Professional Documents

Culture Documents

MSM CS Keramik en KL Def

Uploaded by

Melih AltıntaşOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MSM CS Keramik en KL Def

Uploaded by

Melih AltıntaşCopyright:

Available Formats

White Paper

MSM 19 CS LE

schurter.com/downloads

Ceramic: a high-performance material with enormous potential for design appeal

Ceramic components are used increasingly in the design of equipment and machines. These components often go unnoticed, working somewhere in the background. While understated, ceramic is not only extremely rugged but also visually attractive. It stands out as the elite choice, when it comes to demand for design appeal. One example of such a component is a pushbutton ceramic switch made by Swiss company SCHURTER.

as a high degree of hardness and wear resistance. These qualities are coupled with further advantages such as relative low weight, also the ability to withstand thermal shock and high electrical resistance. Based on these advantages, ceramics used in technical applications are experiencing continual growth. This trend is based not only on the emergence of new markets, such as medical and energy technologies, but also because of the increasing demands on material properties in many other application areas. It is common today to expect that machines and systems will provide a long service life, which makes lowwear ceramic components ever more popular. As varied as today's application areas are, they all have one thing in common: ceramic is working somewhere in the background. The background, however, needn't be the only area for technical ceramics to be used. Ceramics can also be very attractive from a visual standpoint. In fact, they are known for providing creative and exceptional design appeal coupled with functionality. The Swiss component and systems manufacturer SCHURTER is taking advantage of these features and has developed a ceramic actuator. The matte, white material on its own is visually attractive. In addition, SCHURTER uses translucent Switches ceramics, which allow the actuator to be back-lighted, achieving a uniform lighting across its entire surface. These flat, soft glowing lamps ultimately turn a switch into a true designer object. Lettering or symbols can be placed on the illuminated surfaces, and inscriptions can either appear brighter or darker depending on the desired visual effect in their surroundings. Together with an exact actuation and a clicking sound, the changing colors give users a distinctly clear feedback. The inscription holds up well against scratching and common cleaning agents because it is applied directly on the ceramic with a laser. These switches and pushbuttons are also rugged due to their front structure; their impact strength meets Protection Class IK07, making them vandal-proof. In addition, they meet the requirements of Protection Class IP69K and withstand highpressure cleaning without suffering any damage. They stand up easily to the frequent use of cleaning agents, just as well as environmental influences. Added to this ruggedness, the switches are manufactured in Switzerland, a country known for its high expectations for quality. For instance, every switch is individually tested. Their qualities shine especially where the demands on design and functionality are both equally high. This is why ceramic actuators are

MSM 19 CS LE ceramic pushbutton switches

Today, ceramics are used in technical applications virtually everywhere. They are used in the construction of machines to protect against wear of the machine parts, as in press molds and cutting inserts; they can be found in home plumbing devices, such as bearings and shafts for hotwater circulating pumps; you will find them in automotive applications too, as is illustrated by their application in the disk brakes of high-performance luxury cars. These examples illustrate that ceramic materials are in high demand when it comes to requirements for indestructibility. They exhibit particular resistance to the most varied power loads. They offer great mechanical stability, even at high temperatures, excellent resistance to acids and chemical bases, as well

White Paper

MSM 19 CS LE

schurter.com/downloads

used to start motors in yachts, just as they are in bridge controls. When combined with a special steel alloy, a ceramic switch becomes corrosionresistant and impervious to salt spray.

fundamentally different than doing so with metals or plastics. Consider that these other materials take their final shape only at the end of the process. Ceramic however, takes shape during the production of the material. This means that once ceramic has been fired, practically nothing about its shape can be changed due to its hardness. In addition, ceramic typically undergoes shrinkage due to the sintering process; the compression of the structure during sintering leads to a reduction in volume of as much as 30 percent. An absolute prerequisite for the manufacturing of ceramic components is thus the mastery of ceramics manufacturing. This, in turn, also opens up an opportunity. SCHURTER, for instance, has been able to patent the use of ceramics for ceramic actuators. Further information: schurter.com/components/switches/ metal-line-switches

Company

SCHURTER continues to be a progressive innovator and manufacturer of electronic and electrical components worldwide. Our products ensure safe and clean supply of power, while making equipment easy to use. We offer a broad range of standard products including circuit protection, connectors, switches, EMC products and input systems, as well as electronic manufacturing services. Moreover, SCHURTER is ready to work with our customers to meet their application specific requirements, not covered in our standard range. You can rely on SCHURTER's global network of companies and partners to guarantee a high level of local service and product delivery. Division Components SCHURTER Group SCHURTER AG Werkhofstrasse 8-12 PO Box 6002 Lucerne Switzerland T +41 41 369 31 11 contact@schurter.ch schurter.com

Customer-specific application of a ceramic pushbutton switch (source: KLAFS GmbH & Co. KG)

Because design appeal, together with rugged performance, is becoming increasingly important as a differentiating feature, the potential application areas are countless. They range from pushbuttons for lights and doorbells at home entryways to sanitary systems; from transportation vehicles to medical equipment and every kind of machine in between. The ceramic actuator from SCHURTER is available in standard or customer-specific versions. In addition, ready-to-mount customerspecific electro-mechanics can be supplied, as well as sub-systems that incorporate not just the switches but additional electronic circuitry. In this way, SCHURTER is able to offer complete electronic manufacturing services (EMS). The actuators from SCHURTER illustrate that ceramics for technical applications can be used in a wide range of areas, but they also point out the challenges this material brings with it. Processing ceramic is

SCHURTER headquarters in Lucerne

Switches

0165.0619/10.12/UD EN 2

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Dolch Words - Pre Primer ListDocument40 pagesDolch Words - Pre Primer Listbjw19000100% (2)

- Food Labelling For Dummies Screen v9 041013Document16 pagesFood Labelling For Dummies Screen v9 041013Melih AltıntaşNo ratings yet

- Guide To Raising Healthy BeefDocument4 pagesGuide To Raising Healthy BeefMelih AltıntaşNo ratings yet

- 2011 Tire Startup Paged SDocument8 pages2011 Tire Startup Paged SMohamed AbdullaNo ratings yet

- 2014 Exhibitor List: Company Booth NumberDocument2 pages2014 Exhibitor List: Company Booth NumberMelih AltıntaşNo ratings yet

- ECyclingUSA Tire Recycling Businesses 26 Feb 2013Document18 pagesECyclingUSA Tire Recycling Businesses 26 Feb 2013Melih AltıntaşNo ratings yet

- Global Advanced WordlistDocument198 pagesGlobal Advanced WordlistMelih Altıntaş100% (1)

- MPNP Application Kit 2Document54 pagesMPNP Application Kit 2Timoy Cajes0% (1)

- Beekeeping BasicsDocument102 pagesBeekeeping Basicsibd1ibuc100% (1)

- 2011 Tire Startup Paged SDocument8 pages2011 Tire Startup Paged SMohamed AbdullaNo ratings yet

- York U at A Glance 2014Document2 pagesYork U at A Glance 2014Melih AltıntaşNo ratings yet

- 100 Ways To Say It PDFDocument55 pages100 Ways To Say It PDFVikas NarangNo ratings yet

- Doing Business in Japan: 2013 Country Commercial Guide For U.S. CompaniesDocument138 pagesDoing Business in Japan: 2013 Country Commercial Guide For U.S. CompaniesMelih AltıntaşNo ratings yet

- Al Gharasi Profile 2008Document9 pagesAl Gharasi Profile 2008Melih AltıntaşNo ratings yet

- Turkey Textiles (Panel)Document73 pagesTurkey Textiles (Panel)Melih AltıntaşNo ratings yet

- 52 RefractoriespittsburghDocument29 pages52 RefractoriespittsburghDefriNo ratings yet

- Up Words SentencesDocument587 pagesUp Words SentencespriyaspvNo ratings yet

- 125 Useful English PhrasesDocument11 pages125 Useful English PhrasesMohan PereraNo ratings yet

- Turkish Plastic Sector 2010Document8 pagesTurkish Plastic Sector 2010Melih AltıntaşNo ratings yet

- The Representative MaterialsDocument1 pageThe Representative MaterialsMelih AltıntaşNo ratings yet

- Top 5 Us Export and Import Commodities: FollowonheadonmasterpageaDocument6 pagesTop 5 Us Export and Import Commodities: FollowonheadonmasterpageaMelih AltıntaşNo ratings yet

- 30 - Aaqr 12 04 Oa 0094 - 1145 1150 PDFDocument6 pages30 - Aaqr 12 04 Oa 0094 - 1145 1150 PDFMelih AltıntaşNo ratings yet

- 12 06 2013 PDFDocument1 page12 06 2013 PDFMelih AltıntaşNo ratings yet

- U.S. Manufacturing and The Importance of International Trade: It's Not What You ThinkDocument24 pagesU.S. Manufacturing and The Importance of International Trade: It's Not What You ThinkMelih AltıntaşNo ratings yet

- Brochure Export Guarantee Program PDFDocument2 pagesBrochure Export Guarantee Program PDFMelih AltıntaşNo ratings yet

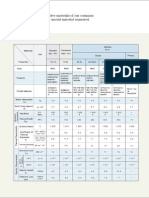

- 8510-1042 Ceramic Material Properties PDFDocument1 page8510-1042 Ceramic Material Properties PDFMelih AltıntaşNo ratings yet

- Global Trade Magazine Free The Free Trade Zone Rare Bird Trading March April 2012Document7 pagesGlobal Trade Magazine Free The Free Trade Zone Rare Bird Trading March April 2012Melih AltıntaşNo ratings yet

- 100 Ways To Say It PDFDocument55 pages100 Ways To Say It PDFVikas NarangNo ratings yet

- Aradur 2963Document39 pagesAradur 2963saku_asmaNo ratings yet

- IEQ CompleteDocument19 pagesIEQ Completeharshal patilNo ratings yet

- SOIL ASSESSMENT AND PLANT PROPAGATION OF BELL PEPPERS (Capsicum Annuum)Document35 pagesSOIL ASSESSMENT AND PLANT PROPAGATION OF BELL PEPPERS (Capsicum Annuum)Audrey Desiderio100% (1)

- JY Series Single-Phase Capacitor Induction MotorsDocument1 pageJY Series Single-Phase Capacitor Induction MotorsAditya PrasetyoNo ratings yet

- Cost Analysis and Financial Projections for Gerbera Cultivation ProjectDocument26 pagesCost Analysis and Financial Projections for Gerbera Cultivation ProjectshroffhardikNo ratings yet

- Placenta Previa Case Study: Adefuin, Jay Rovillos, Noemie MDocument40 pagesPlacenta Previa Case Study: Adefuin, Jay Rovillos, Noemie MMikes CastroNo ratings yet

- Fundermax Exterior Technic 2011gb WebDocument88 pagesFundermax Exterior Technic 2011gb WebarchpavlovicNo ratings yet

- Gas Natural Aplicacion Industria y OtrosDocument319 pagesGas Natural Aplicacion Industria y OtrosLuis Eduardo LuceroNo ratings yet

- Project Binder 2Document23 pagesProject Binder 2Singh DhirendraNo ratings yet

- Quaternary Protoberberine Alkaloids (Must Read)Document26 pagesQuaternary Protoberberine Alkaloids (Must Read)Akshay AgnihotriNo ratings yet

- Tutorial On The ITU GDocument7 pagesTutorial On The ITU GCh RambabuNo ratings yet

- VT6050 VT6010 QuickGuide ENDocument19 pagesVT6050 VT6010 QuickGuide ENPriyank KumarNo ratings yet

- NDE Procedure - Radiographic TestingDocument43 pagesNDE Procedure - Radiographic TestingJeganeswaranNo ratings yet

- KoyoDocument4 pagesKoyovichitNo ratings yet

- Xii Neet Chemistry Mcqs PDFDocument30 pagesXii Neet Chemistry Mcqs PDFMarcus Rashford100% (3)

- Brochure Personal CareDocument38 pagesBrochure Personal CarechayanunNo ratings yet

- Hypophosphatemic Rickets: Etiology, Clinical Features and TreatmentDocument6 pagesHypophosphatemic Rickets: Etiology, Clinical Features and TreatmentDeysi Blanco CohuoNo ratings yet

- VA TearDownDocument5 pagesVA TearDownfaj_larcfave5149No ratings yet

- MS For Brick WorkDocument7 pagesMS For Brick WorkSumit OmarNo ratings yet

- Who will buy electric vehicles Segmenting the young Indian buyers using cluster analysisDocument12 pagesWho will buy electric vehicles Segmenting the young Indian buyers using cluster analysisbhasker sharmaNo ratings yet

- Steam Turbines: ASME PTC 6-2004Document6 pagesSteam Turbines: ASME PTC 6-2004Dena Adi KurniaNo ratings yet

- Peptic Ulcer Disease: Causes, Symptoms and TreatmentDocument24 pagesPeptic Ulcer Disease: Causes, Symptoms and TreatmentOktaviana Sari Dewi100% (1)

- Chain Surveying InstrumentsDocument5 pagesChain Surveying InstrumentsSachin RanaNo ratings yet

- Sibuyan Island ResiliencyDocument12 pagesSibuyan Island ResiliencyEndangeredSpeciesNo ratings yet

- LSUBL6432ADocument4 pagesLSUBL6432ATotoxaHCNo ratings yet

- Certificate Testing ResultsDocument1 pageCertificate Testing ResultsNisarg PandyaNo ratings yet

- Chapter 16 - Energy Transfers: I) Answer The FollowingDocument3 pagesChapter 16 - Energy Transfers: I) Answer The FollowingPauline Kezia P Gr 6 B1No ratings yet

- g4 - Stress Analysis of Operating Gas Pipeline Installed by HorizontalDocument144 pagesg4 - Stress Analysis of Operating Gas Pipeline Installed by HorizontalDevin DickenNo ratings yet

- Apollo TyresDocument78 pagesApollo TyresADITYA33% (3)

- AI Model Sentiment AnalysisDocument6 pagesAI Model Sentiment AnalysisNeeraja RanjithNo ratings yet

- EP - EngineDocument4 pagesEP - EngineAkhmad HasimNo ratings yet