Professional Documents

Culture Documents

Mes Mddd6 5 Rev1

Uploaded by

mohantyomCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mes Mddd6 5 Rev1

Uploaded by

mohantyomCopyright:

Available Formats

MECHANICAL ENGINEERING GUIDELINE

MES-MDDD-6.5 Rev.: 1 Rev. Date: 03-28-2003 Page 1 of 6

COMPONENT SUPPORT DESIGN CRITERIA

(Entire Guideline Reformatted)

APPROVED:

Signature on File

1.

PURPOSE This guideline defines the design criteria that shall be followed by component support designers for both fossil and nuclear projects, unless otherwise directed by the Project Manager.

2. 2.1.

DEFINITIONS Components - Pressure - retaining vessels in a power plant, such as concrete reactor vessels, concrete containments, piping systems, pumps, valves, core support structures, storage tanks, etc. Component Support - The entire range of structural and mechanical elements whose functions include carrying the weight of components and providing them with structural stability during any postulated loading conditions. Structural elements whose sole function is to carry dynamic loads caused by a postulated loss of pressure-retaining integrity (i.e., pipe rupture restraints) are excluded. Anchor - A component support used to prevent any translational or rotational movement of the component. A is used to designate an anchor. Rigid Support - A device used to prevent translation of component in only one axis. R designates all rigid supports carrying vertical loads. Rigid supports carrying loads other than vertical are designated by X. X supports are also commonly referred to as rigid restraints. Guide - A component support used to prevent translational movement of a pipe in two directions except axial to the pipe. G designates a guide. Constant Support - A spring-type vertical support used to carry weight loads at locations subject to relatively large vertical thermal movement and at locations where a substantially uniform supporting force throughout the travel range is required. C designates a constant support. Variable Support - A spring-type vertical support used to carry weight loads at locations subject to vertical thermal movement and at locations where some variation in the supporting force may be allowed. V designates variable supports. Snubber or Shock Arrestor - A device used as a shock and vibration arrestor that allows thermal movement of the component but locks and acts as a rigid restraint when subjected to acceleration motion or force along its axis. S is used to designate a snubber.

2.2.

2.3.

2.4.

2.5.

2.6.

2.7.

2.8.

This document contains information that is confidential and proprietary to Sargent & Lundy, L.L.C. (S&L). It shall not be reproduced in whole or in part or released to any third party without the prior written consent of S&L. Copyright Sargent & Lundy, L.L.C. 1996 all rights reserved. Standards located on the Intranet at http://SLWEB.SARGENTLUNDY.COM are to be considered as the official version of the Standard. MES-MDDD6-5-REV1.DOC

MECHANICAL ENGINEERING GUIDELINE

MES-MDDD-6.5 Rev.: 1 Rev. Date: 03-28-2003 Page 2 of 6

2.9.

Load Capacity Data Sheet (LCDS) - Certified document issued by the vendor which includes load carrying capacities, load directions, and dimensions of component supports. The LCDS also identifies the file locations of the calculations and test results performed in the qualification. The LCDS may consist of one or more pages accompanied by a cover sheet stamped by the Vendors engineer. Integral Attachments - Any attachments welded to, cast with, or forged to the pressureretaining component, such as lugs, stanchions , ears, rings and skirts, that transmit the loading induced by the component. Nonintegral Attachments - These are support elements that mechanically connect to the integral attachments or to pressure-retaining components and transmit the loading induced by the component. Nonintegral attachments include sliding joints, clamps, cradles, saddles, or straps. PROCEDURES AND INSTRUCTIONS General Design Component supports shall be designed consistently with the results of the piping subsystem analysis as to the type of support and the magnitude and direction of loads and movements. Component support design shall be in accordance with governing codes as follows. For S&L Class A, B, and C (ASME Section III, Classes 1, 2, and 3, respectively) components, the design shall be per Subsection NF of Section III of the ASME Boiler and Pressure Vessel Code. Supports for these components are termed safety-related supports. For S&L Class D (ANSI/ASME B31.1) components, the design, in general, shall be per ANSI/ASME B31.l. Supports for these components are termed non-safety-related supports. For the purpose of defining the jurisdictional boundary between piping supports and the building structure, the following definition shall apply when Subsection NF is invoked. Structural members shown on the civil structural drawings of the plant and analyzed in the building structural analysis may be designated building structure even though these members are located in the piping or component support load path. Structural members installed and used for the primary purpose of supporting piping or components shown on mechanical system drawings shall be designated component supports and shall be constructed according to the defined jurisdictional boundary for a particular project.

2.10.

2.11.

3. 3.1. 3.1.1.

3.1.2.

3.1.3.

The component support design configuration shall be simple, economical, and constructible based on coordination of design requirements with the plant and piping specifications.

This document contains information that is confidential and proprietary to Sargent & Lundy, L.L.C. (S&L). It shall not be reproduced in whole or in part or released to any third party without the prior written consent of S&L. Copyright Sargent & Lundy, L.L.C. 1996 all rights reserved. Standards located on the Intranet at http://SLWEB.SARGENTLUNDY.COM are to be considered as the official version of the Standard. MES-MDDD6-5-REV1.DOC

MECHANICAL ENGINEERING GUIDELINE

MES-MDDD-6.5 Rev.: 1 Rev. Date: 03-28-2003 Page 3 of 6

3.1.4.

In-place embedment plates and structural steel shall be used for attachments whenever possible; use of expansion anchor plates shall be minimized. Special consideration shall be given to hydrostatic testing; temporary support shall be designed if necessary. Shear lugs shall be used whenever the line of action of the support using pipe clamp makes an angle greater than 10, or the angle specified by the clamp vendor, whichever is smaller, from the line drawn at the point of support perpendicular to the axis of the pipe. MES-EMD6.2 shall be used for designing shear lugs. Rigid riser supports shall be designed such that each arm shall carry the total support load. Unequal arm riser supports should be avoided. The type of support or restraint hardware to be used on either leg of an axial support attached to a riser type support shall be designed as follows: If the support is rigid (R or X) or a snubber (S), each leg shall be designed to carry the total load. If the support is variable or constant, each spring shall be selected to carry the actual load as determined by weight-balance calculations.

3.1.5.

3.1.6.

3.1.7.

3.1.8.

3.1.9.

Two or more non-safety-related, nonseismic cold lines (temperatures below 150F) may be supported on one trapeze beam. Pipes on a trapeze design shall always be held firmly on the trapeze beam (i.e., use of U-bolt, box-type, etc.). In trapeze design, each leg shall be designed to support the actual load as determined by load balance calculations. For a rigid support, both legs may be designed based on the larger reaction. For variable supports, the trapeze beam should be loaded at mid-span to have identical spring cans on each leg. Pin-connected vertical supports (e.g., rod-type, variable, constant, sway strut, etc.) shall be designed: So that the range of angular movement of the support between the cold and hot positions does not exceed a 4 cone centered at the vertical axis or as specified by the vendor, or With an offset on the upper attachment so that the support is vertical in the hot position. The maximum angular offset from the vertical in any case is 4.

3.1.10.

3.1.11.

3.1.12.

3.1.13.

Sufficient clearance, after thermal movements, shall be provided between the support and the adjacent components or equipment. Between a support and a dynamically supported component, a minimum clearance of 3 in. shall be provided, and between a support and a nondynamically supported component a minimum clearance of 6 in, shall be provided.

This document contains information that is confidential and proprietary to Sargent & Lundy, L.L.C. (S&L). It shall not be reproduced in whole or in part or released to any third party without the prior written consent of S&L. Copyright Sargent & Lundy, L.L.C. 1996 all rights reserved. Standards located on the Intranet at http://SLWEB.SARGENTLUNDY.COM are to be considered as the official version of the Standard. MES-MDDD6-5-REV1.DOC

MECHANICAL ENGINEERING GUIDELINE

MES-MDDD-6.5 Rev.: 1 Rev. Date: 03-28-2003 Page 4 of 6

3.1.14.

When the support cannot be designed in accordance with the piping system analysis as to the location or direction relative to the pipe, redesign must be coordinated with the Stress Analyst. When a component support is attached to any part (standard or nonstandard) of another support, the affected support shall be qualified. Pipe Attachments Pipe clamps used with the rigid-rod-type, variable or constant support shall be selected as follows: Single-bolt clamp (sometimes called two-bolt clamp) or adjustable clevis clamps may be used on pipes with insulation 1 in. thick or less. Double-bolt clamp (sometimes called three-bolt clamp) on pipes with insulation thickness more than 1 in. The ordinary double-bolt clamp in the preceding item shall not be used with sway struts or snubbers. Sway strut and snubber clamps are specially designed to withstand tensile and compressive loads.

3.1.15.

3.2. 3.2.1.

3.2.2.

Integral pipe attachments shall be of a material that is compatible with the pipe. (Refer to MES-EMD-6.2 for specifics.) Support elements directly in contact with the pipe, not integrally attached. Shall be of the same material as the pipe if the pipe operating temperature is higher than 500F. Where wet or corrosive environments are expected, and the pipe and clamp or strap are made of dissimilar materials, an insulating pad of non-conducting material (such as neoprene or red rubber) shall be placed between the pipe and the support clamp. The insulating pad material shall be suitable for the operating temperature of the pipe, and the load to be supported. If suitable insulating pads cannot be obtained, then the clamp or strap material shall be the same as, or have the same electrode potential as the pipe material.

3.2.3.

3.2.4.

Insulated piping shall be provided with standard pipe-covering protection saddle except where special details are indicated or required. Unless specifically qualified, the standard pipe-covering protection saddle shall not be used as a sliding element on sliding supports. U-bolts shall be designed as follows: If a U-bolt is used as a guide, clearance between the U-bolt and the pipe shall be provided (usually with the use of jam/hex nuts on both sides of the supporting steel) and specified, and the combined effect of the tensile and side loads shall be checked.

3.2.5.

3.2.6.

This document contains information that is confidential and proprietary to Sargent & Lundy, L.L.C. (S&L). It shall not be reproduced in whole or in part or released to any third party without the prior written consent of S&L. Copyright Sargent & Lundy, L.L.C. 1996 all rights reserved. Standards located on the Intranet at http://SLWEB.SARGENTLUNDY.COM are to be considered as the official version of the Standard. MES-MDDD6-5-REV1.DOC

MECHANICAL ENGINEERING GUIDELINE

MES-MDDD-6.5 Rev.: 1 Rev. Date: 03-28-2003 Page 5 of 6

If the U-bolt is designed to hold the pipe tight (wrench-tight or torqued) against the supporting steel (which in turn is rigidly attached to the building structure), the U-bolt is basically a three-directional support. The combined effect of the tensile, side, and axial loads shall be checked. Published LCDS for U-bolts with ratings in three directions shall be checked. If the U-bolt is used to hold the pipe on the trapeze beam of a pin-connected trapeze design, it shall be loaded only in tension.

3.3. 3.3.1.

Standard Support Elements Standard support elements shall be selected from an approved and qualified manufacturers catalog or LCDS for nuclear power plant applications. In no case shall hanger rods smaller than 3/8 in. diameter be used for supporting 2 in. diameter and smaller pipes, or shall hanger rods smaller than 1/2 in. diameter be used for supporting 2-1/2 in. diameter or larger pipes. Rod-type supports shall be used only for vertical downward loads. Variable spring supports shall be designed for the following maximum variations in supporting effect for the total vertical travel between hot and cold positions: + 6% from the design load for main steam and hot and cold reheat steam piping. + 10% from the design load for all other piping having a service temperature of 350F and higher. + 25% from the design load for all other piping.

3.3.2.

3.3.3. 3.3.4.

3.3.5.

Constant supports shall be used where the following conditions exist. Where a large thermal growth cannot be accommodated by a variable spring support. Where the load variations for a variable spring support exceed + 6% from the design load or 12% overall. Constant support shall not be used if the design travel is less than 1/2 inch.

3.3.6.

Constant supports shall have a minimum adjustable supporting weight margin of + 10% from the calculated load and an over-travel margin of not less than 25% but in no case less than 1 in. Snubbers shall be initially selected such that the stroke or total travel shall be at least 20% greater than the actual travel. Where the actual travel (caused by pipe thermal movements) is less than 1/8 inch, a detailed review for applicability shall be made prior to the design.

3.3.7.

This document contains information that is confidential and proprietary to Sargent & Lundy, L.L.C. (S&L). It shall not be reproduced in whole or in part or released to any third party without the prior written consent of S&L. Copyright Sargent & Lundy, L.L.C. 1996 all rights reserved. Standards located on the Intranet at http://SLWEB.SARGENTLUNDY.COM are to be considered as the official version of the Standard. MES-MDDD6-5-REV1.DOC

MECHANICAL ENGINEERING GUIDELINE

MES-MDDD-6.5 Rev.: 1 Rev. Date: 03-28-2003 Page 6 of 6

3.3.8.

Where possible, the cold and hot settings of snubbers shall be equidistant from the middle of the stroke. Two lengths of rods shall not be joined by welding. Threaded rod coupling or turnbuckle shall be used. Auxiliary Steel and Structural Attachment When attaching to the top or bottom flange of in-place beams, welding across the flange is not allowed. Welds shall be per AISC or Section III of the ASME Boiler and Pressure Vessel Code. Cantilever design attached to embedment plate shall always be checked against the pullout capacity of the embedment plate, as specified by the Responsible Structural Engineer. For the preliminary selection of auxiliary steel, use SDS- E37, Mechanical Component Auxiliary Support Steel Framing, if the seismic accelerations do not exceed 4g along the vertical or 2g along the horizontal. Welds parallel to the edge of an in-place embedment plate shall not be closer than 1-1/2 in. from the edge of the embedment plate. REVISIONS Revisions to the design criteria shall be processed in the same manner as the original.

3.3.9.

3.4. 3.4.1.

3.4.2.

3.4.3.

3.4.4.

4.

5. 5.1. 5.2. 5.3. 5.4. 5.5. 5.6. 5.7.

REFERENCES AISC Steel Construction Manual. ANSI/ASME B31.1, Power Piping Code. ASME Boiler and Pressure Vessel Code, Section III, Subsections NF and NCA. SDS-E37, Mechanical Component Auxiliary Support Steel Framing. MES-EMD-6.2, Evaluation of Welded Attachments. MES-4.11, Numbering System for Pipe Supports. MES-MDDD-6.13, Preparation of Component Support Design Drawings.

This document contains information that is confidential and proprietary to Sargent & Lundy, L.L.C. (S&L). It shall not be reproduced in whole or in part or released to any third party without the prior written consent of S&L. Copyright Sargent & Lundy, L.L.C. 1996 all rights reserved. Standards located on the Intranet at http://SLWEB.SARGENTLUNDY.COM are to be considered as the official version of the Standard. MES-MDDD6-5-REV1.DOC

You might also like

- Cable Tray Structural Design PDFDocument3 pagesCable Tray Structural Design PDFChristian D. OrbeNo ratings yet

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsFrom Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsRating: 4 out of 5 stars4/5 (1)

- Subsea Pipeline Design, Analysis, and InstallationFrom EverandSubsea Pipeline Design, Analysis, and InstallationRating: 3 out of 5 stars3/5 (1)

- Unistrut Seismic BracingDocument48 pagesUnistrut Seismic BracingrasheedillikkalNo ratings yet

- Pipe SupportDocument19 pagesPipe SupportScarlet Shwe50% (2)

- Design of Steel Structures: Materials, Connections, and ComponentsFrom EverandDesign of Steel Structures: Materials, Connections, and ComponentsNo ratings yet

- High Energy Piping InspectionDocument40 pagesHigh Energy Piping InspectionmohantyomNo ratings yet

- Micromechanical Testing of Thin Die: (Nordson DAGE UK)Document2 pagesMicromechanical Testing of Thin Die: (Nordson DAGE UK)Thanalachmy GopiNo ratings yet

- Us Cat Seismic Bracing Systems 5151 IlDocument48 pagesUs Cat Seismic Bracing Systems 5151 IlGianpietro de FilippoNo ratings yet

- A Primer On Pipe Supports - Hydraulics Content From Machine DesignDocument8 pagesA Primer On Pipe Supports - Hydraulics Content From Machine DesignSharun SureshNo ratings yet

- Deep Foundation Elements Under Bidirectional Static Axial Compressive Load AASHTO Designation TP 100-12Document15 pagesDeep Foundation Elements Under Bidirectional Static Axial Compressive Load AASHTO Designation TP 100-12رضوان الياسريNo ratings yet

- OSHA Technical ManualDocument102 pagesOSHA Technical ManualthugpanditNo ratings yet

- Prestress Manual: State of California Department of Transportation Engineering ServicesDocument77 pagesPrestress Manual: State of California Department of Transportation Engineering Servicesras_deepNo ratings yet

- PrestressManual Rev1Document77 pagesPrestressManual Rev1cordobaluisfNo ratings yet

- Design Guide For Cold-Formed Steel TrussesDocument22 pagesDesign Guide For Cold-Formed Steel Trusseseng_ali_khalafNo ratings yet

- HSE Report - Fatigue Provisions Comparison ReportDocument70 pagesHSE Report - Fatigue Provisions Comparison Reportmehdi64090% (1)

- Taf Truss Manual en EsDocument14 pagesTaf Truss Manual en Esagustin senoffNo ratings yet

- AXION Design Guidelines For Thermoplastic Bridges by Parsons BrinckerhoffDocument21 pagesAXION Design Guidelines For Thermoplastic Bridges by Parsons BrinckerhoffAxionInternationalNo ratings yet

- 2.3.2.4 Sway Stiffness and Resistance To Overall Lateral or Torsional BucklingDocument1 page2.3.2.4 Sway Stiffness and Resistance To Overall Lateral or Torsional BucklingAlex LoNo ratings yet

- Gin Pole Rev 16Document38 pagesGin Pole Rev 16missifussNo ratings yet

- New Fatigue Provisions For The Design of Crane Runway GirdersDocument9 pagesNew Fatigue Provisions For The Design of Crane Runway Girdersdicktracy11No ratings yet

- Stability Analysis of Pipe Rack in Petrochemical Facilities-IJAERDV04I0264348Document11 pagesStability Analysis of Pipe Rack in Petrochemical Facilities-IJAERDV04I0264348Editor IJAERDNo ratings yet

- BrassCulvert-2 3 2-TechnicalManualDocument33 pagesBrassCulvert-2 3 2-TechnicalManualJazzy BadshahNo ratings yet

- 3000-DC-2090-4 - Standard Pipe Support DrawingDocument137 pages3000-DC-2090-4 - Standard Pipe Support DrawingAob AprilNo ratings yet

- RVS 15.45 Englisch KomplettDocument44 pagesRVS 15.45 Englisch KomplettSlavisa PanticNo ratings yet

- Design Memorandum: WSDOT BDM Revisions: Bridge Design Manual Section 9.3.3 and Design-Build SectionDocument2 pagesDesign Memorandum: WSDOT BDM Revisions: Bridge Design Manual Section 9.3.3 and Design-Build SectionR_kabirNo ratings yet

- ' Dhofar Power Company Saog: - MacdonaldDocument1 page' Dhofar Power Company Saog: - Macdonald54045114No ratings yet

- 2.3.2 Establishing Equivalent Static Fatigue Loads For Noncantilevered Support StructuresDocument1 page2.3.2 Establishing Equivalent Static Fatigue Loads For Noncantilevered Support Structuresanwarali1975No ratings yet

- 1724e153 AnclasDocument29 pages1724e153 AnclasMario SantizoNo ratings yet

- Chapter 3 - Structural Design: 3.0 GeneralDocument22 pagesChapter 3 - Structural Design: 3.0 GeneralLucky TraderNo ratings yet

- Pipe Stress Analysis - FWDocument32 pagesPipe Stress Analysis - FWmasoud132No ratings yet

- Neral Specification For Skid Mounting Assemblyt - 03-GTS-02 REV. 1Document10 pagesNeral Specification For Skid Mounting Assemblyt - 03-GTS-02 REV. 1Ashok Kumar100% (1)

- 2007 Catalog Constant SpringDocument36 pages2007 Catalog Constant Springinfo592No ratings yet

- Design Guidelines For V Retainer Couplings Rev 0414Document12 pagesDesign Guidelines For V Retainer Couplings Rev 0414Santosh Komire100% (1)

- Pipes SupportDocument19 pagesPipes SupportoliveiralauroNo ratings yet

- Guide Suspended Swing Stage ScaffoldsDocument14 pagesGuide Suspended Swing Stage Scaffoldsahmed rafeeq100% (1)

- Engleski 2Document8 pagesEngleski 2ropez019No ratings yet

- Nauticus Hull - Steel Plates UnstiffenedDocument90 pagesNauticus Hull - Steel Plates Unstiffenedbosskoj100% (1)

- Pipe Support Basic - Seminar III, G.palaniDocument67 pagesPipe Support Basic - Seminar III, G.palaniAnonymous Xy309m9Sm9100% (2)

- MAURER Girder Grid JointsDocument12 pagesMAURER Girder Grid JointsbriankimbjNo ratings yet

- Load BindersDocument16 pagesLoad BindersMuresan VirgilNo ratings yet

- Astm E73Document5 pagesAstm E73Lupita RamirezNo ratings yet

- Hangers SupportsDocument10 pagesHangers Supportscarlos37No ratings yet

- G01CRANESDocument11 pagesG01CRANESjessaniNo ratings yet

- ML13198A245Document32 pagesML13198A245Paulo César Rezende da Silva RezendeNo ratings yet

- Shell Thickness PDFDocument6 pagesShell Thickness PDFLucia ZambranoNo ratings yet

- Product Design Guideline W07 & W77Document170 pagesProduct Design Guideline W07 & W77Andrea Tapia FuentesNo ratings yet

- Re Bar Couplers PDFDocument16 pagesRe Bar Couplers PDFJayadurga SathyamoorthyNo ratings yet

- Chapter 9 Bearings and Expansion Joints: WSDOT Bridge Design Manual M 23-50.06 Page 9-I July 2011Document34 pagesChapter 9 Bearings and Expansion Joints: WSDOT Bridge Design Manual M 23-50.06 Page 9-I July 2011Sravanthi MeharNo ratings yet

- PJM Design and Application of Overhead Transmission LinesDocument12 pagesPJM Design and Application of Overhead Transmission Linessupernaenergy100% (1)

- Combining Spatial Components in Seismic DesignDocument11 pagesCombining Spatial Components in Seismic DesignjemanuelvNo ratings yet

- Brass Culvert 2.7 TechnicalManualDocument35 pagesBrass Culvert 2.7 TechnicalManualEdelyn Lindero AmbosNo ratings yet

- Process Specification For Friction Stir Welding: Engineering Directorate Structural Engineering DivisionDocument21 pagesProcess Specification For Friction Stir Welding: Engineering Directorate Structural Engineering DivisionKyle BennettNo ratings yet

- 1 Applicability: Installation Manual For Structural Bearings and Seismic IsolatorsDocument15 pages1 Applicability: Installation Manual For Structural Bearings and Seismic IsolatorsWillygan PmNo ratings yet

- ACI-439.3R-91 Mechanical Connections of Reinforcing BarsDocument16 pagesACI-439.3R-91 Mechanical Connections of Reinforcing BarsMichi AGNo ratings yet

- Sub Station DesignDocument43 pagesSub Station DesignZIPDASH86% (7)

- Pipe Rack Design Philosophy (Continuous Pipe Racks)Document17 pagesPipe Rack Design Philosophy (Continuous Pipe Racks)Umer AleemNo ratings yet

- EPC Vs EPCMDocument22 pagesEPC Vs EPCMmohantyom100% (2)

- Om Prakash Mohanty: Course Code: SIMOL202009Document1 pageOm Prakash Mohanty: Course Code: SIMOL202009mohantyomNo ratings yet

- Mining Guide Epc and Epcm Contracts 104178Document40 pagesMining Guide Epc and Epcm Contracts 104178mohantyom100% (1)

- Gas Turbines A Manual PDFDocument74 pagesGas Turbines A Manual PDFHenry Pannell100% (1)

- Trans Chapter6 PDFDocument106 pagesTrans Chapter6 PDFsammar_10No ratings yet

- Ge Frame Gas Turbines Turbine Control Sppa r3000 enDocument2 pagesGe Frame Gas Turbines Turbine Control Sppa r3000 enmohantyomNo ratings yet

- Sppa T3000Document16 pagesSppa T3000Vellai Pandi PNo ratings yet

- CMTP006Document8 pagesCMTP006mohantyomNo ratings yet

- Summer Internship Report OnDocument15 pagesSummer Internship Report OnmohantyomNo ratings yet

- Project ManagementDocument56 pagesProject ManagementmohantyomNo ratings yet

- Aravindh .S 71 BDocument98 pagesAravindh .S 71 BmohantyomNo ratings yet

- 06 Essential Components of ComputersfDocument22 pages06 Essential Components of ComputersfmohantyomNo ratings yet

- FM Catalog 2002Document44 pagesFM Catalog 2002mohantyomNo ratings yet

- Key Parameters For Air Cooled Condenser DesignDocument12 pagesKey Parameters For Air Cooled Condenser DesignmohantyomNo ratings yet

- Mohit Sharma - SOW 3Document1 pageMohit Sharma - SOW 3mohantyomNo ratings yet

- Epididymo OrchitisDocument18 pagesEpididymo OrchitisRifqi AlridjalNo ratings yet

- X-Pruf Crystalcoat: Cementitious Crystalline Waterproof Coating For ConcreteDocument2 pagesX-Pruf Crystalcoat: Cementitious Crystalline Waterproof Coating For ConcreteAmr RagabNo ratings yet

- Plumbing Design Calculation - North - Molino - PH1 - 5jun2017Document5 pagesPlumbing Design Calculation - North - Molino - PH1 - 5jun2017Jazent Anthony RamosNo ratings yet

- This Study Resource Was: Current Asset - Cash & Cash Equivalents CompositionsDocument2 pagesThis Study Resource Was: Current Asset - Cash & Cash Equivalents CompositionsKim TanNo ratings yet

- Real Time EvaluationDocument3 pagesReal Time Evaluationأيوب علاءNo ratings yet

- 7-13-1996 Joel Nance MDDocument3 pages7-13-1996 Joel Nance MDAnother AnonymomsNo ratings yet

- Sail ProjectDocument28 pagesSail ProjectShahbaz AlamNo ratings yet

- Define and State The Purpose of Therapeutic DietDocument10 pagesDefine and State The Purpose of Therapeutic DietKen GarciaNo ratings yet

- Jose de Villa National School: Home Visitation FormDocument3 pagesJose de Villa National School: Home Visitation FormNoli AsuroNo ratings yet

- Eliasmith2012-Large-scale Model of The BrainDocument5 pagesEliasmith2012-Large-scale Model of The Brainiulia andreeaNo ratings yet

- Fpubh 10 1079779Document10 pagesFpubh 10 1079779Dona WirdaningsiNo ratings yet

- Implementation Plan SLRPDocument6 pagesImplementation Plan SLRPAngelina SantosNo ratings yet

- 04 TitrimetryDocument7 pages04 TitrimetryDarwin Fetalbero ReyesNo ratings yet

- Fischer General-CatalogueDocument108 pagesFischer General-Cataloguebo cephusNo ratings yet

- 3 Day WorkoutDocument3 pages3 Day Workoutsonu091276No ratings yet

- PHC Visit: Chandreswor Primary Health Care Centre: TH TH TH THDocument6 pagesPHC Visit: Chandreswor Primary Health Care Centre: TH TH TH THShashanka PoudelNo ratings yet

- Disease PreventionDocument14 pagesDisease PreventionJoan InsonNo ratings yet

- Tests Conducted On Under Water Battery - YaduDocument15 pagesTests Conducted On Under Water Battery - YadushuklahouseNo ratings yet

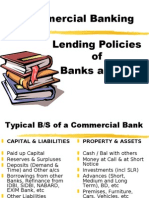

- Lending Policies of Indian BanksDocument47 pagesLending Policies of Indian BanksProf Dr Chowdari Prasad80% (5)

- Skilled Labour Supply Proposal: Aiming To Be The Best Practice Skilled Labour Supplier For Construction in 2017Document7 pagesSkilled Labour Supply Proposal: Aiming To Be The Best Practice Skilled Labour Supplier For Construction in 2017Abdul BaseerNo ratings yet

- Finding Clara: Establishing The Biographical Details of Clara Peeters (Ca. 1587-After 1636)Document15 pagesFinding Clara: Establishing The Biographical Details of Clara Peeters (Ca. 1587-After 1636)victoriagalapedroNo ratings yet

- Chrono Biology SeminarDocument39 pagesChrono Biology SeminarSurabhi VishnoiNo ratings yet

- Bar Exam Questions Week 1Document30 pagesBar Exam Questions Week 1Mark Bantigue100% (1)

- Inverter ProjectDocument19 pagesInverter ProjectRavi Sharma100% (1)

- G1 CurvedDocument16 pagesG1 CurvedElbert Ryan OcampoNo ratings yet

- Siremobil Compact MaintenanceDocument22 pagesSiremobil Compact MaintenanceRafael Tejeda100% (1)

- Antibacterial Effects of Essential OilsDocument5 pagesAntibacterial Effects of Essential Oilsnightshade.lorna100% (1)

- WW.04.05 Contraction Stress Test (Oxytocin Challenge Test) PDFDocument3 pagesWW.04.05 Contraction Stress Test (Oxytocin Challenge Test) PDFDiah Kurniawati100% (1)

- Norsok R 002Document186 pagesNorsok R 002robson2015No ratings yet