Professional Documents

Culture Documents

Terms

Uploaded by

ijustyadavCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Terms

Uploaded by

ijustyadavCopyright:

Available Formats

Terms

pattern block or sloper

Definitions

guide for cutting one or more garments - tag board pattern/digital pattern of a garment section; follows the natural contours of body or dress form - used to: develop original bodice, skirt, dress, pant, and sleeve designs create first patterns of new or modified styles

first pattern working pattern final pattern

original or initial pattern; includes seam and hem allowances pattern in revision; work in progress - paper or digital pattern; includes garment sections; trued seam lines, seam allowances (notches, grainlines, pattern identification) - used for: making physical muslin or virtual proof cutting out trial or sample garment

pattern card (pattern chart)

form containing info about production pattern: style number sketch of garment size range color offerings yardage needed for fabrics, linings... trims size, amount, and description of findings lost of all pattern pieces and number to be cut

production pattern

tag board or digital copy of tested and perfected final pattern complete pattern set (all pieces needed for a complete garment); including seam allowances, perforations, notches, grainlines, and pattern identifications

graded pattern

individual patterns of a particular garment or style; proportioned to standardized body measurements; for each size within a size range

drafted pattern

- developed through the use of measurements taken from dress form or

live model (2D) - used to: cut a test muslin cut a sample garment flat pattern developed through the manual manipulation of drafted blocks or manipulation using CAD draping manipulating cloth to conform to one or more curves of the body; allows designer to visualize garment on 3D form; usually drape lengthvertically on body; bias allows fabric to skim or cling to body reverse engineering punch holes begins with finished product; garment deconstructed into pieces, which are used to create pattern; used to create knock-offs small circles on pattern or holes made in fabric to mark dark points, curved darts, pocket placement, where to end stitching for stitched pleats seam allowance portion of pattern from seam line to edge of pattern; based on development of first pattern muslin, position and type of seam, fabric type and weave, type and purpose of garment, specifications of manufacturers, and intended price point sweep circumference measurement of garment's hem edge; hem edge for sleeves as well hem width depth of hem or amount turned under; wide hem require more fabric (costlier), benefits are garments tend to hang smoothly, hem can be let down Straight grain runs in warp direction (wovens), runs in wale direction (knits), parallel to selvage, most stable, most garments cut on it Bias grain true bias at 45 degrees to warp or wale, grain lines; not parallel to warp or wale, most stretch for woven fabric

Cross grain

runs in filling direction (woven), runs in course direction (knits), border printed parallel to selvage

Cut on Bias

creates body-skimming silhouettes on garments made from soft, lightweight, and loosely woven fabrics, produces softer drapes or silhouettes for garments cut from heavyweight or closely woven fabrics, emphasizes geometric fabric prints, sheen and light refraction, or metallic yarns

Ease

amount of fabric in pattern design to accommodate body movement; difference between measurement of finished product and body measurements for intended size

functional ease (wearing ease) design ease (garment ease/style ease) Darts

allows for body movement

used to achieve desired design and look of garment

means of shaping fabric to fit the figure; allow for extra fabric to be taken up and molded around the curves of body

Seams

eliminate fabric excess by manipulating two or more panel to conform to the style line and body contour; place where garment parts are sewn together

Side Panel

garment section that provides fit and shape in place of a side seam; side panels used on jackets, coats, tops...

gores

panels in skirt or skirt portion of dress created by dividing the skirt into vertical sections; number of panels = number of gores

Gathers Casing

introduce fullness to clothing fold-over edge or applied strip that encloses a drawstring of elastic used to draw in garment circumference to fit corresponding body areas;

used on garments intended to accommodate more than one size or as design detail Drawstring Casing drawstring inserted into casing; allow wearer to control garment circumference; can be made from variety of materials; may emerge from slits, buttonholes, metal eyelets, grommets, or seam openings; can be used to manipulate necklines, sleeves, hems, waistline areas Elastic Casing inserted into casing; available in variety of widths; facilitates ease of dressing children; allows adjustable-style effects on necklines, lower sleeve edges, and pants legs; provides snug leg openings of swimwear and leotards Seamed Waistline empire waistline natural waistline long torso raised waistline lowered waistline Unseamed Waistline horizontal seam or seams join upper and lower sections of garment just below the bust at the actual body waistline around the hip area slightly above natural waistline slightly below natural waistline no delineation of upper and lower sections of garment by a horizontal seam; waistline spans the body above and below the waist areas; enhances hem or cuff Godet triangular or rounded piece inserted into slashed opening or seam in a garment section or sections; creates fuller circumference; enhances lower portion of skirts, pants....; creates flounce; effect on sheaths or fitted garments; creates fuller silhouette in fitted evening gowns and dresses Gusset diamond-shaped unit or one or more pieces; inserted into slashed opening on a larger garment section or sections; allows freedom of

movement when set into a fitted sleeve or crotch area Ruffle gathered or pleated single or double-ply strip of fabric drawn up and sewn into a smaller; adjoining seam line; enhances hems, cuffs, plackets, and necklines Smocking elastic shirring with an overlay pattern of decorative stitches applied to the face of fabric; creates an expandable or contractible decorativepatterned effect; simulates handwork in; mass-produced garments; forms the effect of a yoke, midriff, band, or cuff; accommodates more than one size or body configuration; releases fullness above and below the stitching on the waistline of one-piece garments Contoured Waistband band formed to fit the body's curve between midriff and hip; may provide a band finish for special design features (i.e. low-rise pants, lowered/raised waistlines) Straight Waistband 2" or less in width two more more plies; attached at waistline; can open at center (CF), center back (CB), side seam Pleats take-up of excess fabric at edge of garment; doubling the fabric ply upon itself; can be single or series; always in the vertical direction Accordion Pleats series of evenly spaced pleats; creates a raised and recessed pattern; permanently set with industrial pleating machine; panels cut and hemmed prior to pleating; unhemmed edge is fitted Box Pleats evenly spaced folds; fabric ply doubled over to face away from each other; depth of box pleat may not equal width of box Inverted Pleat Knife Pleat two fold in fabric ply; doubled under to meet at central point pleat doubled upon itself; series of folds; forming underlay of 5/8" or less; permanently press to lie in one direction; not suitable for stretch, bulky or napped fabrics Side Pleats (see Knife Pleat)

Kick Pleats Sunburst Pleat

inverted or side pleat released at knee level or below series of radiating pleats; creates raised and recessed pattern; on sheer and; lightweight fabric; permanently set by an industrial pleating machine; hemline and hem finish establish after garment complete

Iseey Miyake's Pleats Please Pin Tucks

crystal pleats; accordion like; narrow

evenly spaced parallel folds 1/8" or less (narrow); stitched at designated length from; pattern edge or area to be fitted; tucks can be placed in any direction on garment

Release Tucks

evenly spaced parallel folds; 1/4" to 5/8" partially stitched down to fit an area of a garment; then released to produce fullness; may lie on inside or outside of garment; may be turned towards or away from each other in groups

Placket

finished opening in a garment section; should be long enough to allow for ease of dressing; planned as extension for the placement of buttonholes, snaps, and other closures

Band Placket or Tab Placket Bound Placket

two finished strips of equal width; produces a lapped closure; overlap strip visible on face of garment opening that does not overlap; formed by a fabric strip applied, slashed, turned and finished as a bound seam; strip can be of bias, straightgrain self fabric or contrasting fabric

Continuous Lap Placket Faced-Slashed Placket Centered Zipper Insertion (Slot

finished opening; formed by one strip of bias of straight grain fabric encasing raw edge of slash clean-finished opening; no overlap; produced by facing turned inside of garment; applied where garment edges meet vs. overlap two seam edges folded, abutted, or faced over center of zipper

Zipper Insertion) Tailored Placket or Shirtsleeve Placket Centered Zipper Insertion Fly-front Concealed Zipper Insertion Lap Zipper Insertion Trouser Fly Zipper Insertion Hemline folded seam edge stitched along stitching guidelines on zipper tape; only one line of stitching is visible; used on trousers, pants, jeans designated line along which the hem is folded, faced, finished, and may be stitched or held in place with bonding agents hem allowances (HA) high quality garments = wider hems; Why wider hem is better: garment tends to hang smoothly when weighted by wide HA; wide HA can be let down to suit different needs/preferences; wide HA can be let down to conform to changing fashion Type of hem depends on type, finish, weight, and hand of fabrics; depends on style, design, type, use, and care of garment; depends on methods of production and manufacturing Band Hem shaped, bias, or straight grain double ply strip of fabric folded or seamed; applied to garment edge (visible on face of garment); uses: produces a clean finish, introduces color or textural contrast to garment edge, increases length of garment Faced Hem clean finished hem produced on shaped edge; uses: maintain curved edge, reduce bulk on garments made of heavy fabric, maintain illusion two strips of unequal widths of fabric; encloses raw edges of opening; topstitched, overlapped decorative zipper; enlarged teeth and wide tape; visible on face of garment extension conceals of zipper; used on rain or snow weather garments; used when other fasteners or zipper applications would detract from appearance folded seam edge laps over zipper; zipper concealed

of fabric on garments made of lace, support and maintain shape of scalloped edges, lengthen hemline Bound Hem (Hong Kong Finish or Welt Finished Edge) Glued Hem produced by turned-up fold with unfinished edge glued to body of garment; purpose: in lieu of undesirable machine stitching, used on leather, suede, other skins, felt, and other matted fabrics Horsehair Hem hem produced using stiff, transparent woven bias braid; adds body to hem; produces a billowing affect at lower edge; allows for controlled fullness Blind Stitched Hem folded hem secured by series of interlocking loop stitches (modified zigzag stitch); not visible on face of garment; can be applied with or without tape or binding Machine Stitched Hem hem held in place with one or more parallel rows of machine stitching raw edge is folded under; penetrates all plies; visible on face of fabric; uses: garments subjected to increased wear, frequent washings; produces: flat finish for firmly woven or bulky fabrics Over Edged Hem clean finish on raw edge by interlocking thread loops; produces: finish to unturned raw edge, edges that do not ravel, lettuce edge finish on knit and stretch fabrics Mitered Hem hem that turns corner; seamed an angle bisecting corner; purposes: eliminates bulk at corners, achieves a flat look at corner or points, squares corner of faced and other hems, produces continuous fitted look when trim added Rolled Hem narrow double-folded hem, 1/8 inch (.2 mm); raw edge is folded and stitched in one operation, or machine stitched in stages; purpose: lightweight edge finish on very full garments of sheer and lightweight fabrics, also used on scarves hem finish using a bias strip of material; applied to conceal and bind the raw hem edge; applied as decorative detail or for flat hem finish on thick material which could fray

Weighted Hem

hem in which metal chain, square or round lead disk, lead pellets, are added or attached to hem; purposes: control drape of hem, help hem fall evenly, keep hem straight, hold hem detail in place, prevent hem areas from shifting or riding up on body, add body to hem of lightweight fabrics; uses: lower edge of pleats and slashed openings, front corner of hem and facings of coats and jackets

Wired Hem

stiffened edge produced by incorporating plastic monofilament or wire into the fold of a narrow hem; purposes: adds body without weight to hem, produces hem areas that billows or stand out, creates structural detail to ruffles and trimmings, produces a lettuce edge on sheer and lightweight fabrics

You might also like

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

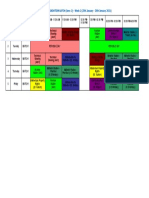

- TT Foundation BatchDocument1 pageTT Foundation BatchijustyadavNo ratings yet

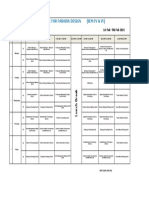

- Time Table For Fashion Design (Sem Iv & Vi) : 1st Feb-5th Feb 2021Document1 pageTime Table For Fashion Design (Sem Iv & Vi) : 1st Feb-5th Feb 2021ijustyadavNo ratings yet

- TT Foundation BatchDocument1 pageTT Foundation BatchijustyadavNo ratings yet

- Time Table For Fashion Design (Sem Iv & Vi) : 1st Feb-5th Feb 2021Document1 pageTime Table For Fashion Design (Sem Iv & Vi) : 1st Feb-5th Feb 2021ijustyadavNo ratings yet

- TT Foundation BatchDocument1 pageTT Foundation BatchijustyadavNo ratings yet

- Time Table For Fashion Design (Sem Iv & Vi) : 1st Feb-5th Feb 2021Document1 pageTime Table For Fashion Design (Sem Iv & Vi) : 1st Feb-5th Feb 2021ijustyadavNo ratings yet

- Fddi Admission 2024 DetailsDocument87 pagesFddi Admission 2024 DetailsijustyadavNo ratings yet

- TT Foundation BatchDocument1 pageTT Foundation BatchijustyadavNo ratings yet

- Dr. Shafali Nagpal: Associate Professor in Commerce (RGNIYD)Document4 pagesDr. Shafali Nagpal: Associate Professor in Commerce (RGNIYD)ijustyadavNo ratings yet

- Fashion Marketing BFT (SEM III) Multiple Choice QuestionsDocument26 pagesFashion Marketing BFT (SEM III) Multiple Choice QuestionsijustyadavNo ratings yet

- Private Car Package Policy - Zone B Motor Insurance Certificate Cum Policy ScheduleDocument3 pagesPrivate Car Package Policy - Zone B Motor Insurance Certificate Cum Policy ScheduleijustyadavNo ratings yet

- The Oriental Insurance Company Limited: Particulars of Insured VehicleDocument2 pagesThe Oriental Insurance Company Limited: Particulars of Insured VehicleijustyadavNo ratings yet

- The Oriental Insurance Company Limited: Particulars of Insured VehicleDocument2 pagesThe Oriental Insurance Company Limited: Particulars of Insured VehicleijustyadavNo ratings yet

- Gupta PeriodDocument7 pagesGupta Periodanon-73768285% (13)

- Don't Forget To Read This..Document3 pagesDon't Forget To Read This..ijustyadavNo ratings yet

- Clothing, Textiles, and Fashion 10, 30: Curriculum Guide A Practical and Applied ArtDocument75 pagesClothing, Textiles, and Fashion 10, 30: Curriculum Guide A Practical and Applied ArtAredaNo ratings yet

- Textile Testing - Importance of Testing in Textiles - TestexDocument1 pageTextile Testing - Importance of Testing in Textiles - TestexijustyadavNo ratings yet

- Textile Testing - Importance of Testing in Textiles - TestexDocument1 pageTextile Testing - Importance of Testing in Textiles - TestexijustyadavNo ratings yet

- Time Table 14 Jan - 18 Jan 2019Document37 pagesTime Table 14 Jan - 18 Jan 2019ijustyadavNo ratings yet

- Textile Testing - Importance of Testing in Textiles - TestexDocument1 pageTextile Testing - Importance of Testing in Textiles - TestexijustyadavNo ratings yet

- Qualified PackDocument2 pagesQualified PackijustyadavNo ratings yet

- Trademarks: KIPS-Kids Intellectual Property SeriesDocument1 pageTrademarks: KIPS-Kids Intellectual Property SeriesijustyadavNo ratings yet

- List of Enquiry Numbers of Various Bus StandsDocument1 pageList of Enquiry Numbers of Various Bus StandsijustyadavNo ratings yet

- Intellectual Property Rights Creativity and InnovationDocument1 pageIntellectual Property Rights Creativity and InnovationijustyadavNo ratings yet

- Annexure M - UpdatedDocument1 pageAnnexure M - UpdatedijustyadavNo ratings yet

- Valid Documents List PDFDocument2 pagesValid Documents List PDFAnjani KumarNo ratings yet

- 17Document4 pages17ijustyadavNo ratings yet

- "E-Resources For Self Learning": Ch-08 (For Science Students)Document2 pages"E-Resources For Self Learning": Ch-08 (For Science Students)ijustyadavNo ratings yet

- Trainee Feedback - English PDFDocument1 pageTrainee Feedback - English PDFijustyadavNo ratings yet

- Valid Documents List PDFDocument2 pagesValid Documents List PDFAnjani KumarNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Woman in The Mirror - Imaging The Filipino Woman in Short Stories in English by Filipino Woman AuthorsDocument16 pagesThe Woman in The Mirror - Imaging The Filipino Woman in Short Stories in English by Filipino Woman AuthorsIJ-ELTSNo ratings yet

- Bonjour Hi 2Document2 pagesBonjour Hi 2JWilhNo ratings yet

- Passive Smart TextilesDocument15 pagesPassive Smart Textilesmurad0007No ratings yet

- The Compartmentalized Life MatrixDocument2 pagesThe Compartmentalized Life Matrixivan chuaNo ratings yet

- Model Pl5 Service ManualDocument31 pagesModel Pl5 Service ManualEd CalheNo ratings yet

- The Stunts in The Jackass MovieDocument4 pagesThe Stunts in The Jackass MovieHOSKINGJ100% (1)

- Yeske, Eryn Counting Principles Unit ExamDocument7 pagesYeske, Eryn Counting Principles Unit ExamEryn YeskeNo ratings yet

- Indian Textile Industry: October 2006Document22 pagesIndian Textile Industry: October 2006Pratik UdaniNo ratings yet

- Prevention of BarreDocument5 pagesPrevention of BarreKavi DhingraNo ratings yet

- Another Pattern From "A La Nouveauté - La Boutique De: Jeanne"Document2 pagesAnother Pattern From "A La Nouveauté - La Boutique De: Jeanne"adinaNo ratings yet

- Sunkyunkwan Scandal NovelDocument89 pagesSunkyunkwan Scandal NovelNathasia WinartoNo ratings yet

- CHN NCP Group 1 Docx Final PromiseDocument6 pagesCHN NCP Group 1 Docx Final PromiseLeo Buquiran AcabalNo ratings yet

- Persian Henna PatternsDocument83 pagesPersian Henna Patternsmymuseclio100% (1)

- Dan Eden - The Never EndingDocument142 pagesDan Eden - The Never EndingPaulo BarrosNo ratings yet

- Chang Ju Ann 5SC1Document2 pagesChang Ju Ann 5SC1Ummu SalmahNo ratings yet

- The Sound of MusicDocument73 pagesThe Sound of MusicSP Kee0% (1)

- Steel Toe Safety ShoesDocument17 pagesSteel Toe Safety ShoesKneth RyeNo ratings yet

- Spinning Hafizur Rahman PDFDocument1 pageSpinning Hafizur Rahman PDFAwais ImranNo ratings yet

- Write An Essay On SidneyDocument5 pagesWrite An Essay On SidneyRatan RoyNo ratings yet

- Orlando Research PaperDocument11 pagesOrlando Research Paperapi-332475988No ratings yet

- Zappa AuctionDocument248 pagesZappa AuctionlisasunshineNo ratings yet

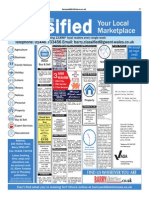

- Bar Classifieds 220514Document3 pagesBar Classifieds 220514Digital MediaNo ratings yet

- Metamorphoses, The - Ovid and A. S. KlineDocument681 pagesMetamorphoses, The - Ovid and A. S. Klinealex_allen_3No ratings yet

- Michèle LamyDocument22 pagesMichèle LamyGastrique Lungani TshabalalaNo ratings yet

- Bill Kazmaier - Squat and Deadlift PDFDocument11 pagesBill Kazmaier - Squat and Deadlift PDFAndy Paine90% (20)

- Astm D6193 2016 PDFDocument142 pagesAstm D6193 2016 PDFMichaelNo ratings yet

- Berlin: To See To Do To EatDocument107 pagesBerlin: To See To Do To EatCTR100% (1)

- Supacord Spec PDFDocument1 pageSupacord Spec PDFFloorkitNo ratings yet

- Peace Corps Mali Welcome Book - October 2011Document94 pagesPeace Corps Mali Welcome Book - October 2011Accessible Journal Media: Peace Corps DocumentsNo ratings yet

- Accents 2015Document51 pagesAccents 2015Ankit Biswas100% (1)