Professional Documents

Culture Documents

The Flow Chart of Tires Pyrolysis Equipment

Uploaded by

pyrolysisoilOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

The Flow Chart of Tires Pyrolysis Equipment

Uploaded by

pyrolysisoilCopyright:

Available Formats

Henan DOING Mechanical Equipment Co.

,ltd Building 18, Area A, Yingxie Garden, Yingxie Road, Jinshui District, Zhengzhou, Henan Province, China TEL: +86-371-56771821 +86-371-56771823 FAX: +86-371-86129922

The flow chart of tires pyrolysis equipment

The flow chart of tires pyrolysis equipment The whole tires pyrolysis equipment system composite by 11 parts, those are reactor ,driving device ,vertical catalytic chamber, cooling tube, oil and water separator ,condenser ,heavy oil tank ,light oil tank , anti-back fire device vacuum system and dedusting device. Reactor is one of the most important parts. The material and welding technology of reactor will have a direct impact on safety and durable life. In order to guarantee the quality of reactor, we use auto welder .The welding seam will get X-ray detection and heating treatment. Condensers adopt water cooling way and the inner cooling tube are made of seamless steel pipe ,the diameter is 48mm.the heat exchanging area is about 13 square

E-mail: market@doinggroup.com

Website: http://www.doinggroup.com/

Henan DOING Mechanical Equipment Co.,ltd Building 18, Area A, Yingxie Garden, Yingxie Road, Jinshui District, Zhengzhou, Henan Province, China TEL: +86-371-56771821 +86-371-56771823 FAX: +86-371-86129922

meter ,the total heat exchanging area is 40 square meter to get the best temperature for oil gas liquefied. The vacuum system of tires pyrolysis equipment system will guarantee no oil gas leak, safety, and environment protection and energy saving and lower the temperature for pyrolysis and save fuel while continuous feeding. The main characters of tires pyrolysis equipment system: Safety: 1. Reactor with auto welding to quarrantee the quality of welding seams and avoids cracking 2. Professional heating treatment and x-ray detection chamber for welding seam. 3. Vacuum system to prevent oil gas is back to reactor causing accident. 4. with temperature meter, pressure meter and safety valve.

Environment friendly: 1.dedusting system to prevent gas and dust from coal burning 2.the exhaust gas will be recycled for heating reactor, no gas pollution 3.well sealing on every junction parts to prevent gas leak, no smelly

Longer life: use Q245R special steel plate, thickness 14mm. welding seam with auto welding and will get heating treatment and x-ray detection to extend the life of reactor to the most extend. The life will be 8 years Energy saving: 1. Well sealing for heating system, no gas leak and saving fuel. 2. The exhaust gas will be recycled for reactor heating. <

E-mail: market@doinggroup.com Website: http://www.doinggroup.com/

2

Henan DOING Mechanical Equipment Co.,ltd Building 18, Area A, Yingxie Garden, Yingxie Road, Jinshui District, Zhengzhou, Henan Province, China TEL: +86-371-56771821 +86-371-56771823 FAX: +86-371-86129922

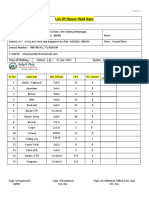

Technical parameter of DOING Pyrolysis Equipment NO. 1 2 3 Items Equipment type Raw material Structural form 24-hour Capacity Oil yield Operating pressure Material of Reactor Thickness of Reactor Rotate speed of Reactor Total power Mode of cooling Cooling area of condenser Kind of transmission Noise dB(A) Size of 15 Reactor(D L) 16 Working form Delivery time Weight Intermittent operation 20days 27T Intermittent operation 20days 30T Intermittent operation 20days 35T 22006000 22006600 26006600 DY-1-6 tires/Plastic Horizontal rotation 6 ton 2.7ton Normal Q245R 14mm Contents DY-1-8 tires/Plastic Horizontal rotation 8 ton 3.6 ton Normal Q245R 14mm DY-1-10 tires/Plastic Horizontal rotation 10 ton 4.5 ton Normal Q245R 14mm

4 5 6 7 8

9 10 11

0.4turn/minute 12KW Water cooling

0.4turn/minute 12KW Water cooling

0.4turn/minute 12KW Water cooling

12

40 Internal gear drive 85

40 Internal gear drive 85

53 Internal gear drive 85

13 14

17 18

E-mail: market@doinggroup.com

Website: http://www.doinggroup.com/

Henan DOING Mechanical Equipment Co.,ltd Building 18, Area A, Yingxie Garden, Yingxie Road, Jinshui District, Zhengzhou, Henan Province, China TEL: +86-371-56771821 +86-371-56771823 FAX: +86-371-86129922

The formula of economic benefit analysis The cost of 8 ton tire Oil output Fuel(coal): Electricity : Workers salary Crude oil Carbon black Tires wire A B=8ton*45%=3.6ton C=0.8ton*price/ton D=15kw*20hour E=4(persons) *Price/Person F=8ton*45%*Price/ton G=8ton*35%*Price/ton H=8ton*10%*Price/ton type as equipment;

If take waste truck tires as raw material, and DY-1-8 Economic benefit analysis of DY-1-8 type equipment 1.Daily cost: a. b. c. d. e. f.

Raw material: 8 ton*1700.00RMB/ton=13600.00RMB Fuel: 0.4ton*800RMB/ton=320.00RMB Water and electricity: 15kw*20hour*0.71RMB/Kw=213.00RMB Workers salary: 4(persons) *50.00RMB/Person=200.00RMB Tax (remark): free from tax for environmental protection equipment Total: 14333.00RMB

2.Daily turnover: a. Carbon black: 8ton*35%=2.8ton*1500RMB=4200.00RMB b. Crude oil: 8ton*45%=3.6ton*4500RMB/ton=16200.00RMB c. Tires wire: 8ton*10%=0.8ton*2500RMB/ton=2000.00RMB Total: 22400.00RMB 3.Daily gross profit: Gross profit=daily turnover-daily cost=22400.00RMB-14333RMB=8067.00RMB - See more at: http://www.doinggroup.com/index.php?u=show-96.html#sthash.4nqDccVX.dpuf

E-mail: market@doinggroup.com

Website: http://www.doinggroup.com/

You might also like

- Linotype Manual: Giving Detailed Instructions of the Proper Adjustment and Care of the LinotypeFrom EverandLinotype Manual: Giving Detailed Instructions of the Proper Adjustment and Care of the LinotypeNo ratings yet

- The Flow Chart of Tires Pyrolysis Equipment For 6TDocument3 pagesThe Flow Chart of Tires Pyrolysis Equipment For 6TpyrolysisoilNo ratings yet

- The 4th Generation Waste Plastic Rubber Tire Recycling Pyrolysis PlantDocument3 pagesThe 4th Generation Waste Plastic Rubber Tire Recycling Pyrolysis PlantpyrolysisoilNo ratings yet

- The Flow Chart of Waste Tires Recycling Pyrolysis Equipment For 8TDocument3 pagesThe Flow Chart of Waste Tires Recycling Pyrolysis Equipment For 8Tpyrolysisoil100% (1)

- DY-1-5 Plastic Pyrolysis Plant of Doing GroupDocument3 pagesDY-1-5 Plastic Pyrolysis Plant of Doing GrouppyrolysisoilNo ratings yet

- Waste Plastic Pyrolysis Oil Plant DY-1-10Document4 pagesWaste Plastic Pyrolysis Oil Plant DY-1-10pyrolysisoilNo ratings yet

- Doing Waste Tire Recycling Equipment DY-1-8Document5 pagesDoing Waste Tire Recycling Equipment DY-1-8pyrolysisoilNo ratings yet

- Henan Xinghuo Bioenergy Co., LTD - Plant InformationDocument12 pagesHenan Xinghuo Bioenergy Co., LTD - Plant InformationStefan EnacheNo ratings yet

- Doing Waste Tire Pyrolysis PlantDocument4 pagesDoing Waste Tire Pyrolysis PlantpyrolysisoilNo ratings yet

- Waste Tire Recycling Pyrolysis Equipment of Doing GroupDocument2 pagesWaste Tire Recycling Pyrolysis Equipment of Doing GrouppyrolysisoilNo ratings yet

- Technical Parameter of Doing Waste Tyre Recycling Pyrolysis Oil MachineDocument4 pagesTechnical Parameter of Doing Waste Tyre Recycling Pyrolysis Oil MachinepyrolysisoilNo ratings yet

- Waste Tyre Pyrolysis Plant of Doing GroupDocument2 pagesWaste Tyre Pyrolysis Plant of Doing GrouppyrolysisoilNo ratings yet

- Waste Oil Distillation MachineDocument12 pagesWaste Oil Distillation Machinenazif100% (1)

- Professional Vacuum Evaporation MachineDocument7 pagesProfessional Vacuum Evaporation MachineMario QuiroaNo ratings yet

- Complete Pellet LineDocument15 pagesComplete Pellet LineHendi HendriansyahNo ratings yet

- Vertical Pyrolysis Plant OfferDocument5 pagesVertical Pyrolysis Plant OfferGaurav BihaniNo ratings yet

- Xinxiang Lefilter Filter Corporation Ltd Shangqiu Branch Project ReportDocument12 pagesXinxiang Lefilter Filter Corporation Ltd Shangqiu Branch Project Reportshamim samNo ratings yet

- Anjali Exim - 5 TonDocument15 pagesAnjali Exim - 5 TonAjay Jain100% (1)

- JC-41200 4 Color Flexographic Printing Machine SpecsDocument4 pagesJC-41200 4 Color Flexographic Printing Machine SpecsFathi MustafaNo ratings yet

- !!!1MW Fengyu ProposalDocument12 pages!!!1MW Fengyu ProposalUmer_Altaf_5934100% (1)

- 4 Lines Cold Cutting Bag Making MachineDocument12 pages4 Lines Cold Cutting Bag Making MachineAakash HassanNo ratings yet

- DY-1-20 Scrap Tires Recycling Pyrolysis Oil Plant of Doing GroupDocument3 pagesDY-1-20 Scrap Tires Recycling Pyrolysis Oil Plant of Doing GrouppyrolysisoilNo ratings yet

- Ambient Tribal Energy proposes tire recycling plant to produce oil, carbon black and steelDocument12 pagesAmbient Tribal Energy proposes tire recycling plant to produce oil, carbon black and steelElias RizkNo ratings yet

- Innova Engineering & FabricationDocument20 pagesInnova Engineering & FabricationManojj NatarrajanNo ratings yet

- Hatflex ChinaDocument31 pagesHatflex ChinaedgarmerchanNo ratings yet

- Proposal of Pyrolysis Plant 10 Ton Per DayDocument15 pagesProposal of Pyrolysis Plant 10 Ton Per DayByamukama HenryNo ratings yet

- EEP Automatic Plastic Rev.1.2 EnglishDocument16 pagesEEP Automatic Plastic Rev.1.2 EnglishMArwin NGNo ratings yet

- NCC Nangsing HaisiDocument10 pagesNCC Nangsing HaisiLam NgoNo ratings yet

- Dosing & Metering Gear Pumps: Nitrided Cast Iron (G25) Nitrided Cast Iron (G25)Document8 pagesDosing & Metering Gear Pumps: Nitrided Cast Iron (G25) Nitrided Cast Iron (G25)2009tamerNo ratings yet

- Plastic Recycling Pyrolysis PlantDocument2 pagesPlastic Recycling Pyrolysis PlantpyrolysisoilNo ratings yet

- 36CBM SK RBDocument13 pages36CBM SK RBJayadev KarthaNo ratings yet

- Krishna ElectronicsDocument10 pagesKrishna Electronicsrishi070881100% (1)

- Project Plan Tyre RecyclingDocument4 pagesProject Plan Tyre RecyclingAjit Chauhan100% (3)

- Company Profile & Catalogue PDFDocument24 pagesCompany Profile & Catalogue PDFhbookNo ratings yet

- 1500MM Film Blowing Machine QuotationDocument6 pages1500MM Film Blowing Machine QuotationPearls of WisdomNo ratings yet

- Proposal For Mj-2 Model Mobile Type Waste Pyrolysis PlantDocument13 pagesProposal For Mj-2 Model Mobile Type Waste Pyrolysis PlantMaik SpayNo ratings yet

- Hydraulic clamping arrangement reduces connecting rod milling timeDocument60 pagesHydraulic clamping arrangement reduces connecting rod milling timeAjinkya MoreNo ratings yet

- Sai Guru 10KLDocument11 pagesSai Guru 10KLRishi KathirNo ratings yet

- FIN400 Production LineDocument5 pagesFIN400 Production LineMd Masudur RahmanNo ratings yet

- Gas Turbine Generator: A Summer Intern Project Report inDocument43 pagesGas Turbine Generator: A Summer Intern Project Report inSantosh KondepudiNo ratings yet

- Keshav 10tn QuotationDocument3 pagesKeshav 10tn QuotationSaurabh GuptaNo ratings yet

- Sadaqat 1Document40 pagesSadaqat 1Umar DrazNo ratings yet

- 45-R1 Indoor & Outdoor Unit & Installation Accessories (Samsung)Document155 pages45-R1 Indoor & Outdoor Unit & Installation Accessories (Samsung)ridNo ratings yet

- The PSA Approach For The Safety Assessment of Low-Power and Shutdown StatesDocument47 pagesThe PSA Approach For The Safety Assessment of Low-Power and Shutdown Stateszsh50No ratings yet

- SHD Series Field Butt Fusion Welding Machine Technical ParametersDocument19 pagesSHD Series Field Butt Fusion Welding Machine Technical ParametersPipa Hdpe Indonesia100% (1)

- Keshav Enterprise MailDocument11 pagesKeshav Enterprise MailSaurabh GuptaNo ratings yet

- Clock Spring Pipe Repair System PDFDocument2 pagesClock Spring Pipe Repair System PDFNeo_1982No ratings yet

- Quotation For 1000kg Waste Incinerator With Wet Scrubber Device From Shandong Tianlang Co,.Ltd - Caroline.2023.11.17Document18 pagesQuotation For 1000kg Waste Incinerator With Wet Scrubber Device From Shandong Tianlang Co,.Ltd - Caroline.2023.11.17Jose NiltonNo ratings yet

- Commercial Offer About The PET Washing Line, Capacity 1000 KG/HDocument13 pagesCommercial Offer About The PET Washing Line, Capacity 1000 KG/HAnkitNo ratings yet

- PyrolysisDocument22 pagesPyrolysisHande Cambaz100% (3)

- Tyre Recycling Pyrolysis PlantDocument2 pagesTyre Recycling Pyrolysis PlantpyrolysisoilNo ratings yet

- BEIER MACHINERY 110MM PIPE PRODUCTIONDocument9 pagesBEIER MACHINERY 110MM PIPE PRODUCTIONAdoniyas Abayneh Negash100% (1)

- Technical Comparison Between Guodian Futong Steel Belt Conveyor and Chain Conveyor - REV1Document13 pagesTechnical Comparison Between Guodian Futong Steel Belt Conveyor and Chain Conveyor - REV1joydrathdeyNo ratings yet

- Advantage of DOING Oil Distillation Machine2014.2.22Document3 pagesAdvantage of DOING Oil Distillation Machine2014.2.22Kelly EdwardsNo ratings yet

- Keshav 5tn QuotationDocument3 pagesKeshav 5tn QuotationSaurabh GuptaNo ratings yet

- Tire 2 OilDocument5 pagesTire 2 OilRajesh Edupuganti100% (1)

- Instructions To Mod. Zyt5402tzj Mobile Drilling RigDocument135 pagesInstructions To Mod. Zyt5402tzj Mobile Drilling RigYimmy Alexander Parra MarulandaNo ratings yet

- MARUTI ENGINEERING Hydraulic Goods Loading PlatformDocument8 pagesMARUTI ENGINEERING Hydraulic Goods Loading PlatformKush ThumarNo ratings yet

- Glatt Waterjet Cutting Machine QuotationDocument19 pagesGlatt Waterjet Cutting Machine QuotationSergio Araya CortésNo ratings yet

- Plastic Recycling Pyrolysis PlantDocument2 pagesPlastic Recycling Pyrolysis PlantpyrolysisoilNo ratings yet

- How To Make BiodieselDocument1 pageHow To Make BiodieselpyrolysisoilNo ratings yet

- What Is Pyrolysis TechnologyDocument1 pageWhat Is Pyrolysis TechnologypyrolysisoilNo ratings yet

- What's The Application of Palm Oil and Palm Kernel OilDocument3 pagesWhat's The Application of Palm Oil and Palm Kernel OilpyrolysisoilNo ratings yet

- What Is PP and PEDocument1 pageWhat Is PP and PEpyrolysisoilNo ratings yet

- Rubber Recycling Pyrolysis MachineDocument2 pagesRubber Recycling Pyrolysis MachinepyrolysisoilNo ratings yet

- Used Tire Recycling Pyrolysis MachineDocument2 pagesUsed Tire Recycling Pyrolysis MachinepyrolysisoilNo ratings yet

- Tyre Recycling Pyrolysis PlantDocument2 pagesTyre Recycling Pyrolysis PlantpyrolysisoilNo ratings yet

- Doing Used Tire Recycling Machine DY-1-10Document4 pagesDoing Used Tire Recycling Machine DY-1-10pyrolysisoilNo ratings yet

- Waste Plastic Recycling Machine DY-1-8Document3 pagesWaste Plastic Recycling Machine DY-1-8pyrolysisoilNo ratings yet

- Waste Plastic Pyrolysis Plant DY-1-6 of Doing GroupDocument2 pagesWaste Plastic Pyrolysis Plant DY-1-6 of Doing GrouppyrolysisoilNo ratings yet

- Waste Plastic Pyrolysis Plant DY-1-6 of Doing GroupDocument2 pagesWaste Plastic Pyrolysis Plant DY-1-6 of Doing GrouppyrolysisoilNo ratings yet

- Waste Plastic Pyrolysis Plant DY-1-6 of Doing GroupDocument2 pagesWaste Plastic Pyrolysis Plant DY-1-6 of Doing GrouppyrolysisoilNo ratings yet

- Waste Plastic Pyrolysis Plant DY-1-6 of Doing GroupDocument2 pagesWaste Plastic Pyrolysis Plant DY-1-6 of Doing GrouppyrolysisoilNo ratings yet

- Waste Plastic Pyrolysis Plant DY-1-6 of Doing GroupDocument2 pagesWaste Plastic Pyrolysis Plant DY-1-6 of Doing GrouppyrolysisoilNo ratings yet

- Waste Plastic Pyrolysis Plant DY-1-6 of Doing GroupDocument2 pagesWaste Plastic Pyrolysis Plant DY-1-6 of Doing GrouppyrolysisoilNo ratings yet

- 8T Waste Tyre Recycling Pyrolysis Oil Machine of Doing GroupDocument2 pages8T Waste Tyre Recycling Pyrolysis Oil Machine of Doing GrouppyrolysisoilNo ratings yet

- Doing Waste Tire Recycling Equipment DY-1-8Document5 pagesDoing Waste Tire Recycling Equipment DY-1-8pyrolysisoilNo ratings yet

- Doing Tire Recycling Plant DY-1-6Document4 pagesDoing Tire Recycling Plant DY-1-6pyrolysisoilNo ratings yet

- Waste Tyre Pyrolysis Plant of Doing GroupDocument2 pagesWaste Tyre Pyrolysis Plant of Doing GrouppyrolysisoilNo ratings yet

- Doing Waste Tire Pyrolysis PlantDocument4 pagesDoing Waste Tire Pyrolysis PlantpyrolysisoilNo ratings yet

- Technical Parameter of Doing Waste Tyre Recycling Pyrolysis Oil MachineDocument4 pagesTechnical Parameter of Doing Waste Tyre Recycling Pyrolysis Oil MachinepyrolysisoilNo ratings yet

- DY-1-20 Scrap Tires Recycling Pyrolysis Oil Plant of Doing GroupDocument3 pagesDY-1-20 Scrap Tires Recycling Pyrolysis Oil Plant of Doing GrouppyrolysisoilNo ratings yet

- Tire Recycling Machine of Doing GroupDocument2 pagesTire Recycling Machine of Doing GrouppyrolysisoilNo ratings yet

- Oil-Water Separator of Waste Tyre Recycling Pyrolysis Oil Machine of Doing GroupDocument1 pageOil-Water Separator of Waste Tyre Recycling Pyrolysis Oil Machine of Doing GrouppyrolysisoilNo ratings yet

- Condenser of Waste Tires Recycling Pyrolysis Oil Machine of Doing GroupDocument3 pagesCondenser of Waste Tires Recycling Pyrolysis Oil Machine of Doing GrouppyrolysisoilNo ratings yet

- 03 - 42 STCP-Ahm AssetDocument46 pages03 - 42 STCP-Ahm AssetARP MEILNo ratings yet

- Complete Guide To E-Commerce TechnologyDocument420 pagesComplete Guide To E-Commerce Technologypilatus100% (4)

- Types of NumbersDocument11 pagesTypes of NumbersbrajanosmaniNo ratings yet

- SS1c MIDTERMS LearningModuleDocument82 pagesSS1c MIDTERMS LearningModuleBryce VentenillaNo ratings yet

- Barcelona Smart City TourDocument44 pagesBarcelona Smart City TourPepe JeansNo ratings yet

- Presentation 1Document20 pagesPresentation 1nikitakhanduja1304No ratings yet

- DLL Grade7 First 1solutions ConcentrationDocument5 pagesDLL Grade7 First 1solutions ConcentrationJaneth de JuanNo ratings yet

- Vincent Ira B. Perez: Barangay Gulod, Calatagan, BatangasDocument3 pagesVincent Ira B. Perez: Barangay Gulod, Calatagan, BatangasJohn Ramsel Boter IINo ratings yet

- Catalogo Head FixDocument8 pagesCatalogo Head FixANDREA RAMOSNo ratings yet

- Financial Accounting IFRS 3rd Edition Weygandt Solutions Manual 1Document8 pagesFinancial Accounting IFRS 3rd Edition Weygandt Solutions Manual 1jacob100% (34)

- Project Report Software and Web Development Company: WWW - Dparksolutions.inDocument12 pagesProject Report Software and Web Development Company: WWW - Dparksolutions.inRavi Kiran Rajbhure100% (1)

- Act 1&2 and SAQ No - LawDocument4 pagesAct 1&2 and SAQ No - LawBududut BurnikNo ratings yet

- Guillermo Estrella TolentinoDocument15 pagesGuillermo Estrella TolentinoJessale JoieNo ratings yet

- 3.1 C 4.5 Algorithm-19Document10 pages3.1 C 4.5 Algorithm-19nayan jainNo ratings yet

- Geometric Sculpture From 72 PencilsDocument5 pagesGeometric Sculpture From 72 PencilsHugo Iván Gonzalez CruzNo ratings yet

- Lean Management AssignmentDocument14 pagesLean Management AssignmentElorm Oben-Torkornoo100% (1)

- Omobonike 1Document13 pagesOmobonike 1ODHIAMBO DENNISNo ratings yet

- 8.4 Example: Swiss Market Index (SMI) : 188 8 Models of VolatilityDocument3 pages8.4 Example: Swiss Market Index (SMI) : 188 8 Models of VolatilityNickesh ShahNo ratings yet

- 3 - Content - Introduction To Java, JVM, JDK PDFDocument8 pages3 - Content - Introduction To Java, JVM, JDK PDFAnonymous zdY202lgZYNo ratings yet

- Oracle Apps Quality ModuleDocument17 pagesOracle Apps Quality ModuleSantOsh100% (2)

- List of household items for relocationDocument4 pagesList of household items for relocationMADDYNo ratings yet

- Analysis and Design of Multi Storey Building by Using STAAD ProDocument5 pagesAnalysis and Design of Multi Storey Building by Using STAAD Prolikith rockNo ratings yet

- Types of Speech StylesDocument31 pagesTypes of Speech StylesRomnick BistayanNo ratings yet

- Mechanical Engineer with Experience in Heavy Mining Machinery MaintenanceDocument1 pageMechanical Engineer with Experience in Heavy Mining Machinery MaintenanceCertified Rabbits LoverNo ratings yet

- BarclaysDocument5 pagesBarclaysMehul KelkarNo ratings yet

- GD&T WIZ Tutor Covers The Vast Breadth of Geometric Dimensioning and Tolerancing Without Compromising On The Depth. The Topics Covered AreDocument1 pageGD&T WIZ Tutor Covers The Vast Breadth of Geometric Dimensioning and Tolerancing Without Compromising On The Depth. The Topics Covered AreVinay ManjuNo ratings yet

- Advanced Presentation Skills: Creating Effective Presentations with Visuals, Simplicity and ClarityDocument15 pagesAdvanced Presentation Skills: Creating Effective Presentations with Visuals, Simplicity and ClarityGilbert TamayoNo ratings yet

- Grade 8 Lily ExamDocument3 pagesGrade 8 Lily ExamApril DingalNo ratings yet

- Abbreviation Meaning Notes: Cibo ("With Food")Document4 pagesAbbreviation Meaning Notes: Cibo ("With Food")TantriNo ratings yet

- BOQ - Hearts & Arrows Office 04sep2023Document15 pagesBOQ - Hearts & Arrows Office 04sep2023ChristianNo ratings yet