Professional Documents

Culture Documents

Manual For LINE FOLLOWING BOTs (Circuit)

Uploaded by

GUSACOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Manual For LINE FOLLOWING BOTs (Circuit)

Uploaded by

GUSACCopyright:

Available Formats

Line

Follower

Robot

Robotics Workshop

Currents 15

th

march 2008

EEE Department

NIT Trichy

Developed By:

Mayur Agarwal

Prashant Agrawal

Krishna Nand Gupta

Hitesh Meghani

To Our Readers

We are glad to have had an opportunity to share our knowledge with

interested robotics enthusiasts. In this book we have attempted to provide a brief

compilation of our experiences in robotics (participating and winning in Technical

Festivals all over the country), extending over last three years.

The prospect of practically implementing engineering concepts is the

hallmark of robotics. By reading the basics in this book you will gain a significant

insight into various tools employed in shaping a robot. However to participate in

technical festivals with ever changing problem statements you will be required to

apply these basics concepts and come up with innovative algorithms and superior

designs.

Do not expect this book to be a panacea for all robotic problems, rather

you will have to sit and work for hours to get a functioning robot. Transform each

failure into a stepping stone instead of stumbling over it. We appreciate the beauty

of diamond but little do we wonder how it became so bright? Its perseverance

extending thousands of years transformed it into its present sparkling state.

We encourage you to plunge further into the field of robotics with

dedicated perseverance, make your own mistakes and gain valuable experience

from them.

ALL THE BEST

Your valuable suggestions and inquisitive doubts are welcome. You can

contact us at

Mayur Agarwal (mayurmagic.nitt@gmail.com )

Krishna Nand Gupta (kng_sweet94@yahoo.com)

Prashant Agarwal (pras_nitt@yahoo.co.in )

Hitesh Meghani (h.nittian@gmail.com )

~ 1 ~

Introduction

The line follower is a self operating robot that detects and follows a line that is

drawn on the floor. The path consists of a black line on a white surface (or vice versa).

The control system used must sense a line and maneuver the robot to stay on course,

while constantly correcting the wrong moves using feedback mechanism, thus

forming a simple yet effective closed loop System. The robot is designed to follow

very tight curves.

Sample Paths

The path is a black line on a white background with width of 3 cm (except at

bends where a little variation may be present). It may contain paths laterally displaced

by around 3 cm and also gap of at most 5 cm. (All these specifications may vary from

one competition to another).

Figure1:BasicSampleArena

Figure2:SampleArenaofKurukshetra08(AnnaUniversity)

Figure3:SampleArenaofPragyan07(NITTrichy)

Figure4:SampleArenaofRoboRelayofKishitij08(IITKGP)

From above images we can conclude that in most of line follower competitions, some additional

taskhastobeperformedapartfromfollowingtheline.

R

o

b

o

t

i

c

s

W

o

r

k

s

h

o

p

N

I

T

T

r

i

c

h

y

Basic

The

consisting

and contr

tracking t

opto-coup

IR LED

of compa

input to

Microcon

Basic

The

1. C

F

is

2. S

th

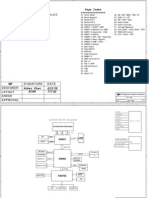

BlockD

Lets see

design

robot is b

g of a toy

rolling wh

tape. Line

plers moun

and an

arator, LM3

o the mic

ntroller AT

operat

basic oper

Capture lin

For this a c

s used. The

Steer robot

his we use

Diagram

all the sys

and re

built usin

car chassi

heels. It h

position i

nted at the

IR Senso

324 is low

crocontrol

Tmega8L a

tion

rations of th

ne position

ombination

e line sensi

to track t

two motor

stem in det

quirem

g ATmeg

is (or hand

has infrared

is captured

front end

or). When

w, while fo

ler for a

and Motor d

he line foll

with optic

n of IR LE

ing proces

the line wi

rs that gov

ail.

~ 2 ~

ments

ga8L, L29

d made Al

d sensors

d with the

of the robo

n the sen

r white su

accurate c

driver L29

lower are a

cal sensors

ED and Pho

s requires h

ith a suitab

vern the mo

3D, IR se

luminum s

on the bo

help of th

ot. (Each o

nsors detec

rface the o

control a

93D are use

as follows:

s mounted

oto Transis

high resolu

ble steerin

otion of the

ensors, LM

sheet chass

ottom for

hese optica

opto-coupl

ct black

output is h

and steerin

ed to drive

:

d at front e

stor called

ution and h

ng mechani

e wheels on

M324, pla

sis), two m

detecting

al sensors

er consists

surface, o

high. It is s

ng of m

e the motor

end of the

an opto-co

high robust

ism. To ac

n either sid

atform

motors

black

called

s of an

output

sent as

motors.

rs.

robot.

oupler

tness.

chieve

de.

R

o

b

o

t

i

c

s

W

o

r

k

s

h

o

p

N

I

T

T

r

i

c

h

y

INPUT

Sensor

Eac

or photo d

If w

sensed by

hence rec

Photo dio

(from say

divider ci

T SYSTE

rs

ch opto-co

diode.

white surfa

y the receiv

ceiver does

ode has a p

y 150k

ircuit (as sh

EM

oupler has

ace is prese

ver, while

s not sense

property th

to 10k).

hown in fig

one emitte

ent beneath

in case of b

IR rays.

hat if IR lig

For sens

gure below

~ S ~

er (IR LED

h the IR LE

black surfa

ght falls on

ing the ch

w).

D) and one

ED, IR ray

ace, the lig

n it, its elec

hange in r

receiver (P

ys are reflec

ght gets abs

ctrical resis

resistance

Photo-Tran

cted and ar

sorbed and

stance dec

we use v

nsistor

re

d

reases

voltage

R

o

b

o

t

i

c

s

W

o

r

k

s

h

o

p

N

I

T

T

r

i

c

h

y

~ 4 ~

Sample Calculation:

Say Receiver has resistance-

Rs=150k without light (on black surface)

Rs=10k with light (on white surface)

The voltage that goes to comparator

Without light: (on black surface)

Vp=

Rs

Rs+R

- Icc =

150

150+10

*5 V=4.6875 V

With light: (on white surface)

Vp=

Rs

Rs+R

- Icc =

10

10+10

*5 V=2.500 V

Thus we get the variation in voltage, which is sensed by the comparator IC

(LM324). The comparator then, gives logical high or low according to input.

Comparator

Comparator is a device which compares two input voltages and gives

output as high or low. In a circuit diagram it is normally represented by a

triangle having-Inverting (negative) Input (-), Non-Inverting (positive)

Input(+), Vcc, Ground, Output.

Properties of comparator:

If V+ > V-

then Vo=Vcc

(Digital High 1 output)

If V+ < V-

then Vo=0

(Digital Low 0 output)

R

o

b

o

t

i

c

s

W

o

r

k

s

h

o

p

N

I

T

T

r

i

c

h

y

~ S ~

Lets see some examples

Use of comparator in IR sensor

As above we see that two inputs are required for comparator. One input is from

photo-receiver (like photo-diode), other is generated by us using potentiometer

(preset). The second voltage is also called as reference voltage for that sensor.

Setting of reference voltage (Vref)

We can vary reference voltage by using potentiometer, such that it can

vary from 0V to Vcc. We set the reference voltage as mean value of the sensor outputs

measured with and without light.

From above example Vref =

4.675+2.500

2

= 3.5875 V

Lets connect Inverting Input of Comparator to photo- receiver, Non-Inverting Input to

potentiometer (as shown in figure) and output to micro controller.

Sample Calculation:

Let V+ = 3.5875 V

With light :(on white surface)

V- = 0.9090 V

Thus V+>V- and Vo= Vcc = 5 V

Thus we get digital HIGH output.

Without light:(on black surface)

V- = 3.333 V

Thus V+<V- and Vo = 0 V

Thus we get digital LOW output.

R

o

b

o

t

i

c

s

W

o

r

k

s

h

o

p

N

I

T

T

r

i

c

h

y

Note: If w

Inverting

we get Lo

IC LM

IC

You can

Arran

An

the front

We

then the

sharp tu

smooth

program

sensors.

T

we connect

g Input to p

ow output a

M324

LM324 co

see the da

ngemen

n array of

t of the ro

e can use

e robot m

urns. If we

and rel

mming and

he distan

1. Numb

2. Width

3. Distan

logic).

t Inverting

photo- rece

and for bla

ontains fou

tasheet of

t of Sen

f sensors

bot. It is u

any num

movement

e use high

liable fo

d more ha

nce betwee

ber of sens

h of straig

nce betwe

.

Input of C

eiver, the o

ack surface

ur compara

IC LM324

nsors

arranged

used to lo

mber of sen

will not

her numbe

or sharp

ardware. T

en sensor

sors used

ht line

een sensor

~ 6 ~

Comparato

nly differe

e we get Hi

ators.

4 for more

in a stra

cate the p

nsors. If w

be smoo

er of sens

turns,

Thus we m

rs depend

rs may no

or to potent

ence observ

High output.

e details.

ight row

position of

we have le

oth and it

ors robot

however

must choo

ds on

ot be cons

tiometer (p

ved is that

.

pattern is

f line belo

esser num

t may fac

movemen

it requ

ose optim

stant (it d

preset) and

at white su

s bolted u

ow the rob

mber of se

ce problem

nt will be

uires com

mum numb

depends o

d Non-

urface

under

bot.

ensors

ms at

ecome

mplex

ber of

on the

R

o

b

o

t

i

c

s

W

o

r

k

s

h

o

p

N

I

T

T

r

i

c

h

y

Sample f

Tips f

figure:

for Inp

Signifi

connec

Set pr

differe

You ha

on rou

The ad

case w

ambien

To get

we gen

Proper

good v

the oth

If an o

across

photo d

Left

put Sys

cant prob

ctions use P

reset value

ntly and m

ave to adju

ughness of s

dvantage of

we use LDR

nt light.

t a good vo

nerally use

r orientatio

voltage swi

her opto-co

opto-coupl

IR LED i

diode for b

Figur

tem

blems are

PCB.

e for each

may give dif

ust preset

surface.

of IR senso

R as photo

oltage swi

e 10k ress

on of the I

ing. Also I

oupler.

ler is not

is 1.1-1.2

black and w

e 2: Align

~ 7 ~

faced in

h sensor,

fferent volt

value for

or is that it

o detector,

ing, the va

sistance.

IR LED an

IR rays of

working th

V, then ch

white surfa

ment of S

R

input syst

because e

tage on the

new surfa

t is less aff

its sensiti

alue of R1

nd Photo d

one opto-c

hen first c

eck the vo

aces, then s

ensor in a

Right

tem. So to

each sens

e same surf

ce, as refl

ffected by a

vity will h

must be c

diode is mu

coupler sh

check whet

oltage varia

set the refe

an opto-cou

o make re

sor may b

rface.

lectivity de

ambient lig

ighly depe

carefully ch

ust so as to

ould not d

ther the vo

ation acro

erence volt

upler

eliable

behave

epends

ght. In

end on

hosen,

o have

disturb

oltage

oss the

tage.

R

o

b

o

t

i

c

s

W

o

r

k

s

h

o

p

N

I

T

T

r

i

c

h

y

Volta

Voltage r

commonl

voltage is

They hel

input volt

If input v

may be 5

maximum

To identi

writing to

voltage re

age Re

regulators

ly used on

s in betwee

lp to main

tage variat

voltage is <

5V or 4.8V

m output cu

fy the lead

o your sid

egulator.(1

Fig a

Fig

cou

for

use

The

egulato

convert f

nes are 780

en 7.5V to

ntain a stea

tions.

<7.5 V then

V, but the

urrent capa

ds of the 78

de, (see th

1-input,2-g

b shows h

upling capa

it in norm

capacitor,

e mainly av

or 78x

fixed DC

05 and 78

20V.

ady voltag

n regulation

ere are som

ability, line

805, you h

he figure b

gnd,3-outp

how to use

acitors are

mal case. B

, otherwise

vailable 78

~ 8 ~

xx

output vo

12. 7805

ge level de

n won't be

me parame

e regulation

have to kee

below). Yo

put).

e 7805 volt

used for g

But if 7805

e the noise

8xx IC's are

oltage from

gives fixed

espite vary

proper i.e

eters for th

n etc.. , tha

ep the lead

ou can see

Fig b

tage regula

good regula

5 is used in

e in the ou

e 7805, 78

m variable

d 5V DC

ying curren

e. if input is

he voltage

at won't be

downward

e the heat

ator. Here

ation. But

n analog ci

utput volta

809,7812,7

DC. The

voltage if

nt demand

s 6V then o

e regulator

e proper.

d (Fig a) an

sink abov

you can se

there is no

ircuit we s

age will be

815,7824.

most

f input

ds and

output

rs like

nd the

ve the

ee that

o need

should

e high.

R

o

b

o

t

i

c

s

W

o

r

k

s

h

o

p

N

I

T

T

r

i

c

h

y

POTE

Potentiom

shaft. Pot

Potentiom

then you

used to ge

Note: To

resistance

ENTIOM

meter is a v

tentiometer

meter is a v

can get v

enerate ref

reduce th

e.

METER

variable re

rs are avai

voltage div

voltages fro

ference vol

e value of

R (PO

sistor whic

lable from

vider. If we

om 0 to V

ltage for L

f current dr

~ 9 ~

OT ' )

ch is used

m 100 ohm t

e connect L

Vcc by at L

M324.

rawn, use

to vary the

to 470Koh

Lead A to V

Lead W. M

the preset

e resistance

hm (or mor

Vcc and L

Mainly po

ts that hav

e by rotatin

re).

Lead B to g

tentiomete

ve higher o

ng the

ground

ers are

overall

R

o

b

o

t

i

c

s

W

o

r

k

s

h

o

p

N

I

T

T

r

i

c

h

y

Above fi

potentiom

occasiona

Second a

fixed. Th

body of th

igure show

meters are

ally while

and third o

hey are also

he potentio

ws differen

mainly use

the first o

ones are ea

o called P

ometer.

nt types o

ed when y

one is used

asy to inse

Preset. R

~ 1u ~

of potentio

ou only w

d when we

ert in brea

Resistance i

meters av

ant to chan

e have to v

adboard an

is varied b

vailable. Se

nge the val

vary resist

nd PCB, a

by rotating

econd and

lue of resi

ance frequ

also they r

g the shaft

d third

stance

uently.

remain

in the

R

o

b

o

t

i

c

s

W

o

r

k

s

h

o

p

N

I

T

T

r

i

c

h

y

PROCE

Pro

correspon

several

Microchip

robot. It i

WhyA

algorithm

it has fol

1. It

(Bu

No

cod

2. It h

16

3. It

4. It c

A)

ESSING

ocessing sy

nding inpu

companies

p, Intel, M

is an ATM

ATmeg

Line f

ms. We can

llowing ex

is an ISP

urning) of

ote: Progr

de from co

has on chi

and 17). W

has an inbu

consumes l

Hardw

G SYST

ystem acts

uts. For th

s that m

Motorola et

MEL produc

ga8L

follower ro

n use any m

xtra feature

P (In Sys

ATmega8

ramming (B

mputer to

p PWM (

We have ex

uilt RC osc

lesser pow

ware De

TEM

as the Bra

hat we use

manufacture

tc. We wil

ct. It is also

obot requi

microcontr

es:

stem Prog

L IC can b

(Burning)

microcont

Pulse Wid

xplained PW

cillator. (O

wer than oth

etails

~ 11 ~

ain of robo

e microcon

e microco

ll be using

o called AV

ires simple

roller for th

grammabl

be done wit

of a micr

troller .Bur

dth Modu

WM in app

Oscillator i

her microco

t, which ge

ntrollers. I

ontrollers,

g ATmega

VR.

e microcon

hat. But w

le) device

thout remo

rocontrolle

rning is exp

ulation) cir

pendix sec

is a clock g

ontrollers.

enerates de

In present

for exam

a8L microc

ntroller as

we use ATm

. It mean

oving it fro

er means

plained lat

rcuit at thr

tion.

generator c

esired outp

days, the

mple AT

controller

s it uses s

mega8L, be

ns program

om the syst

transferrin

ter.

ree pins (P

circuit).

put for

re are

TMEL,

in our

simple

ecause

mming

tem.

ng the

Pin 15,

R

o

b

o

t

i

c

s

W

o

r

k

s

h

o

p

N

I

T

T

r

i

c

h

y

~ 12 ~

BasichardwareconnectionsofATmega8L

Pin 1 (Reset):

The use of reset pin is to reset the ATmega8L microcontroller. This can be done

by connecting this pin to ground. In normal mode of execution it should have at least

2.7V. Thus it is connected to +5 V through 10k ohm resistance .We should make sure

that its potential be above 2.7 for proper execution of code.

Pin 7 and 20 (Vcc):

Pin 7 and 20 should be connected to Power supply. (2.7 to 5.5 volt for

ATmega8L)

Pin 8 and 22 (Ground):

Pin 8 and 22 should be connected to Ground. This ground should be common to

for the entire circuit.

Input and Output Ports

In ATmega8L we have three I/O (input/output) ports viz. Port B, Port C and

Port D.

One can configure any pin of each of these ports as input or output pin by

appropriate programming.

Pin PORT Connection PWM

14 PB0 Negative of right NO

15 PB1 Positive of right YES

16 PB2 Positive of Left YES

17 PB3 Negative of Left NO

Thus we can use Port C or Port D or remaining Pins of Port B as input. But for the

sake of simplifying hardware connections we choose Port D pins as input pins.

Make sure Ground and Vcc do not get interchanged and Vcc should not exceed 5.5

V. If you connect supply wrongly, ATmega8L will suffer permanent damage.

We will be using Port B pins (PB0 to PB3) as output pins because at pinPB1 and

PB2 we have on-chip PWM output that can control the speed of motors.

R

o

b

o

t

i

c

s

W

o

r

k

s

h

o

p

N

I

T

T

r

i

c

h

y

Burne

Burner (o

microcon

available

We will b

stk200

Requi

Pa

5 P

5 w

Th

er (or p

or program

ntroller IC

Eg stk200

be using st

0 Progr

irements

arallel Port

Pin RMC c

wired Bus

hey are show

rogram

mmer) is t

C. For pro

0, stk500, j

tk200 prog

rammer

t DB 25 co

connector (

wn in follo

mmer)

the circuit

ogramming

tag2 etc.

grammer.

r:

onnector (c

(connects t

owing figu

~ 1S ~

used to t

g AVR th

onnects to

to AVR PC

ure.

transfer th

here are d

the compu

CB).

he code fro

different ty

uter )

om compu

ypes of bu

uter to

urners

R

o

b

o

t

i

c

s

W

o

r

k

s

h

o

p

N

I

T

T

r

i

c

h

y

Conne

Co

Explanat

ections

onnections

tions of Pi

R

are given b

ins of ATm

SCK

MOSI

RESET

MISO

GND

by the follo

mega8L

S

M

M

~ 14 ~

owing figu

SPI Bus M

Master Ou

Re

Master Inp

G

ure.

aster clock

utput/Slave

eset pin

put/Slave O

Ground

k Input

Input

Output

R

o

b

o

t

i

c

s

W

o

r

k

s

h

o

p

N

I

T

T

r

i

c

h

y

~ 1S ~

B) Software Details:

Programming and Simulating

The program code acts as the decision-maker embedded in the micro-

controller i.e. it decides what will be the outputs for particular set of input

combination.

Programs for the AVR series of microcontrollers can be written in assembly

(AVR ASM), C and BASIC. AVR Studio, WinAVR, etc. are some free

development softwares for programming the AVR Microcontrollers. We will be

using winAVR for programming and AVR Studio for simulating (Simulation

means debugging the code on software, one can virtually give the input and

check the output for that code).

In winAVR programmers Notepad we write our C code, after compilation it

generates .hex file which is a hardware level code.

SampleCode:To blink a LEB connecteu at pin 6 (PB4) of ATmega8L.

#include<avr/io.h>//headerfiletoincludeinputoutputport

#include<util/delay.h>//headerfiletoincludedelayfunction

#defineLEDPD4

intmain(void)

{

DDRD=(1<<LED);

/*DDR=DataDirectionregister...itstodefinePD4OUTPUTpin

restbitsofDDRDcanbe0or1doesnotmakeanysignificance*/

while(1)

{

PORTD=(1<<LED);//switchon

_delay_ms(200);

PORTD=(0<<LED);//switchoff

_delay_ms(200);

}

return0;

}

R

o

b

o

t

i

c

s

W

o

r

k

s

h

o

p

N

I

T

T

r

i

c

h

y

MOTO

For movi

Why DC

DC

its operat

supply ac

Use of

Th

connectin

of its spee

Mathema

Ro

Th

Pr is con

inversely

Thus to in

Note:

In

Ge

R OUTP

ing a robot

C motors

C motors ar

tion. If we

cross it. We

gears

he DC mo

ng wheels

ed.

atical inte

otational po

Pr=Tor

hus

stant for D

proportion

ncrease the

toy car, th

eared moto

PUT SY

we have t

s

re most ea

e want to

e can vary

otors don

in it. Gear

erpretation

ower (Pr) i

rque (T) *

DC motor w

nal to spee

e value of t

here is a ge

or has a gea

YSTEM:

wo dc mot

asy to contr

change its

speed by v

t have en

rs used to i

n:

s given by

Rotationa

with cons

ed ().

torque we

ar box that

ar box at it

~ 16 ~

:

tors attache

rol. One dc

s direction

varying the

nough tor

increase th

y:

l Speed (

stant input

have to sa

t contains

ts front end

ed to whee

c motor req

n just reve

e voltage a

rque to dr

he torque o

)

electrical

crifice spe

several com

d.

els and gea

quires only

erse the po

across moto

rive a rob

of dc motor

power. Th

eed.

mbinations

ar system.

y two signa

olarity of p

or.

bot direct

r on the ex

hus torque

s of gears.

als for

power

tly by

xpense

(T) is

R

o

b

o

t

i

c

s

W

o

r

k

s

h

o

p

N

I

T

T

r

i

c

h

y

Why tw

By

mechanis

Lets che

wo mot

y using tw

sm of robot

ck how it w

tors

o motors

t is called d

works

Fi

F

we can m

differentia

gure. Descri

Figure. Mo

~ 17 ~

move the ro

al drive.

iption of var

ovement of

obot in an

rious parts

f Robot

ny direction. This ste

eering

R

o

b

o

t

i

c

s

W

o

r

k

s

h

o

p

N

I

T

T

r

i

c

h

y

The table

Left Mot

Straight

Stop

Reverse

Straight

Straight

Reverse

Use of

Fro

microcon

a current

motor dri

Mo

correspon

IC L293

Th

how we u

e:

tor

f Motor

om micro

ntroller can

t enhancin

iver betwee

otor drive

nding outp

3D

his is a mo

use this IC.

R

S

S

S

S

R

R

r Driver

ocontroller

n not give s

ng device;

en the mot

r takes th

ut for moto

otor driver

.

Right Moto

Straight

Straight

Straight

Stop

Reverse

Reverse

r

we can

sufficient c

it can als

tor and mic

he input

or.

IC that ca

Figure. Pin

~ 18 ~

or

n not co

current to d

so act as a

crocontroll

signals fr

an drive tw

n Details of L

Rob

Stra

Lef

Sha

Rig

Sha

Rev

onnect a

drive the D

a Switchin

ler.

rom micro

wo motor

L293D

bot Movem

aight

ft

arp left

ght

arp Right

verse

motor di

DC motors.

ng Device.

ocontroller

simultane

ment

irectly be

. Motor dr

Thus we

r and gen

ously. Let

ecause

iver is

insert

nerates

ts see

R

o

b

o

t

i

c

s

W

o

r

k

s

h

o

p

N

I

T

T

r

i

c

h

y

~ 19 ~

Electrical Characteristics of L293D

Symbols

Parameter Testing

Condition

Min. Max. Units

Vss LogicSupplyVoltagePin16 4.5 36 V

Vs SupplyVoltagePin8 Vss 36 V

VenL EnableLowVoltagePin1and9 0.3 1.5 V

VenH EnableHighVoltagePin1and9 Vss<=7

Vss>7

2.3

2.3

Vss

7

V

VIL InputLowVoltagePin2,7,10and15 0.3 1.5 V

VIH InputHighVoltagePin2,7,10and15 Vss<=7

Vss>7

2.3

2.3

Vss

7

V

PointsregardingL293D

Supply voltage (Vss) is the Voltage at which we wish to drive the motor.

Generally we prefer 6V for dc motor and 6 to 12V for gear motor, depending

upon the rating of the motor.

Logical Supply Voltage will decide what value of input voltage should be

considered as high or low .So if we set Logical Supply Voltage equal to +5V,

then -0.3V to 1.5V will be considered as Input Low Voltage and 2.3 V to 5V

will be considered as Input High Voltage.

L293D has 2 Channels .One channel is used for one motor.

Channel 1 - Pin 1 to 8

Channel 2 - Pin 9 to 16

Enable Pin is used to enable or to make a channel active. Enable pin is also

called as Chip Inhibit Pin.

All Inputs (Pin No. 2, 7,10and 15) to L293D IC are the respective outputs from

microcontroller (ATmega8L).

E.g.-We connected Pin No. 2, 7, 10 and 15 of L293D IC to Pin No. 14,

15,16and 17 of ATmega8L respectively in our robots, because on pin 15

and 16 of ATmega8L we can generate PWM.

All Outputs (Pin No. 3, 6,11and 14) of L293D IC goes to the inputs of Right

and Left motors.

Output Connections

OUTPUT 1 (Pin No 3) --- Negative Terminal of Right Motor

OUTPUT 2 (Pin No 6) --- Positive Terminal of Right Motor

OUTPUT 3 (Pin No 10) --- Positive Terminal of Left Motor

OUTPUT 4 (Pin No 14) --- Negative Terminal of Left Motor

R

o

b

o

t

i

c

s

W

o

r

k

s

h

o

p

N

I

T

T

r

i

c

h

y

~ 2u ~

For one motor:

Positive Terminal Negative Terminal Motor Output

0 0 No movement

Vss 0 Straight

0 Vss Reverse

Vss Vss No Movement

One channel can control one motor.

Enable pin should be high for activating

the corresponding channel.

Input 1 corresponds to Output 1.

If Enable 1=High (1)

Input1 =High (1), Output1=Vss

Input1 =Low (0), Output1=0

If Enable 1=Low (0)

Input1 =High (1), Output1=0

Input1 =Low (0), Output1=0

if Enable pin low, the output will always

be 0. If its high output depends on input

Lets check the sample outputs for some sample inputs (when both the Enable pins are high):

Input

1

Input

2

Input

3

Input

4

Output

1

Output

2

Output

3

Output

4

Motors Output Movement

Right Left

Low High High Low 0 Vss Vss 0 Straight Straight Straight

Low High Low Low 0 Vss 0 0 Straight No mov Left Turn

Low Low High Low 0 0 Vss 0 No mov Straight Right Turn

Low High Low High 0 Vss 0 Vss Straight Reverse Sharp Left

High Low High Low Vss 0 Vss 0 Reverse Straight Sharp Right

High Low Low High Vss 0 0 Vss Reverse Reverse Backward

You can see the datasheet of that IC for more details.

R

o

b

o

t

i

c

s

W

o

r

k

s

h

o

p

N

I

T

T

r

i

c

h

y

~ 21 ~

Algorithm for Line Follower

There are various line follower algorithms. The main use of the algorithm is to

move the robot on the line in a smooth fashion. Apart from the task, the algorithm also

depends on hardware including number of sensors, type of motors, chassis etc.

Same problem can be approached by different algorithms. Readers are

encouraged to develop their own algorithms.

R

o

b

o

t

i

c

s

W

o

r

k

s

h

o

p

N

I

T

T

r

i

c

h

y

~ 22 ~

Appendix:

1. Print ed Circuit Board

When making the circuit with the electronic parts of the resistors, the

capacitors, the transistors, the ICs and so on, it is necessary to connect the lead line of

each part appropriately. Also, each part must be fixed, too. The printed circuit board is

used to do the wiring among the parts and the fixation of the part.

Advantages:

Reliability and durability due to compact nature of the circuit especially needed

for mobile applications like robotics.

Easy debugging.

Large number of circuits can be made with a greater accuracy and at a cheap

cost.

Chances of loose connections get eliminated.

Disadvantages

Once the circuit is made on a PCB its layout cannot be changed.

PCB leads can burn at higher values of current rendering it useless for further

use

PCB designing can be a tedious and time consuming process.

R

o

b

o

t

i

c

s

W

o

r

k

s

h

o

p

N

I

T

T

r

i

c

h

y

Bottom

PCB

m View

B layou

:

Figure:

ut that w

PCBLayou

Figu

Figure:A

~ 2S ~

will be

utdesigne

ure:Photo

AfterSolde

given i

dbySoftw

o

ering

in Work

ware

kshop

R

o

b

o

t

i

c

s

W

o

r

k

s

h

o

p

N

I

T

T

r

i

c

h

y

Top VView:

Figure:

Figure

Mirrorim

:Afterpla

~ 24 ~

mageofB

acingallC

ottomLa

Compone

ayout

ents

R

o

b

o

t

i

c

s

W

o

r

k

s

h

o

p

N

I

T

T

r

i

c

h

y

Explanation of all compponents:

~ 2S ~

:

R

o

b

o

t

i

c

s

W

o

r

k

s

h

o

p

N

I

T

T

r

i

c

h

y

Bottom

Explan

1) Sen

m Layou

2) Bo

3) To

nation:

nsor PC

ut:

ottom Vi

op View

B

iew:

:

~ 26 ~

R

o

b

o

t

i

c

s

W

o

r

k

s

h

o

p

N

I

T

T

r

i

c

h

y

PWM

Pulse Wi

various fr

Th

frequency

Definitio

From abo

M

idth Modu

requencies

he periodic

y and duty

ons:

ove figure w

Time p

is calle

Frequ

On Tim

Off Ti

Duty C

Avera

ulation (PW

s (time peri

square wa

-cycle.

we can def

period (T)

ed as Time

ency (f):

me (Ton):

ime (Toff)

Cycle ():

ge Value(V

(Vm is val

WM) is a m

iod) or duty

ave has two

fine some t

): The min

e period.

=1/T

Time for

: = T-Ton

=(Ton)/T

Vavg): =V

lue of high

~ 27 ~

method to

y-cycles.

o levels (hi

terms.

nimum tim

which fun

Vm*

h voltage)

generate P

igh or low)

me after wit

ction is at

Periodic Sq

), with som

tch functio

high voltag

quare Wav

me constan

n repeats i

ge.

e of

t

tself

R

o

b

o

t

i

c

s

W

o

r

k

s

h

o

p

N

I

T

T

r

i

c

h

y

~ 28 ~

Examples

R

o

b

o

t

i

c

s

W

o

r

k

s

h

o

p

N

I

T

T

r

i

c

h

y

USE of

For

only has c

resistance

Th

1.

2.

No

pulse, hen

can be va

In

average v

We

PWM in

r example:

constant V

e in series

he drawbac

The resist

There will

ow By adj

nce the 'PW

aried, and h

other word

voltage (Va

e can desig

n DC Mot

: If a perso

Voltage sup

with the m

ks of this c

tance value

l be unnec

justing the

WM') i.e., t

hence the m

ds by varyi

avg) across

gn the syste

tor

on wants to

pply. As an

motor (As s

connection

e cannot be

essary pow

duty cycle

the time fra

motor spee

ing the dut

s the motor

em as show

~ 29 ~

o drive a D

n alternativ

shown in fi

n are:

e varied dy

wer loss ac

e of the sig

action for w

ed.

ty cycle we

r resulting

wn in the f

C motor w

ve for PWM

igure).

ynamically

ross the re

gnal (modu

which it is

e are gettin

in differen

following f

with variabl

M he can ad

(automati

esistor.

ulating the

s "on", the

ng different

nt speeds.

figure:

le speed bu

dd a variab

on is diffic

width of th

average po

t values of

ut he

ble

cult).

he

ower

f

R

o

b

o

t

i

c

s

W

o

r

k

s

h

o

p

N

I

T

T

r

i

c

h

y

~ Su ~

DC Motor Speed

Now

And

Thus

Advantages of PWM:

1. Here the switch is either on or off unlike normal regulation(using variable

resistance), so less power is wasted as heat and smaller heat-sinks can be

used.

2. Since no resistor is used, there is no power loss.

3. Can be easily automated by programmable control.

Disadvantages:

1. We require extra circuitry to implement PWM (in AVR we have in built

PWM-circuitry on chip).

2. Some authorities claim the pulsed power puts more stress on the DC motor

bearings and windings, shortening its life.

Implementation of PWM:

For developing PWM, we require two properties:

1. Time Period (T)

2. On-Time Period (Ton)

Implementation of PWM in microcontroller:

In microcontroller we use clock of several Mega Hz. Thus time of one clock

E.g. In ATmega 8 clock frequency is approximately 1 Mega Hz.

Tclk=1/(1M Hz)=1 s

Vavg

DC Motor Speed Vavg

Tclk =1/(clock frequency)

R

o

b

o

t

i

c

s

W

o

r

k

s

h

o

p

N

I

T

T

r

i

c

h

y

For imple

Nt=

OC

Ni=

cyc

ementation

= Number

CR= Numb

= It is a ind

cle.

When i

And if

n of PWM

of clock c

Nt=

ber of cloc

OCR

dex of cou

if Ni O

f Ni < O

in microco

cycles for o

=T/Tclk

ck cycles fo

R= Ton/T

unter, that c

OCR th

OCR th

~ S1 ~

ontroller w

one time pe

or On Time

Tclk

counts from

hen PW

hen PWM

we require t

eriod of PW

e of PWM

m Nt to zer

WM Outp

M Outp

these varia

WM

ro and Zero

put=Low

put=Hig

ables:

o to Nt in e

w

gh

each

R

o

b

o

t

i

c

s

W

o

r

k

s

h

o

p

N

I

T

T

r

i

c

h

y

You might also like

- Description: 2009 Dodge Journey SE 2009 Dodge Journey SEDocument312 pagesDescription: 2009 Dodge Journey SE 2009 Dodge Journey SEChristian Martinez100% (1)

- Critical Path Method FormularsDocument2 pagesCritical Path Method FormularsGimKonsultNo ratings yet

- Draft FRS Document For Preedective Maintenence-Revised 1.0Document25 pagesDraft FRS Document For Preedective Maintenence-Revised 1.0voru89No ratings yet

- 3 Channel IR Remote ControlDocument47 pages3 Channel IR Remote ControlMehmet GüçyetmezNo ratings yet

- Lab 1 Report (Venturi Meter)Document21 pagesLab 1 Report (Venturi Meter)Mathaneshan RajagopalNo ratings yet

- 7-Liquid Level ControlDocument83 pages7-Liquid Level ControlJaneider GomezNo ratings yet

- Pepsi Marketing MixDocument15 pagesPepsi Marketing Mixvishi12395% (20)

- Controlling A Brushed DC Motor With An ST6265C or ST6260C MCU-CD00003822Document14 pagesControlling A Brushed DC Motor With An ST6265C or ST6260C MCU-CD00003822dcesentherNo ratings yet

- FreeNAS 11.2Document370 pagesFreeNAS 11.2phong nguyen huuNo ratings yet

- Programmable Logic ArrayDocument6 pagesProgrammable Logic Arraysrividya0444No ratings yet

- MOSFET PA - PDF PDFDocument16 pagesMOSFET PA - PDF PDFDoDuyBacNo ratings yet

- Organizational Behavior - John MiddletonDocument129 pagesOrganizational Behavior - John MiddletonNisha71% (7)

- Dds 2016vmanualDocument11 pagesDds 2016vmanualalirisad aliNo ratings yet

- Line - Following - Robot 2019 09 11 12 49 PDFDocument3 pagesLine - Following - Robot 2019 09 11 12 49 PDFMegharaj GoudarNo ratings yet

- Active Disturbance Rejection Control for Nonlinear Systems: An IntroductionFrom EverandActive Disturbance Rejection Control for Nonlinear Systems: An IntroductionNo ratings yet

- Design of Traffic Light Controller Using Timer CircuitDocument3 pagesDesign of Traffic Light Controller Using Timer CircuitVinooja cNo ratings yet

- Project Report: Line Following RobotDocument12 pagesProject Report: Line Following RobotAhsan MuradNo ratings yet

- MICROPORCESSOR 8085 Lab ManualDocument53 pagesMICROPORCESSOR 8085 Lab ManualAjay PatilNo ratings yet

- Zapi h2 Pump Controller 969Document3 pagesZapi h2 Pump Controller 969SaveliyGovorkovNo ratings yet

- Project PPT Line Follower RobotDocument24 pagesProject PPT Line Follower Robotbhuvnesh33% (3)

- An Intelligent Line-Following Robot Project For Introductory Robot CoursesDocument7 pagesAn Intelligent Line-Following Robot Project For Introductory Robot CoursesAmla SingNo ratings yet

- Line Following: A Basic Tutorial: The IdeaDocument4 pagesLine Following: A Basic Tutorial: The IdeaRaman KumarNo ratings yet

- Line Follower Robot Using 8051 Micro ControllerDocument34 pagesLine Follower Robot Using 8051 Micro Controllerm.abdullah100% (2)

- RMCS 3002Document10 pagesRMCS 3002Dhiraj MistryNo ratings yet

- EMBEDDED BASED Automatic AUDITORIUM CONTROLLER 0TH REVDocument36 pagesEMBEDDED BASED Automatic AUDITORIUM CONTROLLER 0TH REVspringsource100% (1)

- Injector PWM ModificationDocument6 pagesInjector PWM Modificationpablo j vargas100% (1)

- 3-30v 3A Power Supply Circuit ManualDocument12 pages3-30v 3A Power Supply Circuit ManualRavindra ParabNo ratings yet

- JYQD-V7.3E2 Brushless DC Motor Driver Board: Application GuidelinesDocument3 pagesJYQD-V7.3E2 Brushless DC Motor Driver Board: Application Guidelinesluis angel alvarez camposNo ratings yet

- 3-Wire LCD Driver For CCS PIC C CompilerDocument6 pages3-Wire LCD Driver For CCS PIC C CompilerJonathan LazoNo ratings yet

- CST231 Test 1 1314Document2 pagesCST231 Test 1 1314Adron LimNo ratings yet

- Micro Controller and Embedded Systems (Revised)Document2 pagesMicro Controller and Embedded Systems (Revised)Ashok ShahNo ratings yet

- The Simplest Way To Examine The Advantages and Disadvantages of RISC Architecture Is by Contrasting It With ItDocument11 pagesThe Simplest Way To Examine The Advantages and Disadvantages of RISC Architecture Is by Contrasting It With ItsaadawarNo ratings yet

- 6.voice Integrated Speed and Direction Control For DC MotorDocument4 pages6.voice Integrated Speed and Direction Control For DC MotorRamsathayaNo ratings yet

- Course Code: CSE360 Course Title: Computer Architecture Section: 02 Project Title: Suggest and Design A Minimal CPU Group NumberDocument7 pagesCourse Code: CSE360 Course Title: Computer Architecture Section: 02 Project Title: Suggest and Design A Minimal CPU Group NumberrimonNo ratings yet

- CMOS RF Circuit Design Question BankDocument2 pagesCMOS RF Circuit Design Question BankRanidhanuNo ratings yet

- 651-M Rev-2.0Document34 pages651-M Rev-2.0not_only_naughtyNo ratings yet

- RC Phase Shift Oscillator Full DerivationDocument12 pagesRC Phase Shift Oscillator Full DerivationPranav Itraj0% (1)

- 5 Channel IR Remote Control System Using MicrocontrollerDocument4 pages5 Channel IR Remote Control System Using MicrocontrollerAbd-e-Munaf KalimeeNo ratings yet

- Zhao. Space Vector PWM Control of Dual Three-Phase Induction Machine Using Vector Space DecompositionDocument10 pagesZhao. Space Vector PWM Control of Dual Three-Phase Induction Machine Using Vector Space DecompositionAnonymous 1D3dCWNcNo ratings yet

- Tripping Sequence Recorder Cum IndicatorDocument7 pagesTripping Sequence Recorder Cum IndicatormahbubunnisaNo ratings yet

- ARM Cortex M3 Based Collision Detection SystemDocument3 pagesARM Cortex M3 Based Collision Detection SystemseventhsensegroupNo ratings yet

- Generating PWM With PIC Microcontroller - MikroC ProDocument3 pagesGenerating PWM With PIC Microcontroller - MikroC Proemilfrancu100% (1)

- Sample Question Paper Digital Communication SystemsDocument4 pagesSample Question Paper Digital Communication Systemspawan_32No ratings yet

- Question Bank SensorsDocument2 pagesQuestion Bank SensorsJasmine Kaur ButtarNo ratings yet

- SPEED CHECKER FOR HI-WAsYSDocument26 pagesSPEED CHECKER FOR HI-WAsYSAbhinav KumaarNo ratings yet

- UNIT-I Digital System DesignDocument28 pagesUNIT-I Digital System DesignNarasimha Murthy YayavaramNo ratings yet

- Arduino CNC Controller For ESTLCAMDocument10 pagesArduino CNC Controller For ESTLCAMglamuraNo ratings yet

- Practical 6: AIM: Study The Operation and Maintenance of Ups. UPSDocument2 pagesPractical 6: AIM: Study The Operation and Maintenance of Ups. UPSVasundharaNo ratings yet

- Multiple Transformers Oil Temperature Monitoring With Automatic CircuitDocument25 pagesMultiple Transformers Oil Temperature Monitoring With Automatic CircuitPrem Narayan Singh100% (1)

- AmplitronDocument7 pagesAmplitronTalat TürkaslanNo ratings yet

- Reverse CAR Parking: Aec J Component Review - 2Document16 pagesReverse CAR Parking: Aec J Component Review - 2kanthan100% (1)

- New Generation Polling Method Using RFDocument10 pagesNew Generation Polling Method Using RFEnoch IsraelNo ratings yet

- Stair Climbing Robot: Ayman Homadi, Electrical EngineeringDocument42 pagesStair Climbing Robot: Ayman Homadi, Electrical EngineeringgyandevNo ratings yet

- Analog Line FollowerDocument8 pagesAnalog Line FollowerRichard ArturoNo ratings yet

- Electrical and Electronics Lab Manual For Mechanical EngineeringDocument21 pagesElectrical and Electronics Lab Manual For Mechanical EngineeringSreerag Kunnathu SugathanNo ratings yet

- Pozyx - Tutorial 1 Ready To RangeDocument8 pagesPozyx - Tutorial 1 Ready To RangeMarsala NistoNo ratings yet

- Unit-4 PPT. Embedded Systems by SuryaDocument34 pagesUnit-4 PPT. Embedded Systems by SuryaAnonymous 3yqNzCxtTz100% (1)

- EMBEDDED BASED Automatic AUDITORIUM CONTROLLER 0TH REVDocument14 pagesEMBEDDED BASED Automatic AUDITORIUM CONTROLLER 0TH REVspringsource100% (1)

- Smart Stick For Blind Man: Nitish Sukhija, Shruti Taksali, Mohit Jain and Rahul KumawatDocument8 pagesSmart Stick For Blind Man: Nitish Sukhija, Shruti Taksali, Mohit Jain and Rahul KumawatE-zat IlmanNo ratings yet

- Algorithm For Line Follower Robots To Follow Critical Paths With Minimum Number of SensorsDocument10 pagesAlgorithm For Line Follower Robots To Follow Critical Paths With Minimum Number of SensorsEdiNo ratings yet

- Line Maze Solving RobotDocument18 pagesLine Maze Solving RobotAsitha Kulasekera0% (1)

- Non Programmable Line Follower RobotDocument27 pagesNon Programmable Line Follower RobotAsish Kumar Sharma100% (1)

- Automatic Land Mine Detection and Sweeper Robot Using MicrocontrollerDocument8 pagesAutomatic Land Mine Detection and Sweeper Robot Using Microcontrollersrujana reddyNo ratings yet

- Research Report - CEPDocument3 pagesResearch Report - CEPFahad AliNo ratings yet

- Line Maze Solving RobotDocument10 pagesLine Maze Solving Robottcteh86No ratings yet

- Project ReportDocument10 pagesProject ReportchaitanyaNo ratings yet

- Evaluation of Kinematic Walker For Domestic Duties: Hansika Surenthar, Akshayaa Rajeswari, Mr.J.GurumurthyDocument5 pagesEvaluation of Kinematic Walker For Domestic Duties: Hansika Surenthar, Akshayaa Rajeswari, Mr.J.GurumurthySubu ManiNo ratings yet

- Hindustan Coca Cola Beverages Pvt. LTDDocument13 pagesHindustan Coca Cola Beverages Pvt. LTDRahul GuptaNo ratings yet

- DrainageDocument2 pagesDrainageRahul GuptaNo ratings yet

- Honda Final Project PresentationDocument30 pagesHonda Final Project PresentationRahul GuptaNo ratings yet

- Market Segmentation and TargetingDocument23 pagesMarket Segmentation and TargetingRahul GuptaNo ratings yet

- AVRDocument79 pagesAVRPrasenjit SahaNo ratings yet

- Health: Needs of Good HealthDocument6 pagesHealth: Needs of Good HealthRahul GuptaNo ratings yet

- SWOT A TutorialDocument5 pagesSWOT A TutorialRahul GuptaNo ratings yet

- SWOT Analysis of Honda CityDocument2 pagesSWOT Analysis of Honda CityRahul GuptaNo ratings yet

- Create Resume Word 2007Document3 pagesCreate Resume Word 2007Bozz BostonNo ratings yet

- Software Download ManualDocument10 pagesSoftware Download Manualcidcam100% (2)

- DGF PIPERACK - CALC-commentsDocument81 pagesDGF PIPERACK - CALC-commentsAhmed MohamedNo ratings yet

- Fake ReviewDocument6 pagesFake ReviewHarshal PimpalshendeNo ratings yet

- Basic Data Science Interview QuestionsDocument18 pagesBasic Data Science Interview QuestionsRamesh kNo ratings yet

- Research Methodology Template: Topic ObjectivesDocument4 pagesResearch Methodology Template: Topic ObjectivesChristopher RajNo ratings yet

- Chapter11 PDFDocument88 pagesChapter11 PDFShajit KumarNo ratings yet

- High Speed Harmonic Drive GearingDocument3 pagesHigh Speed Harmonic Drive GearingMohanraj SelvakumarNo ratings yet

- TBA 1013 Assignment 1 SEM 2 2010/2011Document3 pagesTBA 1013 Assignment 1 SEM 2 2010/2011Zafiera ZukriNo ratings yet

- Manufacturing Engineering II Chapter 1.1Document23 pagesManufacturing Engineering II Chapter 1.1Layike Alemayehu100% (1)

- Data SheetDocument5 pagesData SheetMindSet MarcosNo ratings yet

- ABC's of Component TestingDocument17 pagesABC's of Component TestingDee RajaNo ratings yet

- Shivani Mehan - ResumeDocument1 pageShivani Mehan - ResumeShivani MehanNo ratings yet

- Qip Ice 16 Ignition - SystemsDocument60 pagesQip Ice 16 Ignition - SystemsAjay KumarNo ratings yet

- Segmented Shaft Seal Brochure Apr 08Document4 pagesSegmented Shaft Seal Brochure Apr 08Zohaib AnserNo ratings yet

- MM 1Document6 pagesMM 1Rana Naveed0% (1)

- Ibm Rs G8124eDocument40 pagesIbm Rs G8124edanibrbNo ratings yet

- SFR/U2955: Advanced Power MOSFETDocument7 pagesSFR/U2955: Advanced Power MOSFETStuxnetNo ratings yet

- Serie T4 PDFDocument17 pagesSerie T4 PDFRené Isaac Martínez OlivaNo ratings yet

- Chapter - 3 Information SecurityDocument94 pagesChapter - 3 Information SecurityJebesaNo ratings yet

- O RAN - WG3.E2SM RC R003 v04.00Document413 pagesO RAN - WG3.E2SM RC R003 v04.00animesh.vermaNo ratings yet

- Dropsa Catalog Progressive Dividers Smo SMXDocument92 pagesDropsa Catalog Progressive Dividers Smo SMXRICARDO MAMANI GARCIANo ratings yet

- MEL 3020 Kinematics and Dynamics of Machines: Week 7: Gear TrainsDocument40 pagesMEL 3020 Kinematics and Dynamics of Machines: Week 7: Gear TrainsRavi VermaNo ratings yet

- Euro 50 Tripod Ansys-Calculation4Document12 pagesEuro 50 Tripod Ansys-Calculation4HẬU Nguyễn NhưNo ratings yet

- Burnishing Is A Process by Which A Smooth Hard Tool (UsingDocument9 pagesBurnishing Is A Process by Which A Smooth Hard Tool (UsingΒασίλης ΜπουντιούκοςNo ratings yet