Professional Documents

Culture Documents

Sebu7763-03 B

Uploaded by

Hernan SanchezOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sebu7763-03 B

Uploaded by

Hernan SanchezCopyright:

Available Formats

BEFORE OPERATION

Operation and Maintenance Manual Excerpt

2010 Caterpillar All Rights Reserved

SEBU7763-03 July 2009

Operation and Maintenance Manual

D8T Track-Type Tractor

J8B1-Up (Machine) KPZ1-Up (Machine)

SAFETY.CAT.COM

40 Operation Section Before Operation

SEBU7763-03

Operation Section Before Operation

i03644679

Mounting and Dismounting

SMCS Code: 7000

Do not mount a moving machine. Do not dismount a moving machine. Never jump off the machine. Do not try to mount the machine when you carry tools or supplies. Do not try to dismount the machine when you are carrying tools or supplies. Use a hand line to pull equipment onto the platform. Do not use any controls as handholds when you enter the operator compartment or when you exit the operator compartment.

i03640822

Daily Inspection

SMCS Code: 1000; 7000 NOTICE Accumulated grease and oil on a machine is a re hazard. Remove this debris with steam cleaning or high pressure water, at least every 1000 hours or each time any signicant quantity of oil is spilled on a machine. A thorough, regular visual inspection of the machine is necessary to maintain machine performance, availability, and safety. Make the inspection at the beginning of every shift or make the inspection after every 10 hours. Methodically inspect all exposed, easily accessible areas of the machine for the following items: loose fasteners, missing parts, damaged parts, cracked parts, broken parts, worn parts, debris buildup, oil leaks, coolant leaks, and fuel leaks. Initiate corrective action for the following problems: uid leaks, damaged parts, excessively worn parts, loose fasteners, and missing parts. Remove accumulated trash, dirt, grease, or oil from the tractor. Perform the following procedures on a daily basis.

Illustration 38

g00037860

Illustration 37

g01955732

Operation and Maintenance Manual, Backup

Alarm - Test

Use steps and handholds whenever you mount the machine. Use steps and handholds whenever you dismount the machine. Before you mount the machine, clean the step and the handholds. Inspect the step and handholds. Make all necessary repairs. Face the machine whenever you mount the machine and whenever you dismount the machine. Maintain a three-point contact with the step and with handholds. Note: Three-point contact can be two feet and one hand. Three-point contact can also be one foot and two hands.

Operation and Maintenance Manual, Braking

System - Test

Operation and Maintenance Manual, Cab Filter

(Fresh Air) - Clean/Inspect/Replace System Coolant Level - Check Level - Check

Operation and Maintenance Manual, Cooling Operation and Maintenance Manual, Engine Oil Operation and Maintenance Manual, Engine Air

Filter Service Indicator - Inspect

SEBU7763-03

41 Operation Section Before Operation

Operation and Maintenance Manual, Fuel System

Primary Filter (Water Seperator) - Drain

Inspect the lights for broken bulbs and for broken

lenses. Inspect light guards and shields for damage. and wear.

Operation and Maintenance Manual, Horn - Test Operation and Maintenance Manual, Hydraulic

System Oil Level - Check and Gauges - Test Oil Level - Check Check

Inspect exposed wiring and connectors for damage Inspect steps and handholds for damage and

cleanliness.

Operation and Maintenance Manual, Indicators Operation and Maintenance Manual, Pivot Shaft Operation and Maintenance Manual, Seat Belt Operation and Maintenance Manual, Transmission

Oil Level - Check During this general machine inspection, give special focus to the following items.

Inspect the precleaner screen for debris buildup. Inspect the engine compartment for uid leaks,

buildup of debris or trash, loose fasteners, worn hoses, and damaged wiring. debris buildup.

Inspect the crankcase guard under the engine for Inspect the Roll Over Protective Structure (ROPS)

for damage. Inspect the Falling Object Protective Structure (FOPS) for damage. Consult your Caterpillar dealer for necessary repairs.

Inspect the tracks, track roller frames, idlers, and

rollers for oil leaks, and excessive wear. Visually evaluate the tightness of the track. See the Topic Tracks Check/Adjust in this manual.

Inspect the operator compartment for cleanliness.

Refer to the Operation and Maintenance Manual, Maintenance Interval Schedule for the list of the daily maintenance.

Inspect the nal drives for debris that may be

wrapped around the drive. Check duo-cone seals for oil leaks, and sprocket segments for wear.

Inspect the GET (ground engaging tool(s))

(bulldozer and ripper) and other wear surfaces for excessive wear and damage. linkage for the ripper. Also, inspect the fasteners for the linkage.

Inspect the linkage for the bulldozer and inspect the

Inspect exposed guards, shields, and covers. Inspect the winch for oil leaks. Inspect the implement hydraulic cylinders for

damaged rods or bent rods and for leaks. damage, wear, and leaks.

Inspect exposed hoses and hose couplings for Inspect the radiator for debris buildup, coolant

leaks, and damaged ns and tubes.

Inspect the aftercooler for debris buildup, coolant

leaks, and damaged ns and tubes. leaks.

Inspect the fan for damage to the blades or for oil

You might also like

- Outboard Manual 70-75-80-90-100-115Document391 pagesOutboard Manual 70-75-80-90-100-115Possis76% (74)

- CHANGHE Freedom Service Manual PDFDocument341 pagesCHANGHE Freedom Service Manual PDFFabian Carrasco Naula100% (10)

- 3512 Industrial Engine-Maintenance IntervalsDocument40 pages3512 Industrial Engine-Maintenance Intervalssiul789493% (15)

- GM Automatic Overdrive Transmission Builder's and Swapper's GuideFrom EverandGM Automatic Overdrive Transmission Builder's and Swapper's GuideRating: 4.5 out of 5 stars4.5/5 (8)

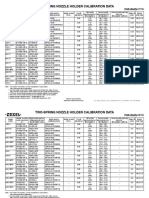

- Zexel Two Spring Nozzle Holder Calibration DataDocument63 pagesZexel Two Spring Nozzle Holder Calibration DataИльнур Султанов100% (6)

- Sebu7687-08 BDocument4 pagesSebu7687-08 Bkevin jeyson merma aragon0% (1)

- 320cl Hydraulic System-testing&AdjustingDocument60 pages320cl Hydraulic System-testing&Adjustingnegro83100% (7)

- Break-Out Machines Level 1Document34 pagesBreak-Out Machines Level 1llereador100% (3)

- Moduspec ChecklistDocument64 pagesModuspec Checklistbehnam197100% (8)

- JCB 3DX Maintenance ManualDocument12 pagesJCB 3DX Maintenance ManualDavid Palash100% (2)

- Sebu7173-12 BDocument7 pagesSebu7173-12 BSantos Junnior Hipolito SandovalNo ratings yet

- Crane InspectionDocument234 pagesCrane InspectionAyman64100% (11)

- Bobcat 753 Service ManualDocument502 pagesBobcat 753 Service ManualOsama Farah71% (7)

- Hanix H09D Service and PartsDocument207 pagesHanix H09D Service and PartsBaciu NicolaeNo ratings yet

- 922LCDocument31 pages922LCHernan Sanchez88% (8)

- Sebu7247-01 SDocument19 pagesSebu7247-01 SHernan SanchezNo ratings yet

- Sebu5555-00 BDocument3 pagesSebu5555-00 BHernan SanchezNo ratings yet

- ECU Wiring AlteaDocument4 pagesECU Wiring AlteaMocanu Stefan ArtemonNo ratings yet

- Before Operation: Operation and Maintenance Manual ExcerptDocument4 pagesBefore Operation: Operation and Maintenance Manual Excerptgeorgejr8950% (2)

- Before Operation: Operation and Maintenance Manual ExcerptDocument4 pagesBefore Operation: Operation and Maintenance Manual ExcerptAnthony PozoNo ratings yet

- Sebu7709-05 BDocument4 pagesSebu7709-05 BJaime SuaNo ratings yet

- SEBU8124-03 B Oruga PDFDocument4 pagesSEBU8124-03 B Oruga PDFAnthony PozoNo ratings yet

- CAT Antes de Usar TH460BDocument4 pagesCAT Antes de Usar TH460Bmiguel0% (1)

- Before Operation: Operation and Maintenance Manual ExcerptDocument4 pagesBefore Operation: Operation and Maintenance Manual ExcerptHernan Sanchez100% (1)

- Before Operation: Operation and Maintenance Manual ExcerptDocument4 pagesBefore Operation: Operation and Maintenance Manual ExcerptPercyLeonNo ratings yet

- Before Operation: Operation and Maintenance Manual ExcerptDocument4 pagesBefore Operation: Operation and Maintenance Manual ExcerptFabian Ariza ArizaNo ratings yet

- Mantenimineto Caterpillar Antes de OperarDocument4 pagesMantenimineto Caterpillar Antes de OperarTeofilo Flores100% (1)

- Before Operation: Operation and Maintenance Manual ExcerptDocument5 pagesBefore Operation: Operation and Maintenance Manual Excerptalice_dickson523No ratings yet

- Before Operation: Operation and Maintenance Manual ExcerptDocument4 pagesBefore Operation: Operation and Maintenance Manual ExcerptAnthony PozoNo ratings yet

- Before Operation 320C PDFDocument5 pagesBefore Operation 320C PDFFabian Ariza ArizaNo ratings yet

- IT62G Integrated Toolcarrier and 950G and 962G Wheel Loaders-Before OperationDocument7 pagesIT62G Integrated Toolcarrier and 950G and 962G Wheel Loaders-Before OperationRODOLFO ESTEBAN VARGAS TORONo ratings yet

- Antes Da Operação 777F Ing.Document10 pagesAntes Da Operação 777F Ing.Jardel Fernandes de MoraesNo ratings yet

- SS - TLS - TL3465HF TL3570 TL3870HF - S4 B41N B41P B3ZS B3ZT B3zu B3ZV enDocument3 pagesSS - TLS - TL3465HF TL3570 TL3870HF - S4 B41N B41P B3ZS B3ZT B3zu B3ZV enKamil SiudowskiNo ratings yet

- 320C U Excavator-Before OperationDocument4 pages320C U Excavator-Before OperationPedro BarriosNo ratings yet

- Before Operation: Operation and Maintenance Manual ExcerptDocument4 pagesBefore Operation: Operation and Maintenance Manual ExcerptHeber Arcana100% (1)

- SEBU6965-06 Before StartDocument6 pagesSEBU6965-06 Before StartLUIZ GUSTAVONo ratings yet

- CS76 Before OperationDocument4 pagesCS76 Before OperationJosé Carlos CarvalhoNo ratings yet

- 16M Motor Grader - Before OperationDocument7 pages16M Motor Grader - Before Operationmamaqita100% (1)

- Before Operation: Operation and Maintenance Manual ExcerptDocument4 pagesBefore Operation: Operation and Maintenance Manual Excerptanon_828943220No ratings yet

- 307C Excavator - Before StartingDocument4 pages307C Excavator - Before StartingNanang RizalNo ratings yet

- Procedure For The Inspection, Repair, and Component Replacement On The Frames of CertainDocument217 pagesProcedure For The Inspection, Repair, and Component Replacement On The Frames of Certainfoca88100% (1)

- MotoculteurDocument25 pagesMotoculteurNicolas DejaiffeNo ratings yet

- Checklist RigDocument104 pagesChecklist RigKiryaki Francis100% (2)

- Walk-Around InspectionDocument2 pagesWalk-Around InspectionMarco Antonio Rivera DoteroNo ratings yet

- Measuring Bores and Installing Seals in Standard and Oversized Hydraulic CylindersDocument14 pagesMeasuring Bores and Installing Seals in Standard and Oversized Hydraulic CylindersFredy Alvarez CespedesNo ratings yet

- 330D L Excavator-Before OperationDocument8 pages330D L Excavator-Before Operationvkannan07666No ratings yet

- Excavator Instructors NotesDocument31 pagesExcavator Instructors Notescandracute33% (3)

- Maintenance: Outboard CareDocument18 pagesMaintenance: Outboard Careshygal1981100% (1)

- Periodic Maintenance: J45-70XN (A276)Document87 pagesPeriodic Maintenance: J45-70XN (A276)Baciu Nicolae100% (1)

- Sebu7731-08 BDocument6 pagesSebu7731-08 BTeo Deustch100% (2)

- Gmi 2202312228096Document5 pagesGmi 2202312228096Kishan PatelNo ratings yet

- Observe and ObeyDocument3 pagesObserve and ObeyMalaravan RamNo ratings yet

- Service Brokk 330Document34 pagesService Brokk 330Ricardo TolmoNo ratings yet

- Manitowoc 4600 S4 Lubrication Guide PDFDocument40 pagesManitowoc 4600 S4 Lubrication Guide PDFnamduong368100% (1)

- Driver'S/Operator'S Pre-Employment Orientation: Taganito Mining CorpDocument60 pagesDriver'S/Operator'S Pre-Employment Orientation: Taganito Mining CorpKai Esperon100% (1)

- Technical Manual Rotary ValveDocument8 pagesTechnical Manual Rotary ValvexichengrenNo ratings yet

- Gear Pump SIS CAT 2Document53 pagesGear Pump SIS CAT 2iliuhinNo ratings yet

- 924F Pruebas y AjustesDocument26 pages924F Pruebas y AjustesSan Gabriel Representaciones100% (1)

- Track Excavator ManuaDocument29 pagesTrack Excavator ManuaKike Davila50% (2)

- Tiger Tractor TC-50 PDFDocument692 pagesTiger Tractor TC-50 PDFCarlos SolisNo ratings yet

- Chapter 2 Machine Maintenance.: General Workshop ProceduresDocument22 pagesChapter 2 Machine Maintenance.: General Workshop ProcedureswillifenlonNo ratings yet

- Maintenance & Repair WorkDocument29 pagesMaintenance & Repair WorkAhmed Hassan Abo Asem100% (3)

- VAN Type Лепестковые насосыDocument38 pagesVAN Type Лепестковые насосыiliuhinNo ratings yet

- Presiones 988bDocument24 pagesPresiones 988bMarielisa Zertuche FloresNo ratings yet

- Calibration Relief Valve ExcavatorDocument36 pagesCalibration Relief Valve Excavatorcriman4550% (2)

- Before Operation: Operation and Maintenance Manual ExcerptDocument8 pagesBefore Operation: Operation and Maintenance Manual ExcerptHernan Sanchez100% (1)

- Before Operation: Operation and Maintenance Manual ExcerptDocument5 pagesBefore Operation: Operation and Maintenance Manual ExcerptHernan Sanchez0% (1)

- Safety: Operation and Maintenance Manual ExcerptDocument7 pagesSafety: Operation and Maintenance Manual ExcerptHernan SanchezNo ratings yet

- Before Operation: Operation and Maintenance Manual ExcerptDocument4 pagesBefore Operation: Operation and Maintenance Manual ExcerptHernan Sanchez100% (1)

- Sebu6891-03 BDocument4 pagesSebu6891-03 BHernan SanchezNo ratings yet

- Safety: Operation and Maintenance Manual ExcerptDocument10 pagesSafety: Operation and Maintenance Manual ExcerptHernan SanchezNo ratings yet

- Before Operation: Operation and Maintenance Manual ExcerptDocument4 pagesBefore Operation: Operation and Maintenance Manual ExcerptHernan SanchezNo ratings yet

- Before Operation: Operation and Maintenance Manual ExcerptDocument3 pagesBefore Operation: Operation and Maintenance Manual ExcerptHernan SanchezNo ratings yet

- Sebu6891-03 BDocument4 pagesSebu6891-03 BHernan SanchezNo ratings yet

- Especificaciones Tecnicas Bulldozer D51EX-22Document12 pagesEspecificaciones Tecnicas Bulldozer D51EX-22Hernan Sanchez100% (1)

- Manual Book Isuzu TBR E2 PDFDocument2 pagesManual Book Isuzu TBR E2 PDFYoPiNo ratings yet

- Tobago T10 ChecklistDocument2 pagesTobago T10 ChecklistinklabsNo ratings yet

- Learner'S Licence: Form 3 (See Rule 3 (A) and 13)Document1 pageLearner'S Licence: Form 3 (See Rule 3 (A) and 13)Nishant PaulNo ratings yet

- E90 Alarm RetrofitDocument11 pagesE90 Alarm RetrofitAbdulrahman ShammaNo ratings yet

- 3408 Automatic Timing Advance PDFDocument6 pages3408 Automatic Timing Advance PDFmanu luvungaNo ratings yet

- NeoDyne Accessory CatalogDocument9 pagesNeoDyne Accessory Catalogrikof rikofNo ratings yet

- Aw 60-40Document3 pagesAw 60-40danielnefthali100% (5)

- AGESH Customer SatisfactionDocument59 pagesAGESH Customer SatisfactionAmbient100% (1)

- Summary Changes For NCHRP Report 350 GuidelinesDocument28 pagesSummary Changes For NCHRP Report 350 GuidelinesrodolfoNo ratings yet

- En500 c6fc7fc8fc9f Parts List PDFDocument90 pagesEn500 c6fc7fc8fc9f Parts List PDFOliverNo ratings yet

- Autos PDFDocument242 pagesAutos PDFjornada660No ratings yet

- "Self Propelled Snow Cutter Blower": Submitted To Rajiv Gandhi Proudyogiki Vishwavidyalaya, Bhopal (M.P)Document22 pages"Self Propelled Snow Cutter Blower": Submitted To Rajiv Gandhi Proudyogiki Vishwavidyalaya, Bhopal (M.P)sai associatesNo ratings yet

- SUPER 1803-3 EN 2509980 MPW 1117Document22 pagesSUPER 1803-3 EN 2509980 MPW 1117chintia nugraheniNo ratings yet

- Audi 80Document5 pagesAudi 80dattilom100% (1)

- MRT 50 Owner ManualDocument38 pagesMRT 50 Owner ManualOshada GamageNo ratings yet

- Katalog Škoda Bicikala 2021Document21 pagesKatalog Škoda Bicikala 2021Stefanija TankosicNo ratings yet

- Thesis AudiDocument6 pagesThesis AudiHelpWritingCollegePapersUK100% (2)

- Sumitomo SCX800-2・24p PDFDocument24 pagesSumitomo SCX800-2・24p PDFGibbs Per100% (2)

- Service Manual: Vacuum Cleaner FC8344Document5 pagesService Manual: Vacuum Cleaner FC8344Ana PfefferkornNo ratings yet

- Isx15 CM2350 4310638Document1 pageIsx15 CM2350 4310638Anderson Salazar100% (2)

- A-COVER 1-CD-F479 P.S.C.C.H.Co Comm.15.13Document5 pagesA-COVER 1-CD-F479 P.S.C.C.H.Co Comm.15.13Islam AttiaNo ratings yet

- Aisin Aw Tr-60snDocument1 pageAisin Aw Tr-60snJesus Alejandro Miranda PalaciosNo ratings yet

- Sharukh R Kapadia CVDocument3 pagesSharukh R Kapadia CVsharukh kapadiaNo ratings yet

- Mitsubishi Lancer Evolution Viii MR Service Manual Electrical Wiring DiagramDocument7 pagesMitsubishi Lancer Evolution Viii MR Service Manual Electrical Wiring Diagramsamantha100% (50)

- Puc Certificate New 5794Document1 pagePuc Certificate New 5794dilip polutionNo ratings yet

- The Walschaerts Valve GearDocument2 pagesThe Walschaerts Valve Gearstaustell92No ratings yet

- Valve Guides EngDocument35 pagesValve Guides EngKaiser IqbalNo ratings yet