0 ratings0% found this document useful (0 votes)

770 views354 pagesEngineering Design Handbook Part Three

The only source of knowledge when it comes to designing a helicopter. Contains information on quality assurance in all phases of engineering and designing a helicopter.

Uploaded by

JeremiahJohnsonCopyright

© Attribution Non-Commercial (BY-NC)

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF or read online on Scribd

0 ratings0% found this document useful (0 votes)

770 views354 pagesEngineering Design Handbook Part Three

The only source of knowledge when it comes to designing a helicopter. Contains information on quality assurance in all phases of engineering and designing a helicopter.

Uploaded by

JeremiahJohnsonCopyright

© Attribution Non-Commercial (BY-NC)

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF or read online on Scribd

AMC PAMPHLET. AMCP 706-203

ENGINEERING DESIGN

HANDBOOK

HELICOPTER ENGINEERING

PART THREE

QUALIFICATION ASSURANCE,

HEADQUARTERS, U.S. ARMY MATERIAL COMMAND APRIL 1972

[REPRINT by eae Eye Solutions, LLE ‘won tagletyaSolationstiC.com

CECECEECCEC CCE CE

"EEC ECE EOEEEEC &(

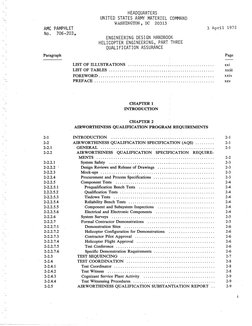

HEADQUARTERS

UNITED STATES ARMY MATERIEL COMMAKD

‘WASHINGTON, OC 20315

ANC PANPHLET 3 Ape 1972

No. 706-203,

ENGINEERING DESIGN HANDBOOK

HELICOPTER ENGINEERING, PART THREE

‘QUALIFICATION ASSURANCE

Paragraph

LIST OF ILLUSTRATIONS we

LIST OF TABLES : sil

FOREWORD. ee es xiv

PREFACE : : av

cuarrER 1

INTRODUCTION

CHAPTER 2

AIRWORTHINESS QUALIFICATION PROGRAM REQUIREMENTS

a NTRODUCTION a

22 AIRWORTHINESS QUALIFICATION SPECIFICATION (AQS) 2

221 GENERAL, 2

222 AIRWORTHINESS QUALIFICATION SPECIFICATION REQUIRE.

MENTS 2a

zag System Sate 23

2222 Design Reviews and Release of Drawings 23

2333 Moceups 23

2234 Procurement and Process Specifications 23

2035 (Component Tests 7 2

23351 Prequalification Bench Texts 2a

22252 Qualifeaion Tests 2

22333 ‘Tedown Tests a

pasa Relay Bench Tests a

2aass (Component and Subsytem Inspections 2

22256 letrical and Electronic Components FI

2226 System Surveys Bs

2237 Formal Contractor Demortions 2s

22271 ‘Demonstration Sites 26

22972 “Helopter Configuration for Demonstvations 26

22273, Contractor Plot Approval 26

23a74 “llcopter Flight Approval 26

2aa35 ‘Tes Conference 26

23376 Specie Demonstration Raguirments 26

233 ‘TEST SEQUENCING a

224 ‘TEST COORDINATION

aaa “Test Coordinator

2942 “Test Witness

2243 Cognizant Service Plant Activity 2

2244 ‘eat Witnessing Procedores 23

225 AIRWORTHINESS QUALIFICATION SUBSTANTIATION REPORT: 29

AMP 706-203

Paragraph

3124

3125

336

3137

3138

319

31210

san

313)

sia

a3

3s

Mo

2

Baa

323

32a

3332

3233

323

324

a

+

45

454

452,

a6

a

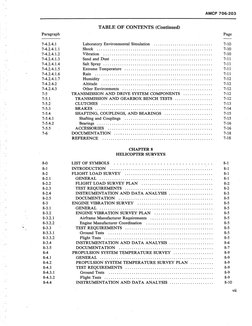

TABLE OF CONTENTS (Continued)

Page

cuarrers

‘SYSTEM SAFETY

INTRODUCTION

‘OBJECTIVES

SYSTEM SAFETY PROCESS oS

Keown Presedent (Block A, Fig. 3-2)

Syem Delineation (Black B) :

System Hazard Analyses (lock C)

Hazard Identfeation (Block D)

Hazard Categorization and Evalution (Block F)

‘Ations) to Eliminate or Conteol Hazara) (Block F)

Medication of Systm Element() (Block G)

Effeivenesr Evaluation of Action Taken (Blok Hf) :

‘Acsident/Tncident Analysis lock 1)

‘Component/Sytem Test and Demonsrtion (Blok J)...

Tncrened Safty Assurance (Block K) :

Airworthiness Qualieation (Block L) :

ANALYTICAL METHODOLOGY :

KNOWLEDGE OF HAZARDS H

CLASSIFICATION OF HAZARDS. ==... 7

RESOLUTION OF HAZARDS i

SUBSTANTIATION OF HAZARD RESOLUTION =. 7

SYSTEM SAFETY PROGRAM PLAN (SSP?) :

‘GENERAL

SAFETY ANALYSIS AND HAZARD EVALUATION PROCEDURES

‘System Subeystem Haar Analysis

Fault Tree Analysis eee

Faire Mode and Hazardoas Effact Analysis (FMHEA) :

SAFETY TESTS. part

DATA, F

REFERENCES : 2

CHAPTER +

DATA AND DOCUMENTATION PROCEDURES AND

"REQUIREMENTS

INTRODUCTION ee 4

‘APPLICABLE DOCUMENTS : a

DATA REQUIREMENTS. es a

PROGRAM PLANS : pe

DESIGN REVIEWS : a

DESIGN DRAWING REVIEWS 000.0... D4

DATA FOR DESIGN REVIEWS 7 : 2

MOCK-UPS... 7 oo

ENGINEERING DATA os

‘AERODYNAMIC AND FLUTTER INVESTIGATION PROGRAM RE-

PORT 7 as

[AERODYNAMIC STABILITY AND CONTROL REPORTS 43

‘AMP 706-203

‘TABLE OF CONTENTS (Continued)

Page

Digital and Aaclog Computer Program Report 4

Fight Simulator Progam Report ce

‘Aerodynamic Stablity and Control and Fying Quality Reports +

CHARACTERISTIC AND PERFORMANCE DATA. 4

ase Aerodynamic Data =... fee

Sibrantiaon of Performance Data Report Aeron as

Sandard Alzeraft Characteristics (SAC) Charts = a

WEIGHT AND BALANCE DATA... : 4s

STRUCTURAL DESIGN, ANALYSIS, AND TEST DATA a

HUMAN FACTORS ENGINEERING DATA, : as

SYSTEM SAFETY DATA eer +6

RELIABILITY AND MAINTAINABILITY DATA 46

SUBSYSTEM DESIGN APPROVAL DATA 4 46

General Arrangement Dravings 46

Inboard Profile Deawings ‘i 46

Rotors) and Propels) Drawings oo... +6

{tablsng/Coatal Surface Drawings a

Wing (Compound Hepes) Drawings a

ody Drawings a

Hull Drawing -- co a

landing Gene (Wheeliype) : o

Landing Gear (Stipe) a

Tanding Gear (Fea) a

Landing Gear (Skisype and Bear Paws) as

Engine (Main and APU), Transmission, nd Drives = +

ight Conran Sty Angmetton Spans “

‘leoreal Loe _ °

Mydrules and Pacumatis : to

Avionie = : “

‘nstrumestation and Navigational Equipment... 10

‘Seow Stations, Furnishings, end Eqopment 410

Survival Sytem to.

Environmental Control System. : 410

Equipment ae : “0

Armor and Armament au

Msoallaneoos : 4

PHOTOGRAPHS en

CONTRACT DETAIL SPECIFICATION REVISION PAGES 42

HELICOPTER INVENTORY RECORD. 42

TEST PLANS AND QUALIFICATION TEST REPORTS. +3

FORMAL DEMONSTRATION PLANS AND REPORTS ou

ENGINEERING MANUFACTURING DRAWINGS AND CON:

SOLIDATED DRAWING LIST _ e ais

4s Preparation of Drawings : 45

ens2 Consolidated Drawing List 415

“716 SUMMARY OF DATA AND DOCUMENTATION 45

“ REIORTS AND DATA ais

aan DATA SUBMITTAL, INSPECTION, AND ACTION 5

AMCP 706-203

st

32

521

sata

5212

$213

5214

S243

5218

522

523

324

S24

3242

ot

ou

612

613

614

1s,

16

6

eu

622

ou

632

‘TABLE OF CONTENTS (Continued)

Page

‘Seba 420

Inspection 420

Actions 40

REVISION OF DATA AND DOCUMENTATION on

MODIFICATION OF REQUIREMENTS ‘i 2

‘APPENDIX A~GENERAL ARRANGEMENT DRAWINGS an

HAPTER s

MOCK-UPS

INTRODUCTION

MOCK-UP DEMONSTRATION REQUIREMENTS

FUSELAGE

Flight Crew Stations

‘Other Crew Stations, and Passenger and Cargo Compartments

Propulsion and Power Ssstem Mosk-up

Eletial/Elestonie Sytem Mocksp

ygralic and Preumatie System Moskeaps

Armament and Armor Mock-upe :

ROTOR HUBS AND BLADES.

LANDING GEAR :

LIGHTING MOCKUP

Interior Lighting

Extror Lighting

MOCK-UP REVIEW AND APPROVAL

‘MOCK-UP DISPOSITION

(OTHER SUBSYSTEM MOCK-UPS

REFERENCE anes

(CHAPTER 6

PROCUREMENT AND PROCESS SPECIFICATIONS

INTRODUCTION 6

GENERAL ei

MAKE-OR-BUY PLAN-PROCUREMENT. «1

END-ITEM COMPONENT SPECIFICATIONS 1. 6

PURCHASE SPECIFICATIONS e

PROCESS SPECIFICATIONS : 61

(QUALITY ASSURANCE PROGRAM 62

FERROUS MATERIALS 62

GENERAL ; eo

RECEIVING INSPECTION AND TEST : 62

NONFERROUS METALLIC MATERIALS. e

‘GENERAL eo

RECEIVING INSPECTION AND TEST oss... 63

NONMETALLIC MATERIALS 6

‘AMC? 706-203

TABLE OF CONTENTS (Continued)

Paragraph Page

oat GENERAL 7 co 8

a2 RECEIVING INSPECTION AND TEST 6

421 Pasi ry

422 Elastomers 6a

e423 ‘ines and Other Ceramic Materials e

oa PROCESS SPECIFICATIONS 6

6s ‘COMPOSITES 64

65 (GENERAL : E 6

32 RECEIVING INSPECTION AND TEST 64

e521 Laminates 6

6522 Fllament-wound Strvtares e 6s

6523 Honeycomb and Sandwich Stactures 66

e524 ‘Amor Materials. fi 67

6525 ‘Advanced Compost: 67

6526 Special Requirements ee 67

66 ADHESIVES 6

661 ‘GENERAL : : : 6

662 RECEIVING INSPECTION AND TEST 6

663 PROCESS SPECIFICATIONS 6s

67 PAINTS AND FINISHES

ena ‘G2NERAL_ ee fi fi

67a, RECEIVING INSPECTION AND TEST

oa PROCESS SPECIFICATIONS

oe LUBRICANTS, GREASES, AND HYDRAULIC FLUIDS. :

eu GENERAL ete

a2 RSCEIVING INSPECTION AND TEST

os (CASTINGS, FORGINGS, AND EXTRUSIONS :

634 GENERAL

692 RECEIVING INSPECTION AND TEST 1) i

6921 Castings

6922 Forgings :

6923 Extrosions

10 SHEET METAL FORMING 5s

e101 ‘GENERAL. eis

102 RECEIVING INSPECTION AND TEST : 6s

103 PROCESS SPECIFICATIONS eis

en MACHINING OPERATIONS

eu GENERAL 61s

e112 RECEIVING INSPECTION AND TEST i : 616

613 PROCESS SPECIFICATIONS 616

62 JOINING OPERATIONS... iene : 618

e121 GENERAL es

6122 RECEIVING INSPECTION AND TEST =... : 6:6

61221 Welding cove 616

61222 Brazing Se

61223 Soldering : :

ens Riveting : 617

e225 wage Tints and Cables : : en

en HEAT TREATMENT en

AMP 706-203

Paragraph

en1

6133

e134

61332

61333

61334

ra

eat

6182

eis

eis

6152

pare)

isa

mM

aa

722

723

724

eB

734

73

733

a

7332

rat

ran

ra221

742221

742322

742223,

ra2325

7423

yaaa

‘TABLE OF CONTENTS (Continued)

GENERAL.

RECEIVING INSPECTION AND TEST

PROCESS SPECIFICATIONS

‘Stel

Alina Alloys

Copper Alloys

Tania

PEENING

GENERAL

RECEIVING INSPECTION AND TEST

PROCESS SPECIFICATIONS,

RECEIVING INSPECTION AND TEST

PROCESS SPECIFICATIONS :

INSPECTION, QUALITY CONTROL, AND CONFIGURATION CON:

‘TROL -

cuarrer7

COMPONENT TESTS AND QUALIFICATION

INTRODUCTION

(QUALIFICATION REQUIREMENTS 0111.) :

FUNCTIONAL TESTS

‘STRUCTURAL TESTS

ENDURANCE TESTS.

ENVIRONMENTAL TESTS :

(QUALIFICATION PROCEDURES

"TEST SPECIMENS

‘TEST PLANS ....

(QUALIFICATION BY SIMILARITY

Previously Qualified Contractor rises Euipment (CFE)

Previously Qualifled Governmencfurished Equipment (GFE)

(QUALIFICATION TESTS

‘TYPES OF COMPONENTS

‘TYPES OF TESTS :

unedonal Tests

‘Strutarel Tests

‘Component State Loud Tass

‘Component Fatigue Teste

Fatigue Test Requirements

Test Specimens

Frequency of Loading

Verifestion of Test Fixtures

Use of Tested Part

Endurance Tests ¥ oe f

Environmental Tete

Page

on

617

en

an

ei

oe

e9

69

69

os

619

6s

620

6m

620

70

AMcP 706-203,

TABLE OF CONTENTS (Continued)

Paragraph Page

yaaaa Laboratory Eavronmentl Simulation 730

Tada Shock 730

r424i2 “Vibration 710

742413 Send and Dist : a

ra3ate Slt Spray mn

yaaa Exteme Temperature a

T4246 in : mt

ya34ay Humidity a2

4242 Alttode : a

reve) Other Envizonmaats a

ts ‘TRANSMISSION AND DRIVE SYSTEM COMPONENTS mm

51 ‘TRANSMISSION AND GEARBOX BENCH TESTS ta

132 CLUTCHES... a3

153, BRAKES +4

34 SHAFTING, COUPLINGS, AND BEARINGS 000... 7s

Ta ‘Shating and Couplings ws

saa Barings : : 716

155 ACCESSORIES 76

16 DOCUMENTATION 78

REFERENCE. a eae m8

HELICOPTER SURVEYS

LIST oF SYMBOLS

INTRODUCTION

‘GENERAL

FLIGHT LOAD SURVEY PLAN >

‘TEST REQUIREMENTS

INSTRUMENTATION AND DATA ANALYSIS

OCUMENTATION

ENGINE VIBRATION SURVEY

GENERAL

ENGINE VIBRATION SURVEY PLAN

Airframe Manufactarer Requirements.

Engine Manufacturer Coordination

‘TEST REQUIREMENTS,

(Ground Teste

Fight Tests osc

INSTRUMENTATION AND DATA ANALYSIS

DOCUMENTATION : 7

PROPULSION SYSTEM TEMPERATURE SURVEY ee

GENERAL woos 88

PROPULSION SYSTEM TEMPERATURE SURVEY PLAN 2

TEST REQUIREMENTS 89

Ground Tests 2

Fight Tests 3

INSTRUMENTATION AND DATA ANALYSIS #10

‘AMP 706-203

Paragraph

eas

es

51

53

e532

e833

esa

bss

6

B61

62

63

e631

rr)

S91

$92

92

sont

eon

ee21i2

e213

#9212

e212

92122

92123

a

TABLE OF CONTENTS (Continued)

DOCUMENTATION

ENGINE AIR INDUCTION SYSTEM SURVEY :

GENERAL

ENGINE AIR INDUCTION SYSTEM SURVEY PLAN

‘TEST REQUIREMENTS

Ground Tests

Flight Tes

Effect on Engine Performance

INSTRUMENTATION AND DATA ANALYSIS

DOCUMENTATION

[ENGINE EXHAUST SYSTEM SURVEY

GENERAL :

ENGINE EXHAUST SYSTEM SURVEY PLAN

TEST REQUIREMENTS

‘Grovnd Tess

Fight Tests : ‘i

haus Sytem Endurance Tet

INSTRUMENTATION AND DATA ANALYSIS

DOCUMENTATION

‘TOTAL SYSTEM VIBRATORY SURVEY

GENERAL

GROUND VIBRATION TESTS

Airfame Vibration

Rotor System Vibration

FLIGHT TESTS

INSTRUMENTATION :

DOCUMENTATION

‘CREW ENVIRONMENTAL SURVEY ‘

GENERAL

(CREW ENVIRONMENTAL SURVEY PLAN

TEST REQUIREMENTS

Ground Tests

Flight Tet

Climatic Hangar Tests

INSTRUMENTATION AND DATA ANALYSIS

DOCUMENTATION

HELICOPTER SYSTEM SURVEYS.

GENERAL

INFRARED (IR) RADIATION AND COUNTERMEASURE SYSTEM

SURVEY

Passive IR Gountermeasare Tes

‘Aitame/IR Suppressor Compatity Tests

Ground Tests ss

Fight Tests

Instrumentation and Data Analyse

1 Signature Survey

Ground and Hovering Conditions ‘

Flyby Test Condition

Instrumentation and Dae Anaya

26

26

24

524

2s

225

526

£26

aucr 706-203

296211

96212

#96213,

soszia

s96215

94622

96221

£96222

96223,

e963

e964

897

on

#972

9721

9722,

$973

TABLE OF CONTENTS (Continued)

usteation Teste

Active IR Countermeasure Sytem

Flight Test Conditions

Instrumentation and Data Analysis

Documentation :

RADAR REFLECTIVITY SURVEY

‘Radar Refletiviy Survey Plan :

Scale Model Tecniqnes

‘eat Requirements

Instrumentation and Dats Anais

Documentation 7

LIGHTNING PROTECTION SURVEY

ighning Protection Survey Plan

iphning Laboratory Tests

iphining Chest

Documentation

IGG SURVEY

ising Survey Plan

est Requirements

Teing Tunnel Tests

(Clear, Dry Ait Flight Teste

Simulate Icing Fight Tests

[Natural Teing Fight Tess

Insiramentation and Data Analysis

‘Photographic Recording i

Recording of leing Conditions|

System Performance and Power Recording

ACOUSTICAL NOISE SURVEY (INTERNAL AND EXTERNAL)

‘Acoutial Note Survey Plan

Test Requtemens

Tnteral Nese

Helicopter Operational Modes

Instrumentation

Noe Measurement

‘Weapon Noe Messorement

Inieigiilty Tete

Extemal Nee

Helicopter Operational Modes

Instromentaon

Nowe Measurement

Dasa Analysis

Dooumentaton :

(CLIMATIC LABORATORY SURVEY

timate Laboraton

(Gimati Laboratory Tests

Test Requirements

Instrumentation and Data Analysis

Documentation

REFERENCES i

‘Aucp 706-203

TABLE OF CONTENTS (Continued)

CHAPTER 9

HELICOPTER SYSTEM DEMONSTRATIONS

90. LIST OF SYMBOLS:

. INTRODUCTION

92 STRUCTURAL INTEGRITY DEMONSTRATION

baa GENERAL

923 STATIC TEST PROGRAM es e a

9221 Test Requtemens

9222 Instrumentation and Data Analysis 7 : :

9223 Documentation

923 LANDING GEAR DROP TESTS : :

9234 Test Requirements

baa ‘Whee! Gear : : 7 :

923.14 ‘Test Procaures

paaii2 Tastrmentation and Data Analysis peer :

92342 Skid Gear

pasta “Test Procedies en

923122 Instrumentation and Data Anslyas

o232 Documentations... eee

one STRUCTURAL DEMONSTRATION

oat ‘Test Requirements o-sssseeesesee . i

Saat “Test Manesvers

bata Iastrmentation and Data Anal - 0... l0sccccsooseceeneoee

5242 Dooumentation|

38 PROPULSION AND POWER SYSTEM DEMONSTRATION

534 GENERAL

532 ENGINE/AIRFRAME COMPATIBILITY TESTS ssc... ssss0o0.

9321 Test Requirements

pata “Ground Tes ws. : SUIS

oan ropalson Contras

5328114 Power Lever Coats. EE :

S32L1LL1 —— Eopina(s) Stopped

S32ULIL2 Engels) Running

p3auii2 Starting and Acceleration to Ground fle

o3anit3 Acceleration and Deoderation Tests :

oaautls ‘Gas Gmnerstor Control and Power Turbine Governor Seni:

9320118 Power Control Anilpaoe and Droop Cum Characteristics

oaaui2 ‘Rotor Contras vs.

9328124 Hehcopter Dynamic Syatem-—Eagine Compati

9324122 ‘Allgament and Output Sbat Unbalane ss... ei

93a42 ‘right Tess

932124 Propulsion Controle 2) 7 e :

saztaa Ate Restars :

9321212 gine Acceleration nd Decleation Tests es

9321213 Gat Generator Fos! Control

gani2ie Power Tartine Governor and Spied Response Time

gaatais Power Control Aniipator and Droop Compensation Cam Characters

Paragraph

ga21216

eazi22

o32i221

53a1222

93213,

932131

932434

Persery

9321313

ss213t4

saai32

932133,

oaate

93215

933

pan

S334

93312

53343

9333

9334

9335

9336

9337

O34

9341

sand

934814

S32

934113

patie

oats

S3atte

3407

saatit4

s3a1i72

saani73

o3eLira

s3ati7s

S3ALLI6

S3AtI77

94a

3421

o34ni2

o342t3

‘TABLE OF CONTENTS (Continued)

[Esablishment of Minimum and Masimom Power Turbine Speeds

Holiopter Contras

Haliopier Dynamic Sten-Engine Compatisy

Alignment and Outpo Shaft Untalance

Enginestarting Tests

Ground Tests

Ambient Temperature Tots

Lowetemperatire Tests

ighvtemperatne Tests

Ground Power/Ambient Temperature Tests

Fight Tet

Instrumentation

striction Tess

Stcondary Power Sys Tests

Docimentation|

“TRANSMISSION AND DRIVES

Test Requirements

Prequalification Tests

ualiication Tests

‘Tadown Tests

Istrementation

Disssembly

Inspection

Rett,

CGhtches and Brakes

‘Shafing, Couplings, and Bearings

LUBRICATION AND FUEL SUBSYSTEM DEMONSTRATION

LLabriction Subsystems Demonstration

“Tet Requirements

Measurement of Usable Oi1

Measurerient of Oil Tank Expansion Space

if Tank Pressre Tet

‘il Syst Bypass Demonszaion

(i Vent System Test

‘Oi! Tank Quantity Calibration

(it Cooling

Hover Coating

tint Cooting

(Crise Coning

(Other Flight Conditions

Addisonal Cooling Tests

Deterinacion of Cooling Merging

Chip Detector Demonstration

‘us Subsystem Demonstration

TIntemal and External Ful Tank Cepaciies

Tank Capacity

‘Avalable Fue!

‘Semp Capacisy

AMC? 706-203,

948

oe

pee

out

ok

ou

oe

ong

549

su

9

919

519

319

319

99

920

920

521

92

22

52

5.3

9.35

925

95

9.

925

925

5.6

7 925

96

96

56

9.26

5.26

9.5

926

926

oa)

oa

9.27

923

9

‘ANC 706-203

TABLE OF CONTENTS (Continued)

)

Paragraph Page -

gaat Residual Fost oat +

oan Expansion Space : 927 -

93.4216 Aunlary Foe! Provisions 327

934217 Loweletel Fast Warning Sytem 927 >

934218 Fuel Quanity Gaging Subsystem Tests 928 o

93422 Refcting and Defoling Test ae

934221 Refueling 528 a

534222 Surge Pressre Test 928 A

934223, Detueling Tet 928

o34a28 {loved Gronit Refusing Systm Tests 928 a

934225 Siphoning Tests ; 9.8 7

934226 (Centers gravity (CG) Travel Tet 538

93423 Boost and Transfer Pump Faire Tete 9.28 7

o34a31 Ground Tete 329 -

934232 Flight Tests 9.29

934233 ‘Vapor/Liquid Ratio Teste 529

saaa8 [Fu Supply and Fuel Transfer Teste 929

934241 Pel Supply Tests 929 S

934242 Inurl Tank Switchover and Fuel Transfor Rates 929

934243 Exteral Tank Fesdout 529 7

534248 Fal Jetson 9.29

53425 Fuel and Veot Sytem Tass 9.29 -

934251 Presurzation and Pel Vent Systrn Tete 9.29 +

934252 Vent Outlet Teng Tess 5.30

934233 Vent Sytem Failure Tes : 330 *

33426 Fel Tank Purge (¥ applicable) 930 -

934261 Ground Tess : 330

b34n62 Flight Tests ssc... 930 o

93427 Crshworthy Fal § : 50 ~

935 ROTORS AND PROPELLERS 9-30

9354 oor System Demonstration : 30 *

pasta Rotor Whirl Tes =. 530 >

o3sa2 Praiminary Fight Approval Text 30

93513 1s0-hr Tiedown Test : 331

9352 Prope System Demonstrations oa 7

93521 "Test Requirements oa

935214 Ground Tests baa 7

935212 Flight Tests. 33 e

93522 Spacal Tess oa

935221 ‘Whit Flaner 333 eT

935222 Balance oa 4

93523 Instrumentation 933 -

oasaa Documentation 96 :

936 ENGINE VIBRATION DEMONSTRATION 936 ~

93.61 Engine Vibration Demonstration Pl 337 -

9362 ‘st Requirements 337 7

93.621 Ground Tete 3° a

93622 ight Tess 938 os

9363 Insermentation and Dats Anaya 339

AMC? 706-203,

‘TARLE OF CONTENTS (Continued)

Paragraph Page

9364 Documentation 939

baz PROPULSION SYSTEM TEMPERATURE DEMONSTRATION 939

937 ‘ropubsion System Temperature Demonstration Pian 939

5372 ‘est Requirements 939

93721 Ground Tests 539

93722 Flight Tests 939

oa33 Inetrmentation nd Data Anais 539

9374 Documentation 9.39

baa ENGINE AIR INDUCTION SYSTEM DEMONSTRATION 339

538 “gine Air Induction System Demonstration Plan S40

eres Test Requirements 340

93821 Ground Tests 540

92822 Fight Tests 940

938221 Inlet Presture Recovery 40

s3aaa2 Inlet Temperature Level 340

o38223 (ther Inlet Pressure and Teropeatore Distortion Mets 540

reves Instrumentation ad Data Analisis oat

ose Documentation 942

oe DYNAMIC INSTABILITY DEMONSTRATION : 92

oa GENERAL, ive

942 GROUND RESONANCE 2

9421 Test Requiemens| 92

baa Documentation 943

943 BLADE FLUTTER e oa

Sas SURHARMONIC VIBRATORY MODE

AERODYNAMIC DEMONSTRATION

PERFORMANCE SUBSTANTIATION

“Tet Requirements

sata Level Plight Performance

osa12 CCimb Performance

95213 Hover Performance

os214 ‘Avtortalonl Performance

55215 ‘Aepeed Calibration

95216 Determination of Power Available

983 FLYING QUALITIES DEMONSTRATION

9531 “est Requirements

os ‘Sate Longin Staity

95312 Sate Lateral-irectonal Stay

osat3 Sideward and Rearward Fight

sate ‘Trim Requirements

Peer) Controllability 950

95316 Dynamic Say 330

psa “Manexvering Stab 3-0

sae Roll Characteristics, ost

95319 ‘Astoroaton Eotries ost

$5310 ‘Stalty Augmentation Sysicm Files ost

e531 Quaiative Pot Evalesion 931

9532 Documentation 3st

MCP 706-203,

TABLE OF CONTENTS (Continued)

Paragraph Page Z

96 ELECTRICAL DEMONSTRATION 92 7

96 GENERAL, 3 2

9-62 ELECTRICAL ANALYSIS REPORT 953

963 ELECTRICAL SYSTEM AIRWORTHINESS QUALIFICATION TESTS 953, ~

9-631 Ground Tests 353

9.63.11 letrieal Lond Measurements $s

$6312 Primary Power Sytem Tests os :

563124 [AC Primary Electrical Sytem Tass os =

963122 De Primary Electra! Sytem Tests 3 °

56313 Conversion Power Texts : ose re

oesi4 Emergency Power Tests os

56315 Fault Protection and Detection 955

96316 leccial System Installation oss >

5-63.17 leeieal Engine staring Sytem Tests 955 a

5632 Flight Tess 955

564 DOCUMENTATION 956 :

97 AVIONIC DEMONSTRATION 936 -

oa GENERAL 956

972 AVIONIC AIRWORTHINESS QUALIFICATION : 356 a

721 “Avloae Airworthiness Quafeaton Test Ground Staton 956 Bh

9722 Production Tests : 836

9723 ‘Avinie Test Specifications 937 a

9728 letrical Power Verifoation 937 f

973, ANTENNA PERFORMANCE SUBSTANTIATION 95 t

9731 Seale Model Antenna Test Program 95 a

9732 ‘Antanas Subsystem Qualification 97 5

9733 [Antenna Performance Tests 38

5734 Ground Tests ose -

5738 Flight Tess 38 =

97350 ‘Antenna Pater Tests 3s

o7382 ‘Maximam Range Tests 3 -

9736 Operation! Tents 38

9737 octmentstion| 339

ora (COMMUNICATION EQUIPMENT 30 a

974 ‘Component Tests 0 as

742 ‘Aslone Subsystem Ground Tess 9.60

97421 “Test Requirements $0 F

97422 Acworthines: Qualification Grovnd Tess 90 4

s7aa21 Visual Inspection 50

974222 Cooling Tests 90

974223 RF Output Power and VSWR Tass s

974228 ‘Transmitter Modulation Checks $1

974225 Operational Tests re

974226 Maintainapiity Tests 61 ps

974227 Rejeton Criteria 3.1 :

o74a Prodtion Ground Teste ot .

saga Visual Inapestion 3-81 :

97432 [RF Output Power and VSWR Tess ost

97433 Operational Tests oot

‘AMcP 706-203,

‘TABLE OF CONTENTS (Continued)

Paragraph re

o7434 Rejetion Criteria 7 981

oa Avion Sabajtem Fight Tess. 361

o74a “Airworthiness Qualifaion Fight Tats ot

Saat ‘Antenna Patierss : é 3a.

sada Range Tests 3a

974413 Performance Tests 5.6

74d Vibratory Tes : 9.0

STAkIs Cooling Tests ees 9.83

97442 Production Fight Tes : : 963

boaana Test Requirements. i 9.65

o74422 Operational Tests 98

974423 Rejection Cetera : 363

935 NAVIGATION EQUIPMENT ‘i oe

9753 Component Fess oe

9732 [Navigation Subeystem Ground Teis 58

97521 Test Procedures = 9.63

o7s2a ‘Avion Airworthnes Qualification Ground Tests 5.88

975221 ‘rua Inpostion a eceee seo 9-66

595222 Cooling Tests : i Sst

975223 Operational Tests : oe

9752231 VOR Systems | ee

9752232 ADF Sytem ea oe

9752233 Gyromagnete and Standby Compass Systems 964

975224 Rejetion Criteria : 8.65

97323, Production Ground Tests anne os

9752 Navigation Subsystem Flight Tests : 5-65

S738 ‘Attworhines Qualifetion Pghe Tess. : os

oassta ‘Test Requirements... 3.65

9753114 VOR systems : 368

o753112 ADF Stems = 9.65

S753 Gyromagnei and Standby Compass Syste 9.68

o7s3ti8 Vibration Tests : 9-66

s7sanis Cooling Tests a : 9.56

9754 Production Fight Tess 9.65

976 ELECTROMAGNETIC COMPATIBILITY (EMC) 966

oe HYDRAULIC AND PNEUMATIC SUBSYSTEM DEMONSTRATION 9.6

981 GENERAL : 3686

932 HYDRAULIC SUBSYSTEM 3.67

3821 Ground Tests 7 98

ant Hydrate Steps Mockyp 261

ania Sytem Provisions vos : 36

98213 Contamination Prottlon 2000s 5.68

seats “est Requirements : : 5.60

saatai Peak Presse : 9.69

os2ia2 Sytem Temperature Determination way)

9a2i43 ‘Subsystem Cyting 20

oentas Minimum Reservoir Level and Presure 3:70

santas ‘Ausllary Pump Operation « ae 5:70

982146 Stating Systems : 970

errs 3

TABLE OF CONTENTS (Continued)

Paragraph Page

992147 Brake Subeystem Tests (Whee! end Rotor) “

9822 Fight Tes 7

oa2a Servicing Cs

98222 Instrumentation es

98223 Preflight Tess

902234 Ground Teste

982232 Taxi and Hover Tess 3

oaaa4 Flight Tests és

oaa24t Fight Control Syste Flight Tet = A

592242 Unity Subsystem Fight Test, -

383 PNEUMATIC SUBSYSTEM DEMONSTRATION ze

oat ‘Ground Tess :

93.1 High-pressure Poeumatie Sbeysems a

os3i2 Low-pressure Pneumatic and Vacuum Subrystems :

basa light Tests

9333 Docamentation >

3 INSTRUMENT DEMONSTRATION A

on ‘GENERAL

992 (QUALIFICATION TESTS a

393 ‘ACCEPTANCE TESTS :

394 ENVIRONMENTAL TESTS

505 INSTALLATION TESTS >

9951 ‘Shock snd Vibratory Qulieation i

5952 Fensional Tests

basa Mainainabilty Qualification >

5-10 FURNISHING AND EQUIPMENT DEMONSTRATION *

suo GENERAL :

102 PERSONNEL ACCOMMODATIONS : A

9-102, Personnel Vsbilty : e

9.10211 Sey side Pilot Hiopier

9.19212 Single ilt/Tandem Pilot or Observer 7

9.1022 ‘Crew Sation Environmental Contol Spam (ECS) i

9.1023 Internal Acoustical Environment

s1024 ‘Toxicology C

9.1025 Seating Parnishines

ou1026 Ingress and Eases :

9.1027 Emergency Evacuation =

9.103 ‘CARGO PROVISIONS, ‘ :

‘Cargo Compartment Floors

‘Tiedown Fitings and Devices e -

Cargo Doors and Ramee ao

Wineh Systems e

Conveyors and Tracks >

Hoist Systems ~

Carga Hook Syste

Tefight Demonstration

ENVIRONMENTAL CONTROL SYSTEMS os -

eating, Ventilating, and At-onditioning Systems as

Defoging, Defrosting, and Anteiing/Desing Syetems : 96 ~

3

AMP 706-203,

a

‘TABLE OF CONTENTS (Continued)

Paragraph Page

1043 Onygen System on

out ELECTROMAGNETIC COMPATIBILITY (EMC) DEMONSTRATION 987

outa GENERAL 987

ona HELICOPTER ELECTROMAGNETIC COMPATIBILITY PROGRAM. 9-38

out ELECTROMAGNETIC COMPATIBILITY BOARD oat

our4 SUBSYSTEM INTERFERENCE CONTROL

sana ‘Acpliable Specification

sunaa Interference Contrl Pan. 7

suias Stieytem Test Pl :

uaa Laboratory Test on

outa Sibeymem Test Report

8 INSTALLATION OF EQUIPMENT IN HELICOPTERS

3 HELICOPTER SYSTEM COMPATIBILITY

Sune! “Appiable Speciation (System) : :

sur62 ulcoper Systm Test Plan 7

sabes Stem Test :

sun6a Stem Text Report :

312 ARMOR AND ARMAMENT SUBSYSTEM DEMONSTRATION 5.90

in ‘GENERAL 7 7 30

922 ‘ARMOR DEMONSTRATION 5.90

suzza "at Program es 9at

91222 ‘eat Requirements : ‘ : 9a

9222 “elcoper Pevformance Tests : 931

sun222 ‘Armor Compatibility 7 9a

92223 alii Tests : : : 992

9223 Validation : 992

pareeny ‘Suvivaiy 592

17232 Vulnerable Area Determination ‘ 89

912233 Penetration Data 993

sunze survivability Analjis Repor 993

923 [ARMAMENT SUBSYSTEM DEMONSTRATION : 308

ona ‘Test Requirements o 995

ours Failure Analysis =. : 55

5ua342 Ground Tests 998

sua324 ‘Cockpit Procedures 7 995

puz3i22 ‘Armament and/or Fire Controls 993

su23123 Sighting and Boresghtng 995

ouasi24 Arming Procedares at)

Parened) Firing Test 996

5123126 Environmental Considerations e 9.96

923427 Blast ots fi 9.96

523128 Flach Intensity : 996

su2313 Fight Tests : oa

sua3t34 NNonfising Flight Tes 997

sz343ta Handling Quaies and Performance 99

Su2ar312 Jetson on

su3st313 Loads and Vibration 997

ou23132 Firing Fight Tests 397

1231324 [Noise Leve! Determination : % 997

‘AMcP 705-203

‘TABLE OF CONTENTS (Continued) v

Paragraph Page

9231322 Gas Contamination Measurement 997 =

9231323 Debris Dispersion 3o7

91231324 Handling Qualities e 9.98 7

9u2ai32$ “Loads and Vibration 9.98 x

91231326 ‘Accelerated Service Tests 5.98

9.231327 Engine Performance 998

9231328 Temperature Profile Determination for Armament Subsjeicm Conicls. 9.98

91231329 System Accuricy . 998

su2a.4 letromapneie Compatiiity (EMC) Tes 9.98 a

1232 Documentation 9.98 =

ous EXTERNAL STORE SEPARATION DEMONSTRATION 5.98

ou GENERAL 998 e

oz SEPARATION CHARACTERISTICS ©... 9.99

3103 JETTISON REQUIREMENTS, 99

s34 RELEASE SYSTEMS . 9.9 2

S135 RECOVERY OF STORES 99 s

o36 FAILURE MODE 5.99

95137 ‘TEST REQUIREMENTS : 999 °

ousza Weight and CG Losstons| ee aeon| +

9.13.72 ‘Speed Envelope 999

9373 Aide 9-100 >

e378 ‘Anitede ‘i : 9.100 a

ou378 Flight Modes : 9-100

one DOCUMENTATION 9.100 z

ous HELICOPTER ENDURANCE TEST S01 -

REFERENCES, 9.101 f

CHAPTER 10 :

[RELIABILITY AND MAINTAINABILITY

100 LIST OF SYMBOLS. : rot :

101 RELIABILITY. : Tot

out [RELIABILITY MATHEMATICAL MODELS wot 4

rout Soooes Citra tot a

rou Relslity Block Disgrame : 102

ros Model Construction and Combining Rais 02 o

1012 INITIAL APPORTIONMENTS i 103

1013 RELIABILITY PREDICTIONS 10s

1014 RELIABILITY ANALYSIS—DEVELOPMENT AND TEST PHASES 104 >

roa “Test Plans os -

10142 Reliability Considerations for Development Testing os

10143 Reliability Demonstration tos >

02 MAINTAINABILITY zi 108 :

1021 -MAINTAINABILITY CRITERIA. os

m2 Mainainabiicy Analysis 06 >

Maintenance Policy =. os -

0213 Maintenance Enginceing Anaiyis Dats Sytem (MEADS) 108

1022 MAINTAINABILITY DEMONSTRATION, 108

ai

auc 706-2

103

Paragraph

1224

102221

02222

10223

woa2s

102242

io225

102251

10226

02261

102262

102263

1023

10231

10232

3234

1432344

‘TABLE OF CONTENTS (Continued)

Change Approval Policy fi

Contractor Component Verifeation

(Component Repair

{Component Overs

Yendor and Subcontractor Maina

Makeup

‘System VeiScation

‘Configuration Review

‘ategory I Tet (Contain)

‘Preventive Maintenance (PM)

Corrective Maintenance

Category I Tests (Goverament Test Agency)

“Task Selection :

Contractor Maintainabity Demonstration

Contract Compliance Demonstration

‘TRANSPORTABILITY z

Transportabiity Criteria

Transportabity Demonstration

REFERENCE. :

CHAPTER 11

GOVERNMENTAL TESTING

tasr oF svaemois

INTRODUCTION :

COORDINATED TEST PROGRAM (CT)

Connors Devdopomt sad Alors Qa ee

frmy Pliny Basson (APE)

Sadun Fos

Awrdines sa Fight Charice Tos .

Gimate To

Save Tee

Anu PRELIMANARY EVALUATION (APD)

12D PREREQUISITE

Derails on TEST

onstonal Tee

ening Quits

Petrie .

sonseacttn Axi PRELAANARY EVALUATIONS

MEM PRELIMINARY EVALUATION REPORTS

FINAL AIRWORTHINESS AND FLIOHY CHARACTERISTIC TESTS

GENERAL

‘st Poi

uameoce Tre

Sibi aad Cotl Tae

Miao Toe

‘irony Te Sane

Treat Regurencas

a

Tet

wa

‘AMP 706-203,

Paragraph

ma2312

1132313,

113232

1132324

1132322

1132323,

113233

1132331

1323314

14323312

1132332

1132333,

113234

132341

1323611

1323412

3236

1132361

323.62

32363

113237

1132394

maz3711

11323712

32372

1132373

i

s

TABLE OF CONTENTS (Continued)

Insrumentation :

Documentation es

Static Longitudinal Sabiy Tes

Test Requirements =... :

Instrumentation

aocumentation

Dymic Longitudinal Sabily Tess

‘Test Requirements

Short Period Mode

[Long Period Mode

Instrumentation

Documentation... ete

Maneuvering Staiity Tests

‘Test Raquiremeass

Symmetrical Pullaps

‘Stablize Turning Flight

Inctrumentation

‘Documentation He

‘Sta Lateral-rectional Sait Tests

‘Test Requirements :

Insromenttion

Documentation 10.0... E

Dynamic Latera-trectonal Sabity Tes

‘Test Requirements r= 7 cana

Instrumentation

Documentation

Controlaity Tes

‘Test Requirements 00... eee

Longiesdinal Coatrallty

“Lateral and Directional Conrail

Inetrumeniation

Documentation --- ey

Control Harmony

CLIMATIC TESTS

DOCUMENTATION

GLOSSARY

LIST OF ABBREVIATIONS :

SPECIFICATIONS AND STANDARDS, AND OTHER GOVERNMENTAL

DOCUMENTS

BIBLIOGRAPHY : :

INDEX . : :

AMP 706-203,

————————

5:10

out

22

8

oa

LIST OF ILLUSTRATIONS

‘Title

system Safety Milestones in Enginering Development fi

System Salary Process i"

"The Load Characterstce of Five Types of Destructive Tests for Aakesives

‘Mart Tooling Coordination

Proton Criterion

Vibrtory Tolerance Criteria

Heopter Configurations =~

Data Flow for Engine/Airfame Vibration Evaluation

‘est Iasvumeatation :

Inlet Resovery vs Fight Speed 2.0.0.1

Presure Distortion Plot

Example Summary of Text Penis -0.....

‘Typial Plots of Rotor Natural Prequency ve Operating Spent

US Army Payebrometric Chart

‘Gri for Typeal Hebooptr Fly-by of Misi Simuitor

Flight Test Demonstration Methods...

igt-vltage Long are Tes Arrangement

{Component Sparking and Induce Voltage Test Arangement

‘Clinatic Laboratory, Main Hangar, Eglin AFB, Florida

Enghestarting Characteristics z on

‘Starer Performance - ei

Engine and Transmission Oi Systems During Stars

Summary, Engine Ol Temperature and Pressure

Sunmary, Windshield Detog Temperature a

‘Windshield Defog Temperature Survey

“lensr System Tenpertare and Pressure Survey

Sommary, Corkpt Inet Temperate and Prasre :

Summary, Cockpit Temperatize

(Cockpit Temperature Survey, Bled Air Heater

‘Sonmary, Control Breakout Force: Rotors Stationary, Fiction OT

‘Summary, Control Breakout Force: Rotors Turning, Hyéraulie Boost On, Friction

‘ant Force Tein OF ss

Sonmary, Engine Temperature Survey Be

UAtitade of Seid Gear for Drop Conditions TT and 11 37

‘Engine Tremient Torque Response to a Step Demand for Torque Change os

Dut Reduction (Determination of Damping Ratio and Frequency from Tine

“Hktory Recordings) 920

“Typical Lubrication Subsystem 928

‘Tyieal Propeller Vibratory Survey Instrumentation ot

Ouillopraph Recording 7 935

Revording Instrumentation in Aira... 936

Prepllr Stes Survey Sip Char 937

Vitratory Stress Survey Summary 538

[Ect of Prerore Recovery on Engine Performance : oat

ample of Cloverlst Fight Pia, 30-deg Intervals 939

Sytem Setup end Instrumentation ot

‘Ruborne Compressor charged System O74

‘Low-presure Pneumatic Spply q 995

wi

‘AMCP 706-203,

SS

sail

LIST OF ILLUSTRATIONS (Continued)

Tite Page

Lowpresure Pneumatic Subsystem ‘i 975

Test Apparatus Schematic . 9.76

‘Typical Vacuum Subsystem : 9.76

Sie-byide Helicopter Vision Plot oat

Single Pilot/Tandem Pot Helicopter Vision Pict )s000... 9.82

Winch System Angular Displacement... ot

Winch System Operational Demonstration

‘Typcal Format for Specifying Vulnerable Areas fi

Vulnerable Area vs Weight... '

Jetson Envelope Caleultion :

Vibeatory Leet eesoen

Satis Longitudinal Calecive Fined Stability

‘Stas Longitudinal Hovering Stblty

Forward Longitudinal Pale

Alt Longludinal Pulse ei Fer

Maneuvering Stay

State Latraliretion Stability... cars

Right Lateral Pulse

Normal Ascleration Development During Sudden Control Dispiacemeat

‘Damping Characteristics i Frequency s+. 5

“Longitudinal Control Sensitivity Summary eres

‘Longitudinal Contol Seat sever. 000 A

‘Longitudinal Control Response Summary... :

‘Longitudinal Control Respone, Level Flight :

Longitudinal Control Power +. oe

“Table No,

a

22

3

34

a

Pay

er

6

6s

66

6

m4

2

a

AMP 706.203,

LIST OF TABLES

Tite

SUMMARY OF CTP TEST REQUIREMENTS—HELICOPTER SYSTEM

SUMMARY OF CTP TEST REQUIREMENTS—ALLIED EQUIPMENT

HAZARD SEVERITY FOR HELICOPTERS. =

HAZARD PROBABILITY FOR HELICOPTERS

HAZARD ELIMINATION/CONTROL RESOURCES

HAZARD TOTEM POLE.

DATA AND DOCUMENTATION REQUIREMENTS

SAMPLE BASELINE CHECKLIST FOR SEATS AND FURNISHINGS

METALS, TEST METHODS OF FEDERAL TEST METHOD STANDARD

NG. 151

‘TEST METHODS FOR PLASTICS AND BONDED STRUCTURES

‘TESt METHODS FOR CORE MATERIALS AND SANDWICH STRUC-

‘TURES :

ALPHABETICAL INDEX’ OF TEST METHODS OF FEDERAL TEST

"METHOD STANDAED NO. 175

SELECTED TEST METHODS OF FEDERAL TEST METHOD STANDARD

‘NO. 141

SELSCTED TEST METHODS OF FEDERAL TEST METHOD STANDARD

‘NO. 791

ACCEPTANCE REQUIREMENTS FOR CASTINGS, MIL-C¢021

STEEL, FORGING TEST REQUIREMENTS BY GRADE.

REPRESENTATIVE HEAT TREAT TEMPERATURES,

EXAMPLE COMPONENTS REQUIRING QUALIFICATION

EXAMPLE FUNCTIONAL TESTS.

[ARMOR MATERIAL SPECIFICATION

‘TYPICAL HELICOPTER MANEUVER SPECTRUM

READ OPTION TERMS

‘TARGET ECHOING AREA

SIGNIFICANT RADAR FREQUENCY NOMENCLATURE :

LIGHTNING CURRENT COMPONENTS AND EFFECTS

ICING PROTECTION SYSTEM TEST FACILITIES ..

DATA. REQUIREMENTS, ENGINE/AIRFRAME COMPATIBILITY

DEMONSTRATION

SPECIFICATIONS FOR FLIGHT, NAVIGATION, AND ENGINE INSTRU-

MENTS 7

[ARMAMENT SUBSYSTEM TEST REQUIREMENTS

LATERAL-DIRECTIONAL DYNAMIC STABILITY

Ee

Er

46

63

66

69

eu

on

ra

15

ee

235

40

ous

978

9.96

m0

AMC? 706-203,

FOREWORD

‘The Helicopter Engineering Handbook forms a part ofthe Engineering Design =

Handoook Series which presents engineering dats forthe design and constuction of

‘Aamy equipment.

This volume: AMCP 706-203, Qualfcation Assurance, & Prt Thee ofa tnee-

part Engincering Design Handbook led Helicopter Engineering. Along with AMCP

706-201, Preliminary Design, and AMCP 706-202, Deal Dest ths pat stew

dd to set forth explicit design standards for Army belcopers to cxablsh “

‘ualincation requirements, and to provide technical guidance to Nelcopet designers

Im both the industry and within the Army ¢

The first volume ofthe handbook, AMCP 706-201, discuss the characteristics “

and subsystems which must be conskered during preliminary design of helicopter,

‘Additionally, possible design problems encountered during helicopter desig are

scused and pomsible soltion suggested A

'AMCP 706-202 deals with the evolution of the veicle from an approved

preliminary design cotiguration. As a result ofthis phase, the design mst provide

suicient detail to permit construction and qualification ofthe helicopter in com +

Pliance with the approved detail specication aad other teqivenent. Design

oquirements forall vehicle subsjteme alto are included in AMCP 706-202,

This volume, AMCP 706-203, defines the requirements for airworthiness >

‘qualification ofthe helicopter and for demonstration of contact compliance, an alo .

esrbes the test procedures accomplished by the Army. The volumes divided ino

1 ctupter, and is organized as described in Chapter 1, the intedacton to the +

volume

2aiv z

‘AMCP 706-203

PREFACE

‘Tis wohume, AMICP 706203, Quatifesion Assuronce, is the final section of =

tweet engnesing handbook, Helkoprer Engineering, in the Engineering Design

‘andtosk srea It was prepared by For Actespace, Ine, Washington, D.C. under

fobeontsct to the Engioering Handbook Office, Duke University. Durham, N.C.

"The Sagincting Design Handbooks fl into two bai categories, hose approved for

oles ant, andthwe clase for sou reatons. The Army Mateit Command

‘oly to eles thse Engineering Desig Handbooks to other DOD activites and thei

‘onto, sid other Goverment agencies in accordance with core Army Regulation

SOS1, ted 9 September 1966 Iw be noted that he sort of these Handbooks

‘a bs sbtined fom the Nelonal Technical laformation Service (NTIS). Procedures for

‘Sepiig thse Handbooks Flo:

kris win AMC, DOD agence, and Goverment agencies ater thar DOD

‘ving ned forte Handbook sould dest ther equest onan fil form to

Commanding Otis

leterkenny Ary Depot

ATIN: ANXLE-ATD

Cambersars, Pennsylvania 17201

by. onteetors and uveitis must forward ther quest to:

‘ational Tesh! Information Service

Department of Commerce

Springeld, Vila 22151

(Requsts for lasiied documents mst be sent, wth appropriate “Needo-Know”

justia, to Leterkemny Army Depot)

srs of the handbook sie enouraged to contact USAAVSCOM St, Louis, Mo

agit Standards and Quaifeston Devon (ANSAV-EFD, with thir recommendations

ind comments concerning the handbook. Comments should be specie and include

‘Reomonended text changes and pipportiag atone. DA For 2028, Recon

Tandnd Changes to Publications (available through normal

Publications eupply chansele) may be used for thie purpose.

Wresy of the coments should be sent to the Comanding

Gensel, AAC, ATTN: AMCRD-TV, Washington, DC 20315,

Resisions to the handbook will be made on an asrequred tals end will be

distrnutd on 8 normal basis through the Leterkenny Army Depot

COOCECEE CC EOE EEE MET CE CIEE OO HEEOC ERE GEBE CEE EEE

AMP 706-203

CHAPTER 1

INTRODUCTION

AMCP 106-201, Helicopter Engineering, Part One

Preliminary Design, ihe fist volume ofthe Helicopter

“Handbook Series avd siscuses the preliminary design

phase and contract definition procedure, incluing the

roles and applications of weight and performance est

sation; ying quality predictions, and systent safety,

reliability, and maintsinabilty considerations) At the

conclusion ofthe preliminary definition period, «he

copter configuration wll have been selected and its

‘eneral characteristics and capabilites defined in pro-

[urement specifications Data required during contact

definition, in responseto a Request for Proposal (RFP)

‘or a Request for Quotation (RFQ), have been defined

in Chapter 14 of AMOP 706-201,

‘The same disciplines and procedures continue in

‘greater detail throughout design and_ qualification

‘AMCP 706-202, Helicopter Engineering, Part Twa, De-

tail: Design, the second volume, describes the follow-

‘on detail (or engineering development) phase in terms

‘of design requirements, eriteria, and procedures forthe

total cysts and ite cabeyetems. The eyetam and ub

stems are reexamined, refined, and defined as the

design and optimization proces continu. The specif

cation requirements end qualification plans are trans

Jated into hardware hyou', with appropriate investi-

ations, analyses, and exploratory. testing, Detail

‘drawings, reanalysesand qualification testing follow.

This volume, AMCP 706-203, includes the require-

‘ments. and procedures for substantiation ofthe airwor-

‘thiness of the vehicle rough proof of compliance with

contractual designrequirementsiand performance guar-

Airworthiness, as defined in AMCR 70-3, is “a

demonstrated capablty of an aircraft, or airraft sub-

system or componen fo function satisfactorily when

‘sed within the prescribed limits

‘Ts the intent of ths volume to delineate the respon-

“sblitesofboch the rocaring activity and the contrac

tor in the planning ad execution ofthe airworthiness

‘qualification program fora new model helicopter. The

Inlcopte systems to which such program is applica-

ble may be completdy new, or may be the result of

‘major mosification of « previously qualified system.

For simpy, the internal workings ofthe Govern-

rent are not dsoused. Govermmenial raponatiies

sre always related to only che procuring activity.

‘Although dependent limatly upon specie tats

and demonstrations of the complet helicopter system,

Sicworthines_qunlifeason is a continuing. proces

‘whic gine with he ination of stem development

Teeluded ar design eviews, during both theinial sb

system definition phase and the final detail design of

‘Seenbles and intallatons. The construction and ia-

Section of full-scale mock-up by experts is spe

‘ad deg review. Conducted 8 carl inthe program,

5 posible, the mock-up review permis evaluation of

the rlationahip and interaction between all required

‘beystemsin a msnner whic ie imposible when ng

nly two-dimensional layouts and drawings.

Dring the design and intial fabrication phase, prior

to the avalsbilty of components or complete systems

rts analyses re performed to subsatiatsSubsyse

tem cofigaratons and performance. Alo during this

Paviod detailed plane ate prepare forthe tasting of

Components, subsystems, andthe complete helicopter

ss equ to ver compliance wth applicable design

‘nd performance requrenenss The peparauon of

‘hese analyses and plans by the contractor and their

review and approval by dhe procuring atv ate sg-

nificant elements of the srworshines qualieton pro

eam,

(anlieton of = new model helicopter includes

qualification of component, ofsubsystems, and ally

‘fthecompete hiopterrytem. Rach of thse oss

Is deseibed in the chapters which flow. Also included

isa cineanson of Govemmentl texting, which com

usted to confirm that system performance eomplics

vith contract quirements, This testing ncdes that

{eqired to obtain the data neoessary for verifying safe

Inlicopter operation for fllowon Governmental t=

ing and forthe preparation of operational and service

manual forthe sytem. Following completion ofthe

Dbalcopter qualication and preparation by the procur

‘ng activity of th Airworthiness Qualification Subta

tation Report, Governmental testing conics, in the

form of Service Tet, to inte operational suitability

ul

AMP 706-203

snd to determine 1 what ogee the helicopter meets

the characteristics stated inthe requirement document

Hlowever, discussion ofthese efforts beyond arworthi-

‘ness qualification is not within the seope of hie and

book

“Throughovt this volume, the mandatory qualicn

toa requirements have bee identified with the coo-

‘ractallangoage which makes we of the imperative

sword “shall” To assist nthe use of this document in

the planning of a qualification program, the word

“shall” has been alized i thestatement of each suc

sequicement

Since the qualification requirements for individual

programs may vary fom the level of detail describ

In ths volume, the procuring activity will pei its

‘Reset for Proposl the extent to which these roi:

iments are applicable to the qualieation of given

hsiopter. Deviations fom this handbook nt epeci-

cally included in the REP will be considered when

!deguately ubtantited inthe contractors espanse

the REP. This handbook wil not be incorporated in a

contact by reference in whole arin part. Homer, the

Jnmdtook may be farses to contractors ae base for

‘stablishng contrac requirement tobe cluded inthe

‘Airworthiness Qulifestion Speciation (Chapter 2)

AMP 706-203

CHAPTER 2

AIRWORTHINESS QUALIFICATION PROGRAM REQUIREMENTS

2:1 INTRODUCTION

‘The Coordinated Test Program (CTP) i the pri-

mary development pinning document used to des

ibe the formal, comprehensive program for tes-

ing. The CTP is roguived by AR 70-10 for all e-

search and development projects entering engineer-

ing development, The CTP for helicopters normally

ie prepared by the Anny Project Manager, and has

the folowing objective:

1. Toservessa munagement ton tinsure that he

nccesiy elements of text program are addresied

2-To insure that aequat coordination i effected

among the agencies which request dat

2. To insure that adequate testing i planned for

riving a ype clasifetion and a production decision

4 To provide justfaton forthe numberof pot

types to be used daring testing

‘TheCTP also mus provide the justification fr com-

bining tess, for condeting them concurrently, ofr,

climinating them in an effort to avoid duplicate and

‘amecesary testing

Helicopters and slind equipment are developed um

er a specific analtal proces to substantiate that

they are airworthy. The total of all elements in this

‘nage proces isthe Airworthiness Qua ton

rogram (AQP). ‘The program is deserbed filly in

the CTP and ison clenent of the Request for Proposal

(RFP) o Request for Quotation (RFQ). The AQP peo-

‘ides general guidance on enginering analyse, formal

inspetions, design reviews, safety asessmenis, com

‘eacor demonstrations, ad all conractar and Gover

‘ental qualification tas esetal to dafaing and in

Plementing the procirement of any major Army air

Sem and/or sled guipment. This general informa

‘Son then will povide the basis forthe Airworthiness

(Qualfestion Speiftion (AQS), which is weten by

the contactor Inert in the AQS ithe dissemina-

tion of data nesetsny to demonstrate roa of eompl

ance with thesystem eserption or deta specication.

‘The AQSs designed to isure that the necessary ifor-

tation obtained to permit the issance ofthe Salty

lof Fight Reeies and/or Interim Statemeats of t=

‘worthines Quaifeaion required during enginering

evelopment Te also pennts the issuance ofa Sta=

‘ent of Airworthines Qoliston, and Army publ

‘ation ofan Airworthiness Qualification Substantation

Repor, upon the compleson ofthe program. Last,

the AQS wil ahere to the pales, bjestvs, defn

tions, nd procedures spect in

TAR 70-10, Testand Bvalaton During Research

and Development of Materiel

2, AMCR 70:32, deronautoal Design Standards

ADS) for US. Army” Airraft Systems ond

Sibostoms

3. AMCR 70-33, Airworthiness: Qualification of

US. Army dircaf Stems and Subsystems

The types of tats which comprise the CTP, as well

sas thetest agency, est hardware and test objectives for

{feomplet opie system a alegupmety we

summarized in Tables 2-1 and2-2. These tests normally

Should be conducted in the sequence shown in the ta-

bes, especially where text results are equted prior to

further testingand in those uations where extreme

climatic conditions wil be encountered. Concurrent

fad integrated text phasing willbe ured when justified

by fund and ine linitatons.

2:2 AIRWORTHINESS

QUALIFICATION SPECIFICATION

(QS)

(GENERAL,

As noted inthe previous paragraph he contractor's

sirworthines qualification test plan ithe ke element

in the overall coordinated plan for development of new

heicopters,

Fr each baicopter system subject to qualifston or

requaliation tecause of major modification,

‘qualication speciation wil be prepared to establish

a

22a

‘AMCP 706-203

those enginerng tots or analyes which ae ssn

to the arworthinessubtanation ofthe yee. This

‘work is vided into those testo be performed ander

‘a eagncringdavlopment contract, oF any oer ap-

propriate procurement action such esa product im

22.2 AIRWORTHINESS QUALIFICATION

SPECIFICATION REQUIREMENTS

‘The Airworthiness Qualification Spcication will

be prepara bythe rime system contactor in responce

TABLE 24, SUMMARY OF CTP TEST REQUIREMENTS—HELICOPTER SYSTEM

cosas a

Pr ee

oe See | Me mia um neo

a EE |S TE eno, ures

Se pees a

cn ROVE RELNDaRY SreRATNAL EDT

scores | 2 mereaen caerhare eden

nacrnaes | Ea | pone | ENG cates Heke ewernenes

ote Ta hare ee ere

on ee

a

ee

aor aineresins or Tie adnol NT ash NT

seers [CE | meager

‘com (TECOWTEST, er ‘DETERMINATION OF COMPONENT SERVICE LIFE AND QUICK CRANGE KITS

Be ite

—

‘TABLE 2.2 SUMMARY OF CTP TEST REQUIREMENTS—ALLIED EQUIPMENT

TEER TOC IE TE WENT SALCTNL COIN,

FLEermea amps frre

TeoTi | DevEmmaTionte Rawk 6 APETY NPATION

[umtrcano rests

eo

EVDTRATON OF PERFORM ABT COMTRRGT

ETE oF Hu FEoRNICS REOURENENTS

TART GEVELOMENT a ARTA

aALrearon tests,

Tac

Sevenaenr

igeerhuce

sts mown | ores

hurt Ne oe ureter

cvoneeane

a8

wares

Sem an pane

(aati air tiem

TES A FLT GHEACTERTIE

DEyEAMIMIN oF THE OEREE TS The TESTS TH

(arr | amerenetes or Te Wegunetens cocwet

2

AMCP 706-203

to the requirements tablished bythe procuring 2c-

‘ivy ia the REP. Eleents ofthe AQS include:

1. System Safty

2 Design Revie and Release of Drawings

3. Mockeups

4, Procurement and Process Specifications

5, Component Ts

6. Sytem Survers

17. Formal Conttor Demonstrations.

‘These elements are deserted in the paragraphs

which fallow

2.2.2.1 System Safety

‘Aspartof the Airworthiness Qualification Spica

tion the contractor wil tablish the means by which

the results ofthe Syszm Safety rogram (SSP) ae to

be eplid inthe airorthines qualiieation of the

ton. The provisions and requirements of the System

Safty Program Pin SSPP) ae stated in par. 3-2. This

program produces data and information leading 0&8

Furies that the opium degtee of hazard elimina-

ton or control has ten stained in the design of the

sistem. The contacor wil nclae\two areas which

‘linately combine 9 form the bass forthe Sytem.

Safety portion of sivorthiness qualification: (1) i

term fal safety statements and (2) system species

Son compliance. In addition, the contactor wil n=

fore that all components tei, system surveys, and

{ormal demonstrations are planned tnd Soedacted i

clone coordination withthe System Safety Program,

Hazard analyse wll bean integral nd een factor

‘nal such ests and demonstrations to insure that these

‘ctvtes are conde’ with minimum ak

22.2.2 Desigy Reviews and Release of

Drawings

Design reviews wil be conducted on an as-equired

basi, This portion ofthe AQS wil one the contac:

tor procedures for -onductng such reviews. Speiic

‘equrements ae not presented in his volume because

‘ach contractor uray has his own review procedures

nd drawing appro proces. Is not considered eae

‘ble to ry to standardive these areas. Partition in

the design reviews dos ot limit oF rect tha le

rent ofthe proarng setivity fom the responsibility

tt nsuring that the drawings conform tthe requ

‘ments of MIL-D-T010 through normal contract chan-

mel

Design review of deal drawings is required for

‘ach subsystem Base reason forthe ineuson ofthese

reviews inthe qualifation program of hsioptrs are

ines as fellows

1. To insure tht there are no obvious exists

with design tera

2. To ingare that there reno obvious design pit

falls dicpline sacha fey, ellabilty, and mao

‘ainably

5. To maintain postive record ofthe conigurs:

tion which i being propored for analysand testing

4 To establish bas or updating and ident

pasts which pas o all the qolfaton tes,

5. To provides foundation fran aust tal of

worthiness substantiating ations

2223

“The specications forthe mock-ups required by the

[RFP wil be inclaed in the AQS. See Chapter 5 fora

etled deus of mock-ups.

Moekups

2.2.2.4 Procurement and Process

‘Speciications|

In order forthe procuring stv to manta cop

ance over the detail configurations for which srwor

thine ubstantation ie dese, review ofcertainpet-

feat drawings and approval of procurement

fpecicaons of contractorfurished equipment

(CFE) components are een. To insure adequate

‘rucuralitepty, material and proces spesifentions

leo mst be subjected to the approval he procuring

ety

‘This section of the AQS should list those procure-

ment and process specifications which most be sub-

Jest to approval By the procuring activi.

“Type examples ofthe key procurement snd pec.

ssseaications (rawings defined in MIL-D-1000 t0

be submited are

1. Specification contrat

2. Soure control

2. Interface control

4 Instalaton contro

5. Installon

6 Contra.

Spesfeton control drawings or source conta

rawings which constitute conracior procurement

peciletions shouldbe included automaticaly fo the

'AQS. Details of procurement and proas specication

requirements are described in Chapter 6

23

‘AMC? 706-203,

2.2.2.5 Component Tests

‘The objectives of component testing are to make a

preliminary determination whether the reliably re

‘quirements for component life will be met by the

Tardware under tet and to ingure adequate integrity

for sein higher level assemblies inground and fight

tests, This section of the AQS wil dtine complete est

requirement

2225.1 Prequalification Bench Tests

Prequalification bunch tests are not clisied at

“must pas ess, The primary objective of prequal

ution testing 10 uncover any defect or design de

‘ieney and to detect any fatigu-vitialcompaeat oF

pare Tn addition, the program wil be used for the

‘incorporation and evaluation of "ines" and in gener,

1o refine the component or subsjiem design. The

preguaiiation test tne and severity wil be specifi

and funded as part ofthe contract,

22252 Qualification Tests

The objective ofthe gualicaton est it demon

stent formally that the prequalication testing has de

{ectad any delet or flgutimited prt athe com-

ponent or subajtem. Exablishment of int time

{etwoen veriauls (THO) willbe made by the procur-

{ng sty atthe completion ofthe testing otned in

pir. 2-22.5.1 and revised periodically depending on

Serve or adaional bench test experienc. The length

fand severity ofthe quaieaton tests wll be specified

by the procuring astiity and funded as part of the

2.2.25.3 Tiedown Tests

The total propulsion system—incuding all goa

‘boxe, enginG) shftng, rotor systems brakes, clutch

fs, aconsores, and controls—willbe installed on the

{round lest vehicles and subjenal to qulifcation tt

ing in accordance wit atest procedure approved by

the procuring aciity. The Best test period wl be the

preliminary Right approval test (PPA) and must be

‘Completed stsatoly before fst Might. The procur-

fing activity wll determine satsactory completion of

the test. Retesting may be required, depending on the

ature and severity ofthe flores.

2.2.2.5.4 — Rolibilty Bonch Tests

Additional bench sting wl be fequee by the pro-

curing activity to enhance the pregualifction stats of

selected components or subsystems. The test schedule

Should be ima to that sein pa. 22.2.5. uliing

24

as much ofthe orginal hardware as possible. Duration

‘ofthe est wil be determined by the procuring activi.

22.255 Component and Subsystem

Inspections

‘Asa minimom, formal military qualification sts of

components and subeystems Wl inch:

1. Engines,

2. Main transmissions

3. Main rotor and tail oor subsystems inloing

io and Bide |

4 Propller and propeller pasboses

‘Tall rotoe gearboxes

Torermediae gearboxes

Flight controls

Poel systems

5

6

2

5

9. Landing gsr

0. Elect

‘These tess wl be followed bya disassembly inspection

accomplished in he presence of representatives of the

‘Contactor, the procuring activity, andthe Army Com:

‘modity Commands if applicable. The inspections will

‘be performed to determine ifthe components and sab-

‘stems have sucessfully posed the quliaton test

‘efned inthe AQS.

The inspection of mechanical and hydromeskanca

components is divided ita two phases, The fis in

voles inspection af all parts immediatly afer dss

sembly the second inspection invalves a review of the

‘sults ofthe ital ispection. Data should be made

svalbl othe inspection tem fr both phase.

‘Al mechanical and hydromechanial components

sod assembles willbe subjected toa complete anal

cal isssembly and inspection. Inspection techniques

tay inlad, but ot be Hrd fr (1) visual, @)

‘mensional, (3) magnetic partie, () fluorescent pene-

tant, (5) Keay, and (6) las

‘Photographic coverage of ll items of significance is

required during inspections for ltr ubization ithe

qualifiestion text report

22.256 Electrical and Electronic

‘Components

ns general ls sophisticated inspections will be con

{dacted on elas nd eletrnie components st the

[end of component testing than those speifed for me-

hanical and hydeemechanial components in the

previous paragraphs. Appropriate inspection reports

Wil be prepared. A desertion of component te

quirements is sven in Chapter 7.

-AMCP 706-203,

22.2.6 System Surveys

System surveys incade all tests designed to deter.

sine system characteristics and demonstrate satisfic-

tory sytem operation within the normal Might en

elope as well 38 10 determine conformance with

sirrame unit design requirements. In determining 398-

fem characterise, acount wil be taken ofthe inti

ence ofall sabsystems, ned and movable, and expected

operating envionment. The requivemeats of pat. 2-

227 alo will apply 1 the system surveys specifi

here

‘System surveys should include, but not be ited to

1. Fight Load Survey. Flight lads wil be ob

tained throughout the fight envelope fr allenic

‘components Sufficient data wll be abisined to allow 2

Preliminary estimate of fatigue lives and to determine

‘resonant frequeniesof eral components are tuned

fo the fequencies ofthe primary exiting frees (ee

par. 82)

2, Engine Vibratory Survey. Flight and ground

vibratory surveys willbe conducted to verify that en-

{ne vibrations donot exceed the allowable vibratory

limit specified inthe engine model specification (Gee

par 63)

5. Propulsion System Temperature Survey. Fight

and ground temperature surveys willbe conducted 19

erly that the engin), engine accessors, engine

Avid. siframe stractre transmission system. ga

bones, Ret exchangers et, donot exceed their allow

able temperature limit (ee par 8).

4. Engine Air Induction System Survey. Flight

snd ground engine inkt surveys wil be conducted 0

‘verify proper inlet presure recovery and distortion pat

ters (Ge pa. 8-5),

5. Engine Eshaus Survey. Fight and ground en-

ine exhast subsjstem surveys wll be conducted to

‘lute operation an performance (pressure survey)

fd tr olin petri pal ex

6. Total System Vibratory Survey. Those tts are

required to demonstate compliner with vibrator)

comfort requirements and to demonstrate thatthe bel

copter i fre from exesive wbraons, or roughoess

sffectng ts streturalinterity ots capably to per-

orm its mision. Vibratory measurement instrumenta-

tion will be installed at the requied locations. Quan-

titative data shouldbe collected during wnaoslertad

tnd aeeerte fight over the fall ange ofthe Might

tmvlope and of allonable rotor speeds (ee pa. 7).

7. Crew Envieonmentl Survey. A survey shold

bv performed to demonsrate compliance with erew

environmental requirements under all peed oper:

ing conditions and modes (ee par 8).

8. Infrared (IR) Radiation and Countermeasare

System Suriey. An IR radiation and countermeasure

system survey should be performed, if applicable, to

demonstrat that the TR sigaatae bas ben reduced to

acceptable levels The survey wil inlude documents-

tion ofall trade-off made in miniminng the signature

(ex par 892),

9. Radar Reflectivity Survey. A surey should be

pesformed to demonsrae that thera elecviy

inimal and absorption is maximum. The survey wll

include a detailed report of techniques to minimize

radar reflectivity (8 par 8.93).

10, Lightning Protection Survey. A survey wil be

performed to establish a high degree of confidence that

{he helicopter sjstem can survive lighining strike AS

‘minimum, the survey wll demonstrate thatthe Fs!

‘stem meets Faderal Aviation Administeation AC20-

53, Further, the bonding. concepts of MIL-B.SO87

shouldbe demonstrated as capable of surviving ight-

ning strikes Gee par. 884,

11. Acoustical Survey. An acoustic survey will

be performed, if applicable, wo demonstrate thatthe

scoutical signature meets the appropiate require:

‘ments. Thi survey wil be performed under all pe

Fit operating conditions and modes (ee par. 8.6,

22.2.7 Formal Contractor Demonstrations

‘This portion of the airworthiness qualifeaion

specication will contin the specific Army req

‘ments for the formal demonstration ofthe heiooptr to

show its eayabilty to comply with requirements of the

Inlicopter detail speciation

‘The purpose of the formal contactor demonstra:

1. To demonstrate thatthe helicopter can be op

crated safely by Army pilotsdrng the prosring ==

‘iiy’s test program tits consent with the con-

tract design limits without excessive malfunctions,

flues, of other unetsatory conditions

2. To demonstrate those specification require:

‘ments which wil ot be substantieted during the pro

ring activity test program. These contractor demon

Ssrations are usally "pas tests of @ specie

‘esgn requirement.

3. Toobtain quantitative information on safe ight

limits for operation by Army gilts

2s

‘AMP 706.203,

4. To verify that the hellcoper has completed con-

tractor tt and is ready for delivery tothe procuring

stivity for Governmental test

222.71 Demonstration Sites

‘Thedemonsration normally is conducted atthe con

tractors ght test fact other ght test tts

may be used with prior Governmental approval. Tests

involving the earring and release of guided misses,

txposves, and armament should be performed at &

Toston specified by the procuring activi.

2.2.2.7.2 Helicopter Configuration for

Demonstrations |

Hlcopers uss for the performance of formal

demonstrations shoul be dential, within production

tolerance, to hecoptere which are to be delivered or

have boon delivered for Governmental tests or opers:

‘donl use. For thote demonstrations in which engine

power isa crite parameter, calibrated engines will Be

wtlized.

2.22.7. Contractor Plt Approval

For formal demonstrations, al contractor test plots

wil te approved, by name, bythe procuring att

Contactors should ineruct demonstration pills

thoroughly cocering the design, serodynamis and

struciral features, and/or oer umusil characterise

tis of the demonstration helicopters.

2.2.2.7.4 —Hellopter Fight Approval

Demonstration belcopters should not be operated

by contractor lots without Safety-of Fight Release

lniued By the procuring activity.

2227.5 Test Conference

Pio othe development of detail test plans forthe

formal demonstration program, oe of more test la

ring conferences shoals be bel Between the contractor

fnd the procarng activity to iasure that the require:

‘ents ofthe formal demonstration programs ae us

‘erstoed and to expedite the conduc he program by

‘esoling any questions or ambiguities that may exit

‘Aasivonal test conferences may beheld as required

2.2.2.7.8 Speci Demonstration

Fequiorents

Demonstration requirements wil be developed dr

ing contact defnitions, and generally Wil include the

falling

1. Strctral Demonstration. Structural demon

stration shoold coat of quantitative Hight test mex

26

surements ofall combinations of gross weight confgu-

ration, center of gravity (CO), albtude sped, load

fete, and eoatrl mations required to demonstrate

complince with the helicopter detail speciation

‘Sructural requirement (4c pa. 92)

2. Engine/Aieframe Compatiility Test. Both

round and ight tes of engin/airrame competi-

Iryare conducted to verify engine, engine contol dive

tenn, and rotor subaystem dynamic matching (ot

‘Sonal stability) characterises (ee par. 93.2)

3, Lubrication Subsjstom Demonstration. A ue

‘rcationsobeystem demonstration i conducted to de-

‘ermine ithe engine ol system(s) and transmission ot

system() operate sntifactors, maintain the required

til pressure, and are fe from excessive ol decharge

1 the Brenthers and to demonstrate the adaquacy of

{he ol cooling and bypass sytem. The ol cooling test

may be condicte during the engine temperature su

vey (ee par. 9.34.

44 Fue Subeystem Demonstration. A ful sobsys-

tem demonstration ss conducted to determine the

capacity of the fl tank() of the heliopter and

Amount of unusable fil, fe! vent system adequsey,

{he operational characteristics of he fel supply system

‘under varios toost pump file conditions, the em

perature suey limits of fe system equipment, andthe

fel system operational cpabitis under scaal se

‘ioe conditions In adition, the satisfactory operation

ofthe fue supply under extreme operating conditions

‘hoald be demonstrsted (ee par. 9-342).

5. Dynamic Instability Demonstration, The con-

tractor will demonstrate thatthe halcopter is fiee of

‘ochanial inability aall operating conditions, the

nti range of gros weights, and throughout the ex

treme temperate range (spar. 9).

6. Flying Quality Demonsiration. The yng qual

ity demonstration will consis of quantitative ight ts.

reaturements demonstrating compliance with the r=

suiremens of the handing quality speciation. This

omplance wil be demonseted throughout the fal

Aight envelope in both powered and astoruaive ight,

‘nd should include demonstration of«heightvelosty

curve (se pa. 95.3,

17. Eletial Demonstration, The contractor wil

demonstrat the performanceaf the complete eetial

system. The demonstrtion, consisting of ground and

Aight tests, wl adequate to determine the capability

ofthe system to perform the factions required bythe

Spplicable specications (separ 9.6)

{ Avionie Demonstration, The contractor ail

demonstrate the performance of the eomplee avioic

Insalaion The demonstration, consisting of round

AMP 706-203

$70 203

and igh tet, should verify the eapeiity ofthe sys

tem to perform the funtion dictated bythe apace

specifications Gee pr. 9-7)

9, Bectromagnete Compatibility EMC) Demon-

stration. The contacto: wll demonsirate thatthe ar

fous subsytems funston propery in any posse cle

‘eomagetic envionment that can be generated by

operation of onboard equipment. The contractor also

il demonstrate dat 9 single subst operates as

1 pousible source of cssomagnetc energy that can