Professional Documents

Culture Documents

Personal Protective Equipment Selection Chart: Appendix A

Uploaded by

Mangala RaniOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Personal Protective Equipment Selection Chart: Appendix A

Uploaded by

Mangala RaniCopyright:

Available Formats

University of North Carolina at Chapel Hill

APPENDIX A

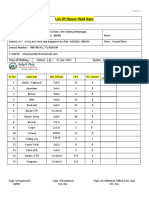

PERSONAL PROTECTIVE EQUIPMENT SELECTION CHART

EYE AND FACE PROTECTION

Source IMPACT-Chipping, grinding, machining, masonry work, woodworking, sawing, drilling, chiseling, powered fastening, riveting, and sanding. HEAT-Furnace operations, pouring, casting, hot dipping, and welding Assessment of Hazard Flying fragments, objects, large chips, particles, sand, dirt, etc. Hot sparks Protection Spectacles with side protection, goggles, face shields. See notes(1), (3), (5), (6), (10). For severe exposure, use face shield. Face shields, goggles, spectacles with side protection. For severe exposure use face shield. See notes (1), (2), (3). Face shields worn over goggles. See notes (1), (2), (3). Screen face shields, reflective face shields. See notes (1), (2), (3). Goggles, eyecup and cover types. For severe exposure, use face shield. See notes (3), (11). Special-purpose goggles. Goggles, eyecup and cover types. See note (8). Welding helmets or welding shields. Typical shades: 10-14. See notes (9), (12) Welding goggles or welding face shield. Typical shades: gas welding4-8, cutting 3-6, brazing 3-4. See note (9) Spectacles or welding face-shield. Typical shades, 1.5-3. See notes (3),(9) Spectacles with shaded or specialpurpose lenses, as suitable. See notes (9), (10).

Splash from molten metals High temperature exposure CHEMICALS-Acid and chemicals handling, degreasing, plating. Splash

DUST- Woodworking, buffing, general dusty conditions. LIGHT and/or RADIATIONWelding: Electric arc Welding: Gas

Irritating mists Nuisance dust Optical radiation Optical radiation

Cutting, Torch brazing, Torch soldering Glare

Optical radiation Poor vision

Notes to Eye and Face Protection Selection Chart: (1) Care should be taken to recognize the possibility of multiple and simultaneous exposure to a variety of hazards. Adequate protection against the highest level of each of the hazards should be provided. Protective devices do not provide unlimited protection. (2) Operations involving heat may also involve light radiation. As required by the standard, protection from both hazards must be provided. (3) Face shields should only be worn over primary eye protection (spectacles or goggles). (4) As required by the standard, filter lenses must meet the requirements for shade designations in 1910.133(a)(5). Tinted and shaded lenses are not filter lenses unless they are marked or identified as such. (5) As required by the standard, persons whose vision requires the use of prescription (Rx) lenses must wear either protective devices fitted with prescription (Rx) lenses or protective devices designed to be worn over regular prescription (Rx) eye wear. (6) Wearers of contact lenses must also wear appropriate eye and face protection devices in a hazardous environment. It should be recognized that dusty and/or chemical environments may represent an additional hazard to contact lens wearers. (7) Caution should be exercised in the use of metal frame protective devices in electrical hazard areas. (8) Atmospheric conditions and the restricted ventilation of the protector can cause lenses to fog. Frequent cleansing may be necessary. (9) Welding helmets or face shields should be used only over primary eye protection (spectacles or goggles). (10) Non-side shield spectacles are available for frontal protection only, but are not acceptable eye protection for the sources and operations listed for ``impact.'' (11) Ventilation should be adequate, but well protected from splash entry. Eye and face protection should be designed and used so that it provides both adequate ventilation and protects the wearer from splash entry. (12) Protection from light radiation is directly related to filter lens density. See note (4). Select the darkest shade that allows task performance.

January 1998 4-12-1

University of North Carolina at Chapel Hill

Head Hazards

hazard head injury job working below others using tools or materials that could fall working under machinery where materials could fall working on energized electrical equipment PPE Required hard hat

electrical

class A helmets for protection from low voltage conductors (less than 2,200 volts) class B helmets for protection from high voltage conductors (less than 20,000 volts) class C helmets should not be used around electrical hazards

Hand Hazards

hazard chemicals job chemical handling operations that may result in skin exposure cleaning with chemicals chemical spill clean up working around hot materials or flames welding handling materials at extremely low materials material handling glass handling sheet metal operations work that involves knives or razor blades job carrying or handling materials that could be dropped construction, plumbing, masonry, carpentry metal workers, machinists shipping and receiving, storerooms material handling carts, bulk rolls, heavy pipes construction sites where nails, screws, tacks, wires scrap metal could be stepped on chemical spill clean up work around electrically energized parts PPE Required disposable gloves: vinyl, nitrile, latex, polyethylene reusable: butyl, rubber, neoprene, PVA Kevlar, Zetex

heat

cold cuts, abrasions, or punctures

cryogenic leather, metal mesh, Kevlar, combination fabric and metal

Foot Hazards

hazard handling materials that could be dropped PPE Required safety shoes and boots with impact protection

working around heavy objects or equipment that could crush feet puncture

safety shoes and boots with compression protection safety shoes and boots with puncture protection neoprene or rubber boots footwear for protection against electrical hazards

chemicals Electrical

January 1998 4-12-2

You might also like

- Philippine Police Report Suicide InvestigationDocument2 pagesPhilippine Police Report Suicide InvestigationPAUL ALDANA82% (34)

- Fy16 SH 29639 Sh6 ConfinedSpacesPPEDocument64 pagesFy16 SH 29639 Sh6 ConfinedSpacesPPEbenonNo ratings yet

- B1 Speaking Test Examiner Prompts Sample PDFDocument16 pagesB1 Speaking Test Examiner Prompts Sample PDFAlejandro FlorezNo ratings yet

- Cyber Security 2017Document8 pagesCyber Security 2017Anonymous i1ClcyNo ratings yet

- 2-Personal Protective EquipmentDocument16 pages2-Personal Protective EquipmentAhmed AbbasNo ratings yet

- Practical Work Book For Health Safety and EnvironmentDocument69 pagesPractical Work Book For Health Safety and EnvironmentAreejNo ratings yet

- DM-PH&SD-P4-TG09 - (Guidelines For Personal Protective Equipment-Eye and Face Protection) PDFDocument7 pagesDM-PH&SD-P4-TG09 - (Guidelines For Personal Protective Equipment-Eye and Face Protection) PDFdemie figueroaNo ratings yet

- Personal Protective Equipment Day 2Document37 pagesPersonal Protective Equipment Day 2OsamaAlaasamNo ratings yet

- HSE welding safety guideDocument11 pagesHSE welding safety guideDikaAfriandiNo ratings yet

- Health and Safety: November 10Document10 pagesHealth and Safety: November 10nikz17No ratings yet

- EPAS 8 Quarter 1 - Week 5-6Document12 pagesEPAS 8 Quarter 1 - Week 5-6manolito mulatNo ratings yet

- Protect Your Eyes and Face at WorkDocument27 pagesProtect Your Eyes and Face at Workarora_sonia037No ratings yet

- Personal Protective Equipment: Office of Environmental, Health, & SafetyDocument70 pagesPersonal Protective Equipment: Office of Environmental, Health, & SafetyPedro SousaNo ratings yet

- Bosh PpeDocument86 pagesBosh PpekathleenbayotNo ratings yet

- Lab Report # 01: Submitted To: Engr. Faraz Hussain Submitted By: Usman Liaqat 17MME-S1-313Document9 pagesLab Report # 01: Submitted To: Engr. Faraz Hussain Submitted By: Usman Liaqat 17MME-S1-313Usman GujjarNo ratings yet

- Instruction ManualDocument40 pagesInstruction ManualFORYOUMANo ratings yet

- Safety Requirement in Marine EngineeringDocument24 pagesSafety Requirement in Marine EngineeringR.W. SaputraNo ratings yet

- Niranjanaaradhya 1Document16 pagesNiranjanaaradhya 1Akash NNo ratings yet

- Power Plant Enginnering Lab Sheet. 2 PDFDocument2 pagesPower Plant Enginnering Lab Sheet. 2 PDFMd. Mehadi Hasan Shamim 171-33-422No ratings yet

- Personal Protective Equipment (PPE)Document62 pagesPersonal Protective Equipment (PPE)Krisanta Joy CruzNo ratings yet

- Eye and Face ProtectionDocument34 pagesEye and Face ProtectionDriss EddeniaNo ratings yet

- M.Tech. AMC Lab ManualDocument26 pagesM.Tech. AMC Lab ManualupenderNo ratings yet

- PPE Guide for Protecting WorkersDocument58 pagesPPE Guide for Protecting WorkersLemuel Petronio100% (1)

- Sop 004 PpeDocument5 pagesSop 004 PpeShahul ValeedNo ratings yet

- Head Protection: Identifying HazardsDocument1 pageHead Protection: Identifying HazardsElton HasanajNo ratings yet

- Construction Manpower Safety ReportDocument52 pagesConstruction Manpower Safety ReportAnjali Krystal Nosa Elloso100% (3)

- Daily Tool Box TalkDocument55 pagesDaily Tool Box Talkmehtab uddin100% (1)

- Saf102-Lecture 3: Basic Safety in ConstructionDocument8 pagesSaf102-Lecture 3: Basic Safety in ConstructionLin VictoriaNo ratings yet

- 09 Personal Protective Equipment (CST)Document27 pages09 Personal Protective Equipment (CST)LEMUEL CANADANo ratings yet

- Personal Protective Equipment-Ppe: Jindal Saw Limited Bellary by J V Shivaraju-EhsDocument41 pagesPersonal Protective Equipment-Ppe: Jindal Saw Limited Bellary by J V Shivaraju-EhsPrashanth JeerNo ratings yet

- Presentation1 AutosavedDocument18 pagesPresentation1 AutosavedMarissa MarianoNo ratings yet

- WeldingDocument2 pagesWeldingGhodke ParmeshwarNo ratings yet

- 1 Electric Gas Welding SafetyDocument34 pages1 Electric Gas Welding SafetyPrincess Mae DesaculaNo ratings yet

- Lecture-2.1 - GikDocument24 pagesLecture-2.1 - GikAffan KhanNo ratings yet

- Workshop TechnologyDocument24 pagesWorkshop TechnologyOlumide Sikiru AdekunleNo ratings yet

- Welder MIG160Document15 pagesWelder MIG160MatiasNo ratings yet

- Eye and Face Protection PFDocument31 pagesEye and Face Protection PFAwalludin Pandu NegaraNo ratings yet

- Ppe American STDSDocument30 pagesPpe American STDSChetana HamsagarNo ratings yet

- Handy Plasma 125: Plasma Arc Cutting Package - P/N 37884 115V 60HzDocument24 pagesHandy Plasma 125: Plasma Arc Cutting Package - P/N 37884 115V 60Hzbouriahi hassaneNo ratings yet

- ©consultnet Limited 1Document132 pages©consultnet Limited 1John DenverNo ratings yet

- Black and Decker 0900766b8119574aDocument11 pagesBlack and Decker 0900766b8119574aAmmi HamzahNo ratings yet

- EPP-200 Power Supply 0558004676Document56 pagesEPP-200 Power Supply 0558004676Liviu HogeaNo ratings yet

- PPE: Construction Occupational Safety & Health Course on Personal Protective EquipmentDocument57 pagesPPE: Construction Occupational Safety & Health Course on Personal Protective EquipmentRalph John ColomaNo ratings yet

- Safe Welding Practices: Smaw Quarter 1 Week 5 Module 5Document22 pagesSafe Welding Practices: Smaw Quarter 1 Week 5 Module 5Jessel Mejia Onza100% (1)

- JSA FOR WELDING, GRINDING & HEIGHT WORKDocument15 pagesJSA FOR WELDING, GRINDING & HEIGHT WORKGuptaNo ratings yet

- Viper - 2500s 2Document24 pagesViper - 2500s 2johnamer90No ratings yet

- 10-TBT-07 Eye Injury Protection Week-7Document4 pages10-TBT-07 Eye Injury Protection Week-7saad aliNo ratings yet

- M2-Lesson 3Document5 pagesM2-Lesson 3zyx xyzNo ratings yet

- Group 04: MUHAMMAD UMAIR MUNIR (02-132202-029) MUHAMMAD UMER (02-132202-009) MUHAMMAD AHSAN (02-132202-016)Document54 pagesGroup 04: MUHAMMAD UMAIR MUNIR (02-132202-029) MUHAMMAD UMER (02-132202-009) MUHAMMAD AHSAN (02-132202-016)khizgaming worldNo ratings yet

- WELDINGDocument12 pagesWELDINGAsnel TiffaNo ratings yet

- ISE Mod 2Document35 pagesISE Mod 2Atul DrawsNo ratings yet

- Welding Safety - GeneralDocument3 pagesWelding Safety - GeneralrkqaqcweldingNo ratings yet

- Da300p ManualDocument85 pagesDa300p Manualkazambo78No ratings yet

- Manual Destornillador 90600008, LI2000Document28 pagesManual Destornillador 90600008, LI2000alec_james_22No ratings yet

- Mig 250c ManualDocument18 pagesMig 250c ManualBondan PratamaNo ratings yet

- Presentation - Health and Safety - PPEDocument14 pagesPresentation - Health and Safety - PPESayed YusufNo ratings yet

- Demo 1Document27 pagesDemo 1Ferl Joy SedicolNo ratings yet

- PPE Standard Training GuideDocument56 pagesPPE Standard Training Guidehadeed shaikh100% (2)

- CES NC II LMG9 p110-137Document28 pagesCES NC II LMG9 p110-137Rojen SabileNo ratings yet

- 8 Ppe 1232217341605977 3Document41 pages8 Ppe 1232217341605977 3Rey EbasanNo ratings yet

- Personal Protective EquipmentDocument18 pagesPersonal Protective EquipmentBryan Jagroop100% (1)

- Corrosion and Corrosion Protection of Wind Power Structures in Marine Environments: Volume 2: Corrosion Protection MeasuresFrom EverandCorrosion and Corrosion Protection of Wind Power Structures in Marine Environments: Volume 2: Corrosion Protection MeasuresNo ratings yet

- Find leisure in nature's simple pleasuresDocument1 pageFind leisure in nature's simple pleasuresbutterfliesika87No ratings yet

- 008 - BI Pemahaman Bahagian ADocument7 pages008 - BI Pemahaman Bahagian AFaizah IsmailNo ratings yet

- Collective NounsDocument1 pageCollective NounsMangala RaniNo ratings yet

- Idiom Worksheet 3Document2 pagesIdiom Worksheet 3Ed Cartagena-CruzNo ratings yet

- Vocabulary Lists for Occupations, Animals, Hobbies and PlantsDocument7 pagesVocabulary Lists for Occupations, Animals, Hobbies and PlantsMangala RaniNo ratings yet

- Speaking TestDocument3 pagesSpeaking TestMangala RaniNo ratings yet

- Find leisure in nature's simple pleasuresDocument1 pageFind leisure in nature's simple pleasuresbutterfliesika87No ratings yet

- HandoutDocument10 pagesHandoutRogini ThevathasNo ratings yet

- The Living Photograph QuestionsDocument6 pagesThe Living Photograph QuestionsSirMustafa Kamal0% (1)

- Fighters LineDocument3 pagesFighters LineMangala RaniNo ratings yet

- Questions TeachersDocument2 pagesQuestions TeachersMangala RaniNo ratings yet

- Fighters LineDocument3 pagesFighters LineMangala RaniNo ratings yet

- NoticeDocument1 pageNoticeMangala RaniNo ratings yet

- The Living PhotographDocument1 pageThe Living PhotographMangala RaniNo ratings yet

- PT 1 Yearend 2014Document14 pagesPT 1 Yearend 2014Mangala RaniNo ratings yet

- HandoutDocument10 pagesHandoutRogini ThevathasNo ratings yet

- Collective NounsDocument1 pageCollective NounsMangala RaniNo ratings yet

- PT 1 Yearend 2014Document14 pagesPT 1 Yearend 2014Mangala RaniNo ratings yet

- Collective NounsDocument1 pageCollective NounsMangala RaniNo ratings yet

- Collective NounsDocument1 pageCollective NounsMangala RaniNo ratings yet

- Pt3 pt3Document1 pagePt3 pt3Mangala RaniNo ratings yet

- I Wonder Form 2 Poem QuestionsDocument2 pagesI Wonder Form 2 Poem QuestionsMangala RaniNo ratings yet

- Narrative Writing ModuleDocument12 pagesNarrative Writing ModuleMangala RaniNo ratings yet

- English Paper 2Document1 pageEnglish Paper 2Mangala RaniNo ratings yet

- The Living Photograph QuestionsDocument6 pagesThe Living Photograph QuestionsSirMustafa Kamal0% (1)

- Collective NounsDocument1 pageCollective NounsMangala RaniNo ratings yet

- Narrative Writing ModuleDocument12 pagesNarrative Writing ModuleMangala RaniNo ratings yet

- Fighters LineDocument3 pagesFighters LineMangala RaniNo ratings yet

- HandoutDocument10 pagesHandoutRogini ThevathasNo ratings yet

- Time Table Semester II 2019-2020Document18 pagesTime Table Semester II 2019-2020Shiv Kumar MeenaNo ratings yet

- Organizational Behaviour Group Assignment-2Document4 pagesOrganizational Behaviour Group Assignment-2Prateek KurupNo ratings yet

- IPO Fact Sheet - Accordia Golf Trust 140723Document4 pagesIPO Fact Sheet - Accordia Golf Trust 140723Invest StockNo ratings yet

- Internal Peripherals of Avr McusDocument2 pagesInternal Peripherals of Avr McusKuldeep JashanNo ratings yet

- List of household items for relocationDocument4 pagesList of household items for relocationMADDYNo ratings yet

- XXCCCDocument17 pagesXXCCCwendra adi pradanaNo ratings yet

- ChromosomesDocument24 pagesChromosomesapi-249102379No ratings yet

- 3 - Content - Introduction To Java, JVM, JDK PDFDocument8 pages3 - Content - Introduction To Java, JVM, JDK PDFAnonymous zdY202lgZYNo ratings yet

- Year 10 Maths PlaneDocument62 pagesYear 10 Maths Planehal wangNo ratings yet

- Ahu, Chiller, Fcu Technical Bid TabulationDocument15 pagesAhu, Chiller, Fcu Technical Bid TabulationJohn Henry AsuncionNo ratings yet

- Reversing a String in 8086 Micro Project ReportDocument4 pagesReversing a String in 8086 Micro Project ReportOm IngleNo ratings yet

- History and Development of the Foodservice IndustryDocument23 pagesHistory and Development of the Foodservice IndustryMaria Athenna MallariNo ratings yet

- Winkens Et Al 2009Document8 pagesWinkens Et Al 2009Marta SanchezNo ratings yet

- Inertial Reference Frames: Example 1Document2 pagesInertial Reference Frames: Example 1abhishek murarkaNo ratings yet

- C11 Strategy DevelopmentDocument30 pagesC11 Strategy DevelopmentPARTI KEADILAN RAKYAT NIBONG TEBALNo ratings yet

- Siga-Cc1 12-22-2010Document6 pagesSiga-Cc1 12-22-2010Felipe LozanoNo ratings yet

- QP P1 APR 2023Document16 pagesQP P1 APR 2023Gil legaspiNo ratings yet

- Political Engineering and Party Politics in Conflict-Prone SocietiesDocument18 pagesPolitical Engineering and Party Politics in Conflict-Prone SocietiesNashiba Dida-AgunNo ratings yet

- Manual Handling Risk Assessment ProcedureDocument6 pagesManual Handling Risk Assessment ProcedureSarfraz RandhawaNo ratings yet

- United Airlines Case Study: Using Marketing to Address External ChallengesDocument4 pagesUnited Airlines Case Study: Using Marketing to Address External ChallengesSakshiGuptaNo ratings yet

- Useful Relations in Quantum Field TheoryDocument30 pagesUseful Relations in Quantum Field TheoryDanielGutierrez100% (1)

- 1571-1635319494618-Unit 04 Leadership and ManagementDocument48 pages1571-1635319494618-Unit 04 Leadership and ManagementdevindiNo ratings yet

- Steel Glossary RBC Capital GoodDocument10 pagesSteel Glossary RBC Capital Goodrajesh pal100% (1)

- Stages of Intimate RelationshipsDocument4 pagesStages of Intimate RelationshipsKrystalline ParkNo ratings yet

- Answer Questions Only: Chemical Engineering DeptDocument2 pagesAnswer Questions Only: Chemical Engineering DepthusseinNo ratings yet

- Smart EE June 2022 - PackageDocument19 pagesSmart EE June 2022 - PackageMercy FeNo ratings yet

- 13Document47 pages13Rohan TirmakheNo ratings yet

- Barelwiyah, Barelvi Chapter 1 (Part 2 of 5)Document31 pagesBarelwiyah, Barelvi Chapter 1 (Part 2 of 5)Dawah ChannelNo ratings yet