Professional Documents

Culture Documents

Structural Steel Design Project: Calculation Sheet

Uploaded by

rameshbabu_1979Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Structural Steel Design Project: Calculation Sheet

Uploaded by

rameshbabu_1979Copyright:

Available Formats

PLATE GIRDERS - II

Structural Steel Design Project

Calculation Sheet

PROBLEM:

Job No: Sheet 1 of 18 Rev Job Title: PLATE GIRDER Worked Example - 1 Made by Date 15-04-00 SSSR Checked by PU Date 25-04-00

The girder showed in Fig. E1 is fully restrained against lateral buckling throughout its span. The span is 36 m and carries two concentrated loads as shown in Fig. E1. Design a plate girder. Yield stress of steel, fy Material factor for steel, m Dead Load factor, fd Imposed load factor, fl W1 9000 mm = 250 N/mm2 = 1.15 = 1.35 = 1.50 w 18000 mm W2 9000 mm

36000 mm Fig. E1 Example plate girder 1.0 LOADING

Dead load: Uniformly distributed load, wd Concentrated load, W1d Concentrated load, W2d Live load: Uniformly distributed load, wl Concentrated load, W1l Concentrated load, W2l = 35 kN/m = 400 kN = 400 kN = 20 kN/ m (Including self-weight) = 200 kN = 200 kN

Version II

16 - 12

PLATE GIRDERS - II

Structural Steel Design Project

Calculation Sheet

Factored Loads: w W1 W2 2.0

Job No: Sheet 2 of 18 Rev Job Title: PLATE GIRDER Worked Example - 1 Made by Date 15-04-00 SSSR Checked by PU Date 25-04-00

= wd * fd + wl* fl = 20 * 1.35 + 35 * 1.5 = W1d* fd + W1l* fl = 200 * 1.35 + 400 * 1.5 = W2d * fd + W2l* fl = 200 * 1.35 + 400 * 1.5 BENDING MOMENT AND SHEAR FORCE Bending moment (kN-m) UDL effect

= 79.5 kN/m = 870 kN = 870 kN

Shear force (kN)

w1l 2 79.5* 36 * 36 = = 12879 8 8

Wl = 870 * 9 4 = 7830

w1l = 1431 2

Concentrated load effect

W = 870

TOTAL

20709

2301

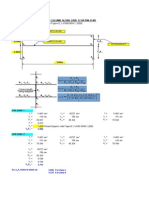

The design shear forces and bending moments are shown in Fig. E2. 3.0 INITIAL SIZING OF PLATE GIRDER

Depth of the plate girder: The recommended span/depth ratio for simply supported girder varies between 12 for short span and 20 for long span girder. Let us consider depth of the girder as 2400 mm.

l 36000 = = 15.0 2400 d

Depth of 2400 mm is acceptable.

Version II

16 - 13

PLATE GIRDERS - II

Structural Steel Design Project

Calculation Sheet

Job No: Sheet 3 of 18 Rev Job Title: PLATE GIRDER Worked Example - 1 Made by Date 15-04-00 SSSR Checked by Date 25-04-00 PU

(For drawing the bending moment and shear force diagrams, factored loads are considered)

79.5 kN/m 870 kN 9000 mm 18000 mm 870 kN 9000 mm

36000 mm 2301 1585.5 715.5

Shear force in kN

715.5 1585.5 2301

20709 Bending moment in kN-m

Fig. E2 Bending moment and shear force diagrams

Version II

16 - 14

PLATE GIRDERS - II

Structural Steel Design Project

Calculation Sheet

Flange:

Sheet 4 of 18 Rev Job Title: PLATE GIRDER Worked Example - 1 Made by Date 15-04-00 SSSR Checked by Date 25-04-00 PU

py = 250/1.15 = 217.4 N/mm2 Single flange area,

Af = M max 20709 *106 = = 39690.7 mm 2 d py 2400 * 217.4

By thumb rule, the flange width is assumed as 0.3 times the depth of the section. Try 720 X 60 mm, giving an area = 43200 mm2.

Web:

Minimum web thickness for plate girder in buildings usually varies between 10 mm to 20 mm. Here, thickness is assumed as 14 mm. Hence, web size is 2400 X 14 mm

4.0 SECTION CLASSIFICATION

Flange:

250 = fy b=

250 = 250

= 1.0

B t 720 14 = = 353 2 2

b 353 = = 5.9 < 7.9 T 60

Hence, Flange is PLASTIC SECTION.

Version II

16 - 15

PLATE GIRDERS - II

Structural Steel Design Project

Calculation Sheet

Web:

Job No: Sheet 5 of 18 Rev Job Title: PLATE GIRDER Worked Example - 1 Made by Date 15-04-00 SSSR Date 25-04-00 Checked by PU

d 2400 = = 171.4 > 66.2 t 14 Hence, the web is checked for shear buckling.

5.0 CHECKS

Check for serviceability:

d 2400 = = 9.6 mm < t 250 250 d Since, t > 250 Web is adequate for serviceability.

Check for flange buckling in to web:

Assuming stiffener spacing, a > 1.5 d

d p yf t 294 250

1/ 2

2400 217.4 = 294 250

1/ 2

= 7.6 mm

Since, t (= 14 mm) > 7.6 mm, the web is adequate to avoid flange buckling into the web.

Check for moment carrying capacity of the flanges:

The moment is assumed to be resisted by flanges alone and the web resists shear only. Distance between centroid of flanges, hs = d + T = 2400 + 60 = 2460 mm Af = B * T = 720 * 60 = 43200 mm2

Version II

16 - 16

PLATE GIRDERS - II

Structural Steel Design Project

Calculation Sheet

Job No: Sheet 6 of 18 Rev Job Title: PLATE GIRDER Worked Example - 1 Made by Date 15-04-00 SSSR Checked by Date 25-04-00 PU

Mc = pyf * Af * hs = 217.4 * 43200 * 2460 * 10-6 = 23103.5 kN-m > 20709 kN-m Hence, the section in adequate for carrying moment and web is designed for shear.

6.0

WEB DESIGN

The stiffeners are spaced as shown in Fig. E5. The spacing of stiffeners is taken as 3000 mm. The spacing can be increased towards the centre of the span for economy. W1 W2 A B C D

12 panels @ 3000 mm [36000 mm]

Fig.E3 Trial stiffener arrangement

Panel AB is the most critical panel (Maximum shear zone), so design checks for the web are made for panel AB only.

End panel ( AB) design:

d = 2400 mm t = 14 mm a 3000 = = 1.25 d 2400

d 2400 = = 171.4 t 14

Version II

16 - 17

PLATE GIRDERS - II

Structural Steel Design Project

Calculation Sheet

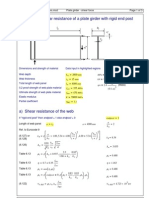

Calculation of critical shear strength, qcr:

Sheet 7 of 18 Rev Job No: Job Title: PLATE GIRDER Worked Example - 1 Made by Date 15-04-00 SSSR Checked by Date 25-04-00 PU

Elastic critical stress, qe (when a/d > 1) = [1.0 + 0.75/(a/d)2][1000/(d/t)]2 = [1 + 0.75/(1.25)2][1000/(171.4)]2 = 50.4 N/mm2 Slenderness parameter, w = [0.6(fyw/m)/qe]1/2 = [0.6(250/1.15)/50.4]1/2 = 1.61 > 1.25 Hence, Critical shear strength (qcr = qe) = 50.4 N/mm2

fv =

FVA 2301*103 = = 68.5 N / mm 2 dt 2400 *14

(68.5 > 50.4)

Since, fv > qcr

Panel AB is designed using tension field action. Calculation of basic shear strength, qb:

t =

1.5qcr a 1+ d

2

1.5 * 50.4 1 + (1.25)2

= 47.2

yb = (pyw2 3qcr2 + t2) 1/2 - t = (217.42 3*50.42 + 47.22) 1/2 47.2 = 157.4

qb = qcr + yb

2 a a 2 + 1+ d d

= 50.4 +

157.4 21.25 + 1 + (1.25)2

= 78.0 N / mm 2

Version II

16 - 18

PLATE GIRDERS - II

Structural Steel Design Project

Calculation Sheet

Since, qb > fv

Job No: Sheet 8 of 18 Rev Job Title: PLATE GIRDER Worked Example - 1 Made by Date 15-04-00 SSSR Checked by Date 25-04-00 PU (78.0 > 68.5)

Panel AB is safe against shear buckling.

Checks for the web panel:

End panel AB should also be checked as a beam (Spanning between the flanges of the girder) capable of resisting a shear force Rtf and a moment Mtf due to anchor forces. (In the following calculations boundary stiffeners are omitted for simplicity)

Check for shear capacity of the end panel: q H q = 0.75 dt p y 1 cr 0.6 p y

qcr = 50.4 N / mm 2

1 2

f v qcr qb qcr

1

50.4 H q = 0.75* 2400 *14 * 217.4 1 0.6 * (250 / 1.15) Hq 2814 Rtf = = = 1407 kN 2 2 Av = t .a = 14 * 3000 = 42000 mm2

68.5 50.4 = 2814 kN . 78 50.4

Pv = 0.6 pyw Av = 0.6 * (250/1.15) * 42000/1000 = 5478 kN Since, Rtf < Pv, the end panel can carry the shear force.

Version II

16 - 19

PLATE GIRDERS - II

Structural Steel Design Project

Calculation Sheet

Job No: Sheet 9 of 18 Rev Job Title: PLATE GIRDER Worked Example - 1 Made by Date 15-04-00 SSSR Checked by Date 25-04-00 PU

Check for moment capacity of end panel AB:

M tf =

y =

Hq d 10

2814 * 2400 *10 3 = 675.4 kN m 10

a 3000 = =1500 2 2 1 3 1 ta = *14 *30003 = 3150 * 107 mm 4 12 12 I 3150 *107 py = * (250 / 1.15) *10 6 = 4565 kN m y 1500

(675.4 < 4565)

I =

Mq =

Since, Mtf < Mq

The end panel can carry the bending moment.

7.0 DESIGN OF STIFFENERS Load bearing stiffener at A:

Design should be made for compression force due to bearing and moment. Design force due to bearing, Fb = 2301 kN Force(Fm) due to moment Mtf, is

Fm =

M tf a

675.4 *103 = 225 kN 3000

Total compression = Fc = Fb + Fm = 2301 + 225 = 2526 kN

Version II

16 - 20

PLATE GIRDERS - II

Structural Steel Design Project

Calculation Sheet

Job No: Sheet 10 of 18 Rev Job Title: PLATE GIRDER Worked Example - 1 Made by Date 15-04-00 SSSR Checked by Date 25-04-00 PU

Area of stiffener in contact with the flange, A:

Area ( A) should be greater than

0.8 Fc p ys

0.8 Fc 0.8* 2526 = * 103 = 9295 mm 2 217.4 p ys

Try stiffener of 2 flats of size 240 X 25 mm thick Allow 15 mm to cope for web/flange weld A = 225 * 25 * 2 = 11250 mm2 > 9295 mm2

Bearing check is ok.

Check for outstand:

Outstand from face of web should not be greater than 20 ts.

250 = fy

250 2 = = 1.0 250

Outstand bs = 240 mm < 20 ts (= 20 * 25 * 1.0 = 500) bs = 240 mm < 13.7 ts (= 13.7 * 25 * 1.0 = 342.5) Hence, outstand criteria is satisfied.

Version II

16 - 21

PLATE GIRDERS - II

Structural Steel Design Project

Calculation Sheet

Job No: Sheet 11 of 18 Rev Job Title: PLATE GIRDER Worked Example - 1 Made by Date 15-04-00 SSSR Checked by Date 25-04-00 PU

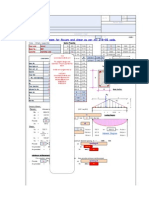

Check stiffener for buckling: (The effective stiffener section is shown in Fig. E4)

Y 25 mm bs = 240 mm 14 mm X bs = 240 mm Stiffener Web

Fig. E4 End bearing stiffener

The buckling resistance due to web is neglected here for the sake of simplicity.

Ix = 25 * 4943 1 * 25*143 = 25115 *10 4 mm 4 12 12

Ae = Effective area = 240 * 25 * 2 = 12000 mm2

I rx = x Ae

1 2

25115 *104 = 12000

= 144.7 mm

Flange is restrained against rotation in the plane of stiffener, then le = 0.7 l = 0.7 * 2400 = 1680 mm

le 1680 = = 11.6 rx 144.7

Version II

16 - 22

PLATE GIRDERS - II

Structural Steel Design Project

Calculation Sheet

For fy = 250 N/mm2 and = 11.6

Job No: Sheet 12 of 18 Rev Job Title: PLATE GIRDER Worked Example - 1 Made by Date 15-04-00 SSSR Checked by Date 25-04-00 PU

c = 250 N/mm2 from table (3) of chapter on axially compressed columns

Buckling resistance of stiffener is Pc = c Ae / m = (250/1.15) * 12000 * 10 -3 = 2609 kN Since Fc < Pc (2526 < 2609), stiffener provided is safe against buckling.

Check stiffener A as a bearing stiffener:

Local capacity of the web: Assume, stiff bearing length b1 = 0 n2 Pcrip = 2.5 * 60 * 2 = 300 = (b1+ n2) t pyw = (0 + 300) * 14 * (250/1.15) * 10-3 = 913 kN Bearing stiffener is designed for FA FA = Fc Pcrip = 2526 913 = 1613 kN Bearing capacity of stiffener alone PA = pys * A = (250/1.15) * 12000/1000 = 2609 kN Since, FA < PA (1613 < 2609) BS 5950: Part 1, Clause 4.5.3

The designed stiffener is OK in bearing.

Stiffener A Adopt 2 flats 240 mm X 25 mm thick

Version II

16 - 23

PLATE GIRDERS - II

Structural Steel Design Project

Calculation Sheet

Design of intermediate stiffener at B:

Job No: Sheet 13 of 18 Rev Job Title: PLATE GIRDER Worked Example - 1 Made by Date 15-04-00 SSSR Checked by Date 25-04-00 PU

Stiffener at B is the most critical intermediate stiffener, hence it will be chosen for the design.

Minimum Stiffness:

I s 0.75 dt 3 for a d 2 Is 0.75 dt 3 for a < d 2 a3

d 2 = 2 * 2400 = 3394 mm a < d 2 ( 3000 < 3394)

Conservatively' t' is taken as actual web thickness and minimum' a' is used.

1.5 d 3t 3 1.5 * 24003 * 143 = = 632 * 10 4 mm 4 2 2 a 3000

Try intermediate stiffener of 2 flats 90 mm X 12 mm

(I s )Pr ovided

12 *1943 12 *143 = 730 * 104 mm 4 12 12

The section provided satisfies the minimum required stiffness.

Version II

16 - 24

PLATE GIRDERS - II

Structural Steel Design Project

Calculation Sheet

Check for outstand:

Outstand of the stiffener 13.7 ts 13.7 ts= 13.7 * 14 * 1.0 = 192 mm Outstand = 90 mm Hence, outstand criteria is satisfied.

Job No: Sheet 14 of 18 Rev Job Title: PLATE GIRDER Worked Example - 1 Made by Date 15-04-00 SSSR Checked by Date 25-04-00 PU

(90 < 192)

Buckling check:

Stiffener force, Fq = V - Vs where, V Vs = Total shear force = Vcr of the web. = 50.4 N/mm2

Elastic critical stress, qe

Vcr = qcr d t = 50.4 * 2400 * 14 * 10-3 = 1693 kN Shear force at B, VB = 2301 [(2301 1585.5)*(3000/9000)] = 2062.5 kN Stiffener force, Fq = [2062.5 - 1693] = 369.5 kN

Version II

16 - 25

PLATE GIRDERS - II

Structural Steel Design Project

Calculation Sheet

Job No: Sheet 15 of 18 Rev Job Title: PLATE GIRDER Worked Example - 1 Made by Date 15-04-00 SSSR Checked by Date 25-04-00 PU

Buckling resistance of intermediate stiffener at B: Y 20tw 20tw

12 90 X 14 90

Fig.E5 Effective section

20 tw = 20 * 14 = 280 mm Ix = 1 560 *143 12 *143 * 12 *1943 + = 743 * 10 4 mm 4 12 12 12

A = 180 * 12 + 560 * 14 = 10000 mm2

743 *104 rx = 10000

= 27.3

le = 0.7 * 2400 = 1680

le 1680 = = 61.5 rx 27.3

For fy = 250 N/mm2 and = 61.5 From table3 of chapter on axially compressed columns,

c = 182.3 N/mm2

Version II

16 - 26

PLATE GIRDERS - II

Structural Steel Design Project

Calculation Sheet

Job No: Sheet 16 of 18 Rev Job Title: PLATE GIRDER Worked Example - 1 Made by Date 15-04-00 SSSR Checked by Date 25-04-00 PU

Buckling resistance = (182.3/1.15) * 10000 * 10-3= 1585 kN Fq < Buckling resistance. (369.5 < 1585) Hence, intermediate stiffener is adequate

Intermediate stiffener at B - Adopt 2 flats 90 mm X 12 mm Intermediate Stiffener at D (Stiffener subjected to external load):

Try intermediate stiffener 2 flats 90 mm X 12 mm thick

It satisfies the minimum stiffness requirement as in case of stiffener at B. Buckling check:

Fq Fx Pq

F Ms + x + 1 Px M ys V = 1585.5 kN

Fq = V- Vs

Vs = Vcr = qcr d t = 50.4* 2400 * 14 * 10-3 = 1693 kN Fq is negative and so we can take Fq Fx = 0 Ms = 0

Fx = 870 kN

Version II

16 - 27

PLATE GIRDERS - II

Structural Steel Design Project

Calculation Sheet

Job No: Sheet 17 of 18 Rev Job Title: PLATE GIRDER Worked Example - 1 Made by Date 15-04-00 SSSR Date 25-04-00 Checked by PU

Buckling resistance of load carrying stiffener at D: (Calculation is similar to stiffener at B)

Buckling resistance, Px = (182.3/1.15) * 10000 * 10-3= 1585 kN Fx / Px = 870/1585 = 0.55 < 1.0 Hence, stiffener at D is OK against buckling

Stiffener at D - Adopt flats 90 mm X 12 mm thick Web check between stiffeners:

fed ped fed = w1/ t = 79.5/14 = 5.7 N/mm2 when compression flange is restrained against rotation relative to the web

ped

2 = 2.75 + a d

( ) ( )

E 2 d t

2 = 2.75 + 2 3000 2400

200000 2400 14

2

3.79 * 20000 = 27.4 N / mm 2 26406

Since, fed < ped [5.7 < 27.4], the web is OK for all panels.

Version II

16 - 28

PLATE GIRDERS - II

Structural Steel Design Project

Calculation Sheet

8.0 FINAL GIRDER

Job No: Sheet 18 of 18 Rev Job Title: PLATE GIRDER Worked Example - 1 Made by Date 15-04-00 SSSR Checked by Date 25-04-00 PU

(All dimensions are in mm)

A B C D E F

3000

3000

3000

3000

3000

3000

3000

3000

3000

3000

3000

3000

(a) Longitudinal section of plate girder

720 60

14 2400

(b) Flange and web proportions

Fig. E6 Final girder

Version II

16 - 29

You might also like

- Chapter 24 WexDocument7 pagesChapter 24 WexCiprian VarlanNo ratings yet

- Bracing Design To Eurocode 3Document13 pagesBracing Design To Eurocode 3B.A H100% (1)

- Design-of-Steel-Structures Notes PDFDocument48 pagesDesign-of-Steel-Structures Notes PDFSatish Manal100% (2)

- Crack Width Calculation For Rectangular RC BeamDocument1 pageCrack Width Calculation For Rectangular RC BeamRomyMohanNo ratings yet

- Composite BeamDocument7 pagesComposite Beamsaif.mullaNo ratings yet

- Pad Foundation Example TeddsDocument7 pagesPad Foundation Example TeddsWei Hong TehNo ratings yet

- Shear Check To Eurocode 2Document4 pagesShear Check To Eurocode 2smkumar121No ratings yet

- Pier Column Design PDFDocument6 pagesPier Column Design PDFJaycee Bareng PagadorNo ratings yet

- Crack Width CheckDocument2 pagesCrack Width CheckJitendra SinghNo ratings yet

- Design of Unbraced Multi-Storey Steel FramesDocument7 pagesDesign of Unbraced Multi-Storey Steel FramestaosyeNo ratings yet

- Mechanical Columns Buckling FailureDocument19 pagesMechanical Columns Buckling FailurePraful Patil100% (1)

- Example - Pile Cap DesignDocument4 pagesExample - Pile Cap DesignAnonymous xcFcOgMiNo ratings yet

- Ec9 Ex61 Shear No StiffenersDocument3 pagesEc9 Ex61 Shear No StiffenersimotalpNo ratings yet

- Effective Length For Moment FrameDocument5 pagesEffective Length For Moment FramenhulugallaNo ratings yet

- Knee ConnectionsDocument13 pagesKnee ConnectionsNag RajNo ratings yet

- Crack Width Calculation ExampleDocument3 pagesCrack Width Calculation Examplebernie romeroNo ratings yet

- Design of CorbelDocument32 pagesDesign of CorbelSathish Kumar Civil100% (1)

- Ec3 Kolon HesabıDocument5 pagesEc3 Kolon HesabınaimalimliNo ratings yet

- Eaves Connection Design and AnalysisDocument37 pagesEaves Connection Design and AnalysisHui LiuNo ratings yet

- Drop Panel CalculationDocument2 pagesDrop Panel Calculationsandiok86No ratings yet

- Eurocode example ex3.1.4 connection designDocument4 pagesEurocode example ex3.1.4 connection designРостислав Василев100% (2)

- Composite Slab Deck ACI318Document4 pagesComposite Slab Deck ACI318jflttwNo ratings yet

- Structrual Concrete Design To Eurocode 2 University of Sheffield Structural Engineering MastersDocument12 pagesStructrual Concrete Design To Eurocode 2 University of Sheffield Structural Engineering Mastersfatabass100% (3)

- CribDocument1 pageCribskumarsrNo ratings yet

- Cantilever Beam ReportDocument5 pagesCantilever Beam ReportJoseph TuzonNo ratings yet

- Crack Width ConcreteDocument1 pageCrack Width ConcreteRuemu Godwin InikoriNo ratings yet

- Design Provisions of BS 5950 Part 1Document21 pagesDesign Provisions of BS 5950 Part 1ISMAEL SHAIK86% (7)

- Load Combination (STEEL AND TIMBER DESIGN)Document11 pagesLoad Combination (STEEL AND TIMBER DESIGN)Mahmuddin AminNo ratings yet

- CRACKED BEAM-Prestressed Concrete Bridge Girder Structural Analysis ProgramDocument3 pagesCRACKED BEAM-Prestressed Concrete Bridge Girder Structural Analysis ProgramNurLelyHardiantiZendratoNo ratings yet

- Case: Simply Supported Case: Simply Supported Case: Simply Supported Case: Simply SupportedDocument7 pagesCase: Simply Supported Case: Simply Supported Case: Simply Supported Case: Simply SupportedAhmad Badsha QuadriNo ratings yet

- Openwell StaircaseDocument8 pagesOpenwell StaircaseAbdul AzeemNo ratings yet

- Day 10 - Wind AnalysisDocument18 pagesDay 10 - Wind AnalysisMaitrayee AdityaNo ratings yet

- Corbel CalculationDocument1 pageCorbel CalculationQuangKhảiNo ratings yet

- Cellar Box Design: Bending Moment LocationsDocument1 pageCellar Box Design: Bending Moment LocationsSudathipTangwongchaiNo ratings yet

- BoltDocument23 pagesBoltMohamad Syahmi0% (1)

- Lecture of FootingDocument195 pagesLecture of FootingMonirul IslamNo ratings yet

- CRACK WIDTH CHECKDocument9 pagesCRACK WIDTH CHECKSaugat ThapaNo ratings yet

- Plate Girders 2008Document20 pagesPlate Girders 2008Tharmalingam VijayNo ratings yet

- Isolated Footing DesignDocument14 pagesIsolated Footing DesignDhandapany ArunNo ratings yet

- Combined Foundation DesignDocument5 pagesCombined Foundation DesignDaniel KariukiNo ratings yet

- Splice 03Document15 pagesSplice 03LexNo ratings yet

- Design of Concrete Corbel ReinforcementDocument4 pagesDesign of Concrete Corbel ReinforcementAaron O'SullivanNo ratings yet

- EC2 Beam DesignDocument4 pagesEC2 Beam Designikanyu79No ratings yet

- SX019a-Example Column Base Connection Under Axial Compression PDFDocument5 pagesSX019a-Example Column Base Connection Under Axial Compression PDFdvelchev100% (1)

- Column Base Plate Design (Bs5950-1:2000) : Project Job RefDocument4 pagesColumn Base Plate Design (Bs5950-1:2000) : Project Job RefronyNo ratings yet

- Design of Isolated Footing with Moment CalculationsDocument28 pagesDesign of Isolated Footing with Moment CalculationsmeenuNo ratings yet

- RV Design of Column Base PlateDocument2 pagesRV Design of Column Base Plateapi-190618655No ratings yet

- Eurocode 3 - Design of JointsDocument18 pagesEurocode 3 - Design of JointsdineshNo ratings yet

- Wind ASCE 7 05 MBMA B01 A01Document30 pagesWind ASCE 7 05 MBMA B01 A01subramanyaNo ratings yet

- Design of Beam Ledge Reinforcement as per ACI 318M95Document2 pagesDesign of Beam Ledge Reinforcement as per ACI 318M95auatipu100% (1)

- Brick Wall Footing Design-1Document12 pagesBrick Wall Footing Design-1mumarbsc7244No ratings yet

- Trash Rack Design of Compression Member As Per Is 800-2007Document12 pagesTrash Rack Design of Compression Member As Per Is 800-2007D SRINIVASNo ratings yet

- Eurocode2 - RC Design SheetDocument2 pagesEurocode2 - RC Design Sheetumutakin100% (1)

- Footing Type Lf1: Step 1 - Check Soil PressureDocument3 pagesFooting Type Lf1: Step 1 - Check Soil PressureseyfeNo ratings yet

- RC BeamDocument77 pagesRC BeamJvv GudboyNo ratings yet

- Compression Members ProblemsDocument23 pagesCompression Members ProblemsReyNo ratings yet

- Composite SlabDocument7 pagesComposite SlabJohn Paul100% (2)

- Moment Connection - Flush End Plate-19.01.06Document48 pagesMoment Connection - Flush End Plate-19.01.06kalpanaadhi83% (6)

- Purlin Cleat 220908Document24 pagesPurlin Cleat 220908kalpanaadhi100% (2)

- Lecture 2 Beams - Concrete CenterDocument99 pagesLecture 2 Beams - Concrete Centerwanksta67No ratings yet

- 15cea01 Industrial Pollution Prevention and ControlDocument273 pages15cea01 Industrial Pollution Prevention and Controlrameshbabu_1979No ratings yet

- Chow - Open Channel HydraulicsDocument350 pagesChow - Open Channel HydraulicsAnish Prasad91% (11)

- Crack Detection Techniques in Concrete StructuresDocument23 pagesCrack Detection Techniques in Concrete Structuresrameshbabu_1979No ratings yet

- Environmental Science and Disaster ManagementDocument52 pagesEnvironmental Science and Disaster Managementrameshbabu_1979100% (1)

- 23rd June 2018 6th PeriodDocument32 pages23rd June 2018 6th Periodrameshbabu_1979No ratings yet

- Shear Strength of Soils: Mr.C.Rameshbabu M.E., (PH.D.,)Document48 pagesShear Strength of Soils: Mr.C.Rameshbabu M.E., (PH.D.,)rameshbabu_1979No ratings yet

- IV Internal Q BankDocument3 pagesIV Internal Q Bankrameshbabu_1979No ratings yet

- Simplified Equation For Young's Modulus of CNT Reinforced ConcreteDocument10 pagesSimplified Equation For Young's Modulus of CNT Reinforced Concreterameshbabu_1979No ratings yet

- Environmental Science and Disaster ManagementDocument52 pagesEnvironmental Science and Disaster Managementrameshbabu_1979100% (1)

- Continuum MechanicsDocument79 pagesContinuum Mechanicskulbrsingh4975No ratings yet

- Environmental Science and Disaster ManagementDocument52 pagesEnvironmental Science and Disaster Managementrameshbabu_1979100% (1)

- 15cea01 Industrial Pollution Prevention and ControlDocument33 pages15cea01 Industrial Pollution Prevention and Controlrameshbabu_1979No ratings yet

- Soil Classification and Index PropertiesDocument93 pagesSoil Classification and Index Propertiesrameshbabu_1979No ratings yet

- Technical Note On Using CNTs As ReinforcementsDocument7 pagesTechnical Note On Using CNTs As Reinforcementsrameshbabu_1979No ratings yet

- Design of Curved BeamsDocument5 pagesDesign of Curved BeamsNambiyanna Davanagere100% (1)

- Offshore StructuresDocument6 pagesOffshore StructuresToya MeilanyNo ratings yet

- Experimental Evidence of Yield CriteriaDocument4 pagesExperimental Evidence of Yield Criteriarameshbabu_1979No ratings yet

- FRACTURE & FATIGUE - Advanced Fracture Mechanics - O'Dowd (Notes)Document107 pagesFRACTURE & FATIGUE - Advanced Fracture Mechanics - O'Dowd (Notes)manmathk100% (1)

- Att 2699Document189 pagesAtt 2699LukasPodolskiNo ratings yet

- Unit 7Document25 pagesUnit 7rameshbabu_1979No ratings yet

- SOIL MECHANICS NOTESDocument119 pagesSOIL MECHANICS NOTESshalikamanoj100% (2)

- 08 Eurocodes Steel Workshop DUBINA PDFDocument311 pages08 Eurocodes Steel Workshop DUBINA PDFTopaca PaecNo ratings yet

- Comprehensive Overview of Earthquake SeismologyDocument697 pagesComprehensive Overview of Earthquake SeismologyalbertmunozNo ratings yet

- ANSYS Mechanical APDL Basic Analysis GuideDocument364 pagesANSYS Mechanical APDL Basic Analysis GuideRodolfoNo ratings yet

- Earthquake-Risk Reduction Measures.Document8 pagesEarthquake-Risk Reduction Measures.Sohinee TinksNo ratings yet

- Ch11 SlopeDocument20 pagesCh11 SlopehanumabendadiNo ratings yet

- Finite Element Analysis of Different Types of Composite ColumnDocument7 pagesFinite Element Analysis of Different Types of Composite Columnrameshbabu_1979No ratings yet

- Air Pollution Database For Tamil Nadu - 2014Document53 pagesAir Pollution Database For Tamil Nadu - 2014rameshbabu_1979No ratings yet

- U of A ANSYS Tutorials - Contact Elements PDFDocument11 pagesU of A ANSYS Tutorials - Contact Elements PDFrameshbabu_1979No ratings yet

- Garadi Final Structural Drawings 1Document15 pagesGaradi Final Structural Drawings 1Adithya HullathiNo ratings yet

- Steelwork Specification Highlights Key RequirementsDocument30 pagesSteelwork Specification Highlights Key RequirementsShrikant UtekarNo ratings yet

- Raft Foundation WWW - BuildinghowDocument3 pagesRaft Foundation WWW - Buildinghowvarma369vina50% (2)

- Full Download Test Bank For Perspectives On International Relations Power Institutions and Ideas 7th Edition Henry R Nau PDF Full ChapterDocument36 pagesFull Download Test Bank For Perspectives On International Relations Power Institutions and Ideas 7th Edition Henry R Nau PDF Full Chapterfloatsedlitzww63v100% (17)

- 02 Addressing ModesDocument53 pages02 Addressing ModesHayder AliNo ratings yet

- THE ANNIVERSARY ISSUE - VOLUME NO. 3 2021: THE DESIGN SOURCEBOOK'S ART OF SLOW ARCHITECTUREDocument138 pagesTHE ANNIVERSARY ISSUE - VOLUME NO. 3 2021: THE DESIGN SOURCEBOOK'S ART OF SLOW ARCHITECTUREJason GraceNo ratings yet

- MRPN10: Gas Pressure Regulator Inlet Pressure 10 Bar DN 25 and DN 50Document4 pagesMRPN10: Gas Pressure Regulator Inlet Pressure 10 Bar DN 25 and DN 50mike.stavrianakos2717No ratings yet

- 10.2478 - Aup 2020 0014Document6 pages10.2478 - Aup 2020 0014MaeNo ratings yet

- Construction of Poultry Shed: Janpad Panchayat Balrampur Distt.-BalrampurDocument6 pagesConstruction of Poultry Shed: Janpad Panchayat Balrampur Distt.-BalrampurUpendra kumarNo ratings yet

- FOOTING DESIGNDocument16 pagesFOOTING DESIGNAmit Kumar PaulNo ratings yet

- Method Statement For Tunnel ExcavationDocument26 pagesMethod Statement For Tunnel ExcavationAnshul KushwahaNo ratings yet

- List of Drawings Project Contacts: Upper Centennial Commercial Development - Building 1Document58 pagesList of Drawings Project Contacts: Upper Centennial Commercial Development - Building 1trungNo ratings yet

- DIY Paving GuideDocument1 pageDIY Paving GuideBiju_PottayilNo ratings yet

- Cypress 01Document20 pagesCypress 01Anton BudionoNo ratings yet

- Medieval Society and ArchitectureDocument6 pagesMedieval Society and Architectureapi-330119274No ratings yet

- Steel Support SystemsDocument8 pagesSteel Support SystemsTAUQEER RAZANo ratings yet

- SCDF BP Submission ChecklistDocument1 pageSCDF BP Submission Checklistd4rkne5sNo ratings yet

- Ghorahi Material Purchase DetailsDocument9 pagesGhorahi Material Purchase Detailsbooks2horizonNo ratings yet

- F3842 D Canterbury Freestanding Instructions 1Document20 pagesF3842 D Canterbury Freestanding Instructions 1MossNo ratings yet

- Mini ProjectDocument2 pagesMini ProjectNursahrinawati SabrangNo ratings yet

- Library Interior Finish MaterialsDocument25 pagesLibrary Interior Finish Materialseresearch44% (9)

- 07 Cuplock SystemDocument37 pages07 Cuplock SystemAbd BaradanNo ratings yet

- Daikin Manual User BRC1C51 61Document12 pagesDaikin Manual User BRC1C51 61Holik UchiNo ratings yet

- BP 344Document16 pagesBP 344Bea MichaelaNo ratings yet

- Batangas State UniversityDocument2 pagesBatangas State UniversityJanissaries NivercaNo ratings yet

- ZulfalahDocument11 pagesZulfalahAbrar AhmadNo ratings yet

- Capiz State University: Construction of Three Storey Commercial BuildingDocument1 pageCapiz State University: Construction of Three Storey Commercial BuildingDIAMA, JOYCE LYNN MAE B.No ratings yet

- CHC 50 Bed - Second FloorDocument1 pageCHC 50 Bed - Second FloorSHUBHAM SINGHNo ratings yet

- Tender Drawing Land KeyDocument1 pageTender Drawing Land KeyModular Design TeamNo ratings yet

- Kangal Malsat-Bengali Final Script-Aug 30 - 2011Document126 pagesKangal Malsat-Bengali Final Script-Aug 30 - 2011ShaantilalMukherjee100% (2)

- The Voice of God: Experience A Life Changing Relationship with the LordFrom EverandThe Voice of God: Experience A Life Changing Relationship with the LordNo ratings yet

- From Raindrops to an Ocean: An Indian-American Oncologist Discovers Faith's Power From A PatientFrom EverandFrom Raindrops to an Ocean: An Indian-American Oncologist Discovers Faith's Power From A PatientRating: 1 out of 5 stars1/5 (1)