDocument24 pagesWK 499 482 Directional Spool Valve Type WEH16 Electro-Hydraulically OperatedРома БлошенкоNo ratings yet

- Proportional Pressure Relief Valve R4V DENISONDocument15 pagesProportional Pressure Relief Valve R4V DENISONBerenice Bautista BelmontesNo ratings yet

- SD 11 eDocument12 pagesSD 11 eseaqu3stNo ratings yet

- 4/2-And 4/3 - Proportional Directional Valves Direct Operated, Type 4WRA, Series 1XDocument8 pages4/2-And 4/3 - Proportional Directional Valves Direct Operated, Type 4WRA, Series 1XlizbethdiosesNo ratings yet

- S3-Ml2400-A - R4VDocument8 pagesS3-Ml2400-A - R4VmecambNo ratings yet

- Pneumatic ComponentsDocument2 pagesPneumatic ComponentsDonny ClintonNo ratings yet

- 4WRZEDocument28 pages4WRZEAugusto RezendeNo ratings yet

- PR LC Lfa e PDFDocument68 pagesPR LC Lfa e PDFmanjappahNo ratings yet

- 2/2-, 3/2-And 4/2-Way Directional Poppet Valves, Solenoid OperatedDocument16 pages2/2-, 3/2-And 4/2-Way Directional Poppet Valves, Solenoid OperatedOgulcan CafNo ratings yet

- 4wre 6-10 Sew1xDocument12 pages4wre 6-10 Sew1x2267airportNo ratings yet

- Eo ValvesDocument58 pagesEo Valvesfahazumee100% (1)

- Hawe Prop Dir Spool Valve PSL, PSM, PSVDocument32 pagesHawe Prop Dir Spool Valve PSL, PSM, PSVCosma Petru-RaulNo ratings yet

- Rexroth电磁阀手册Document12 pagesRexroth电磁阀手册davidwang85120% (1)

- E Series Proportional Pressure Controls: Pilot Relief / Relief / Reducing and RelievingDocument30 pagesE Series Proportional Pressure Controls: Pilot Relief / Relief / Reducing and RelievinghaggNo ratings yet

- REXROTH 4wrz 16 5x-6x Series PDFDocument20 pagesREXROTH 4wrz 16 5x-6x Series PDFمحمدلمينابراهيمالموريتاني100% (1)

- Atos Valv - Dhi 010Document4 pagesAtos Valv - Dhi 010CristianNo ratings yet

- Ra 22058 PDFDocument12 pagesRa 22058 PDFmanjappahNo ratings yet

- Manual: Original InstructionsDocument70 pagesManual: Original InstructionsMelanie GerdesNo ratings yet

- Rexroth 4WE6D6X-G24 Directional ValveDocument12 pagesRexroth 4WE6D6X-G24 Directional ValveCosma Petru-RaulNo ratings yet

- 977205PDocument49 pages977205PChu QuynhNo ratings yet

- Explosion-Proof Hydraulic Valves, Type WE... VE1... : RE 23178-VE1-B0/03.15 Material Number: R901413483Document40 pagesExplosion-Proof Hydraulic Valves, Type WE... VE1... : RE 23178-VE1-B0/03.15 Material Number: R901413483pedro 1No ratings yet

- Weh Series Solenoid Pilot Operated Directional Valves: Technical DataDocument7 pagesWeh Series Solenoid Pilot Operated Directional Valves: Technical DataZoran JankovNo ratings yet

- Ra 23351Document10 pagesRa 23351GuilhermeGFCNo ratings yet

- Válvula Direcional RexRothDocument22 pagesVálvula Direcional RexRothrfcardNo ratings yet

- Re64354 2003-06Document20 pagesRe64354 2003-06thierrylindoNo ratings yet

- 4/3 and 4/2 Directional Control Valves With Hand Lever Type WMMDocument8 pages4/3 and 4/2 Directional Control Valves With Hand Lever Type WMMAhmed Abd ElhakeemNo ratings yet

- BrandDocument66 pagesBrandCentral HydraulicsNo ratings yet

- SD 5 eDocument12 pagesSD 5 eseaqu3stNo ratings yet

- A4 A6 (4weh 4WH)Document3 pagesA4 A6 (4weh 4WH)Richard PalmaNo ratings yet

- Operator'S Manual Exxxxx-Xxx-X: E Series ValvesDocument24 pagesOperator'S Manual Exxxxx-Xxx-X: E Series ValvesMauricio GarciaNo ratings yet

- Manual Posicionador Power GenexDocument2 pagesManual Posicionador Power Genexrexxxx987No ratings yet

- Ervice AND Arts AnualDocument78 pagesErvice AND Arts AnualMelanie GerdesNo ratings yet

- L2 Series NumaticsDocument15 pagesL2 Series NumaticsElmer HuashuayoNo ratings yet

- D1VW UkDocument8 pagesD1VW UksureshllsNo ratings yet

- Bomba Paul 50 NGDocument4 pagesBomba Paul 50 NGLucía Salazar de TeránNo ratings yet

- Series 4 - CAMOZZI General Valves and Solenoid Valves 1Document15 pagesSeries 4 - CAMOZZI General Valves and Solenoid Valves 1ShahNo ratings yet

- Valvaluas Neumaticas PDFDocument15 pagesValvaluas Neumaticas PDFWalter LrNo ratings yet

- Valvula Placa RexrothDocument36 pagesValvula Placa RexrothRafael Koppe100% (1)

- Atos HidraulicaDocument8 pagesAtos HidraulicaFabinhoTowerNo ratings yet

- Re 28163Document12 pagesRe 28163ShortcutterNo ratings yet

- NIMCO CV3000sDocument16 pagesNIMCO CV3000sBruno SamaeianNo ratings yet

- Valvula de Asiento - Dloh E041Document4 pagesValvula de Asiento - Dloh E041DANIZACHNo ratings yet

- Servo Bending TPM Ra - 29646Document10 pagesServo Bending TPM Ra - 29646Fajar Wahyu Nugroho JapraksNo ratings yet

- Ervice AND Arts AnualDocument72 pagesErvice AND Arts AnualMelanie GerdesNo ratings yet

- SD 6 eDocument16 pagesSD 6 eseaqu3stNo ratings yet

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGFrom EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNo ratings yet