Professional Documents

Culture Documents

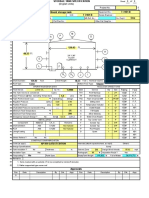

API 650 Tank Design 1

Uploaded by

Umer AleemCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

API 650 Tank Design 1

Uploaded by

Umer AleemCopyright:

Available Formats

Sheet 1 of 1

(English Units)

1

2

3

4

5

6

7

8

9

10

11

12

13 Ft

14

15 Ft

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30 F

31

32

33

34 F

35 F

36

37

38

39

40

41

42

43

44

45

46

47

48 %

49 lb lb

50

51

52

Rev Date Description By Chk. Rev Date Description By Chk.

STORAGE TANK SPECIFICATION

Stress Relieve ? No

Plot Plan No. : P&ID No.

psig

oz/in.2 Set @

Shell Manway

Flush Cleanout MW

Sump

Internals (attach separate sheet, as req'd):

Design Wind Velocity

Design Specifications:

No

API 650 LATEST EDITION

in.

Others:

Paint Spec. Fireproofing ? No

Hot

F. F.

85 Radiograph Inspection Req'd ? Yes

1

4"

4"

OPERATING/DESIGN DATA

oz/in.2

NOZZLES/CONNECTIONS

0.9000 Sp. Gr. : Size Rating Qty

24"x36" 1

R. F.

API

3/4"

3/4"

4"

3/4"

0

8"

150#

12"

0

150#

L. J.

R. F.

R. F.

F. F.

L. J.

API

L. J.

R. F.

F. F.

F. F. Maximum Fluid Temperature

B

A

Shell & Bottom

Roof

Positive Pressure

No

Material

-25

K

Operating Design TH2

G

Service :

Location :

Model :

Unit :

P

M

H

Emergency Vacuum Design ?

METALLURGY

Remarks

Bottom Floor Type:

Manufacturer :

Barrels Feet 101,026

Sloped

Design Engineer : Seth A. Duazo

NMC

46.00

Minimum Fluid Temperature

(Hydro)test Pressure expressed in Psig

Sample Tap

J543

Fluid Stored : LUBE OIL

0.50

Flash Point (Closed Cup) :

Feet

5.5

150#

Mark

TH1

Two

----

Remarks

Project No.

Service

Cone

125.30

Nominal Volume :

Mixer Manway

Vapor Pressure @ Max. Operating Temperature psia

CA, in.

J543

1. Items marked with an asterisk (*) to be completed by Vendor/Fabricator.

2. Rafter supported type cone roof

Appr.

Approvals

0

0.0.3

Fill Nozzle

Stilling Vent

Temperature Indicator

Outlet Nozzle

200

Component

150#

150#

Roof Nozzle

F

F A36 Normalized

Normalized

Water Draw Nozzle

Top Center Vent

0.0625

0.0313

Sample Tap

D

API Lining/Coating 1 Spare

D

mph 120 Thickness :

for:

CONSTRUCTION/FABRICATION

150#

150#

Face

125#

150#

150#

150#

150#

150#

2

1

1

1

2

1

1

0

1

1

11-T-503 Equipment No. :

No. Req'd :

Other Ref. Dwg No. :

USED LUBE OIL

Al Kharj, Saudi Arabia 11T-503

0

Mfr Ref. No. :

24"

24"

8"

Roof Manway

TH 125#

This Tank Service is considered: Cyclic

Roof Type :

Shell Diameter : 125.30 Shell Height : 46.00

Negative Pressure

150#

150#

API

API

A36

0.00

1.00 2.00

Appr.

Tank Insulation ?

Insulation Type:

Code (as appl.):

EmptyTank Weight Full of Water

Seismic Zone 3

Nass

Mechanical

R

e

v

.

N

o

.

24" X 36"

FLUSH

CLEANOUT

F

A

M

P

G

D

E

L

E

H

N

2

N

1

J I

API 650 Storage Tank

6/11/2014

Rev: 0

125.30 38.2 meters

46.00 14.0 meters

Shell Plate Design : FROM ( BOTTOM COURSE) PLATE TO (TOP COURSE) PLATE

0.9

23,200 160 Mpa

1.00

24,900 171 Mpa

0.1180 3.00 mm

For First Course (Bottom) A36 Plate ; 20mm

As per API 5.6.3.2 In US Customary units;

0.569 14.45 mm

0.589 14.95 mm

0.707 17.952 mm

125.30

46.00

1.00

Sd = allowable Stress for Design condition 23,200

E = joint efficiency 1.00

S

t

= allowable stress A36 Hydro Test 24,900

CA = Corrosion Allowance 0.1180

For Second Course A36 Plate 18.000

As per API 5.6.3.2 In US Customary units;

0.632 16.05 mm

0.589 14.95 mm

0.651 16.54 mm

D = Normal tank diameter , in feet 125.30

H = depth of tank , in feet 39.454

1.00

Sd = allowable Stress for Design condition 23,200

E = joint efficiency 1.00

St = allowable stress A36 Hydro Test 24,900

CA = Corrosion Allowance 0.0625

For Third Course A36 Plate 16.000

As per API 5.6.3.2 In US Customary units;

0.540 13.72 mm

0.503 12.78 mm

0.566 14.37 mm

D = Normal tank diameter , in feet 125.30

H = depth of tank , in feet 32.909

1.00

Sd = allowable Stress for Design condition 23,200

E = joint efficiency 1.00

St = allowable stress A36 Hydro Test 24,900

CA = Corrosion Allowance 0.0625

D = Normal tank diameter , in feet

H = depth of tank , in feet

SG = design Specific gravity of liquid

Sd = allowable Stress for Design condition

t

d

= Minimum shell course thickness plus C.A, in inches =

S

t

= allowable stress A36 Hydro Test

D = Normal tank diameter , in feet =

H = depth of tank , in feet =

CA = Corrosion Allowance

t

d

= 2.6(D)(H -1)(SG)/Sd

=

Provided thickness:

E = joint efficiency

SG = design Specific gravity of liquid =

SG = design Specific gravity of liquid =

t

t

= 2.6(D)(H-1)/St =

Provided thickness:

Provided thickness:

t

d

= 2.6(D)(H -1)(SG)/Sd

=

t

t

= 2.6(D)(H-1)/St =

t

d

= Minimum shell course thickness plus C.A, in inches =

t

d

= 2.6(D)(H -1)(SG)/Sd

=

t

t

= 2.6(D)(H-1)/St =

t

d

= Minimum shell course thickness plus C.A, in inches =

SG = design Specific gravity of liquid =

TANK 11-T-503A SHELL PLATE DESIGN CALCULATION by ONE FOOT METHOD

Seth A. Duazo

Nass Mechanical

Page 2 of 5

FileName: 233494728.xls.ms_office

WorkSheet: 11T-503A

API 650 Storage Tank

6/11/2014

Rev: 0

125.30 38.2 meters

46.00 14.0 meters

D = Normal tank diameter , in feet

H = depth of tank , in feet

TANK 11-T-503A SHELL PLATE DESIGN CALCULATION by ONE FOOT METHOD

For Fourth Course A36 Plate 12.000

As per API 5.6.3.2 In US Customary units;

0.488 12.40 mm

0.417 10.60 mm

0.480 12.19 mm

D = Normal tank diameter , in feet 125.30

H = depth of tank , in feet 26.3632

1.00

Sd = allowable Stress for Design condition 21,300

E = joint efficiency 1.00

St = allowable stress A36 Hydro Test 24,900

CA = Corrosion Allowance 0.0625

For Fifth Course A36 Plate 10mm

As per API 5.6.3.2 In US Customary units;

0.388 9.85 mm

0.332 8.43 mm

0.394 10.02 mm

D = Normal tank diameter , in feet 125.30

H = depth of tank , in feet 19.754

1.00

Sd = allowable Stress for Design condition 21,300

E = joint efficiency 1.00

St = allowable stress A36 Hydro Test 24,900

CA = Corrosion Allowance 0.0625

For Sixth Course A36 Plate 8mm

As per API 5.6.3.2 In US Customary units;

0.258 6.56 mm

0.245 6.23 mm

0.308 7.82 mm

D = Normal tank diameter , in feet 125.30

H = depth of tank , in feet 13.194

0.9

Sd = allowable Stress for Design condition 21,300

E = joint efficiency 1.00

St = allowable stress A36 Hydro Test 24,900

CA = Corrosion Allowance 0.0625

For Seventh Course A36 Plate 8mm

As per API 5.6.3.2 In US Customary units;

0.187 4.74 mm

0.160 4.05 mm

0.222 5.64 mm

D = Normal tank diameter , in feet 125.30

H = depth of tank , in feet 6.63

1

Sd = allowable Stress for Design condition 21,300

E = joint efficiency 1.00

St = allowable stress A36 Hydro Test 24,900

CA = Corrosion Allowance 0.0625

SG = design Specific gravity of liquid =

t

t

= 2.6(D)(H-1)/St =

t

d

= Minimum shell course thickness plus C.A, in inches =

t

d

= 2.6(D)(H -1)(SG)/Sd

=

Provided thickness:

Provided thickness:

SG = design Specific gravity of liquid =

Provided thickness:

Provided thickness:

t

d

= 2.6(D)(H -1)(SG)/Sd

=

t

d

= Minimum shell course thickness plus C.A, in inches =

t

d

= 2.6(D)(H -1)(SG)/Sd

=

t

t

= 2.6(D)(H-1)/St =

t

d

= 2.6(D)(H -1)(SG)/Sd

=

t

t

= 2.6(D)(H-1)/St =

t

d

= Minimum shell course thickness plus C.A, in inches =

SG = design Specific gravity of liquid =

t

t

= 2.6(D)(H-1)/St =

t

d

= Minimum shell course thickness plus C.A, in inches =

SG = design Specific gravity of liquid =

Seth A. Duazo

Nass Mechanical

Page 3 of 5

FileName: 233494728.xls.ms_office

WorkSheet: 11T-503A

API 650 Storage Tank

6/11/2014

Rev: 0

125.30 38.2 meters

46.00 14.0 meters

D = Normal tank diameter , in feet

H = depth of tank , in feet

TANK 11-T-503A SHELL PLATE DESIGN CALCULATION by ONE FOOT METHOD

BOTTOM PLATE DESIGN:

As per API 650 11th Ed. 2009 Add. 2 Sect. 5.4.1;

Minimum Nominal Thickness excluding corrosion allowance, Inch 0.25 6.35 mm

Corrosion Allowance for Bottom Plate 0.125 3.18 mm

Required Thickness of Bottom Plate 0.25 6.35 mm

Used bottom plate thickness 0.375 10 mm

Minimum Nominal Width, Inch 70.866 1800.0 mm

Used bottom plate Width,in 78.74 2000.0 mm

ANNULAR BOTTOM PLATE DESIGN:

As per API 650 11th Ed. 2009 Add. 2 Sect. 5.5.2;

Minimum Annular plate Width shall be = 215 t

b 28.62 727 mm

( GH )

0.5

or a Minimum of 23.622 600 mm

Annular Plate width provided; in 29.92 760 mm

Where: tb = Annular plate thickness, mm

H = maximum Design Liquid level, Meter

G = liquid Specific gravity

HENCE, OK.

ROOF PLATE DESIGN: ( Non Frangible roof Tank)

As per API 650 11th Ed. 2009 Add. 2 Sect. 5.10.2.2,

Minimum Nominal Thickness excluding corrosion allowance = 0.1875 5 mm

Corrosion Allowance for Roof Plate, = 0 0 mm

Required Thickness of Roof Plate = 0.1875 5 mm

Used roof plate thickness = 0.1875 5 mm

SHELL STABILITY CHECK;

As per API 650 11th Ed. 2009 Add. 2 Sect. 5.9.7.1

The Maximum height for the unstiffined shell shall be calculated as follows:

H

1

= 600,000*(t)*(((t/D)^3)^0.5)*(120 /V)^2

= , ft 23.82 7.26 Meters

Where;

H1 = Vertical Distance in ft, betwwen the intermediate wind girder and the top angle of the shell or the top wind girder of an open top tank

t = as built thickness, unless otherwise specified of the thinnest shell course (in Inches)

D = Nominal Tank height, Ft

V = Designed wind speed (3 sec gust)mph

Seth A. Duazo

Nass Mechanical

Page 4 of 5

FileName: 233494728.xls.ms_office

WorkSheet: 11T-503A

API 650 Storage Tank

6/11/2014

Rev: 0

125.30 38.2 meters

46.00 14.0 meters

D = Normal tank diameter , in feet

H = depth of tank , in feet

TANK 11-T-503A SHELL PLATE DESIGN CALCULATION by ONE FOOT METHOD

Equivalent stable height of

shell at ' t ' min. HE = sum He

He = W( ' t 'min / ' t 'actual)^2.5

As per API 650 11th Ed. 2009 Add. 2 Sect. V.8.1.4 (b)

Course Width (M) t' min (mm) Wtr (Meter)

1 1.995 20.00 0.202

2 1.995 16.00 0.353

3 1.995 15.00 0.414

4 2.0 12.00 0.726

5 2.0 10.00 1.145

6 2.0 8.00 2.000

7 2.0 8.00 2.000

Minimum Shell Thickness = 8mm

Transformed shell height, W' tr 6.840 Meters

7.26 Meters

H

1

> Wtr, hence intermediate wind girder is not required

Maximum height of unstiffined shell=

Seth A. Duazo

Nass Mechanical

Page 5 of 5

FileName: 233494728.xls.ms_office

WorkSheet: 11T-503A

You might also like

- API 650 Tank Design 1 1Document5 pagesAPI 650 Tank Design 1 1samy7354100% (1)

- Premium TankDocument26 pagesPremium TankAnonymous p0iwBoNo ratings yet

- Diesel Tank TaluksangayDocument70 pagesDiesel Tank TaluksangayBert EngNo ratings yet

- API 650 Tank Design 1Document5 pagesAPI 650 Tank Design 1Fabian Nuñez Diaz100% (1)

- API 650 Storage Tank TCA PreparationDocument86 pagesAPI 650 Storage Tank TCA PreparationBimal DeyNo ratings yet

- Etank Full ReportDocument108 pagesEtank Full ReportFaizal SattuNo ratings yet

- Dead Load Only From The PipeDocument5 pagesDead Load Only From The PipeНемања Караклајић100% (1)

- Safety Valve Reaction Foce Calculation: Isometric: 10Lbg10Br192, Rev. A Project: Kat065 Raslaffan BDocument4 pagesSafety Valve Reaction Foce Calculation: Isometric: 10Lbg10Br192, Rev. A Project: Kat065 Raslaffan BAnonymous Iev5ggSRNo ratings yet

- Fresh HDO Storage TankDocument42 pagesFresh HDO Storage TankHgagselim SelimNo ratings yet

- Api 620 - 2002Document12 pagesApi 620 - 2002ductaiutc100% (1)

- 94-QC20-J-414 - Curb Angle Check On L100X100X15Document92 pages94-QC20-J-414 - Curb Angle Check On L100X100X15Hgagselim SelimNo ratings yet

- API 650 Tank Design 5Document31 pagesAPI 650 Tank Design 5gon972001No ratings yet

- Vdocuments - MX Rectangular Tank CalculationDocument34 pagesVdocuments - MX Rectangular Tank CalculationAtilla TekinNo ratings yet

- 28 Roark Flat PlatesDocument14 pages28 Roark Flat Platesgutmont0% (1)

- Air Eliminator Datasheet PDFDocument2 pagesAir Eliminator Datasheet PDFbecpavanNo ratings yet

- 302 - Nozzle Design Tool Ver E4.01Document2 pages302 - Nozzle Design Tool Ver E4.01Honey TiwariNo ratings yet

- API 650 Water Storage TankDocument6 pagesAPI 650 Water Storage TankJoeNo ratings yet

- Storage Tank Design Calculation - Api 650: Close Floating RoofDocument32 pagesStorage Tank Design Calculation - Api 650: Close Floating RoofhgagNo ratings yet

- API 650 Water Storage Tank - Xls 36Document71 pagesAPI 650 Water Storage Tank - Xls 36rudi 01No ratings yet

- Single Col - Tank-2013Document35 pagesSingle Col - Tank-2013Hgagselim SelimNo ratings yet

- Nozzle Design CalculationDocument1 pageNozzle Design CalculationSachin55860% (1)

- FLB Tank Pump Calculation 7/28/1998 P1: Document No.: Title: Sign Date Made by Rev: Checked by Contract No.: QX0032Document3 pagesFLB Tank Pump Calculation 7/28/1998 P1: Document No.: Title: Sign Date Made by Rev: Checked by Contract No.: QX0032Ekundayo JohnNo ratings yet

- Air SeparatorsDocument2 pagesAir SeparatorsНемања КараклајићNo ratings yet

- API 650 Baseplate DesignDocument3 pagesAPI 650 Baseplate DesignmjlazoNo ratings yet

- Engineering Design Calculation - Dennis Kirk Centrifugal Fan Performance CharacteristicsDocument1 pageEngineering Design Calculation - Dennis Kirk Centrifugal Fan Performance CharacteristicsAnonymous EarAM2100% (1)

- Page No Doc. No. Revision Design Calculation For Set In, Set On Nozzle With and Without Pad and Self Reinforced NozzleDocument25 pagesPage No Doc. No. Revision Design Calculation For Set In, Set On Nozzle With and Without Pad and Self Reinforced Nozzleabdelrahman KhalidNo ratings yet

- Skirt Support Analysis Per en 13445Document13 pagesSkirt Support Analysis Per en 13445karthik1amarNo ratings yet

- Tank Design CalculationDocument20 pagesTank Design CalculationHairil HerliansyahNo ratings yet

- Reference:: Anchor ChairDocument4 pagesReference:: Anchor ChairShaheed HossainNo ratings yet

- Storage Tank Design Calculation - Api 650Document92 pagesStorage Tank Design Calculation - Api 650Abelardo ContrerasNo ratings yet

- MD He Tema Asme v0.1Document31 pagesMD He Tema Asme v0.1Sharon Lambert100% (1)

- Tank DesignDocument2 pagesTank DesignkamleshyadavmoneyNo ratings yet

- Asme Sec. Viii Div-1) : THK - Calc. (Document35 pagesAsme Sec. Viii Div-1) : THK - Calc. (hardik5818No ratings yet

- Sendai: Eversendai Consulting Engineers (P) LTDDocument6 pagesSendai: Eversendai Consulting Engineers (P) LTDfsijestNo ratings yet

- Condensate Line SizingDocument2 pagesCondensate Line SizingAnonymous oVRvsdWzfBNo ratings yet

- Tank DesignDocument89 pagesTank Designpatrickandreas77No ratings yet

- Horizontal Cylindrical Tank Volume and Level CalculatorDocument5 pagesHorizontal Cylindrical Tank Volume and Level CalculatorWaleed EmaraNo ratings yet

- Tank Calc - Api650Document90 pagesTank Calc - Api650kamleshyadavmoney100% (3)

- Memoria ASME-Pressure-Vessel-DesignDocument143 pagesMemoria ASME-Pressure-Vessel-DesignJuan MendozaNo ratings yet

- API 650 Tank Design 1Document5 pagesAPI 650 Tank Design 1Nguyễn Thành Trung100% (1)

- API 650 Tank Design 1foot MethodDocument4 pagesAPI 650 Tank Design 1foot Methodjakjak67% (3)

- Hfo Service Tank - ht003 Data Sheet r1 PDFDocument4 pagesHfo Service Tank - ht003 Data Sheet r1 PDFsocomenin2013No ratings yet

- API 650 Tank Design CalculationsDocument8 pagesAPI 650 Tank Design Calculationsツ ツNo ratings yet

- API 650 Tank Design CalculationDocument9 pagesAPI 650 Tank Design CalculationSunday PaulNo ratings yet

- TangkiDocument8 pagesTangkiCarey Rich67% (3)

- API 650 Tank Design CalculationsDocument8 pagesAPI 650 Tank Design CalculationsMohammed EljammalNo ratings yet

- API 650 Tank Design CalculationDocument8 pagesAPI 650 Tank Design Calculationlecongdinh100% (1)

- API 650 Tank Design CalculationDocument8 pagesAPI 650 Tank Design CalculationNorazlan Shah Mahadi100% (1)

- API 650 Tank Design CalculationDocument8 pagesAPI 650 Tank Design CalculationHoracio RodriguezNo ratings yet

- API 650 Tank Design CalculationDocument8 pagesAPI 650 Tank Design Calculationmail_younes659283% (29)

- SiloDocument21 pagesSilouvarajmecheriNo ratings yet

- FinalDocument12 pagesFinalchompink6900No ratings yet

- Total Middle East New Bitumen Terminal in TlbuDocument25 pagesTotal Middle East New Bitumen Terminal in TlbuAnupam Jana100% (2)

- API 650 Tank Design CalculationsDocument8 pagesAPI 650 Tank Design CalculationsVinoth Rajendra50% (4)

- Steel TankDocument75 pagesSteel Tankace1205No ratings yet

- 26 Pressure VesselDocument21 pages26 Pressure VesseljnmanivannanmechNo ratings yet

- Maximum PressureDocument83 pagesMaximum Pressureanhhung80No ratings yet

- Storage Tanks CalculationsDocument21 pagesStorage Tanks Calculationsjimallen21288% (26)

- Design Calculation TankDocument28 pagesDesign Calculation Tankibiceng100% (4)

- Southern Marine Engineering Desk Reference: Second Edition Volume IFrom EverandSouthern Marine Engineering Desk Reference: Second Edition Volume INo ratings yet

- PCA Rectangular - Tank Design ExampleDocument15 pagesPCA Rectangular - Tank Design ExampleConrad Otieno100% (4)

- Canam Joist CatalogDocument166 pagesCanam Joist Catalogcivil89No ratings yet

- Peso Tuberias y Accesorios SoldablesDocument2 pagesPeso Tuberias y Accesorios SoldablesCésar Jácome CondeNo ratings yet

- Lesson 1, IntroductionDocument1 pageLesson 1, IntroductionDnnys CalderónNo ratings yet

- Sewer CADUser's GuideDocument370 pagesSewer CADUser's GuideJose OrtizNo ratings yet

- Sewer CADUser's GuideDocument370 pagesSewer CADUser's GuideJose OrtizNo ratings yet