Professional Documents

Culture Documents

Steel Making & Blast Furnace

Steel Making & Blast Furnace

Uploaded by

riyamondal0 ratings0% found this document useful (0 votes)

52 views18 pagesCopyright

© Attribution Non-Commercial (BY-NC)

Available Formats

PPT, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

52 views18 pagesSteel Making & Blast Furnace

Steel Making & Blast Furnace

Uploaded by

riyamondalCopyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

You are on page 1of 18

STEEL MANUFACTURING

What is Steel ?

In the beginning, there was iron...

Then came cast iron...

...and finally steel

General Issues about Steel

• Steel has been called the world’s most

useful and inexpensive metal.

• In recent decades, steel manufacturers

have been forced to take a much closer

look at what their processes have been

doing to the fragile environment around

them.

What is Steel used for - I

The structure of the Pyramid of the

Louvre, canned food, oil platforms,

catalytic converters, paper clips, mounts

for electronic chips...are all made of steel.

1. In the construction of bridges 2. In the automobile sector...

or buildings...

What is Steel used for-II

3. For everyday uses: 4. At the heart of food

cans,pots,containers,etc... preservation...

5. In communications... 6. In energy... 7. In health...

Steel products

Semi-finished products(continuous cast steel)

Finished products (rolled steel)

How is Steel made-I

How is Steel made-II

How is Steel made-III

Steel Making Plant

Electric Arc Furnace Ladle Furnace Continuous Casting Machine

What is a Blast Furnace?

•The purpose of a blast

furnace is to reduce and

convert iron oxides into

liquid iron called "hot

metal".

•The blast furnace is a huge,

steel stack lined with

refractory brick.

•Iron ore, coke and limestone

are put into the top, and

preheated air is blown into

the bottom.

Why does Iron have to be extracted in a Blast

Furnace???

•Iron can be extracted by the blast furnace because it

can be displaced by carbon.

•This is more efficient method than electrolysis because

it is more cost effective

The Method

Three substances are needed to enable to extraction of iron from its

ore. The combined mixture is called the charge:

Iron ore, haematite - often contains sand with iron oxide, Fe2O3.

Limestone (calcium carbonate).

Coke - mainly carbon

The charge is placed a giant chimney called a blast furnace. The

blast furnace is around 30 metres high and lined with fireproof

bricks. Hot air is blasted through the bottom.

Several reactions take place before the iron is

finally produced...

•Oxygen in the air reacts with coke to give carbon

dioxide:

C(s) + O 2(g) CO2(g)

•The limestone breaks down to form carbon

dioxide:

CaCO3(s) CO2 (g) + CaO(s)

•Carbon dioxide produced in 1 + 2 react with more

coke to produce carbon monoxide:

CO2(g) + C(s) 2CO(g)

•The carbon monoxide reduces the iron in the ore to

give molten iron:

3CO(g) + Fe2O3(s) 2Fe(l) + 3CO2(g)

•The limestone from 2, reacts with the sand to form slag

(calcium silicate):

CaO(s) + SiO(s) CaSiO3(l)

•Both the slag and iron are drained from the bottom of the

furnace.

•The slag is mainly used to build roads.

•The iron whilst molten is poured into moulds and left to

solidify - this is called cast iron and is used to make railings

and storage tanks.

•The rest of the iron is used to make steel.

You might also like

- The Complete Technology Book On Hot Rolling of SteelDocument13 pagesThe Complete Technology Book On Hot Rolling of SteelGurminder Singh Dhir25% (4)

- Sinter PlantDocument14 pagesSinter PlantKannan ThangarajuNo ratings yet

- Mme405 PDFDocument129 pagesMme405 PDFkanakatharavijayanNo ratings yet

- Iron Ore Pellet Is at IonDocument19 pagesIron Ore Pellet Is at Ionvivekojha14645100% (1)

- Alloys and Types of SteelDocument16 pagesAlloys and Types of SteelRajatNo ratings yet

- Steel Rerolling Mill - TMT BarDocument6 pagesSteel Rerolling Mill - TMT BarNitin Das100% (1)

- Fundamentals of Metallurgical Processes: International Series on Materials Science and TechnologyFrom EverandFundamentals of Metallurgical Processes: International Series on Materials Science and TechnologyRating: 5 out of 5 stars5/5 (1)

- Swe100 120 140Document301 pagesSwe100 120 140Adam Lee100% (4)

- Experiment 4, 5, 6 (Single, Series and Parallel Centrifugal Pumps)Document11 pagesExperiment 4, 5, 6 (Single, Series and Parallel Centrifugal Pumps)Safi Ullah WarraichNo ratings yet

- d8r Hydraulic SystemDocument2 pagesd8r Hydraulic Systemwtn201392% (12)

- Steel Making & Blast FurnaceDocument18 pagesSteel Making & Blast FurnaceHarish LakshminarayananNo ratings yet

- Sinter Making0260307Document47 pagesSinter Making0260307honeygupta12150% (2)

- Sintering Plant at A GlanceDocument72 pagesSintering Plant at A GlanceShailesh Kumar100% (1)

- Iron Ore Pellets and Pelletizing ProcessesDocument5 pagesIron Ore Pellets and Pelletizing ProcessesNirad SinhaNo ratings yet

- Blast Furnace Iron Making, IIT, KGP, Oct 26, 2010Document85 pagesBlast Furnace Iron Making, IIT, KGP, Oct 26, 2010Vikas Solanki100% (1)

- Iron OreDocument15 pagesIron Orevinkumar_hbtiNo ratings yet

- Tramp Elements and Billet CarckingDocument7 pagesTramp Elements and Billet CarckingOmar TahaNo ratings yet

- NPTELDocument587 pagesNPTELSk BeheraNo ratings yet

- Iron Ore Pellet PlantDocument15 pagesIron Ore Pellet PlantvuonghnNo ratings yet

- Operation Manual FurnaceDocument21 pagesOperation Manual FurnaceAshutosh SinghNo ratings yet

- Iron Ore ProcessDocument52 pagesIron Ore Processjafary448067% (3)

- Copper MetallurgyDocument47 pagesCopper MetallurgyHolgerBrand100% (1)

- Operation Study and Analysis of Steel Rolling MillDocument31 pagesOperation Study and Analysis of Steel Rolling MillBharatSubramony100% (1)

- Iron Ore Pelletizing: Metso Grate-Kiln SystemsDocument2 pagesIron Ore Pelletizing: Metso Grate-Kiln Systemsmbamarketing54No ratings yet

- Ironmaking and SteelmakingDocument436 pagesIronmaking and SteelmakingSandip KumarNo ratings yet

- On Steel MakingDocument58 pagesOn Steel Makingallan arthur bare100% (2)

- Detail Study On TMT Bar Manufaturing Industry in NepalDocument93 pagesDetail Study On TMT Bar Manufaturing Industry in NepalNishan GajurelNo ratings yet

- 1 Introduction of The Blast Furnace ProcessDocument9 pages1 Introduction of The Blast Furnace Processhemant patilNo ratings yet

- Iron OreDocument39 pagesIron OreAjay ChauhanNo ratings yet

- Mittal SteelDocument25 pagesMittal SteelApra BishtNo ratings yet

- Advances in SteelmakingDocument189 pagesAdvances in SteelmakingAnjaniAkula100% (1)

- Oxidation of Iron?Ore PelletsDocument4 pagesOxidation of Iron?Ore PelletsKrol PrietoNo ratings yet

- Low Sulphur and Low Si in Hot Metal PDFDocument13 pagesLow Sulphur and Low Si in Hot Metal PDFB V S KumarNo ratings yet

- Factors Affecting Pelletisation of Iron OreDocument11 pagesFactors Affecting Pelletisation of Iron Orejyotirmaya sahoo100% (1)

- Jindal Steel PlantDocument23 pagesJindal Steel PlantPramodPradhanNo ratings yet

- Iron Ore PelletizationDocument20 pagesIron Ore Pelletizationxarnix50% (2)

- Pelletizing ذكيDocument8 pagesPelletizing ذكييوسف عادل حسانينNo ratings yet

- Agglomeration & PelletizationDocument4 pagesAgglomeration & Pelletizationabhishekgarg98No ratings yet

- Blast Furnace OverviewDocument26 pagesBlast Furnace OverviewProfMVSNo ratings yet

- Alu Technologies Book - Lecture-Notes - 1606 PagesDocument1,606 pagesAlu Technologies Book - Lecture-Notes - 1606 PagesPaul RosiahNo ratings yet

- Lecture Notes Iron Making (PCMT4303) - 6th Sem BTech (Metallurgy)Document158 pagesLecture Notes Iron Making (PCMT4303) - 6th Sem BTech (Metallurgy)mandakini baskey100% (2)

- Secondary Steel Making DraftDocument25 pagesSecondary Steel Making DraftSanjeev SahuNo ratings yet

- EIA Guidance For Induction Electric Arc Cupola FurnaceDocument216 pagesEIA Guidance For Induction Electric Arc Cupola Furnacearjmandquest100% (2)

- Iron Ore Processing 2009 PDFDocument41 pagesIron Ore Processing 2009 PDFglz1100% (2)

- Induction FurnaceDocument7 pagesInduction FurnaceDeepak Velusamy100% (2)

- Circular Pelletizing enDocument8 pagesCircular Pelletizing enShukla SuyashNo ratings yet

- Steel: by A S M Fahad Hossain Assistant Professor Department of Civil Engineering, AUSTDocument23 pagesSteel: by A S M Fahad Hossain Assistant Professor Department of Civil Engineering, AUSTMahadi HasanNo ratings yet

- 11-Steel and Iron MakingDocument59 pages11-Steel and Iron MakingGianardo Satria PrimandanuNo ratings yet

- 12-Steel Rolling Final ChapterDocument18 pages12-Steel Rolling Final ChapterET FTNo ratings yet

- Steel Making2Document147 pagesSteel Making2satish_trivediNo ratings yet

- Blast Furnace Gas CleaningDocument25 pagesBlast Furnace Gas CleaningSalil JainNo ratings yet

- Pellet PLNT ManualDocument19 pagesPellet PLNT ManualsubhankarprustyNo ratings yet

- Pellet PlantDocument41 pagesPellet Plantsoumenb2b100% (1)

- TENOVA Brochure Secondary MetallurgyDocument24 pagesTENOVA Brochure Secondary Metallurgyuck65No ratings yet

- BOF Steelmaking ProcessDocument94 pagesBOF Steelmaking Processradynasr100% (1)

- Pub 42 Copper and Copper Alloy CastingsDocument62 pagesPub 42 Copper and Copper Alloy CastingsHardik GandhiNo ratings yet

- Basics of Steel MakingDocument26 pagesBasics of Steel MakingakshukNo ratings yet

- Rolling Mill DetailsDocument32 pagesRolling Mill DetailsGovind RaoNo ratings yet

- Construction of Blast FurnaceDocument90 pagesConstruction of Blast FurnacesuvraNo ratings yet

- Mine Rajhara DetailsDocument331 pagesMine Rajhara DetailsAditya PrakashNo ratings yet

- Deped School Req 2016Document22 pagesDeped School Req 2016EA Kev RamosNo ratings yet

- Moscow PresentationDocument17 pagesMoscow PresentationArendraNo ratings yet

- Glass HandbookDocument126 pagesGlass Handbookiftikharzai92% (12)

- 12-Relay Remote Control Panel InteriorDocument4 pages12-Relay Remote Control Panel InteriorAshutosh MishraNo ratings yet

- GER 3178 LBB ProtectionDocument20 pagesGER 3178 LBB ProtectionsureshnfclNo ratings yet

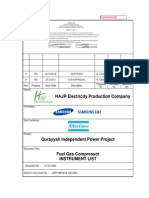

- QIPP MPN018 J00 2304 (1) Instr ListDocument9 pagesQIPP MPN018 J00 2304 (1) Instr Listsivasri999No ratings yet

- Hatfield 97 4Document6 pagesHatfield 97 4mhdstatNo ratings yet

- AngkutanDocument35 pagesAngkutanrahmandpNo ratings yet

- Mandatory Minimum NondestructiveDocument1 pageMandatory Minimum Nondestructiveعصمت ضيف اللهNo ratings yet

- MS275 10 Inch Compound Miter Saw MB4B2ADocument4 pagesMS275 10 Inch Compound Miter Saw MB4B2ArightoutacontrolNo ratings yet

- NLAM - National Library of Ayurved MedicineDocument2 pagesNLAM - National Library of Ayurved MedicineJack LeeNo ratings yet

- Relay PID Auto TuningDocument8 pagesRelay PID Auto TuningKamran KhanNo ratings yet

- RAS Notification 2007Document12 pagesRAS Notification 2007jaipurite100% (5)

- Johnson Wax BuildingDocument23 pagesJohnson Wax Buildingcottchen66050% (1)

- Ecpe Multilevel SchweizerDocument30 pagesEcpe Multilevel SchweizerRajesh Kumar MamidiNo ratings yet

- Zaha Hadid-Price Tower Art CenterDocument4 pagesZaha Hadid-Price Tower Art CenterkienvietNo ratings yet

- Chapter 10 Hollow Cement Concreate Block MansonryDocument5 pagesChapter 10 Hollow Cement Concreate Block MansonryKashif NiaziNo ratings yet

- 160 80 40m End Fed Antenna g0csk Iss 1 11Document4 pages160 80 40m End Fed Antenna g0csk Iss 1 11Al Nino AalNo ratings yet

- BoqDocument9 pagesBoqdeshpande KingNo ratings yet

- Exhaust Manifold: Design, Manufacturing Process and Material To Build An Exhaust ManifoldDocument19 pagesExhaust Manifold: Design, Manufacturing Process and Material To Build An Exhaust ManifoldLUIS PINEDANo ratings yet

- EcoTec 120 Villa Shipping and Trading Co PVT LTD AZ-82632 Lubrication ChartDocument1 pageEcoTec 120 Villa Shipping and Trading Co PVT LTD AZ-82632 Lubrication Chartkuraushan4508No ratings yet

- Paes 203Document7 pagesPaes 203Ryan Anthony LualhatiNo ratings yet

- CS Guide Bracket: Mechanical Engineering Design - CADDocument10 pagesCS Guide Bracket: Mechanical Engineering Design - CADgundhiufsNo ratings yet

- Project Report.Document39 pagesProject Report.Mohit Chouhan100% (3)

- Jabal Sayid ProjectDocument11 pagesJabal Sayid ProjectmchathirNo ratings yet

- Logistic Management System at RELIANCE JamnagarDocument87 pagesLogistic Management System at RELIANCE Jamnagaravinice4uNo ratings yet

- Louisiana Architectural Review 2018 PDFDocument207 pagesLouisiana Architectural Review 2018 PDFAnonymous QkTcXUBeTrNo ratings yet