Main Pressure Packing

Intermediate Packing

�Contents

Main Pressure Packing Intermediate Packing

Basic Understanding Ring Theory Housing Theory Leakage Control Cooling Systems for Packings Typical Packing Types Associated Products - Piston Rods

�Basic Understanding

Task and Types Function Sealing System Design

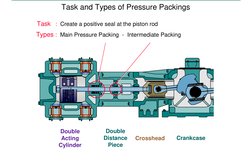

�Task and Types of Pressure Packings

Task : Create a positive seal at the piston rod Types : Main Pressure Packing - Intermediate Packing

Double Acting Cylinder

Double Distance Piece

Crosshead

Crankcase

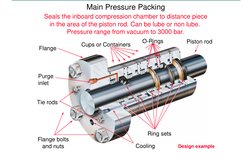

�Main Pressure Packing

Seals the inboard compression chamber to distance piece in the area of the piston rod. Can be lube or non lube. Pressure range from vacuum to 3000 bar.

Flange Cups or Containers O-Rings Piston rod

Purge inlet Tie rods

Ring sets Flange bolts and nuts Cooling

Design example

�Intermediate Packing

Intermediate Packings seal the first distance piece to the second distance piece in the area of the piston rod. Usually they are not lubricated and not water cooled.

Flange Ring sets

Flange bolts and nuts

Piston rod

Cups or Containers Purge (plugged) Tie rods

Design example

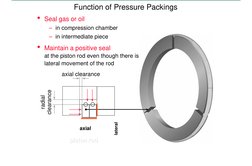

�Function of Pressure Packings

Seal gas or oil

in compression chamber in intermediate piece

Maintain a positive seal

at the piston rod even though there is lateral movement of the rod axial clearance

end nce ara cle

radial clearance

axial

piston rod

lateral

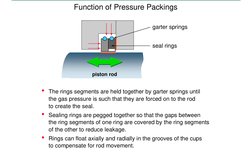

�Function of Pressure Packings

garter springs seal rings

piston rod

The rings segments are held together by garter springs until the gas pressure is such that they are forced on to the rod to create the seal. Sealing rings are pegged together so that the gaps between the ring segments of one ring are covered by the ring segments of the other to reduce leakage. Rings can float axially and radially in the grooves of the cups to compensate for rod movement.

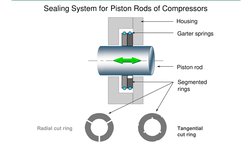

�Sealing System for Piston Rods of Compressors

Housing Garter springs

Piston rod Segmented rings

Radial cut ring

Tangential cut ring

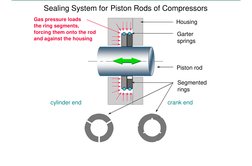

�Sealing System for Piston Rods of Compressors

Gas pressure loads the ring segments, forcing them onto the rod and against the housing

Housing Garter springs

Piston rod Segmented rings cylinder end crank end

�Sealing System for Piston Rods of Compressors

When the packing is not pressurized by gas, the garter springs hold the ring segments in place around the piston rod.

�Sealing System for Piston Rods of Compressors

Axial and radial clearance allow the rings to float in the housing , thus leakage is prevented by always maintaining a positive seal.

If lip seals were used they would not conform to the rod as it would not compensate for the rod movement. For this reason segmental rings are used.

�Sealing System for Piston Rods of Compressors

Gaps of one ring are covered by the face of the other ring. Rings are positioned by a pin

�Sealing System for Piston Rods of Compressors

End clearance between ring segments allows worn rings to compensate for wear automatically. Tangential cut rings act like a camera lens.

�Sealing System for Piston Rods of Compressors

Gas pressure loads the ring segments, forcing them on to the rod and housing Axial and radial clearance allow the rings to float in the housing , thus leakage is prevented by always maintaining a positive seal. When the packing is not pressurized by gas, the garter springs hold the ring segments in place around the piston rod. If lip seals were used they would not conform to the rod as it would not compensate for the rod movement. For this reason segmental rings are used. End clearance between ring segments allows worn rings to compensate for wear automatically. Tangential cut rings act like a camera lens.

Gaps of one ring are covered by the face of the other ring. Rings are positioned by a pin

�Sealing System for Piston Rods of Compressors

Stepwise pressure reduction by each packing ring group:

pressure p

discharge pressure

pressure profile atmospheric pressure leakage

Piston rod

packing ring groups packing assembly

The last sealing ring group is responsible for the leakage to the outside.

Rule of the thumb for packings: Each recess of a new packing will reduce the pressure by half. If one ring pair is worn, the pressure has to be reduced by the remaining ring pairs. The pressure profile will differ then from the pictured profile.

�Design Criteria

Differential pressure Temperature Speed of the rod Gas type and gas condition Lube Rod material Rod surface Customers demand Expected life time Costs

- Number of ringsets, with or without cooling - Cooling, ring material - Cooling , ring material - Vent, ring type,ring material - ring material, number of lube points - ring material - ring material - materials and design - material, design - design and material

�Number of Ring Groups of Main Pressure Packings

Pressure range of HRP filled TFE packings for compressors

pressure (bar) uncooled not vented (Air) uncooled vented (Gas) cooled not vented (Air) cooled vented (Gas) 0 - 12 12.5 - 21 21.5 - 35 35.5 - 70 70.5 - 316 316.5 up

4 sets

5 sets

6 sets

7 sets

5 sets

6 sets

7 sets

8 sets

All packings above 70 bar whether vented or unvented must be cooled and should be lubricated.

4 sets

5 sets

6 sets

7 sets

8 sets

9 sets

5 sets

6 sets

7 sets

8 sets

9 sets

10 sets

1 lube point

2 lube points

�Components of Pressure Packings

Flange Flange Containers Containers (Cups) (Cups)

etc. etc.

Plates Plates

Crank end

Cylinder end

etc.

etc.

Sealing Sealing Ring Ring Sets Sets

O-Rings O-Rings

Soft Soft metal metal gasket gasket (joint) (joint) to to seal seal on on stuffing stuffing box box

�Contents

Function Single Acting Ring Groups Double Acting Ring Groups Side Loaded Ring Groups Special Rings Pressure Breakers Clearance figures

�Function Classification of rings according to their functions:

Seal ring Pressure breaker

reduces the pressure by throttling the gas flow

Anti-extrusion ring - usually called backup ring

for pressures higher than approx. 15 bar made out of stronger material than the seal rings located on low pressure side, with a gap between the ring and the rod smaller than the gap between the housing and the rod

Ring set: consists of several rings

�Function of a Single Acting Ring Pair

Gas enters the cup via the side clearance in the cups and gaps in radial cut ring and loads tangent cut ring onto piston rod.

Cylinder end radial ring

Tangent cut ring gaps are sealed by radial cut ring Axial movement of piston rod

tangential ring

Crank end

Side clearance in the cups and radial cut ring gaps avoid gas traps. They allow the gas inside the cups to return to the cylinder.

Cylinder end

Axial movement of piston rod

Crank end

�Single Acting Ring Group Type 0342

Wear limit:

Gaps decrease to zero when ring wears. Rings without gap are worn out and must be exchanged.

Pressure

ring type 0304

gap

ring type 0306

Radial cut ring Description:

gap

Tangential cut ring

Rings located relative to each by a peg in tangential cut ring mating hole in radial cut ring. By this gaps of tangential cut rings are covered by radial cut ring. Seals only, when the crank end of the cylinder is compressing gas Standard ring set for low to medium pressures

Task: Application:

�Single Acting Ring Group Type 0353

Pressure

ring type 0304

ring type 0322

Radial cut ring Description: Task: Application:

6-piece tangential cut ring

Radial cut ring combined with 6 piece design, instead of 3-piece design tangential cut ring. Tangential cut is continued across the segment creating Bridge Pieces for brittle ring materials , for pressures above 150 bar with metal Bridge Pieces

�Single Acting Ring Group Type 0371

Pressure

ring type 0304

ring type 0306

ring type 0310

Radial cut seal ring

Tangential cut seal ring

Backup or anti-extrusion ring Bronze, Peek, PPS

Description:

Single acting standard ring pair with backup ring. Backup ring is bored to have 0.1 to 0.2 mm clearance on the piston rod and hence no gaps when fitted. Standard ring group for pressures above 21 bar

Application:

�Function of a Double Acting Ring Group

Gas enters the cup via side clearance and loads tangent cut rings onto piston rod. Axial movement of piston rod Gaps in both tangent cut rings sealed because rings are pegged to prevent gaps aligning.

Crank end

Cylinder end

On reverse stroke gas is sealed in the same manner as described for the crank stroke. Axial movement of piston rod

Gas is trapped in the container.

Cylinder end

Crank end

�Double Acting Ring Group Type 0344

Pressure

ring type 0308

ring type 0306

Description:

2 tangential cut rings pegged together in such a way that the segments of one ring mask the end gaps of the other ring. Seal in both strokes of the compression cycle. Low pressures or vacuum, Intermediate Packing, pulsation seal in Wiper Packings, final or vent seal in Main Pressure Packings.

Task: Application:

�Double Acting Ring Group Type 0372

Pressure

ring type 0308

ring type 0306

ring type 0310

Tangential cut seal ring

Tangential cut seal ring

Backup ring or anti-extrusion ring

Description: Application:

Double acting ring set with backup ring Standard set for pressures of less than 12 bar and higher temperatures

�Double Acting Ring Group Type 0347

Pressure

ring type 0316

ring type 0317

Cut lines do not meet the centre !

Description:

Double acting ring pair consisting of two 4-segment radial cut rings pegged together, so that the segments of one ring masks the end gaps of the other. Where brittle materials must be used, e.g. carbon sturdy parts, frequently used with brittle materials no wear limit, difficult to install

Application: Advantage: Disadvantage:

�Side Loaded Pressure Ring Group Type 0373

Pressure

Pressure

ring type 0314

ring type 0313

ring type 0312

Radial cut ring with chamfered recess Description:

Radial cut ring with Tangential cut chamfered boss ring with peg

always maintains a seal between tangential cut and container sealing face due to the inclined nature of the faces of the 2 radial cut rings and garter spring load. Main Packings at low pressure side near vent and purge, also in Intermediate (Partition) Packings and Oil Tight Packings.

Application:

�Special Rings Type 0309 and 0328

Pressure

ring type 0328

Pressure

ring type 0309

Single acting tangential cut ring without wear restriction Description: Application: Disadvantage:

Double acting tangential cut ring without wear restriction

No direct leakage path beween the segments, needs no further ring for proper sealing. Where small containers must be installed. No wear restriction; possibility of damage to inboard feather edges if rod is inserted into assembled packing.

�Pressure Breaker Rings 0301 and 1302

Pressure

ring type 0301

Pressure

ring type 1302

Double acting ring Description: Application:

Single acting ring with relief slots in the middle of segments and chamfers on joint

Reduce pressure and throttle gas pressure pulsations but not to seal. Pressures greater then 20 bar, used on their own filling a recess, or with backup ring when non metallics (PTFE).

�Nomenclature of HRP Rings

Container (cup) thickness Recess depth Ring radial thickness Ring axial width Dimensions of standard rings are according to HRP standard TDSM 115

Container (cup) outer dia

Recess dia

�Pressure and Intermediate Packings

Flanges

Containers

Flanges, Containers (cups), Plates

Types - Function - Clearance - Surface Quality - Materials

Other Parts

Tie rods - O-rings - Static Sealing

�Types of Flanges and Containers

Flanges

Containers (cups) Spigotted Flange HRP Standard Containers (cups) Recessed Flange cannot be lapped

T-Container (cup)

L-Container (cup)

Plate

Containers

for purge

cooled lube vented plain

vented plain

�Functions of Flanges and Containers

Flange :

Contains the connections for lube oil, cooling water, vent and purge. Containers are fixed with tie rods to flange.

Container : Contains the ring sets and the holes

(cup) for lube oil, cooling water, and vent.

Plate :

Contains the holes for vent. Masks the milled cooling water grooves. Compensates the thickness reduction of containers after reconditioning (by installing a thicker plate). Dimensions: Dimensions of flanges, containers, plates are according to HRP standard TDSM 182

�Clearance and Surface Quality

or

FLANGES Spigot dia : Recess dia :

Spigot dia. as Container (cup) outer diameter Recess dia = Stuffing box nom. bore +0 to 0.15 mm As recesses cannot be lapped effectively, recessed type flanges should be avoided.

SEALING FACES on Containers, Flanges and Plates Surface finish and Flatness : low pressure: < 70 bar uncooled Packings

0.4 &

high pressure: > 70 bar low MOL weight or cooled Packings

0.2 & 0.001

0.002

�Materials

Standard :

Grey iron Carbon steel Stainless steel

BS1452 GR.250 BS970 GR 070M55 BS970 GR 316S16

Specials :

As required by customers

Refer to TDSM213 for application details via HRP Intranet

�Details: O-Rings - Static Sealing

O-ring material according to customers order

Tie rod

High material and surface quality

Captive rectangular section gasket (joint) from copper or soft iron

�Details: Static Sealing Function

The joint forms the only static seal as part of the main pressure packing, which seals against the bottom of the stuffing box in the compressor. It is important that the static seal is flat and parallel. It is also important that there is a good surface at the bottom of the stuffing box with no contamination. This is as important a seal as any of the sealing rings.

Calculation of Leakage Rates by HRP Leakage Control System ECM

�Calculation of Leakage Rates to HRP Standards

It is difficult to define exactly how much gas will leak through a pressure packing. A slight leakage is fundamental to the operation of the packing.

Major factors influencing leakage are

the discharge pressure of the compressor, the size of the piston rod the molecular weight of the gas any lubrication.

Secondary factors include surface finish of the rod and the containers, gas contamination and machine misalignments.

Compressors can suffer higher than normal leakage

if operated at very low pressures, if running at partial or off-load, if (new) packings have not bedded in.

�Vent and Purge Arrangement

For dangerous gases or low emission values the containers near to the distance piece of Pressure and Intermediate Packing are purged. A flow of Nitrogen purge gas is inlet into the packing to stop possible leakage of dangerous gas into the crank case and further on into the compressor room. It could also contaminate oil and lower its flash point.

Crankcase side

Nitrogen IN

Cylinder side

Nitrogen

to distance piece vent

Nitrogen

Dangerous gas

Oil drain

Piped controlled leakage to dangerous gas/nitrogen vent

Lubrication (on top)

�Vent and Purge System, Pressures, Leakage flows to API 618 Vent Pressure

- up to1.5 barg maximum to API 618, Appendix 1 depends on both the leakage flow escaping past the packing rings and the back pressure and flow restriction from vent / flare line system. If the vent line back pressure and restriction remains constant, then an increasing vent line pressure indicates increasing packaging leakage.

Purge gas pressure - up to 2.5 barg.

should be at least 1 bar above the Vent Pressure

Purge Gas Flow (Leakage) Rates

< 1 to 6 l /min for packing with rod and containers in good condition and new bedded-in wear parts with back to back SLP (WAT) rings. (Valid for purge systems fitted with SLP rings and AL (5 ring) sets).

Recycling Vent Flows - to suction system of the compressor

If the first stage suction pressure is < 1.5 barg, any leakage may be recycled to reduce the overall leakage (depending on installation).

Intermediate Vent Connections - at higher pressures

High pressure packings may be fitted with an intermediate HP vent connection as well as a low pressure vent connection for even breakdown of pressure across all rings.

�Emission Control and Monitoring System ECM

Purge pressure and purge flow are controlled, consumption of purge gas (N2) is minimized. The equipment adjusts purge gas inlet pressure to compensate for increase in vent pressure and keeps the differential pressure of the purge to vent gas. If gas flow to flare exceeds a limiting value an alarm is switched on.

Modular construction, up to 4 cylinders per cabinet Satisfies emissions legislation to API618 & NACE Optional flow controlled purge for valve unloaders, intermediate & wiper packings

�Purge Panel Diagram of the ECM

Vent pressure

PURGED GASSES FROM PACKING

max pressure 16 bar YYP range 1 3 bar

G1

Vent flow F1 V5

VENT OUTLET TO FLARE

Purge pressure G3 Purge Compensation Regulator, adjustable V2 G2 Purge flow F2 V4 V3

NITROGEN PURGE TO PACKING

NITROGEN SUPPLY

max. 16 bar typ. 10 bar

V1 Shut Off Regulator Gauge F1: Flowmeter (metallic type) Flow range 10 30 l/min F2: Flowmeter (rotameter) Flow range 0 10 l/min

HRP Cooling System HRP Drilled Radial Flow Type

Design of cooled packings is currently under review

�HRP Cooling System

Frictional heat has to be dissipated. For discharge pressures greater than 70 bar water cooling is necessary in general.

For lower pressures water cooling is necessary only under special conditions.

�HRP Cooling System

Forced flow cooling by 340 milled groove gives: improved water flow no stagnancy reduced pressure drop through packing cooling system water outlet cooling water inlet

water inlet

water outlet

Required cooling water: pressure : 0.5 to 5 bar max. temperature: 40C

�HRP Drilled Radial Flow Type- conforms to API 618

Better coolant flow with reduced losses Meets API 618 revision 4 by eliminating O rings which surround the piston rod Easier to change packing rings without removing the piston rod Cooling passages can be cleaned by removal of plugs

Main Characteristics Typical Pressure Packing Types HRP Stationary Gas Seal Features of HRP Pressure Packings Testing of Pressure Packings

�Characteristics

The main characteristics of Pressure Packings are:

lube or non-lube with or without cooling with or without vent with vent and with or without purge

These characteristics are dependent upon:

discharge pressure differential temperature. piston speed customer specification process requirements

Type and number of ring groups depend on the design criteria

see Basic Understanding.

�Non lube, uncooled, not vented, not purged, for discharge pressures less than 10 bar

Cylinder end

RING GROUP 0344

Double acting ring groups are used

0306 0308

Crank end

�Non lube, uncooled, not vented, not purged, for discharge pressures less than 30 bar

Pressure Breaker Ring Single acting ring groups

Cylinder end

RING GROUP 0349

RING GROUP 0371

1302

0310

0304

0306

0310

Crank end

�Lube, Lube uncooled, not vented, not purged, for discharge pressure from 30 bar to 70 bar

Pressure Breaker Ring Single acting ring groups

oil

from cylinder lube pump

Cylinder end

RING GROUP 0349

RING GROUP 0371

1302

0310

0304

0306

0310

Crank end

�Non lube, cooled, not vented, not purged - 170 bar

For pressures greater than 70 bar cooled packings are recommended

Cylinder end

O-rings are used to prevent the process gas from entering the water channels and to also prevent water from leaving the water channels

Crank end

�Non lube, uncooled, vented, not purged - 70 bar

For dangerous gases - toxic or explosive:

Vented gas is piped to flare or to a lower pressure level of compressor. Gas vent Cylinder end Crank end SLP ring group: side load pressurized, behind vent

0314 0313 0312

RING GROUP 0373

�Non lube, uncooled, vented and purged - 70 bar

For very dangerous gases or low emission values

Purge gas (mainly Nitrogen) is inlet in to the last container. Inlet pressure normally is 1 bar minimum above vent pressure.

purge gas Crank end gas mixture

Cylinder end

gas

The mixture of dangerous gas and purge gas is piped to the vent collection

�HRP Design

Segmental Packing Rings only seal during dynamic reciprocating action. Stationary Gas Seal energises when the compressor is stopped

Pneumatically operated externally, when the rod is stationary to prevent cylinder gas emission

Cylinder end

DYNAMIC : NO ROD CONTACT

STATIC

ROD CONTACT

Piston energised

�HRP Design

Cartridge unit fitted to existing Packing increasing length

Segmental packing rings only seal during dynamic reciprocating action. For standstill additional parts are necessary

Distance piece

Cylinder end

�Application Features

Face & outside dia connections make flange more serviceable. Thermocouple to detect increases in temperature

Facility for rod drop indicator to detect rider ring wear

Detachable flange to aid assembly Vent connection can be fitted with an off-line flow measurement device TYPICAL WATER COOLED PRESSURE PACKING

�Design Features

`O'-Ring design can be captive, totally eliminating possibility of gas leakage into water channels Fully lapped faces with O-Rings eliminate static leakage

Spiral wound Gasket, optional, to reduce static leakage Milled groove Coolant Channels to reduce pressure drop to a minimum Tee shaped Cup complete with`SLP' Rings & purge (API618) allows for sealing faces to be machine-lapped TYPICAL WATER COOLED PRESSURE PACKING

�Standard and Extra Leakage Testing Procedures

Standard test of water cooled packings:

Pressurised air (6 bar) is connected to cooling water inlet. Air inlet valve will be closed. Pressure drop is checked at the closed volume

Standard bubble test

Pressurised air (6 bar) is connected to cooling water inlet. Packings are submerged in water, bubbles indicate leakage. After test packings are disassembled, cleaned, dried and reassembled. Test do not show reasseambling errors.

Extra test when required - all packings

Check of the gas tightness between the test flanges

Piston Rods

�Piston Rods

Surface Finish

higher value of Ra preferred - hardened rods

- coated rods

Ra : 0,2 - 0,4 m Ra : 0,2 - 0,25 m

Coating

for reducing rod wear and/or reconditioning

- Chromium oxide - Ceramics (Metco P130), produced with plasma gun method (HVOF) - Tungsten Carbide produced with plasma gun (HVOF) or Detonation Gun method

Materials

Lube air compressor Process gas compr. Coated rods - unhardened 30 HRC, cut threads - Induction hardened (occasionally nitrided) 50 to 55 HRC, rolled threads - Thermal plasma sprayed, mostly to 65 - 70 HRC

�End

of the Training File

Pressure Packings