Professional Documents

Culture Documents

4 Ferretic

Uploaded by

tetirichieOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

4 Ferretic

Uploaded by

tetirichieCopyright:

Available Formats

arflu

technical helps

industrial valves

FERRITIC STEELS

FERRITIC STEELS

CHEMICAL

REQUIREMTS

CHEMICAL

REQUIREMTS ((%%

) )

Carbon

Manganese

Phosphorus

Sulfur

Silicon

MECHANICAL

MECHANICALPROPERTIES

PROPERTIES

Nickel

Chromium

Tensile

Molybdenum

Ksi

CAST CARBON STEEL

Min.

Max

,,,,

0.30

FORGED CARBON STEEL

Min.

,,,,

Max

0.35

,,,,

1.00

0.60

1.05

.

0.040

.

0.040

,,,,

0.045

,,,,

0.05

,,,,

0.60

,,,,

0.35

,,,,

0.50

,,,,

0.40

,,,,

0.50

,,,,

0.20

,,,,

0.30

,,,,

0.12

0.50

0.80

.

0.040

,,,,

0.045

,,,,

0.60

,,,,

0.50

,,,,

0.50

,,,,

0.20

,,,,

0.045

,,,,

0.60

2.0

3.0

.

.

.

.

CAST 3 1/2% NICKEL STEEL FOR LOW TEMPERATURES

Min.

Max

,,,,

0.15

0.50

0.80

0.05

0.20

0.50

0.80

70

95

UNS K03504

70

.

65

90

UNS J22500

70

95

.

0.040

,,,,

0.045

,,,,

0.60

3.0

4.0

.

.

.

.

.

0.040

,,,,

0.045

,,,,

0.60

.

0.60

1.00

1.50

0.45

0.65

70

95

Elongation in

2"

(5

0 mm)

kN

ASTM A216, Grade WCB

485

655

485

36

,,, 250

,

36

,

,,,

22%

.

,,,

22%

.

,

ASTM A105

,,, 250

,

ASTM A352, Grade LCB*

450

620

485

655

35

,,, 240

,,,

24%

,

.

ASTM A352, Grade LC2*

,

40

,,, 275

,

,,,

ASTM A352, Grade LC3*

485

655

40

,,, 275

,

,,,

ASTM A217, Grade WC6

70

.

485

.

40

,,, 275

,

,,,

0.10

0.20

0.30

0.80

.

0.040

UNS K11572

,,,,

0.040

0.50

1.00

.

.

1.00

1.50

0.44

0.65

CAST 2 1/4% CR-1% MO ALLOY STEEL

Min.

Max

.

0.15

0.30

0.60

.

0.040

,,,,

0.045

,,,,

0.60

,,,,

0.50

2.00

2.75

0.90

1.20

,,,,

0.040

,,,,

0.50

.

.

2.00

2.50

0.87

1.13

CAST 4-6% CR ALLOY STEEL

.

0.25

...

0.60

.

0.040

,,,,

0.045

,,,,

0.75

,,,,

0.50

4.00

6.50

0.45

0.65

.

0.040

,,,,

0.030

,,,,

0.50

,,,,

0.50

4.00

6.00

0.44

0,65

CAST 12-14% CR STAINLESS STEEL

.

0.12

.

0.15

0.14

0.20

70

95

UNS K21590

75

.

485

655

515

.

1.00

.

0.040

20%

.

40

,,, 276

,,,

20%

,

.

ASTM A182, Grade F22

45

,,, 310

,,,

20%

.

ASTM A217, Grade C5

90

115

UNS K42544

90

.

,,,

ASTM A217, Grade WC9

620

795

620

60

,,, 415

,,,

18%

,

.

ASTM A182, Grade F5a

65

,,, 450

,,,

22%

.

ASTM A217, Grade CA15

,,,,

1.50

,,,,

1.00

11.5

14.0

,,,,

0.50

90

115

620

795

65

,,, 450

,,,

,

,

ASTM A182, Grade F6a, Class 3

18%

.

,,,,

0.030

,,,,

1.00

,,,,

0.50

11.5

14.0

.

.

110

.

760

..

85

15%

.

,,, 585

.

0.06

0.15

.

,,,,

1.00

.

.

12.0

14.0

1.00

3.00

.

0.04

0.08

0.13

.

.

.

.

.

.

ASTM A582, Type 416

75

110

515

760

40

85

275

585

UNS G11170

.

.

.

.

,,,

UNS S41600

.

1.25

RESULFURIZED STEEL BARS

Min.

Max

,,, 275

,,,,

0.040

FEE-MACHINING 12-14% STAINLESS STEEEL BARS

Min.

Max

40

UNS J91150

Min.

.

.

.

Max

0.15

1.00

0.040

FORGE/ROLLED 12-14% CR STAINLESS STEEL

Min.

Max

485

.

UNS J42045

Min.

.

0.40

Max

0.20

0.70

FORGED /ROLLED 4-6% CR ALLOY STEEL

Min.

Max

ASTM A182, Grade F11

70

.

UNS K21890

Min.

.

0.40

.

Max

0.18

0.70

0.040

FORGED /ROLLED 2 1/4% CR-1% MO ALLOY STEEL

20%

.

arflu

Min.

Max

24%

.

UNS J12072

FORGED/ROLLED 1 1/4% CR-1/2% MO ALLOY STEEL

24%

.

UNS J31550

CAST 1 1/4% CR-1/2% MO ALLOY STEEL

Min.

Max

lbs

UNS J03003

Min.

,,,,

,,,,

.

Max

0.30

1.00

0.040

CAST 2 1/2% NICKEL STEEL FOR LOW TEMPERATURES

,,,,

0.25

Mpa

UNS J03002

CAST CARBON STEEL FOR LOW TEMPERATURES

Min.

Max

Yield

Strenght

Strength

30%

18 %

AISI Type C1117

( 121 BHN)

.

.

23%

.

* Usual minimum service temperatura:LCB at -50F (-45,6C). LC2 at -100 f (-73.3 C). LC3 at -150 F (-101.1C)

Annealed representive mechancal properties.

Temperaed representive mechanical properties.

* Usual minimum service temperatura:LCB at -50F (-45,6C). LC2 at -100 f (-73.3 C). LC3 at -150 F (-101.1C)

Annealed representive mechancal properties.

Temperaed representive mechanical properties.

HEAD OFFICE & DOMESTIC SALES | SEDE CENTRAL Y VENTAS NACIONALES

ARFLU, S.A. | Av. de la Vega 1. edificio veganova, Ed. n 3. Planta 3. Oficina 11. Alcobendas - Madrid 28108 SPAIN

Phone: ++ 34 - 91 662 42 58 | Fax: ++ 34 - 91 661 93 58

FACTORY & INTERNATIONAL DEPARTMENT | FBRICA Y VENTAS INTERNACIONAL

ARFLU, S.A. | Polgono Telleriondo, calle Olabide, 13 Sopelana - Bizkaia (48600) SPAIN

Phone: ++ 34 - 94 6766001 | Fax: ++ 34 - 94 6765650

Re

You might also like

- Product Specifications: Specifications For Continuous Cast ProductsDocument4 pagesProduct Specifications: Specifications For Continuous Cast ProductsvejanidbNo ratings yet

- Mechanical Test Properties (Minimum) : RemarksDocument6 pagesMechanical Test Properties (Minimum) : RemarksSandeepNo ratings yet

- O Imbunatatire PDFDocument2 pagesO Imbunatatire PDFDavid HalaszNo ratings yet

- Chemical Analysis of A Sample50X50X6Document2 pagesChemical Analysis of A Sample50X50X6Amit ChaitNo ratings yet

- SA 283 Grade CDocument1 pageSA 283 Grade CHandri YantoNo ratings yet

- Literatura Tecnica Aço Inoxidável - Normas e AplicaçõesDocument2 pagesLiteratura Tecnica Aço Inoxidável - Normas e AplicaçõesE7 EMPIRE GIGITALNo ratings yet

- Dmls Inconel 625Document1 pageDmls Inconel 625CRISTIANONo ratings yet

- Idoc - Pub - Astm A570 Steel Grade 50 PDFDocument1 pageIdoc - Pub - Astm A570 Steel Grade 50 PDFFrancisco Javier Torres AlvaradoNo ratings yet

- ASTM A570 Steel, Grade 50Document1 pageASTM A570 Steel, Grade 50alejo5412}No ratings yet

- Idoc - Pub - Astm A570 Steel Grade 50 PDFDocument1 pageIdoc - Pub - Astm A570 Steel Grade 50 PDFFrancisco Javier Torres AlvaradoNo ratings yet

- ASTM A570 Steel Grade 50 PDFDocument1 pageASTM A570 Steel Grade 50 PDFranjitNo ratings yet

- Forged Engineering DataDocument4 pagesForged Engineering DataretrogradesNo ratings yet

- Material GradeDocument2 pagesMaterial GradeS. Veeravel100% (1)

- C87600 Copper Silicon: Brass & Bronze AlloysDocument1 pageC87600 Copper Silicon: Brass & Bronze AlloysDeepak KumarNo ratings yet

- Tin Bronze C90300 PDFDocument1 pageTin Bronze C90300 PDFDeepak KumarNo ratings yet

- Stainless Steel SummaryDocument2 pagesStainless Steel SummarybbNo ratings yet

- Astm B62 C83600Document1 pageAstm B62 C83600hemant skNo ratings yet

- Metalshield Clarity MC - 707: Conformances Key FeaturesDocument2 pagesMetalshield Clarity MC - 707: Conformances Key FeaturesRumman Ul AhsanNo ratings yet

- Jis G 3539 SWCH 10aDocument1 pageJis G 3539 SWCH 10asujiyopptsrNo ratings yet

- Astm A572 Steel, Grade 50: Advertise With Matweb!Document1 pageAstm A572 Steel, Grade 50: Advertise With Matweb!wald84No ratings yet

- Chemical Properties of RMDocument8 pagesChemical Properties of RMDINESH SHARMANo ratings yet

- Specifications Casting PDFDocument1 pageSpecifications Casting PDFjahangir_alam44_6764No ratings yet

- Steel Equivalent Table: en / BS To SAE - Page 1 of 20Document3 pagesSteel Equivalent Table: en / BS To SAE - Page 1 of 20LASCARZAMFIRESCUNo ratings yet

- ASTM A36 Steel, Plate: Metal Ferrous Metal ASTM Steel Carbon Steel Low Carbon SteelDocument1 pageASTM A36 Steel, Plate: Metal Ferrous Metal ASTM Steel Carbon Steel Low Carbon SteelStan HonNo ratings yet

- Al Alloys Chemicals MechanicalsDocument1 pageAl Alloys Chemicals MechanicalsFactory FactoryNo ratings yet

- A.S.T.M. B584-09a: WWW - Okendo.mxDocument4 pagesA.S.T.M. B584-09a: WWW - Okendo.mxShariq KhanNo ratings yet

- DK Z DK Uke%& Eksb&Lefkj Ekxz V0Ft0EkDocument1 pageDK Z DK Uke%& Eksb&Lefkj Ekxz V0Ft0EkRajkumar SagarNo ratings yet

- C95200 Aluminum BronzeDocument1 pageC95200 Aluminum BronzeDeepak KumarNo ratings yet

- C95200 Aluminum BronzeDocument1 pageC95200 Aluminum BronzeDeepak KumarNo ratings yet

- Equivalents of Carbon Steel QualitiesDocument2 pagesEquivalents of Carbon Steel QualitiesmichaelNo ratings yet

- Anup SS304L TC 1Document2 pagesAnup SS304L TC 1B.M Industrial Works100% (1)

- AISI 4130 Alloy Steel (UNS G41300) : Chemical CompositionDocument3 pagesAISI 4130 Alloy Steel (UNS G41300) : Chemical CompositionGrimmo1979No ratings yet

- Cold Rolled CR Structural S CM350-G® Steel: General Description Typical UsesDocument2 pagesCold Rolled CR Structural S CM350-G® Steel: General Description Typical UsesBaziNo ratings yet

- Astm A36 Asme Sa36Document3 pagesAstm A36 Asme Sa36Mohamed IsmailNo ratings yet

- Bolting Material Chemical &..Document6 pagesBolting Material Chemical &..arief setiawanNo ratings yet

- Certificados - Mtc-Po 23040-Req 14989Document98 pagesCertificados - Mtc-Po 23040-Req 14989MissionPetroleum InfoNo ratings yet

- C86200 Manganese BronzeDocument1 pageC86200 Manganese BronzeDeepak KumarNo ratings yet

- Mill SheetDocument6 pagesMill SheetSatryaNo ratings yet

- ASTM A325 - Portland BoltDocument3 pagesASTM A325 - Portland BoltHector BalderaNo ratings yet

- Cast Wheel in Indian Rlys-Present StatusDocument6 pagesCast Wheel in Indian Rlys-Present StatusDevarshi GaurNo ratings yet

- Technical Specifications: Chemical CompositionDocument2 pagesTechnical Specifications: Chemical CompositionEmir BećirovićNo ratings yet

- Silicon Bronze PDFDocument1 pageSilicon Bronze PDFFabian Andres Pinilla CarballoNo ratings yet

- Chemical Analysis of A Sample65x65x8Document1 pageChemical Analysis of A Sample65x65x8Amit ChaitNo ratings yet

- ASTM A36 Steel, PlateDocument1 pageASTM A36 Steel, PlateI-SignNo ratings yet

- ASTM A36 Steel, Bar: To View All Available Suppliers For This MaterialDocument1 pageASTM A36 Steel, Bar: To View All Available Suppliers For This Materialapepglory8No ratings yet

- L80 - Continental AlloysDocument1 pageL80 - Continental AlloysHans CohnNo ratings yet

- Astm A216 WCBDocument1 pageAstm A216 WCBAkshay ValaNo ratings yet

- BMD MDS Ti64 210803Document1 pageBMD MDS Ti64 210803Nicola MerzagoraNo ratings yet

- TDS Material Astm-A193-Grade-B8Document1 pageTDS Material Astm-A193-Grade-B8ASTRID AMNo ratings yet

- Chemical Composition and Mechanical Properties of Steel (Indian Standard)Document4 pagesChemical Composition and Mechanical Properties of Steel (Indian Standard)Jyotirmoy BarmanNo ratings yet

- Navy M BronzeDocument1 pageNavy M BronzeDeepak KumarNo ratings yet

- A4 (SS 316) Data SheetDocument1 pageA4 (SS 316) Data SheetSoubra SenmarecNo ratings yet

- Wire RodDocument2 pagesWire RodmljaininsulationNo ratings yet

- Astm b176 Uns c86500Document1 pageAstm b176 Uns c86500Kashif MohiuddinNo ratings yet

- The Superior Durability of Chilled Cast Iron CamshaftsDocument2 pagesThe Superior Durability of Chilled Cast Iron CamshaftsAndri OdeNo ratings yet

- Carbon Steel SpecificationDocument4 pagesCarbon Steel SpecificationSteinol SolutionsNo ratings yet

- Database Management Systems: Understanding and Applying Database TechnologyFrom EverandDatabase Management Systems: Understanding and Applying Database TechnologyRating: 4 out of 5 stars4/5 (8)

- CementDocument37 pagesCementmahantmtechNo ratings yet

- 1600 GB WEB PDFDocument21 pages1600 GB WEB PDFmahantmtechNo ratings yet

- B271M PDFDocument6 pagesB271M PDFmahantmtechNo ratings yet

- HP English PDFDocument12 pagesHP English PDFmahantmtechNo ratings yet

- Ball Mill InspectionDocument9 pagesBall Mill InspectionmahantmtechNo ratings yet

- The GR8 Ms-ExcelDocument222 pagesThe GR8 Ms-ExcelmahantmtechNo ratings yet

- A4-P 1.1 enDocument23 pagesA4-P 1.1 enmahantmtech100% (1)

- Questions For Class 1: Chen 733 Coal CombustionDocument6 pagesQuestions For Class 1: Chen 733 Coal CombustionmahantmtechNo ratings yet

- 2012.08 POV S.S. Bagchi S.V. Ghule and R.T. JadhavDocument4 pages2012.08 POV S.S. Bagchi S.V. Ghule and R.T. JadhavmahantmtechNo ratings yet

- Mill ScanDocument6 pagesMill ScanmahantmtechNo ratings yet

- The Bond Work Index of Binary and Ternary Mixtures of Ceramic Raw MaterialsDocument5 pagesThe Bond Work Index of Binary and Ternary Mixtures of Ceramic Raw MaterialsmahantmtechNo ratings yet

- India's Premier Coal Industry EventDocument8 pagesIndia's Premier Coal Industry EventmahantmtechNo ratings yet

- Visual Clips: at MCC - School-ShahabadDocument5 pagesVisual Clips: at MCC - School-ShahabadmahantmtechNo ratings yet

- OK Vertical Roller MillDocument8 pagesOK Vertical Roller MillHiresomannavar Mahantesh100% (2)

- ME8352-Manufacturing Technology - I (MT-I) With QBDocument91 pagesME8352-Manufacturing Technology - I (MT-I) With QBMohana KrishnanNo ratings yet

- Periodic Table AP ChemDocument1 pagePeriodic Table AP ChemJoshua KimNo ratings yet

- Annex E Severity Levels For Copper Alloy Castings: (Normative)Document2 pagesAnnex E Severity Levels For Copper Alloy Castings: (Normative)bhavin178No ratings yet

- 16 EpidoteDocument15 pages16 EpidoteSangam SNo ratings yet

- Exothermic Weld PDFDocument40 pagesExothermic Weld PDFMaulik ShahNo ratings yet

- AMS-2404-G - Electroless Nickel CoatingDocument9 pagesAMS-2404-G - Electroless Nickel CoatingaadmaadmNo ratings yet

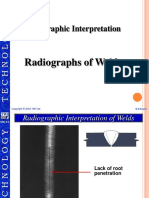

- Radiographic Interpretation: Radiographs of WeldsDocument22 pagesRadiographic Interpretation: Radiographs of WeldsManoj BallaNo ratings yet

- LSS 4140-4142HTDocument2 pagesLSS 4140-4142HTrezaNo ratings yet

- Abdullah I 2017Document14 pagesAbdullah I 2017KatiaPeraltaNo ratings yet

- Strip Casting Technology A Key To Product QualityDocument5 pagesStrip Casting Technology A Key To Product Qualityjijith njNo ratings yet

- Experimental Investigations On Heat Treatment of Cold WorkDocument11 pagesExperimental Investigations On Heat Treatment of Cold WorkJarek PlaszczycaNo ratings yet

- Unit 3 CorrosionDocument26 pagesUnit 3 CorrosionVasudev GuptaNo ratings yet

- Sheet Metal Thickness CHARTDocument2 pagesSheet Metal Thickness CHARTray_k_9177No ratings yet

- MP-II Unit 2 SBPDocument69 pagesMP-II Unit 2 SBPamith jspmNo ratings yet

- MP 29 Soldering PDFDocument19 pagesMP 29 Soldering PDFAnkit SangwanNo ratings yet

- 10 Stepsto Gem IdentificationDocument22 pages10 Stepsto Gem IdentificationfiqoNo ratings yet

- Science Q4 Wk1 D1Document29 pagesScience Q4 Wk1 D1Rowena Samiana PomboNo ratings yet

- Manufacturing Process of Rolling Element Bearing NewDocument26 pagesManufacturing Process of Rolling Element Bearing NewRamakanth P JoshiNo ratings yet

- RTR 1633.30-01-18Document4 pagesRTR 1633.30-01-18LHYT NTUANo ratings yet

- Earth LugsDocument34 pagesEarth LugsManicontrolNo ratings yet

- Metal-Ceramic Shell Interactions During Investment Casting: C. Mahimkar, V. L. Richards, and S. N. LekakhDocument11 pagesMetal-Ceramic Shell Interactions During Investment Casting: C. Mahimkar, V. L. Richards, and S. N. LekakhTraian TiberiuNo ratings yet

- Duplex Welding GuidelinesDocument13 pagesDuplex Welding GuidelinesadelNo ratings yet

- Module - 2Document40 pagesModule - 2deepak2803No ratings yet

- Electrometallurgy 3: Laval University, Quebec City, Canada Fathi - Habashi@arul - Ulaval.caDocument28 pagesElectrometallurgy 3: Laval University, Quebec City, Canada Fathi - Habashi@arul - Ulaval.caBasilia YulianiNo ratings yet

- 2 Iron-Carbon Alloy SystemDocument36 pages2 Iron-Carbon Alloy SystemYour EntertainerNo ratings yet

- Sec 3 Welding Imperfections (Defects)Document31 pagesSec 3 Welding Imperfections (Defects)Abdullah100% (1)

- Neco Catlog 4 FoldDocument2 pagesNeco Catlog 4 FoldSanket PhatangareNo ratings yet

- Handbuch Schnittwerte F B ENDocument164 pagesHandbuch Schnittwerte F B ENAhmad KhalifaNo ratings yet

- Jindal Al SectionsDocument14 pagesJindal Al SectionsAMIT GUPTANo ratings yet

- A Winarta Iron Ore Specpn - 19 - 08 - 2017 - Back Supporting DetailsDocument3 pagesA Winarta Iron Ore Specpn - 19 - 08 - 2017 - Back Supporting DetailsChandan JstNo ratings yet