Professional Documents

Culture Documents

Annex WR

Uploaded by

Lê Mỹ LinhCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Annex WR

Uploaded by

Lê Mỹ LinhCopyright:

Available Formats

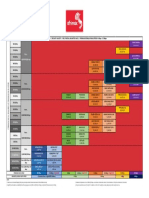

Look out for red parts.

Ah c my ch t k nh/ r nn c j t type ra, b coi th r them v nha >_< y l ci ch m ng ging pack in column ny n m t k hu lm, y l note t ghi: Store + high pressure process (not continuous collection)

1. How should we position the zeolites to increase the effectiveness of it capturing the methane? (Refer to Figure 5 to show our proposed location) 2. As far as we know zeolites are rock-like in shape. Do you suggest breaking it down into powder form to maximize its interactive surface area with methane gas particles? Does it work by the principle of having increasing area leading to increasing sorption? You can break it into smaller grains to increase the surface area. However, zeolite cannot be used in powdered form. The minimum size that it can be is about 3-4mm. For your project, I suggest 4A zeolite to be used, not 5A zeolite. 3. How effective do you evaluate our system to be for the purpose of collecting methane gas and translating them into electricity? 12 metre cube of methane from flatulence and 20 metre cube of methane from manure can be collected daily, so the amount of methane collected from flatulence is smaller than 40%. To consider how effective the system is, you must consider whether the amount of energy produced is more than the amount of energy consumed. If it is not, then the collection is not worth it. Zeolite can capture about 0.2 tons of carbon dioxide per metre cube per day. It cannot be used to concentrate methane without energy. You will need to pass the entire feed of gas through zeolite in high pressure so that zeolite will trap the smaller gas molecules such as carbon dioxide and nitrogen and let methane particles pass through. You need to use pressure swing, you can google on that. Basically, the feed will go from higher pressure region to lower pressure one: from high pressure to atmospheric pressure (atm) or from atm to vacuum environment. Here is where the energy is mostly consumed a lot on the vacuum pump or the gas compressor, depend on which one you use. You can also look for more information about natural gas upgrading. In order to make this system efficient, the concentration of methane must be increased to about 95% from around 20% in the cow ranch, which is very expensive as high energy consumption is needed to extract the gases from zeolite to reuse it. You may consider other methods that require less energy consumption, carbon molecular sieve, for example. You may also consider improving the feeding and removal system and the gas emission of cows.

4. How can we contain the zeolite such that we can prevent it from leaking while allowing the air to pass through it? **So far we have thought of using filter paper or the tea bag packet paper material, ie. we will lay a skeleton for the zeolite first (using stainless steel net/porous metal/wood surface), then a layer of the above-mentioned paper material to wrap up zeolite solids/powder inside. It should be packed in industrial column in parallel units with proper inlet, outlet and valve to regulate

pressure at different times. (diagram)

5. We found that the lifespan of zeolite is 2 months but this is another kind of zeolite, not the methane adsorbing zeolite. Is this information on the lifespan of zeolite accurate? Is there a need to replace them for maintenance? (Ah I just found that lifespan for the ammonia absorbing zeolite is 2 months) Zeolite can be reused by depressurize it. It can be replaced once every two years.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Receipt Ifm July PDFDocument1 pageReceipt Ifm July PDFLê Mỹ LinhNo ratings yet

- French-English Cognate PatternsDocument2 pagesFrench-English Cognate PatternsLê Mỹ LinhNo ratings yet

- Problem and Solution GuidelinesDocument5 pagesProblem and Solution GuidelinesLê Mỹ LinhNo ratings yet

- 14-Day Booty ChallengeDocument1 page14-Day Booty ChallengeLê Mỹ Linh100% (1)

- "I Aced That Test!" "How Do You Always Do So Well in Classes?"Document8 pages"I Aced That Test!" "How Do You Always Do So Well in Classes?"Lê Mỹ LinhNo ratings yet

- Howto Talk With Your RoommateDocument9 pagesHowto Talk With Your RoommateLê Mỹ LinhNo ratings yet

- Demand and Supply Presentation (Coffee Market)Document15 pagesDemand and Supply Presentation (Coffee Market)Lê Mỹ Linh100% (2)

- Straws) To The End of This Wall To Exchange For The Healing Sticks. However, If You Touch These Sticks byDocument2 pagesStraws) To The End of This Wall To Exchange For The Healing Sticks. However, If You Touch These Sticks byLê Mỹ LinhNo ratings yet

- Anothr System Definition FacilityDocument90 pagesAnothr System Definition FacilityllllllluisNo ratings yet

- ChE 132 - Oct 17Document49 pagesChE 132 - Oct 17datUPstudentdoe0% (2)

- Family LetterDocument2 pagesFamily Letterapi-404033609No ratings yet

- Piston and Connecting Rod Assembly TopicsDocument1 pagePiston and Connecting Rod Assembly TopicsgandhiramNo ratings yet

- Oyo Busines ModelDocument1 pageOyo Busines ModelVikash KumarNo ratings yet

- Daf RequestDocument1,692 pagesDaf Requestbrs00nNo ratings yet

- Ansi z245 2 1997Document31 pagesAnsi z245 2 1997camohunter71No ratings yet

- Sunil Bhatia ResumeDocument5 pagesSunil Bhatia Resumepravin gamareNo ratings yet

- BRF90Document10 pagesBRF90Lukas Van VuurenNo ratings yet

- Afrimax Pricing Table Feb23 Rel BDocument1 pageAfrimax Pricing Table Feb23 Rel BPhadia ShavaNo ratings yet

- Issues in Timing: Digital Integrated Circuits © Prentice Hall 1995 TimingDocument14 pagesIssues in Timing: Digital Integrated Circuits © Prentice Hall 1995 TimingAbhishek BhardwajNo ratings yet

- Revit LookupDocument6 pagesRevit Lookupjuand_121No ratings yet

- Electrophoretic Display Technology The Beginnings, The Improvements, and A Future in Flexible ElectronicsDocument15 pagesElectrophoretic Display Technology The Beginnings, The Improvements, and A Future in Flexible Electronicsslysoft.20009951No ratings yet

- Sony DCR Sr47Document101 pagesSony DCR Sr47Mitesh ChauhanNo ratings yet

- Prospects of Bulk Power EHV and UHV Transmission (PDFDrive)Document20 pagesProspects of Bulk Power EHV and UHV Transmission (PDFDrive)Prashant TrivediNo ratings yet

- SAP LandscapeDocument4 pagesSAP LandscapeSiddharth PriyabrataNo ratings yet

- 1St Flr. Reflected Ceiling Plan 2Nd Flr. Reflected Ceiling PlanDocument1 page1St Flr. Reflected Ceiling Plan 2Nd Flr. Reflected Ceiling PlanMac KYNo ratings yet

- Report.... 555ic and Stepper MotorDocument73 pagesReport.... 555ic and Stepper MotorJenielyn IparbaNo ratings yet

- Soichiro HondaDocument5 pagesSoichiro HondaVeronika YsNo ratings yet

- EPSON WF-6090, WF-6530, WF-6590 Series Service Manual Page 121-140Document20 pagesEPSON WF-6090, WF-6530, WF-6590 Series Service Manual Page 121-140Ion IonutNo ratings yet

- Hfe Panasonic Sa-Akx50 PH PN Service enDocument132 pagesHfe Panasonic Sa-Akx50 PH PN Service enJohntec nuñezNo ratings yet

- J Proc CTRL Vol 19 2009 Q Wang K Astrom - Guaranteed Dominant Pole PlacementDocument4 pagesJ Proc CTRL Vol 19 2009 Q Wang K Astrom - Guaranteed Dominant Pole PlacementmtichyscribdNo ratings yet

- True 63Document2 pagesTrue 63stefanygomezNo ratings yet

- Oracle IRecruitment - By: Hamdy MohamedDocument49 pagesOracle IRecruitment - By: Hamdy Mohamedhamdy2001100% (1)

- 02whole PDFDocument313 pages02whole PDFAme Ra100% (1)

- NHPC ReportDocument53 pagesNHPC ReportVishal SinghNo ratings yet

- Sts Lesson 6Document13 pagesSts Lesson 6Ivy Joy BelzaNo ratings yet

- Volvo Ec35D: Parts CatalogDocument461 pagesVolvo Ec35D: Parts Cataloggiselle100% (1)

- Rahul BhartiDocument3 pagesRahul BhartirahuldearestNo ratings yet