Professional Documents

Culture Documents

Single Crystal Sapphire: 006/002/0710 Printed in Japan 006997

Uploaded by

Edward PittsOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Single Crystal Sapphire: 006/002/0710 Printed in Japan 006997

Uploaded by

Edward PittsCopyright:

Available Formats

SINGLE CRYSTAL

SAPPHIRE

KYOCERA Corporation

Corporate Fine Ceramics Group

6 Takeda Tobadono-cho, Fushimi-ku, Kyoto 612-8501, Japan

Tel: +81-(0)75-604-3441Fax: +81-(0)75-604-3440

http://www.kyocera.co.jp

<U.S.A>

KYOCERA Industrial Ceramics Corporation

TX 11044 Research Blvd, SuiteA-430 Austin TX 78759

Tel: +1-512-336-1725 Fax: +1-512-336-8189

MA 24 Prime Parkway Natick MA 01760

Tel: +1-508-651-3922 Fax: +1-508-650-0625

IL 25 NW Point Blvd., #660 Elk Grove Village lL 60007

Tel: +1-847-981-9494 Fax: +1-847-981-9495

NC 100 Industrial Prk. Rd. Mountain Home NC 28758

Tel: +1-828-693-0241 Fax: +1-828-692-1340

NJ 220 Davidson Avenue, Suite 104 Somerset, NJ 08873

Tel: +1-732-563-4336 Fax: +1-732-627-9594

CA 8611 Balboa Avenue San Diego, CA 92123

Tel: +1-858-614-2511 Fax: +1-858-715-0871

CA 472 Kato Terrace Freemont, CA 94539

Tel: +1-510-257-0200 Fax: +1-510-257-0125

WA 5713 East Fourth Plain Blvd. Vancouver WA 98661

Tel: +1-360-696-8950 Fax: +1-360-696-9804

<EUROPE>

KYOCERA Fineceramics GmbH

Hammfeldamm 6 41460 Neuss, Germany

Tel: +49-(0)2131-16370 Fax: +49-(0)2131-1637150

KYOCERA Fineceramics Ltd.

Admiral House, Harlington Way, FLEET,Hampshire, GU13 8BB.

Tel: +44-(0)1252-776000 Fax: +44-(0)1252-776010

KYOCERA Fineceramics S.A.S

1, Rue Corbusier, SILIC 326, F-94598 Rungis CEDEX, France

Tel: +33-(0)1-45120220 Fax: +33-(0)1-46860133

<ASIA>

KYOCERA Asia Pacific, Ltd.

Hong Kong

Room 801-802, Tower 1, South Seas Centre, 75 Mody Road, Tsimshatsui East, Kowloon, Hong Kong

Tel: +852-(0)2723-7183 Fax: +852-(0)2724-4501

Singapore

298 Tiong Bahru Road, #13-03/05 Central Plaza, Singapore 168730

Tel: +65-6271-0500 Fax: +65-6271-0600

Taiwan

10FL.,No.66, Nanking West Road, Taipei, Taiwan,

Tel: +886-(0)2-2555-3609 Fax: +886-(0)2-2559-4131/4123

Thailand

159 Serm-MIT Tower, 19th Floor, Sukhumvit 21 Road, Wattana, Bangkok 10110 Thailand.

Tel: +66-(0)2 661-6400 Fax: +66-(0)2 661-6413

<CHINA>

KYOCERA (TianJin) Sales&Trading Corporation

Shanghai Branch FineCeramic Sales Dept

Information Tower 11th Floor, 211 Century Avenue,

Pudong New Area Shanghai P.R China

Post code;200120

Tel: +86-(0)21-5877-5366 Fax: +86-(0)21-6876-4935

<KOREA>

KYOCERA Korea Co., Ltd.

Diplomatic Center Room#406, 1376-1, Seocho-2Dong,

Seocho-Gu, Seoul, 137-072 Korea

Tel: +82-2-3463-3538 Fax: +82-2-3463-3539

C 2007 KYOCERA CORPORATION

006/002/0710

Printed in Japan

006997

<JAPAN : Headquaters>

SINGLE CRYSTAL SAPPHIRE

Single Crystal Sapphire is playing an ever-increasingly important role as a material for, high

reliablility Electronics today due to its excellent mechanical characteristics, chemical stability and

light transmission.

Kyocera mass-produces Single Crystal Sapphire in a vertically integrated manner. From "pulling up"

the raw material with EFG (Edge-Defined Film-Fed Growth) methods to machining, Kyocera

produces and supplies various products with large diameters or specific shape requirements.

Large Size Material

Sizing-up of materials allows for a broader range of applications and uses.

Production of Single Crystal Sapphire in Any Desired Sectional Shape

Since any desired sectional shape can be obtained in the form of ribbons, tubes, rods,

and others, cutting processes can be eliminated, allowing for a reduction in cost.

Control of Crystal Orientation

Any axis and plane can be produced by instituting proper control during crystal growth.

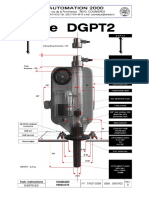

EFG Method

FEATURES OF EFG METHOD

FEATURES OF SINGLE CRYSTAL SAPPHIRE

Unit Cell of Sapphire

High Strength, High Rigidity, High Anti-Abrasion, High Anti-Heat, High Anti-

Corrosion Characteristics, and High Anti-Plasma Characteristics.

Because of these characteristics, Single Crystal Sapphire is widely used for precision

mechanical parts.

Stable Dielectric Constant, Very Low Dielectric Loss, Good Electrical Insulation

Single Crystal Sapphire is used as a material for substrates in super-high frequency

regions. It is also used as an insulation material and microwave window. Single Crystal

Sapphire has become indispensable in the Electronics Industries.

Excellent Light Transmission

Single Crystal Sapphire is used for various kinds of vacuum equipment, windows in

reaction furnace, scanner windows and caps for optical communication due to its

excellent mechanical characteristics and heat resistance.

Good Thermal Conductivity and High Heat Resistance

Excellent thermal conductivity at low temperatures allows Single Crystal Sapphire as a

transparent material to be used in many diverse fields requiring thermal conduction and

heat radiation.

Sapphire Ribbon

Crystal

Die for Crystal

Growth

Crucible

Melt

Supply Slit

Alumina Melt

Heating

Coil

Pull-Up Direction

A plane

C plane

R plane

R plane1102

A plane1120

C plane0001

C Axis

a2

a1

a3

Typical Orientation

1 2

CONTENTS

FEATURES OF EFG METHOD P1

FEATURES OF SINGLE CRYSTAL SAPPHIRE P2

SAPPHIRE MANUFACTURING PROCESS P3

CHARACTERISTICS OF SINGLE CRYSTAL SAPPHIRE P4

SAPPHIRE PRODUCTS P5P6

SINGLE CRYSTAL SAPPHIRE

Single Crystal Sapphire is playing an ever-increasingly important role as a material for, high

reliablility Electronics today due to its excellent mechanical characteristics, chemical stability and

light transmission.

Kyocera mass-produces Single Crystal Sapphire in a vertically integrated manner. From "pulling up"

the raw material with EFG (Edge-Defined Film-Fed Growth) methods to machining, Kyocera

produces and supplies various products with large diameters or specific shape requirements.

Large Size Material

Sizing-up of materials allows for a broader range of applications and uses.

Production of Single Crystal Sapphire in Any Desired Sectional Shape

Since any desired sectional shape can be obtained in the form of ribbons, tubes, rods,

and others, cutting processes can be eliminated, allowing for a reduction in cost.

Control of Crystal Orientation

Any axis and plane can be produced by instituting proper control during crystal growth.

EFG Method

FEATURES OF EFG METHOD

FEATURES OF SINGLE CRYSTAL SAPPHIRE

Unit Cell of Sapphire

High Strength, High Rigidity, High Anti-Abrasion, High Anti-Heat, High Anti-

Corrosion Characteristics, and High Anti-Plasma Characteristics.

Because of these characteristics, Single Crystal Sapphire is widely used for precision

mechanical parts.

Stable Dielectric Constant, Very Low Dielectric Loss, Good Electrical Insulation

Single Crystal Sapphire is used as a material for substrates in super-high frequency

regions. It is also used as an insulation material and microwave window. Single Crystal

Sapphire has become indispensable in the Electronics Industries.

Excellent Light Transmission

Single Crystal Sapphire is used for various kinds of vacuum equipment, windows in

reaction furnace, scanner windows and caps for optical communication due to its

excellent mechanical characteristics and heat resistance.

Good Thermal Conductivity and High Heat Resistance

Excellent thermal conductivity at low temperatures allows Single Crystal Sapphire as a

transparent material to be used in many diverse fields requiring thermal conduction and

heat radiation.

Sapphire Ribbon

Crystal

Die for Crystal

Growth

Crucible

Melt

Supply Slit

Alumina Melt

Heating

Coil

Pull-Up Direction

A plane

C plane

R plane

R plane1102

A plane1120

C plane0001

C Axis

a2

a1

a3

Typical Orientation

1 2

CONTENTS

FEATURES OF EFG METHOD P1

FEATURES OF SINGLE CRYSTAL SAPPHIRE P2

SAPPHIRE MANUFACTURING PROCESS P3

CHARACTERISTICS OF SINGLE CRYSTAL SAPPHIRE P4

SAPPHIRE PRODUCTS P5P6

SAPPHIRE MANUFACTURING PROCESS

Sapphire Manufacturing Process

Polishing

Growth of Raw Material

Grinding

Lapping

Ra1

Shape and Specifications

Shapes other than above are available.

Substrate Rod

Width 200max.

Leugth 300max.

Thickness0.120

R plane 2deg

A plane 2deg

C plane 2deg

Diameter 0.520

Length 1,000max.

C Axis in

Longitudinal

Direction

Tube

Inner Diameter 1.350

Tube Thickness 0.255

Length:1,000mm max.

C Axis in

Longitudinal

Direction

To be

Customized

To be

Customized

Others

As-Grown Materials

Dimensions Crystal Orientation

Dimensions Crystal Orientation Dimensions Crystal Orientation

Dimensions Crystal Orientation

No1.768

Ne1.760

Refer to Fig.5

CHARACTERISTICS OF SINGLE CRYSTAL SAPPHIRE

Characteristics of Kyocera's Single Crystal Sapphire

Standard Dimensional Tolerance

M

e

c

h

a

n

i

c

a

l

C

h

a

r

a

c

t

e

r

i

s

t

i

c

s

Compressive Strength

Young's Modulus

Poisson's Ratio

Hexagonal System a4.763

c13.003

Rhombohedral Single crystal

3.9710

3

kg/m

3

22.5GPaHV1Load9.807N

690MPa

2250MPa

Diameter0.25mm Filament 25

2,940MPa

470GPa

0.180.29

T

h

e

r

m

a

l

C

h

a

r

a

c

t

e

r

i

s

t

i

c

s

Thermal Conductivity

Specific Heat

2,053

40400 C parallel to Caxis 7.710

-6

/

40400 7.010

-6

/

2042W/ mk

0.7510

3

J/ kgK

0.02

2.63.7m880

E

l

e

c

t

r

i

c

a

l

C

h

a

r

a

c

t

d

r

i

s

t

i

c

s

Dielectric Constant

4810

6

V/m

20 10

14

cm

50010

11

cm

C parallel to Caxis 11.51MHz

9.31MHz

110

-4

1MHz

10

-4

10

-4

max.

O

p

t

i

c

a

l

C

h

a

r

a

c

t

e

r

i

s

t

i

c

s

These figures are representative.

Each Crystal Orientation has different characteristics.

Index of Reflection

Optical Transmission

Crystallographic

Structure

Reference Density

Flexural Strength

Vickers Hardness

Tensile Strength

Melting Point

Coefficient of Linear

Thermal Expansion

Emittance

Dielectric Loss Angle

Loss Factor

Dielectric Loss

Tangent

100 100 300 500 700 900 1100 1300 1500 1700

0

2.0

4.0

6.0

8.0

10.0

P

a

r

a

lle

l to

C

A

x

is

P

a

ra

lle

l to

C

A

x

is

P

e

r

p

e

n

d

ic

u

la

r

to

C

A

x

is

P

erp

eu

d

icu

lat to

C

A

xis

C

o

e

f

f

i

c

i

e

n

t

o

f

L

i

n

e

a

r

T

h

e

r

m

a

l

E

x

p

a

n

s

i

o

n

1

0

6

/

K

T

h

e

r

m

a

l

C

o

u

d

u

c

t

i

v

i

t

y

W

/

m

100 300 500 700 900 1100 1300

8.0

9.0

10.0

11.0

12.0

13.0

14.0

15.0

16.0

D

i

e

l

e

c

t

r

i

c

C

o

n

s

t

a

n

t

10

2

10

3

10

4

10

5

10

6

10

7

10

8

10

9

10

10

0

0.001

0.002

0.003

t

a

n

FrequencyHz

100 300 500 700 900 1100 1300 1500 1700

0

10

20

30

40

50

0.15 0.2 0.3 0.4 0.6 1.0 0.8 1.5 0.5 2.0 3.0 4.0 6.0 5.0 0.1

0

20

40

60

80

100

E

x

t

e

r

n

a

l

T

r

a

n

s

m

i

s

s

i

o

n

Wave Length(m)

Fig. 5 Transmission vs. Wave Length

Fig. 4 Dielectric Loss vs. Frequency Fig. 3 Dielectric Constant vs. Temperature

Fig. 1 Thermal Expansion vs. Temperature Fig. 2 Thermal Conductivity vs. Temperature

NOTE: Transmittance range varies depending on thickness of Sapphire Products.

Interfacial Reflection included

Thickness 1mm.

190a

1

Nominal Dimension

Tolerance

Machining accuracy: Tube 1.A.10.A.and standard tube thickness tolerance0.25.

Hole diameter and standard pitch tolerance0.1

1a

0.05

1a4

0.1

4a25

0.2

25a102

0.25

102a190

0.5

Dielectric strength

Volume Resistance

(unit: mm)

Unit mm

@589nm

3 4

Temperature( C) Temperature( C)

Temperature( C)

C perpendicular

to Caxis

C perpendicular

to Caxis

SAPPHIRE MANUFACTURING PROCESS

Sapphire Manufacturing Process

Polishing

Growth of Raw Material

Grinding

Lapping

Ra1

Shape and Specifications

Shapes other than above are available.

Substrate Rod

Width 200max.

Leugth 300max.

Thickness0.120

R plane 2deg

A plane 2deg

C plane 2deg

Diameter 0.520

Length 1,000max.

C Axis in

Longitudinal

Direction

Tube

Inner Diameter 1.350

Tube Thickness 0.255

Length:1,000mm max.

C Axis in

Longitudinal

Direction

To be

Customized

To be

Customized

Others

As-Grown Materials

Dimensions Crystal Orientation

Dimensions Crystal Orientation Dimensions Crystal Orientation

Dimensions Crystal Orientation

No1.768

Ne1.760

Refer to Fig.5

CHARACTERISTICS OF SINGLE CRYSTAL SAPPHIRE

Characteristics of Kyocera's Single Crystal Sapphire

Standard Dimensional Tolerance

M

e

c

h

a

n

i

c

a

l

C

h

a

r

a

c

t

e

r

i

s

t

i

c

s

Compressive Strength

Young's Modulus

Poisson's Ratio

Hexagonal System a4.763

c13.003

Rhombohedral Single crystal

3.9710

3

kg/m

3

22.5GPaHV1Load9.807N

690MPa

2250MPa

Diameter0.25mm Filament 25

2,940MPa

470GPa

0.180.29

T

h

e

r

m

a

l

C

h

a

r

a

c

t

e

r

i

s

t

i

c

s

Thermal Conductivity

Specific Heat

2,053

40400 C parallel to Caxis 7.710

-6

/

40400 7.010

-6

/

2042W/ mk

0.7510

3

J/ kgK

0.02

2.63.7m880

E

l

e

c

t

r

i

c

a

l

C

h

a

r

a

c

t

d

r

i

s

t

i

c

s

Dielectric Constant

4810

6

V/m

20 10

14

cm

50010

11

cm

C parallel to Caxis 11.51MHz

9.31MHz

110

-4

1MHz

10

-4

10

-4

max.

O

p

t

i

c

a

l

C

h

a

r

a

c

t

e

r

i

s

t

i

c

s

These figures are representative.

Each Crystal Orientation has different characteristics.

Index of Reflection

Optical Transmission

Crystallographic

Structure

Reference Density

Flexural Strength

Vickers Hardness

Tensile Strength

Melting Point

Coefficient of Linear

Thermal Expansion

Emittance

Dielectric Loss Angle

Loss Factor

Dielectric Loss

Tangent

100 100 300 500 700 900 1100 1300 1500 1700

0

2.0

4.0

6.0

8.0

10.0

P

a

r

a

lle

l to

C

A

x

is

P

a

ra

lle

l to

C

A

x

is

P

e

r

p

e

n

d

ic

u

la

r

to

C

A

x

is

P

erp

eu

d

icu

lat to

C

A

xis

C

o

e

f

f

i

c

i

e

n

t

o

f

L

i

n

e

a

r

T

h

e

r

m

a

l

E

x

p

a

n

s

i

o

n

1

0

6

/

K

T

h

e

r

m

a

l

C

o

u

d

u

c

t

i

v

i

t

y

W

/

m

100 300 500 700 900 1100 1300

8.0

9.0

10.0

11.0

12.0

13.0

14.0

15.0

16.0

D

i

e

l

e

c

t

r

i

c

C

o

n

s

t

a

n

t

10

2

10

3

10

4

10

5

10

6

10

7

10

8

10

9

10

10

0

0.001

0.002

0.003

t

a

n

FrequencyHz

100 300 500 700 900 1100 1300 1500 1700

0

10

20

30

40

50

0.15 0.2 0.3 0.4 0.6 1.0 0.8 1.5 0.5 2.0 3.0 4.0 6.0 5.0 0.1

0

20

40

60

80

100

E

x

t

e

r

n

a

l

T

r

a

n

s

m

i

s

s

i

o

n

Wave Length(m)

Fig. 5 Transmission vs. Wave Length

Fig. 4 Dielectric Loss vs. Frequency Fig. 3 Dielectric Constant vs. Temperature

Fig. 1 Thermal Expansion vs. Temperature Fig. 2 Thermal Conductivity vs. Temperature

NOTE: Transmittance range varies depending on thickness of Sapphire Products.

Interfacial Reflection included

Thickness 1mm.

190a

1

Nominal Dimension

Tolerance

Machining accuracy: Tube 1.A.10.A.and standard tube thickness tolerance0.25.

Hole diameter and standard pitch tolerance0.1

1a

0.05

1a4

0.1

4a25

0.2

25a102

0.25

102a190

0.5

Dielectric strength

Volume Resistance

(unit: mm)

Unit mm

@589nm

3 4

Temperature( C) Temperature( C)

Temperature( C)

C perpendicular

to Caxis

C perpendicular

to Caxis

SAPPHIRE PRODUCTS

Substrate

Application

(1)High Brightness LED

(2)HB-LED Semiconductor, Piezoelectric Semiconductor, Superconductor,

Thin Film Substrate.

(3)MR Sensor, Precision Resistor

(4)Optical Devices

(5)Thin Film HIC

2"-8" substrate for Optical Devices Selected Transmission Layer for Wave Length Optical Transmission AR Coat External Transmission

Semiconductor Process Equipment Parts

Size O.F. Length

82000.250.7250.05 5560

61500.250.6250.05 4550

51250.250.6250.05 4045

41000.250.53 0.05 3035

376.20.250.43 0.05 1925

250.80.250.33 0.05 1319

Optical Products for LCD Projectors

Characteristic values are subjected to change due to each specs or conditions.

Optical Products Others

Standard Dimension and Tolerance Application Examples

Single Crystal Sapphire is widely used substrate material for

blue, green, ultraviolet and white LEDs. It has excellent

features as a base substrate for GaN deposition and great

mass-productivity. In addition, it can meet future larger-size

demand.

Application

(1)Carrier Plate

(2)Microwave Entrance Tube

(3)Dummy Water

(4)Handling Arm

(5)Vacuum Chuck

(6)Window

It is used as various Semiconductor

Process Equipment due to its high

anti-plasma and high anti-heat

characteristics.

Single Crystal Sapphire is used as a base substrate in thin film

deposition because of its lattice alignment match with a variety

of semiconductor materials combined with excellent thermal

and chemical stability.

Application

1Sapphire Plate

Polarizing Film Attached

Holder Assembled

Dichroic Filter

2LCD Projector

Dust Control Plate

Sapphire material realizes high brightness and high picture

quality for LCD projectors due to its high thermal

conductivity and optical properties.

Coating such as Dichroic Filter, to prevent reflection

features is available.

Standard sizes to fit in various LCD panels are available.

400 450 500 550 600 650 700 750 800

Wave length(nm)

0

20

40

60

80

100

Transmission(%)

Red

Green

Blue

400 425 450 475 500 525 550 575 600 625 650 675 700

Wave length(nm)

80

85

90

95

100

Transmission(%)

Non coating

Both-sides

AR coating

One-side

AR coating

(475nm Target

Multi

coating

Specifications other than above are available.

Available sizes are dependent on a crystal orientation.

Sizes and tolerances other than the above table are

also available under customer requirements. Please

contact or send your requirements to Kyocera.

Application

(1)POS Scanner Window (SOG)

(2)Window

(3)Cap for Optical Communication

(4)Infrared Measuring Device Window

(5)Coin Sensor

(6)Lamp External Tube

High Pressure Sodium, Xenon, Ultra

Pressure mercury

Metallic Halide

(7)Light Receiving Window Accelerating

Tube

Application

(1)Fiber Bar Guide

(2)Insulating Plate and Rod

(3)Single Crystal Material Sheel Holder

(4)Biomaterial (BIOCERAM

R

)

(5)Watch Window

(6)NMR Protection Tube

(7)Thermocouple Protection Tube

(8)HDC Resonator Rod

JP Patent No. 3091183, No.3443549

U.S. Patent No. 6577375, No.6642989

1

3 4

2

5 6

SAPPHIRE PRODUCTS

Substrate

Application

(1)High Brightness LED

(2)HB-LED Semiconductor, Piezoelectric Semiconductor, Superconductor,

Thin Film Substrate.

(3)MR Sensor, Precision Resistor

(4)Optical Devices

(5)Thin Film HIC

2"-8" substrate for Optical Devices Selected Transmission Layer for Wave Length Optical Transmission AR Coat External Transmission

Semiconductor Process Equipment Parts

Size O.F. Length

82000.250.7250.05 5560

61500.250.6250.05 4550

51250.250.6250.05 4045

41000.250.53 0.05 3035

376.20.250.43 0.05 1925

250.80.250.33 0.05 1319

Optical Products for LCD Projectors

Characteristic values are subjected to change due to each specs or conditions.

Optical Products Others

Standard Dimension and Tolerance Application Examples

Single Crystal Sapphire is widely used substrate material for

blue, green, ultraviolet and white LEDs. It has excellent

features as a base substrate for GaN deposition and great

mass-productivity. In addition, it can meet future larger-size

demand.

Application

(1)Carrier Plate

(2)Microwave Entrance Tube

(3)Dummy Water

(4)Handling Arm

(5)Vacuum Chuck

(6)Window

It is used as various Semiconductor

Process Equipment due to its high

anti-plasma and high anti-heat

characteristics.

Single Crystal Sapphire is used as a base substrate in thin film

deposition because of its lattice alignment match with a variety

of semiconductor materials combined with excellent thermal

and chemical stability.

Application

1Sapphire Plate

Polarizing Film Attached

Holder Assembled

Dichroic Filter

2LCD Projector

Dust Control Plate

Sapphire material realizes high brightness and high picture

quality for LCD projectors due to its high thermal

conductivity and optical properties.

Coating such as Dichroic Filter, to prevent reflection

features is available.

Standard sizes to fit in various LCD panels are available.

400 450 500 550 600 650 700 750 800

Wave length(nm)

0

20

40

60

80

100

Transmission(%)

Red

Green

Blue

400 425 450 475 500 525 550 575 600 625 650 675 700

Wave length(nm)

80

85

90

95

100

Transmission(%)

Non coating

Both-sides

AR coating

One-side

AR coating

(475nm Target

Multi

coating

Specifications other than above are available.

Available sizes are dependent on a crystal orientation.

Sizes and tolerances other than the above table are

also available under customer requirements. Please

contact or send your requirements to Kyocera.

Application

(1)POS Scanner Window (SOG)

(2)Window

(3)Cap for Optical Communication

(4)Infrared Measuring Device Window

(5)Coin Sensor

(6)Lamp External Tube

High Pressure Sodium, Xenon, Ultra

Pressure mercury

Metallic Halide

(7)Light Receiving Window Accelerating

Tube

Application

(1)Fiber Bar Guide

(2)Insulating Plate and Rod

(3)Single Crystal Material Sheel Holder

(4)Biomaterial (BIOCERAM

R

)

(5)Watch Window

(6)NMR Protection Tube

(7)Thermocouple Protection Tube

(8)HDC Resonator Rod

JP Patent No. 3091183, No.3443549

U.S. Patent No. 6577375, No.6642989

1

3 4

2

5 6

SINGLE CRYSTAL

SAPPHIRE

SINGLE CRYSTAL

SAPPHIRE

KYOCERA Corporation

Corporate Fine Ceramics Group

6 Takeda Tobadono-cho, Fushimi-ku, Kyoto 612-8501, Japan

Tel: +81-(0)75-604-3441Fax: +81-(0)75-604-3438

http://www.kyocera.co.jp

<U.S.A>

KYOCERA Industrial Ceramics Corporation

TX 11044 Research Blvd., SuiteA-430, Austin, TX 78759

Tel: +1-512-336-1725 Fax: +1-512-336-8189

MA 24 Prime Parkway Natick MA 01760

Tel: +1-508-651-3922 Fax: +1-508-650-0625

IL 25 NW Point Blvd., #660 Elk Grove Village lL 60007

Tel: +1-847-981-9494 Fax: +1-847-981-9495

NC 100 Industrial Park Rd, Hendersonville, NC 28792

Tel: +1-828-693-8244 Fax: +1-828-692-1340

NJ 220 Davidson Avenue, Suite 104, Somerset, NJ 08873

Tel: +1-732-563-4336 Fax: +1-732-627-9594

CA 8611 Balboa Avenue, San Diego, CA 92123

Tel: +1-858-614-2520 Fax: +1-858-715-0871

CA 472 Kato Terrace, Fremont, CA 94539

Tel: +1-510-257-0200 Fax: +1-510-257-0125

WA 5713 East Fourth Plain Blvd., Vancouver WA 98661

Tel: +1-360-696-8950 Fax: +1-360-696-9804

<EUROPE>

KYOCERA Fineceramics GmbH

Hammfelddamm 6 41460 Neuss, Germany

Tel: +49-(0)2131-16370 Fax: +49-(0)2131-1637150

KYOCERA Fineceramics Ltd.

Prospect House Archipelago Lyon Way Frimley Surrey GU16 7ER U.K.

Tel: +44-(0)1276-693450 Fax: +44-(0)1276-693460

KYOCERA Fineceramics S.A.S.

Parc Tertiaire Silic 21 Rue De Villeneuve

BP 90439 94583 Rungis Cedex, France

Tel: +33-(0)1-41737330 Fax: +33-(0)1-41737359

<ASIA>

KYOCERA Asia Pacic, Ltd.

Hong Kong

Room 801-802, Tower 1, South Seas Centre, 75 Mody Road,

Tsimshatsui East, Kowloon, Hong Kong

Tel: +852-(0)2723-7183 Fax: +852-(0)2724-4501

Singapore

298 Tiong Bahru Road, #13-03/05 Central Plaza, Singapore 168730

Tel: +65-6271-0500 Fax: +65-6271-0600

Taiwan

10FL.,No.66, Nanking West Road, Taipei, Taiwan,

Tel: +886-(0)2-2555-3609 Fax: +886-(0)2-2559-4131/4123

Thailand

159 Serm-MIT Tower, 19th Floor, Sukhumvit 21 Road, Wattana,

Bangkok 10110 Thailand.

Tel: +66-(0)2 661-6400 Fax: +66-(0)2 661-6413

KYOCERA Asia Pacic India Pvt.Ltd.

India

PLOT NO.51, Phase-I, Udyog Vihar Gurgaon 122016 Haryana, India

Tel: +91-124-4025000 Fax: +91-124-4025001

KYOCERA Asia Pacic Pte. Ltd.

Manila Branch

11B Kingston Tower, Block 2 Lot 1 Acacia Avenue, Madrigal Business Park Alabang,

Muninlupa City 1780, Phillipines

Tel: +63(2)771-0618 Fax: +63(2)775-0532

KYOCERA (Malaysia) Sdn.Bhd.

Malaysia

Lot 4A, Lower Level 3 Hotel Equatrial, Penang No.1,

Jalan Bukit Jambul 11900 Penang, Malaysia

Tel:+60(4)641-4190 Fax: +60(4)641-4209

<CHINA>

KYOCERA (China) Sales&Trading Corporation

Shanghai Branch FineCeramic Sales Dept

Unit 601 oor of Ocean Towers, No.550 Yan an East Road, Huangpu

District, Shanghai, 200001 P.R. China

Tel: +86-(0)21-5877-5366 Fax: +86-(0)21-5888-5082

KYOCERA (China) Sales&Trading Corporation

Shenzen Ofce Fine Ceramic Sales Dept

Room 1809, Hailrun Complex, No.6021 Shennan Blvd.,

Shenzhen, 518040 P.R.China

Tel: +86-(0)755-82873625 Fax: +86-(0)755-82873640

<KOREA>

KYOCERA Korea Co., Ltd.

Diplomatic Center Room No. 406, 1376-1, Seocho-2Dong,

Seocho-Gu, Seoul, 137-072, Korea

Tel: +82-2-3463-3538 Fax: +82-2-3463-3539

006/008/1207

July,2012

Printed in Japan

004737

<

JAPAN : Headquaters

>

The contents of this catalog are subject to change without prior notice for further improvement.

Application and the using conditions are required to be consulted on when to consider purchase.

C 2012 KYOCERA CORPORATION

You might also like

- High-Temperature Brazing in Controlled Atmospheres: The Pergamon Materials Engineering Practice SeriesFrom EverandHigh-Temperature Brazing in Controlled Atmospheres: The Pergamon Materials Engineering Practice SeriesNo ratings yet

- TechnicalDocument7 pagesTechnicalDaniel RomanNo ratings yet

- ALON (TM) - Optical-Ceramic InglêsDocument12 pagesALON (TM) - Optical-Ceramic InglêsmasimalNo ratings yet

- Electroplating Processes and CoatingsDocument5 pagesElectroplating Processes and CoatingsSinar Cemaramas AbadiNo ratings yet

- Enhanced P L A P: Olyimide Aminate ND RepregDocument4 pagesEnhanced P L A P: Olyimide Aminate ND Repregoutra_pessoaNo ratings yet

- Machinable Materials High TDocument44 pagesMachinable Materials High TtonyjajaNo ratings yet

- Ceramic CompositesDocument29 pagesCeramic CompositesAbhey DograNo ratings yet

- Dkme Profile (2010)Document128 pagesDkme Profile (2010)densandsNo ratings yet

- 9Cr - 1mo Modified With V, NB, and N.: OdificationDocument1 page9Cr - 1mo Modified With V, NB, and N.: OdificationAshok RajNo ratings yet

- GenuineDocument65 pagesGenuineShad OwzNo ratings yet

- Aluminum Oxynitride (Aka Transparent Aluminum) : Reported By: Lulab, Daisy Jane B. Reported By: Lulab, Daisy Jane BDocument20 pagesAluminum Oxynitride (Aka Transparent Aluminum) : Reported By: Lulab, Daisy Jane B. Reported By: Lulab, Daisy Jane BJet Espejon JavierNo ratings yet

- Adhesive Engineering Selection GuideDocument10 pagesAdhesive Engineering Selection GuideAnonymous PWzkeB100% (1)

- 3M Scotch 50 51 Data SheetDocument4 pages3M Scotch 50 51 Data SheetPedro Francisco Hernandez MendozaNo ratings yet

- Sun Mirox™ Flat Technical Sheet Low Resolution - AGC - SunMiroxFlat-LRDocument2 pagesSun Mirox™ Flat Technical Sheet Low Resolution - AGC - SunMiroxFlat-LRcrikalaoNo ratings yet

- Piezoelectric BrochureDocument22 pagesPiezoelectric BrochureYi LiuNo ratings yet

- Complete Guide to Electroplating, Phosphating, Powder Coating and Metal FinishingDocument10 pagesComplete Guide to Electroplating, Phosphating, Powder Coating and Metal Finishingmiguelin9169No ratings yet

- Complete Guide to Electroplating, Phosphating, Powder Coating and Metal FinishingDocument10 pagesComplete Guide to Electroplating, Phosphating, Powder Coating and Metal Finishingmiguelin9169No ratings yet

- Niuelec FullDocument65 pagesNiuelec FullAnonymous XS9jAhY1pENo ratings yet

- TDS Loctite 3355 PDFDocument3 pagesTDS Loctite 3355 PDFffincher4203No ratings yet

- Capacitor Tantalio SMT 1206KEM T2005 T491Document24 pagesCapacitor Tantalio SMT 1206KEM T2005 T491Jeziel Vazquez NavaNo ratings yet

- kc200gt PDFDocument2 pageskc200gt PDFYuvarekha SenthilkumarNo ratings yet

- PCB BookletDocument16 pagesPCB BookletsoybonNo ratings yet

- ThermalRock S Slab Product Data SheetDocument2 pagesThermalRock S Slab Product Data SheetPhan LongNo ratings yet

- 油式非晶質變壓器 英 PreviewDocument16 pages油式非晶質變壓器 英 PreviewisaacwabbiNo ratings yet

- All-Ceramic SystemsDocument20 pagesAll-Ceramic SystemssantaNo ratings yet

- Smic Snr825 eDocument3 pagesSmic Snr825 eJonas Ricafrente MojicaNo ratings yet

- RO4500 Antenna Grade Laminates For High Volume ApplicationsDocument4 pagesRO4500 Antenna Grade Laminates For High Volume ApplicationsMeenakshi Sundaram KaruppiahNo ratings yet

- FirctionDocument1 pageFirctionkahutzed666No ratings yet

- A New Die Material For Longer Service LifeDocument12 pagesA New Die Material For Longer Service LifeLuis SantosNo ratings yet

- Lanka Alluminium - Profile Catlogue - CD PDFDocument152 pagesLanka Alluminium - Profile Catlogue - CD PDFfixfixitNo ratings yet

- All About EPOXYDocument13 pagesAll About EPOXYEllen Kay CacatianNo ratings yet

- Ceramics IntroductionDocument35 pagesCeramics IntroductionSaptarshi SenguptaNo ratings yet

- Coating Thickness MeasurementDocument15 pagesCoating Thickness MeasurementAnonymous w6v7JWfr5100% (1)

- Payton Planar Full CatalogDocument56 pagesPayton Planar Full CatalogpaytonplanarNo ratings yet

- Isopol HR 140 (Electropolishing Process)Document4 pagesIsopol HR 140 (Electropolishing Process)Sinar Cemaramas AbadiNo ratings yet

- RT Duroid 6006 6010 Laminate Data SheetDocument2 pagesRT Duroid 6006 6010 Laminate Data SheetSaravanakumar SermarajaNo ratings yet

- Cerablanket Ac2 EnglishDocument2 pagesCerablanket Ac2 Englishshakti prasad nandaNo ratings yet

- ST Series Soft Termination MLCCsDocument10 pagesST Series Soft Termination MLCCsppanagos5664No ratings yet

- MG DUR 7 electrode for repairing heat treatable steelsDocument1 pageMG DUR 7 electrode for repairing heat treatable steelsEdy SuprayitnoNo ratings yet

- Electroplating Apparatus for Cyanide-Free Silver CoatingDocument29 pagesElectroplating Apparatus for Cyanide-Free Silver Coatingivanjose09No ratings yet

- Silver Catalyst FactsDocument4 pagesSilver Catalyst FactsderimanaNo ratings yet

- Recent Advances in Dental CeramicsDocument48 pagesRecent Advances in Dental CeramicsRugma Sundaresan100% (5)

- Zeron 100 Data SheetDocument2 pagesZeron 100 Data SheetMorgan PalmaNo ratings yet

- 9 - Ceramics Manufacturing, Properties and ApplicationsDocument39 pages9 - Ceramics Manufacturing, Properties and ApplicationsPradeep krNo ratings yet

- Key Aluminum Nitride PropertiesDocument10 pagesKey Aluminum Nitride PropertiesMuhammad TanweerNo ratings yet

- Titanium Nitride (Tin) : Physical Vapour Deposition (PVD) Process. The Coating Has High Hardness and LowDocument19 pagesTitanium Nitride (Tin) : Physical Vapour Deposition (PVD) Process. The Coating Has High Hardness and LowhadeNo ratings yet

- Barniz DolpsDocument3 pagesBarniz DolpsCordero FranciscoNo ratings yet

- The Definitive O Ring Design GuideDocument31 pagesThe Definitive O Ring Design GuideChezNo ratings yet

- HR 48 (Trivalent Temper Resistant Chromate Passivation)Document4 pagesHR 48 (Trivalent Temper Resistant Chromate Passivation)Sinar Cemaramas AbadiNo ratings yet

- Olyimide Aminate and Repreg: FeaturesDocument4 pagesOlyimide Aminate and Repreg: FeaturesAndy ValleeNo ratings yet

- Loctite 222MS™: Technical Data SheetDocument4 pagesLoctite 222MS™: Technical Data SheetbabshuagNo ratings yet

- Content: P P C 3.1 T EDocument43 pagesContent: P P C 3.1 T EVishal ChhabraNo ratings yet

- Data Sheet: Description Prime Features: Typical ApplicationsDocument1 pageData Sheet: Description Prime Features: Typical ApplicationsSkillet48No ratings yet

- Seminar Report On Annealing and Pickling Multi Metals LTD, KotaDocument41 pagesSeminar Report On Annealing and Pickling Multi Metals LTD, Kotavishesh_vijayNo ratings yet

- Mini TOP Views LEDsDocument11 pagesMini TOP Views LEDsRicky CoxNo ratings yet

- Profile Catalogue - 2019Document174 pagesProfile Catalogue - 2019construction udlNo ratings yet

- Cable Cleat Catalogue 2014Document28 pagesCable Cleat Catalogue 2014carlosmandopintoNo ratings yet

- Advanced and Refractory Ceramics for Energy Conservation and EfficiencyFrom EverandAdvanced and Refractory Ceramics for Energy Conservation and EfficiencyHua-Tay LinNo ratings yet

- Processing, Properties, and Design of Advanced Ceramics and CompositesFrom EverandProcessing, Properties, and Design of Advanced Ceramics and CompositesGurpreet SinghNo ratings yet

- A Study of The Electrochemical Oxidation and Polymerisation of 1,3 Dihydroxybenzene and 3-Hydroxybenzyl Alcohol in Acidic, Basic and Neutral Aqueous SolutionsDocument11 pagesA Study of The Electrochemical Oxidation and Polymerisation of 1,3 Dihydroxybenzene and 3-Hydroxybenzyl Alcohol in Acidic, Basic and Neutral Aqueous SolutionsEdward PittsNo ratings yet

- 2008 Obc 4120Document5 pages2008 Obc 4120Edward PittsNo ratings yet

- 2009 0628Document9 pages2009 0628Edward PittsNo ratings yet

- Differential CalculusDocument44 pagesDifferential CalculuswkkchamaraNo ratings yet

- EngDocument8 pagesEngEdward PittsNo ratings yet

- Miscibility ChartDocument2 pagesMiscibility ChartEdward PittsNo ratings yet

- Electrochemical Oxidation of Paracetamol Mediated by Nanoparticles Bismuth Oxide Modified Glassy Carbon ElectrodeDocument10 pagesElectrochemical Oxidation of Paracetamol Mediated by Nanoparticles Bismuth Oxide Modified Glassy Carbon ElectrodeEdward PittsNo ratings yet

- 10-4985JP Published MainmanuscriptDocument21 pages10-4985JP Published MainmanuscriptEdward PittsNo ratings yet

- 16 Solhan YahyaDocument5 pages16 Solhan YahyaEdward PittsNo ratings yet

- Chemical Space Travel: Ruud Van Deursen and Jean-Louis ReymondDocument5 pagesChemical Space Travel: Ruud Van Deursen and Jean-Louis ReymondEdward PittsNo ratings yet

- Differential Calculus: 61 Differentiation of ProcessesDocument67 pagesDifferential Calculus: 61 Differentiation of ProcessesEdward PittsNo ratings yet

- 5990 7890en PDFDocument4 pages5990 7890en PDFEdward PittsNo ratings yet

- Polymer Molecular Weight PropertiesDocument14 pagesPolymer Molecular Weight PropertiesJesus AmbrosioNo ratings yet

- SolutionsHW9 MWDocument8 pagesSolutionsHW9 MWJunlene NgNo ratings yet

- Topic 6Document5 pagesTopic 6Edward PittsNo ratings yet

- Differential Calculus: 61 Differentiation of ProcessesDocument67 pagesDifferential Calculus: 61 Differentiation of ProcessesEdward PittsNo ratings yet

- 8 and 15°C.: Stability ProgramsDocument1 page8 and 15°C.: Stability ProgramsEdward PittsNo ratings yet

- Vocabuilder ThesisDocument32 pagesVocabuilder ThesisEdward PittsNo ratings yet

- X 24Document10 pagesX 24Fawad Ali KhanNo ratings yet

- 78 - 32120Document4 pages78 - 32120Edward PittsNo ratings yet

- Introduction To Research and Research MethodsDocument46 pagesIntroduction To Research and Research MethodsStacie Simmons100% (4)

- NitFix Book Chapter9Document27 pagesNitFix Book Chapter9Edward PittsNo ratings yet

- SSRN Id1583304 PDFDocument18 pagesSSRN Id1583304 PDFEdward PittsNo ratings yet

- Chemistry and Biotechnology: A Productive Union Meets New ChallengesDocument3 pagesChemistry and Biotechnology: A Productive Union Meets New ChallengesEdward PittsNo ratings yet

- 170 - 058 - Conservation of Medicinal Plants in BangladeshDocument22 pages170 - 058 - Conservation of Medicinal Plants in BangladeshEdward PittsNo ratings yet

- Stats ch10 PDFDocument14 pagesStats ch10 PDFEdward PittsNo ratings yet

- Hypothesis TestingDocument8 pagesHypothesis TestingPriyanka SinghNo ratings yet

- SpnotesDocument11 pagesSpnotesBfgi MemberNo ratings yet

- 1996-03-A Comparison of Theoretical and Empirical Reflection Coefficients For Typical Exterior Wall Surfaces in A Mobile Radio EnvironmentDocument11 pages1996-03-A Comparison of Theoretical and Empirical Reflection Coefficients For Typical Exterior Wall Surfaces in A Mobile Radio EnvironmentabdelNo ratings yet

- Unit-Ii - MCQDocument6 pagesUnit-Ii - MCQKeerthi VarmanNo ratings yet

- Energy Storage in Capacitors With DielectricsDocument20 pagesEnergy Storage in Capacitors With DielectricsAli KılıçkayaNo ratings yet

- NitrogenDocument45 pagesNitrogen001tabNo ratings yet

- 223Document17 pages223physicsdocs100% (1)

- Samwha Special Capacitor GuideDocument68 pagesSamwha Special Capacitor Guiderayyan2007No ratings yet

- Digital High Voltage Insulation Tester: 5kV / 10kVDocument2 pagesDigital High Voltage Insulation Tester: 5kV / 10kVMOHSIN_IIUINo ratings yet

- Megnetrol-Kotron RF-Sensing ProbeDocument20 pagesMegnetrol-Kotron RF-Sensing ProbeSaeed VuNo ratings yet

- B. Tech (CSE-CyberSecurity) Course StructureDocument74 pagesB. Tech (CSE-CyberSecurity) Course StructurePatlolla manvithaNo ratings yet

- Corona Testing Ensures Power System ReliabilityDocument6 pagesCorona Testing Ensures Power System ReliabilityJegan PrasadNo ratings yet

- Medium Power Film Capacitor AvxDocument70 pagesMedium Power Film Capacitor AvxPeio GilNo ratings yet

- Lelm 501Document60 pagesLelm 501Hriday GargNo ratings yet

- Overview of Uniform Plane Waves and Maxwells EquationDocument48 pagesOverview of Uniform Plane Waves and Maxwells EquationAkshay BharadwajNo ratings yet

- Part EM - Classical ElectrodynamicsDocument415 pagesPart EM - Classical Electrodynamicsapoorva singhNo ratings yet

- Dielectrics: Unit V Dielectric MaterialsDocument20 pagesDielectrics: Unit V Dielectric MaterialsSpyx MeniNo ratings yet

- Microwave Waveguide ComponentsDocument21 pagesMicrowave Waveguide ComponentsSumit KumarNo ratings yet

- Magnetic Work and Adiabatic CoolingDocument17 pagesMagnetic Work and Adiabatic CoolingsNo ratings yet

- Friction Tapes: Standard Test Methods ForDocument6 pagesFriction Tapes: Standard Test Methods ForMaxNo ratings yet

- Dead Tank Vs Live TankDocument5 pagesDead Tank Vs Live TankSharanNo ratings yet

- Proximity SensorDocument24 pagesProximity Sensoralevoltage187No ratings yet

- SFC TransformerDocument7 pagesSFC TransformerMaheswariravidNo ratings yet

- 10 1016@j Jallcom 2016 09 207Document42 pages10 1016@j Jallcom 2016 09 207SoufianeBenhamidaNo ratings yet

- Atlantis To Tesla Kolbrin Connection (PDFDrive)Document125 pagesAtlantis To Tesla Kolbrin Connection (PDFDrive)enricluz100% (1)

- (Engin 1Document444 pages(Engin 1Esmael AdemNo ratings yet

- Questions & Answers On Capacitance and CapacitorsDocument113 pagesQuestions & Answers On Capacitance and Capacitorskibrom atsbha71% (14)

- NWPPA ETF FR3 PresentationDocument64 pagesNWPPA ETF FR3 PresentationTaryan AgusNo ratings yet

- Is 335 1993 Transformer (Insulating Oil)Document19 pagesIs 335 1993 Transformer (Insulating Oil)Shailesh DaswantNo ratings yet

- Multi-B SDN BHD Translite MF Bus Duct Special FeaturesDocument30 pagesMulti-B SDN BHD Translite MF Bus Duct Special FeaturesSourp VartanNo ratings yet

- JNTU Syllabus Books For EEE (R07 Regulation)Document68 pagesJNTU Syllabus Books For EEE (R07 Regulation)Doanh Le CongNo ratings yet