Professional Documents

Culture Documents

Study of Linear Measuring Instruments: Qis College of Engg. & Tech.:Ongole, A.P. Metrology Lab

Uploaded by

Anand BabuOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Study of Linear Measuring Instruments: Qis College of Engg. & Tech.:Ongole, A.P. Metrology Lab

Uploaded by

Anand BabuCopyright:

Available Formats

QIS COLLEGE OF ENGG. & TECH.:ONGOLE,A.P.

METROLOGY LAB

STUDY OF LINEAR MEASURING INSTRUMENTS

Study of Linear Measuring Instruments

QIS COLLEGE OF ENGG. & TECH.:ONGOLE,A.P.

METROLOGY LAB

STUDY OF LINEAR MEASURING INSTRUMENTS

AIM:

To get acquainted with measuring instruments like Vernier Calipers, Micrometers, Dial Bore Gauge and Vernier height gauge.

APPARATUS:

Vernier Calipers, out side Micrometer, Inside Micrometer, Vernier height gauge. (a) VERNIER CALIPERS: The Vernier Calipers consists of two scales one is fixed and the other is movable. The fixed scale called main scale is calibrated on L-Shaped frame and carries a fixed jaw. The movable scale called Vernier Scale slides over the main scale and carries a movable jaw. The movable jaw carries measuring tip. When the two jaws are closed the zero of the Vernier Scale coincides with the zero of the main scale. For precise setting of the movable jaw an adjustment screw is provided. Also an arrangement is provided to lock the sliding scale on the fixed main scale.

USE: Vernier Calipers are employed for both internal and external measurements. It is generally used by closing the jaws on to the work surface and taking the readings from the main as well as the Vernier scale. To obtain the reading the number of divisions on the main scale is first read off. The Vernier scale is then examined to determine which of its division coincide or most coincident with a division on the main scale. 2

Study of Linear Measuring Instruments

QIS COLLEGE OF ENGG. & TECH.:ONGOLE,A.P.

METROLOGY LAB

PROCEDURE: Verify the number of divisions available on the Vernier. Also

observe, how many number of divisions of main scale divisions are equal to number of divisions on the Vernier. Least count or LC of the Vernier Where M.S.D V.S.D = Also L.C of the Vernier Example: Let the number of divisions on the Vernier are 50 and let us say these 50 divisions are coinciding with 49 divisions on the main scale. If each division on main scale is equal to 1 mm, then the L.C. of the Vernier Calipers may be obtained as follows: L.C = 1MSD - 1VSD = = = (b) MICROMETER: Most Engineering precision work has to be measured to a much greater accuracy than 0.02 mm, which is available with Vernier Calipers, to achieve interchangeability of component parts. To achieve this greater precision, measuring equipment of a greater accuracy and sensitivity must be used. Micrometer is one of the most common and most popular forms of measuring instrument for precise measure with 0.01 mm accuracy. Micrometers with 0.001 mm accuracy are also available. 3

Study of Linear Measuring Instruments

1 M.S.D. 1 V.S.D. = Main Scale Division

Vernier Scale Division

oneM SD No .ofdivision sonthevern ier

49 M.S.D L.C.

50 V.S.D 1 V.S.D = 1 M.S.D. 49 M .S .D 50

49 M .S .D 50

1 M .S .D = 0.02 mm. 50

QIS COLLEGE OF ENGG. & TECH.:ONGOLE,A.P.

METROLOGY LAB

PRINCIPLE OF MICROMETER: Micrometers work on the principle of screw and nut. When a screw is turned through nut by one revolution, it advances by one pitch distance. If the circumference of the screw is divided into number of equal parts say n its rotation through one division will cause the screw to advance through

Pitch length. n

Thus the minimum length that can be measured by such

Pitch . By reducing the pitch of the screw thread or by n

arrangement will be

increasing the number of divisions on the circumference of the screw the length value of one circumferential division can be reduced and accuracy of measurement can be increased considerably. CONSTRUCTION:

The outside micrometer has U-Shaped or C shaped frame. It holds all the micrometer parts together. The gap of the frame permits the maximum diameter or length of the job to be measured. It is generally made of steel, cast steel, malleable C.I or light alloy. It is desirable that the frame of the micrometer be provided with conveniently placed finger grips of heat insulating material.

Study of Linear Measuring Instruments

QIS COLLEGE OF ENGG. & TECH.:ONGOLE,A.P.

METROLOGY LAB

The micrometer has a fixed anvil protruding 3 mm from the left hand side of the frame. Another anvil known as movable anvil is provided on the front of the spindle. The anvils are accurately ground and lapped with its measuring faces flat and parallel to the spindle. The spindle engages with nut and it runs freely and smoothly throughout the length of its travel. There should be no backlash between the spindle screw and nut. Lock nut: A lock nut is provided on the micrometer spindle to lock it when the micrometer is at its correct reading, without altering the distance between the measuring faces. Sleeve or Barrel:The Sleeve is accurately divided and clearly marked in 0.5 mm division along its length which serves as a main scale. It is chrome plated and adjustable for zero setting. Thimble: The Thimble can be moved over the Sleeve. It has 50 equal to assure accurate measurement and to prevent too much pressure being applied to the micrometer.

PROCEDURE:

1. First of all set the micrometer to zero reading. For this rotate the thimble until both anvils touch each other. If the zero line on the thimble coincides with zero line on the Sleeve, error is zero. Otherwise adjust the Sleeve to make the error zero. 2. Rotate the thimble by 5 revolutions and observe the main scale reading. 3. Determine the pitch of the screw as No .of Re volutionso fthimble 4. Finally determine the least count L.C = No .ofdivision sonthethim ble

Pitch MainScale Re ading

Study of Linear Measuring Instruments

QIS COLLEGE OF ENGG. & TECH.:ONGOLE,A.P.

METROLOGY LAB

DIAL BORE GAUGE:

A gauge is a device which checks the actual dimension with true or standard value. A dial bore gauge is devised to inspect the bores of the work pieces. As shown in fig. it consists of a dial indicator and a measuring head. Measuring head consists of an anvil and a contact point. Measuring head must be must be allowed to enter in to the hole of the work piece to be checked and movement from the control but will transferred to the dial indicator showing the deviation from the standard. Anvils may be changed depending up on the size of the bore.

PROCEDURE:

1. Observe the cylinder bore and roughly estimate its diameter 2. Select the appropriate anvil and fix it to the measuring head.

Study of Linear Measuring Instruments

QIS COLLEGE OF ENGG. & TECH.:ONGOLE,A.P.

METROLOGY LAB

3. Set the dial indicator to zero reading with the help of outside micrometer. First set the micrometer to estimated bore diameter and lock the instrument at that position. Then insert the measuring head between the two anvils and adjust the bezel in such away that pointer shows zero reading. This procedure is known as datum point adjustment. 4. Hold the dial gauge vertical and place it in the bore of workpiece such that anvil and contact points touch the walls. 5. Note down the reading of the dial gauge. 6. It directly gives the bore diameter (c) VERNIER HEIGHT GAUGE: Vernier Height Gauge is similar to Vernier Calipers but in this instrument the graduated bar is held in a vertical position and it is used in conjunction with a surface plate.

Study of Linear Measuring Instruments

QIS COLLEGE OF ENGG. & TECH.:ONGOLE,A.P.

METROLOGY LAB

CONSTRUCTION: A Vernier Height Gauge consists of (i) (ii) base. (iii) (iv) (v) Vernier. USE: The Vernier Height Gauge is designed for accurate measurements and marking of vertical heights above a surface plate datum. It can also be used to measure differences in heights by taking the Vernier scale readings at each height and determining the difference by subtraction.

PROCEDURE:

A finely ground and lapped base. The base is massive and robust in construction to ensure rigidity and stability. A vertical graduated beam or column supported on a massive Attached to the beam is a sliding Vernier head carrying the Vernier Scale and clamping screw. An auxiliary head which is also attached to the beam above the sliding vernier head. It has fine adjusting and clamping screw. A measuring jaw or a scriber attached to the front of the sliding

1. Observe the number of divisions on the Vernier and corresponding divisions on the main scale. 2. Find out the L.C. of the Vernier height gauge similar to Vernier Calipers.

PRECAUTIONS:

1. Before using the instrument clean it by cleaning cloth. 2. Readings must be observed without parallax error. 3. The line of measurement must coincide with line of scale. 4. The measuring instrument must always be properly balanced in hand and held lightly in such away that only fingers handle the moving and adjusting screws.

Study of Linear Measuring Instruments

QIS COLLEGE OF ENGG. & TECH.:ONGOLE,A.P.

METROLOGY LAB

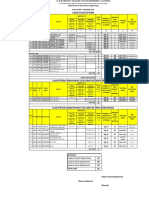

NOTE: By using the above instruments measure the external diameter and

S.NO.

M.S.R.

V.S.R. or P.S.R.

Total Reading (M.S.R. + V.S.R. X L.C.)

1 2 3 the height of the given work piece. Use the following table.

Average

RESULT:

Study of Linear Measuring Instruments

You might also like

- Experiment Measurement of Lengths, Heights, Diameters, Vernier CaliperDocument11 pagesExperiment Measurement of Lengths, Heights, Diameters, Vernier Caliperv sharvan kumar asst.prof(mech)No ratings yet

- Atm-1022 Mechanical Workshop Module 2 PDFDocument16 pagesAtm-1022 Mechanical Workshop Module 2 PDFsufisaifNo ratings yet

- JigDocument13 pagesJigJunaid YNo ratings yet

- Mechanical Measurement and Metrology PDFDocument2 pagesMechanical Measurement and Metrology PDFsuhas_SCEM0% (1)

- Architectural ConcreteDocument24 pagesArchitectural ConcreteSaud PathiranaNo ratings yet

- Financial Management 2E: Rajiv Srivastava - Dr. Anil Misra Solutions To Numerical ProblemsDocument5 pagesFinancial Management 2E: Rajiv Srivastava - Dr. Anil Misra Solutions To Numerical ProblemsParesh ShahNo ratings yet

- ENT 300 Individual Assessment-Personal Entrepreneurial CompetenciesDocument8 pagesENT 300 Individual Assessment-Personal Entrepreneurial CompetenciesAbu Ammar Al-hakimNo ratings yet

- Mechanical Measurement LaboratoryDocument24 pagesMechanical Measurement LaboratoryMahendra SinghNo ratings yet

- Lab ManualDocument19 pagesLab ManualAjij Mujawar100% (1)

- Unit 2 MetrologyDocument32 pagesUnit 2 MetrologyMuthuvel M83% (6)

- Metrology and Quality AssuranceDocument8 pagesMetrology and Quality Assurancehammad ghaffarNo ratings yet

- Metrology Lab Manual NewDocument41 pagesMetrology Lab Manual Newg venkatesh100% (1)

- MicrometerDocument15 pagesMicrometermythos1976No ratings yet

- Metrology and Measurements Lab PDFDocument65 pagesMetrology and Measurements Lab PDFGopal Krishan Sharma0% (1)

- Experiment 4Document3 pagesExperiment 4Arvind BhosaleNo ratings yet

- Metrology Lab ManualDocument33 pagesMetrology Lab ManualRachit_Goyal25_10No ratings yet

- Force MeasurementDocument18 pagesForce MeasurementKali DasNo ratings yet

- The Accuracy of Angle EncodersDocument9 pagesThe Accuracy of Angle EncodersatulNo ratings yet

- English 4 Twisted DrillDocument6 pagesEnglish 4 Twisted DrillBozkurt EkinNo ratings yet

- Roundness IDocument13 pagesRoundness Ibalasubramani_srinivNo ratings yet

- BME UNIT II MeasurementDocument55 pagesBME UNIT II MeasurementVivek Patel100% (1)

- Bore Gauge Manual PDFDocument2 pagesBore Gauge Manual PDFLU CK YNo ratings yet

- Dimensional Measurements: Group 22 MembersDocument12 pagesDimensional Measurements: Group 22 MemberscfellowNo ratings yet

- Straightness Measurement Using AutocollimatorDocument5 pagesStraightness Measurement Using Autocollimatorविशाल पुडासैनीNo ratings yet

- A Brief Introduction To The Measurement of Roundness and Spindle Error SeparationDocument12 pagesA Brief Introduction To The Measurement of Roundness and Spindle Error SeparationaralvoiNo ratings yet

- Metrology: ME3190 Machine Tools and MetrologyDocument64 pagesMetrology: ME3190 Machine Tools and MetrologySujit MuleNo ratings yet

- Lab 2 TurningDocument12 pagesLab 2 TurningLuqman HakimNo ratings yet

- QuickGuide Dial-Indicators PDFDocument4 pagesQuickGuide Dial-Indicators PDFAsyifatunSholihahNo ratings yet

- The Micrometer: V. Ryan © 2004 - 2009Document6 pagesThe Micrometer: V. Ryan © 2004 - 2009Joseph DizonNo ratings yet

- ErrorsDocument20 pagesErrorsAnthony LopesNo ratings yet

- Unit 2 Linear and Angular MeasurementDocument90 pagesUnit 2 Linear and Angular MeasurementVasanth Kumar33% (3)

- Profile ProjectorDocument25 pagesProfile Projectorrummanomar0% (2)

- Engineering Graphics: Course No. 4Document21 pagesEngineering Graphics: Course No. 4vic70r9No ratings yet

- Metrology 1CDocument44 pagesMetrology 1CRadhaMadhavNo ratings yet

- RoundnessDocument7 pagesRoundnessjacobian1810No ratings yet

- MetrologyDocument157 pagesMetrologyVishwajit HegdeNo ratings yet

- W-2119 & W-2120 Series: Parts Manual 823036ENDocument12 pagesW-2119 & W-2120 Series: Parts Manual 823036ENsolrac4371No ratings yet

- Lab Session: 1: Problem StatementDocument9 pagesLab Session: 1: Problem StatementMaria MeharNo ratings yet

- Lathe MachineDocument6 pagesLathe MachineJuno Eron TalamayanNo ratings yet

- Metrology and Quality Assurance Lab: Department of Mechanical EngineeringDocument7 pagesMetrology and Quality Assurance Lab: Department of Mechanical EngineeringAliNo ratings yet

- Analysis and Modeling of Roundness Error PDFDocument6 pagesAnalysis and Modeling of Roundness Error PDFCarlosQuelartNo ratings yet

- Geometric Dimensioning and TolerancingDocument6 pagesGeometric Dimensioning and TolerancingPedro LeosNo ratings yet

- AUTOCOLLIMATORDocument6 pagesAUTOCOLLIMATORAhmed Almujabber100% (1)

- Thread SpecificationDocument8 pagesThread Specificationsaravana perumal100% (1)

- Straightness Flatness Roundness CylindricityDocument7 pagesStraightness Flatness Roundness CylindricityChristopher Plume De ChineNo ratings yet

- MQA Lab ReportDocument15 pagesMQA Lab ReportMuhammad Waleed TariqNo ratings yet

- Unit 1 - Metrology Basics, Elements in Measurements & Line and End StandardsDocument80 pagesUnit 1 - Metrology Basics, Elements in Measurements & Line and End StandardsShayan ChowdaryNo ratings yet

- Indian Standard: Legal Metrology - Material Measures of LengthDocument9 pagesIndian Standard: Legal Metrology - Material Measures of LengthDiptiNo ratings yet

- ME 472 - Engineering Metrology and Quality Control: Linear and Angular MeasurementsDocument19 pagesME 472 - Engineering Metrology and Quality Control: Linear and Angular MeasurementsAtul GaurNo ratings yet

- ComparatorsDocument42 pagesComparatorsNaman Dave100% (2)

- Measurement 1Document16 pagesMeasurement 1FaIz FauziNo ratings yet

- Screw Thread MeasurementDocument55 pagesScrew Thread MeasurementMadhuNo ratings yet

- Me-331 Design of Machine Elements Unit Iv Design of Basic ElementsDocument25 pagesMe-331 Design of Machine Elements Unit Iv Design of Basic ElementsMuthuvel MNo ratings yet

- Outcomes: UnderstandDocument18 pagesOutcomes: UnderstandHundaol FekaduNo ratings yet

- MQA Lab Manual 2018-2019Document27 pagesMQA Lab Manual 2018-2019poluri manicharanNo ratings yet

- Metrology Lab Manual - BrijeshDocument23 pagesMetrology Lab Manual - BrijeshRohitGuptaNo ratings yet

- Metrology Lab ManualDocument36 pagesMetrology Lab Manualuvrsunil_kumar100% (2)

- Production Technoloy Lab 012110045519 1Document35 pagesProduction Technoloy Lab 012110045519 1raajeeradha@gmail.comNo ratings yet

- Experiment: 1 Measurement of Length, and Diameter by Vernier Caliper, Vernier Height Gauge, and MicrometerDocument51 pagesExperiment: 1 Measurement of Length, and Diameter by Vernier Caliper, Vernier Height Gauge, and Micrometerabeauty silungweNo ratings yet

- Metrology Lab Exercise2Document87 pagesMetrology Lab Exercise2Hailu Yimer TeferaNo ratings yet

- Vernier To ComparatorDocument78 pagesVernier To ComparatorAtul GaurNo ratings yet

- Study of Measuring Instruments and Gauges PDFDocument7 pagesStudy of Measuring Instruments and Gauges PDFRishabh HanseliaNo ratings yet

- Handbook of Mechanical and Materials EngineeringFrom EverandHandbook of Mechanical and Materials EngineeringRating: 5 out of 5 stars5/5 (4)

- Final DSY SUMER 21 TIME TABLEDocument1 pageFinal DSY SUMER 21 TIME TABLEAnand BabuNo ratings yet

- Wire EDM: Dielectric Liquid VoltageDocument12 pagesWire EDM: Dielectric Liquid VoltageAnand BabuNo ratings yet

- Dsy Iv Sem Load CalculationsDocument3 pagesDsy Iv Sem Load CalculationsAnand BabuNo ratings yet

- Study of Reduction Behaviour of Iron Ore Lumps A: BINAYAK MOHAPATRA (10504004) DHARANIDHAR PATRA (10504021)Document38 pagesStudy of Reduction Behaviour of Iron Ore Lumps A: BINAYAK MOHAPATRA (10504004) DHARANIDHAR PATRA (10504021)Anand BabuNo ratings yet

- Some Important Terms:: Isometric Axes, Lines and PlanesDocument10 pagesSome Important Terms:: Isometric Axes, Lines and PlanesAnand BabuNo ratings yet

- Rollers and Slip GaugesDocument6 pagesRollers and Slip GaugesAnand Babu50% (2)

- Tool Makers MicroscopeDocument7 pagesTool Makers MicroscopeAnand Babu100% (2)

- Gear MeasurementDocument5 pagesGear MeasurementAnand Babu100% (1)

- Profile ProjectorDocument6 pagesProfile ProjectorAnand Babu100% (1)

- Measurement of Surface FinishDocument6 pagesMeasurement of Surface FinishAnand Babu100% (5)

- Machine Tool TestingDocument9 pagesMachine Tool TestingAnand Babu70% (10)

- Metrology Lab ManualDocument1 pageMetrology Lab ManualAnand BabuNo ratings yet

- Lab Report SBK Sem 3 (Priscilla Tuyang)Document6 pagesLab Report SBK Sem 3 (Priscilla Tuyang)Priscilla Tuyang100% (1)

- SreenuDocument2 pagesSreenuSubbareddy NvNo ratings yet

- Understanding PTS Security PDFDocument37 pagesUnderstanding PTS Security PDFNeon LogicNo ratings yet

- General Chemistry 2 Q1 Lesson 5 Endothermic and Exotheric Reaction and Heating and Cooling CurveDocument19 pagesGeneral Chemistry 2 Q1 Lesson 5 Endothermic and Exotheric Reaction and Heating and Cooling CurveJolo Allexice R. PinedaNo ratings yet

- Modern School For SaxophoneDocument23 pagesModern School For SaxophoneAllen Demiter65% (23)

- Disclosure To Promote The Right To InformationDocument11 pagesDisclosure To Promote The Right To InformationnmclaughNo ratings yet

- Bad Memories Walkthrough 0.52Document10 pagesBad Memories Walkthrough 0.52Micael AkumaNo ratings yet

- 2016 IT - Sheilding Guide PDFDocument40 pages2016 IT - Sheilding Guide PDFlazarosNo ratings yet

- Production of Bioethanol From Empty Fruit Bunch (Efb) of Oil PalmDocument26 pagesProduction of Bioethanol From Empty Fruit Bunch (Efb) of Oil PalmcelestavionaNo ratings yet

- MEd TG G07 EN 04-Oct Digital PDFDocument94 pagesMEd TG G07 EN 04-Oct Digital PDFMadhan GanesanNo ratings yet

- Smart Gas Leakage Detection With Monitoring and Automatic Safety SystemDocument4 pagesSmart Gas Leakage Detection With Monitoring and Automatic Safety SystemYeasin Arafat FahadNo ratings yet

- Cam 18 Test 3 ListeningDocument6 pagesCam 18 Test 3 ListeningKhắc Trung NguyễnNo ratings yet

- Steel Design Fourth Edition William T Segui Solution Manual 1Document11 pagesSteel Design Fourth Edition William T Segui Solution Manual 1RazaNo ratings yet

- List of Some Common Surgical TermsDocument5 pagesList of Some Common Surgical TermsShakil MahmodNo ratings yet

- Module 1 Lesson 2Document31 pagesModule 1 Lesson 2Angela Rose BanastasNo ratings yet

- Phylogeny Practice ProblemsDocument3 pagesPhylogeny Practice ProblemsSusan Johnson100% (1)

- Binge Eating Disorder ANNADocument12 pagesBinge Eating Disorder ANNAloloasbNo ratings yet

- Logiq v12 SM PDFDocument267 pagesLogiq v12 SM PDFpriyaNo ratings yet

- Top Activist Stories - 5 - A Review of Financial Activism by Geneva PartnersDocument8 pagesTop Activist Stories - 5 - A Review of Financial Activism by Geneva PartnersBassignotNo ratings yet

- Chapter 4 - Basic ProbabilityDocument37 pagesChapter 4 - Basic Probabilitynadya shafirahNo ratings yet

- Introduction - Livspace - RenoDocument12 pagesIntroduction - Livspace - RenoMêghnâ BîswâsNo ratings yet

- Cetie Guide No1 EngDocument55 pagesCetie Guide No1 EngJose Manuel Sepulveda RomanNo ratings yet

- PE MELCs Grade 3Document4 pagesPE MELCs Grade 3MARISSA BERNALDONo ratings yet

- Hand Out Fire SurpressDocument69 pagesHand Out Fire SurpressSeptiawanWandaNo ratings yet

- Regional Manager Business Development in Atlanta GA Resume Jay GriffithDocument2 pagesRegional Manager Business Development in Atlanta GA Resume Jay GriffithJayGriffithNo ratings yet

- Concrete Repair Manual (2017)Document59 pagesConcrete Repair Manual (2017)Fernando EscriváNo ratings yet

- Civ Beyond Earth HotkeysDocument1 pageCiv Beyond Earth HotkeysExirtisNo ratings yet