Professional Documents

Culture Documents

Viscosity of Saturated Liquid Dimethyl Ether From (227 To 343) K

Uploaded by

saifu2Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Viscosity of Saturated Liquid Dimethyl Ether From (227 To 343) K

Uploaded by

saifu2Copyright:

Available Formats

Viscosity of Saturated Liquid Dimethyl Ether from(227 to 343) K

J iangtao Wu, Zhigang Liu,* Shengshan Bi, and Xianyang Meng

Di vi si on of Thermodynami cs & Heat Transfer, Xi an Ji aotong Uni versi ty, Xi an Shaanxi 710049,

Peopl es Republ i c of Chi na

Measurements of the vi scosi ty of saturated l i qui d di methyl ether are reported over the temperature range

from (227 to 343) K al ong the saturati on l i ne made wi th a cal i brated capi l l ary vi scometer. The resul ts

were correl ated as a functi on of temperature. The standard devi ati on and the maxi mum devi ati on of the

experi mental resul ts from the correl ati on equati on are 0.5% and 1.3%, respecti vel y.

1. Introduction

As a chemi cal raw materi al , di methyl ether pl ays an

i mportant rol e i n the synthesi s of chemi cal s. At the same

ti me, i t i s often used as a propel l ant gas, assi st sol vent,

vesi cant, fuel addi ti ve, of l i quefi ed petrol eum gas substi -

tute. Al so, i t can be used as a refri gerant and vesi cant.

Especi al l y, i n recent research of cl ean al ternati ve fuel s, i t

has been di scovered that di methyl ether and i ts mi xtures

are possi bl e al ternati ves for di esel oi l i n the future.

1

Hence,

the thermophysi cal property data of di methyl ether are

i mportant. I n the desi gn of the feed and ejecti on systems

of combusti on processes, the vi scosi ty data are i ndi spen-

sabl e, but there are few data on the vi scosi ty of di methyl

ether. I n thi s work, the vi scosi ty of di methyl ether was

measured wi th a seal ed gravi tati onal capi l l ary vi scometer

at temperatures between (227 and 343) K al ong the

saturati on l i ne.

2. Experimental Method

Accordi ng to the Hagen-Poi seui l l e pri nci pl e, i f a fl ui d

fl ows through a capi l l ary under a gravi ty head, then,

often accounti ng for the ki neti c-energy correcti on and

the end correcti on, the vi scosi ty of the fl ui d can be

expressed by

where i s the fl ui d dynami c vi scosi ty, V i s the vol ume of

fl ow through the capi l l ary for a gi ven ti me t, m i s the

ki neti c energy factor, L i s the capi l l ary l ength, R i s the

capi l l ary radi us, F

L

i s the saturated l i qui d densi ty of the

sampl e, F

V

i s the saturated vapor densi ty, h i s the hei ght

of fl ui d i n the capi l l ary, g i s the accel erati on of gravi ty,

and n i s the end-correcti on factor. Equati on 1 coul d be

rewri tten as

where

where i s the ki nemati c vi scosi ty. A and B are temperature

i ndependent and constant, whi l e k general l y decreases as

the temperature i ncreases. When the rel ati ve measurement

method i s appl i ed, L, V, R, h, and g are constants for the

speci fi c vi scometer at a si te, and then A and B are

constants, whi ch are al so cal l ed i nstrument constants. I n

thi s work, L and R equal 120 ( 0.1 mm and 0.165 ( 0.01

mm, respecti vel y, and the uni formi ty of the capi l l ary i s

better than 0.05 mm; h equal s L i s assumed i n our

experi ment. The k val ue can be regarded as 1.0, i f the

temperature i s far l ess than the cri ti cal temperature. But

when the temperature i s cl ose to the cri ti cal temper-

ature, the k val ue has to be taken i nto account. I n thi s

work, the temperature range i s l i mi ted and far l ess than

the cri ti cal temperature. Therefore, i f the ti me of l i qui d

fl owi ng through the capi l l ary i s measured, and the val ues

of A and B are known, the ki nemati c vi scosi ty coul d be

obtai ned.

From eq 2, the fol l owi ng equati on can be deri ved:

where

i s a constant for a speci fi c vi scometer;

E

i s i n i nverse

proporti on to the square of t. I t i s proved that the val ue of

E

for the vi scometer used i n thi s research i s l ess than 0.5%,

i f t > 900 s. Thus, i f the term B/ t i s i gnored, the maxi mum

devi ati on wi l l be l ess than 0.5%, when the ti me of l i qui d

fl ow through the capi l l ary i s more than 900 s. And then

* To whom correspondence shoul d be addressed. E-mai l : jtwu@

mai l .xjtu.edu.cn. Fax: 86-29-2668789.

k )

F

L

- F

V

F

L

(3)

A )

ghR

4

8V(L + nR)

(4)

B )

mV

8(L + nR)

(5)

E

)

B/t

kAt

)

mV

2

2

kghR

4

1

t

2

)

t

2

(6)

)

mV

2

2

kghR

4

(7)

)

gh(F

L

- F

V

)R

4

8V(L + nR)

t -

mF

L

V

8(L + nR)t

(1)

v )

F

L

) kAt - B/t (2)

426 J . Chem. Eng. Data 2003, 48, 426-429

10.1021/je0256232 CCC: $25.00 2003 Ameri can Chemi cal Soci ety

Publ i shed on Web 01/29/2003

http://www.paper.edu.cn

eq 2 can be wri tten as

On the basi s of the above di scussi on, pure water and

ethanol were sel ected as reference l i qui ds to cal i brate the

constant A. I n thi s i nstrument, the fl ow ti me of water and

ethanol i s l onger than 900 s at ambi ent temperature. I n

thi s work, wi th eq 8 and the experi mental data, A i s fi tted

by usi ng the l east-squares method.

The ki neti c-energy factor and end-correcti on factor are

rel ated to the Reynol ds number and shape of the end of

the capi l l ary,

2,3

and there are some di fferent ways to obtai n

B.

From the ref 2, i n the range of Reynol ds numbers 46 e

Ree 1466, the val ues of mare 1.08 to 1.16, whi l e the end-

correcti on factor n i s 0.57, and B can be cal cul ated from

because A, L, R, g, h, m, and n are constants for the speci fi c

vi scometer at a si te and then B i s a constant.

From ref 3, i n the range of Reynol ds number 80 e Ree

500, the ki neti c-energy factor mcan be cal cul ated from the

empi ri cal correl ati on

For thi s i nstrument, the Reynol ds number Re can be

approxi mated by

and then B can be cal cul ated as fol l ows:

The val ue of V i s cal cul ated from eq 4.

I n thi s paper, both methods were appl i ed. The resul ts

i ndi cated that the B cal cul ated from eq 9 i s more workabl e

than that from eq 12 for thi s i nstrument, i f the buoyancy

of the vapor i s negl ected and the k val ue i s regarded as

1.0. Hence, eq 9 was used to obtai n the ki nemati c vi scosi ty

of di methyl ether i n thi s work.

3. Experiment Apparatus and Procedures

The apparatus i s shown i n Fi gure 1.

Three val ves, whi ch are shown i n Fi gure 1, are necessary

for the experi ment. Before the experi ment, the l i qui d

sampl e i s i njected i nto the pressure vessel through val ve

A. Duri ng the experi ment, val ve A i s al ways cl osed, and

the sampl e remai ns at i ts vapor pressure. Pri or to each

measurement, the l i qui d must be forced through the bypass

tube to the upper bul bs. When rai si ng the l i qui d, val ve B

i s cl osed; at the same ti me val ve C i s open and connects to

the atmosphere. When the saturati on pressure i n the vessel

i s hi gher than atmospheri c pressure, the l i qui d wi l l be

rai sed natural l y. When the saturati on pressure i n the

vessel i s l ess than atmospheri c pressure, the vacuum pump

must be used to draw the l i qui d i nto the upper vol ume.

Duri ng each measurement, val ve C i s cl osed and val ve B

i s opened, so the vapor i nsi de and outsi de the capi l l ary are

connected. Due to i ts wei ght, the l i qui d wi l l fl ow down. The

detai l s of the i nstrument coul d be found i n ref 4.

The vi scometer was pl aced i n a thermostat bath, for

whi ch temperature can be vari ed from (220 to 500) K, and

the stabi l i ty of the temperature i n the bath i s better than

(4 mKh

-1

. The total uncertai nty of temperature i s l ess

than (5 mK (I TS-90). The detai l s about the thermostat

bath and temperature measurement have been descri bed

i n ref 5. A stopwatch was used to measure the fl ow ti me,

and the accuracy i s 0.01 s.

4. Calibration

Ethanol and water were used to cal i brate the i nstru-

ment; the mass puri ty of ethanol i s 99.7%, and the

el ectri cal resi stance of water i s no l ess than 40 M. The

speci fi cati ons were provi ded by the producer, and no

further puri fi cati ons were carri ed out. Thei r ki nemati c

vi scosi ty and densi ty data were ci ted from refs 6-8. The

cal i brati on resul ts are l i sted i n Tabl e 1. The fl ow ti mes

gi ven i n Tabl e 1 are the average ti mes, and three to fi ve

fl ow ti mes were measured at each temperature. The repeat-

abi l i ty of fl ow ti me i s better than 1.0% () (measured ti me

- average ti me)/average ti me) and usual l y i s about 0.5%.

Wi th the method di scussed above, A was determi ned (A

) 4.937 10

-10

mm

2

s

-2

), and B depended on the fi tted

method. I f eq 9 was used, B ) 2.142 10

-6

mm

2

s, and i f

eq 12 was appl i ed, the B val ue depends on the shape of

the capi l l ary.

To test the rel i abi l i ty and proper operati on of the

i nstrument, the vi scosi ty of HFC152a was measured. The

sampl e was from Hangzhou Fi rst Chemi cal Co. Ltd., and

i ts mass puri ty was 99.95% and was anal yzed wi th gas

chromatography before the measurement.

The vi scosi ti es of HFC152a are l i sted i n Tabl e 2. The

dynami c vi scosi ty and densi ty data were ci ted from refs 8

) At (8)

B )

mghR

4

64A(L + nR)

2

(9)

m) 0.037Re

0.5

(10)

Re)

2V

RkAt

2

(11)

B ) 0.00117

V

1.5

(kA)

0.5

R

0.5

(L + nR)

(12)

Figure1. Vi scometer schemati c: (A) addi ti onal vol ume; (B) upper

mark; (C) fl ow vol ume; (D) l ower mark; (E) bypass tube; (F) fl ange

pl ate; (G) observati on wi ndow; (H) capi l l ary; (I ) pressure vessel ;

(J) val ve A; (K) val ve B; (L) val ve C.

Table 1. Flow Times and Viscosities of Ethanol and

Water

l i qui d T/K t/s F/kgm

-3

/mm

2

s

-1

/Pas refs

water 315.052 1276.28 991.444 0.6358 630.314

325.109 1099.31 987.111 0.5363 529.348 6

335.207 924.72 982.105 0.4605 452.257

ethanol 309.946 2346.35 774.775 1.1230 870.065

319.786 1921.90 766.068 0.9586 734.355 7, 8

330.124 1622.93 756.700 0.8210 621.245

J ournal of Chemical and Engineering Data, Vol. 48, No. 2, 2003 427

http://www.paper.edu.cn

and 9. To check the feasi bi l i ty of the assumpti on k ) 1.0,

both resul ts (k ) 1.0 and (F

L

- F

g

)/F

L

) were gi ven. I t can be

found that i f B i s obtai ned wi th eq 9, the resul ts of k ) 1.0

are better than those of k ) (F

L

- F

g

)/F

L

, and the maxi mum

devi ati on and the average devi ati on are 2.55% and 1.33%,

respecti vel y. I f B i s obtai ned wi th eq 12, the resul ts of k )

(F

L

- F

g

)/F

L

are better than those of k ) 1.0, and the

maxi mum devi ati on and the average devi ati on are 2.41%

and 1.16%, respecti vel y.

On the basi s of the above di scussi on and the si mi l ari ty

of HFC152a and di methyl ether, the assumpti on k ) 1.0

and eq 9 are used i n the vi scosi ty measurements of

di methyl ether. Another reason i s that i nformati on on the

vapor densi ty of di methyl ether i s currentl y l acki ng.

5. Results and Analysis

The sampl e of di methyl ether was provi ded by Zhong-

shan Fi ne Chemi cal Co. Ltd. I ts mass puri ty was better

than 99.95%, and no further puri fi cati on was needed.

The vi scosi ty of l i qui d di methyl ether was measured

al ong the saturati on l i ne from (227 to 343) K. The experi -

mental data are l i sted i n Tabl e 3. The saturated l i qui d

densi ti es of di methyl ether are ci ted from ref 10. At each

temperature, the fl ow ti me i s measured three to fi ve ti mes,

and the repeatabi l i ty of the fl ow ti me i s better than 1.0%.

The experi mental resul ts l i sted i n Tabl e 3 were cor-

rel ated as a functi on of temperature usi ng the fol l owi ng

equati on:

where the vi scosi ty i s i n mPas and temperature i s i n K.

The standard devi ati on and the maxi mum devi ati on of the

experi mental resul ts from eq 13 are 0.5% and 1.3%,

respecti vel y. Fi gure 2 shows the vi scosi ty of di methyl ether

as a functi on of temperature, and Fi gure 3 shows the

devi ati ons of the experi mental data from eq 13.

Table 2. Experimental Viscosities for Saturated Liquid HFC152a

k ) 1.0 k ) (FL - Fg)/FL

B eq 9 B eq 12 B eq 9 B eq 12

T/K t/s FL/kgm

-3

Fg/kgm

-3

ref/mm

2

s

-1

exp/mm

2

s

-1

a

/% exp/mm

2

s

-1

/% exp/mm

2

s

-1

/% exp/mm

2

s

-1

/%

244.397 632.18 1020.63 2.76 0.3168 0.3087 2.55 0.3109 1.85 0.3079 2.81 0.3101 2.12

253.460 571.75 1001.96 4.03 0.2799 0.2788 0.50 0.2808 -0.32 0.2774 0.91 0.2797 0.08

263.913 497.10 979.64 6.02 0.2465 0.2414 2.20 0.2435 1.23 0.2396 2.81 0.2420 1.84

271.620 464.24 962.58 7.93 0.2269 0.2249 1.03 0.2270 -0.03 0.2227 1.87 0.2251 0.80

281.749 425.72 939.27 11.14 0.2062 0.2055 0.50 0.2076 -0.68 0.2027 1.71 0.2051 0.53

293.103 391.58 911.77 15.89 0.1878 0.1883 -0.02 0.1902 -1.29 0.1845 1.78 0.1869 0.51

303.082 362.46 886.21 21.32 0.1745 0.1735 0.83 0.1753 -0.49 0.1687 3.30 0.1710 1.98

315.345 343.25 852.59 30.03 0.1601 0.1637 -1.98 0.1654 -3.37 0.1573 1.75 0.1595 0.36

315.347 342.47 852.58 30.03 0.1601 0.1633 -1.73 0.1650 -3.12 0.1569 1.99 0.1591 0.60

325.328 321.53 822.00 39.26 0.1489 0.1526 -2.10 0.1542 -3.50 0.1445 2.98 0.1466 1.59

325.132 319.41 823.60 39.06 0.1492 0.1515 -1.22 0.1531 -2.61 0.1435 3.79 0.1456 2.41

a

) 100(exp - ref)/ref.

Table 3. Experimental Viscosities for Saturated Liquid

Dimethyl Ether

T/K t/s F/kgm

-3

/mm

2

s

-1

/Pas

227.218 697.97 757.655 0.3418 258.928

232.277 653.91 751.053 0.3198 240.191

237.471 610.59 744.185 0.2982 221.920

243.152 583.05 736.565 0.2845 209.520

248.297 558.50 729.561 0.2722 198.576

253.138 537.55 722.876 0.2617 189.180

258.153 512.65 715.848 0.2492 178.413

263.141 493.59 708.749 0.2397 169.869

268.154 477.41 701.498 0.2316 162.432

273.157 460.82 694.138 0.2232 154.939

278.156 446.20 686.654 0.2159 148.215

283.151 433.68 679.035 0.2095 142.287

288.152 424.89 671.258 0.2051 137.681

293.145 411.36 663.333 0.1983 131.523

298.157 403.91 655.205 0.1945 127.443

303.162 393.08 646.900 0.1890 122.282

308.148 379.40 638.426 0.1821 116.252

312.534 370.02 630.790 0.1773 111.857

317.518 363.50 621.888 0.1740 108.217

322.498 352.54 612.733 0.1684 103.205

327.501 345.44 603.246 0.1648 99.423

332.493 341.74 593.455 0.1629 96.688

337.467 336.30 583.340 0.1601 93.419

342.448 332.98 572.801 0.1584 90.759

Figure 2. Saturated l i qui d vi scosi ty of di methyl ether as a

functi on of temperature: s, cal cul ati on; [, experi mental data.

Figure 3. Devi ati ons of experi mental data from eq 14.

l og

10

(/mPas) ) -5.7282 + 631.031/(T/K) +

(1.4530 10

-2

)(T/K) - (1.8225 10

-5

)(T/K)

2

(13)

428 J ournal of Chemical and Engineering Data, Vol. 48, No. 2, 2003

http://www.paper.edu.cn

6. Conclusion

I n thi s work, the vi scosi ty of di methyl ether was meas-

ured wi th a capi l l ary vi scometer at temperatures between

(227 and 343) K al ong the saturati on l i ne. The repeatabi l i ty

of the fl ow ti me i s better than 1.0% at a certai n tempera-

ture, and the total rel ati ve uncertai nty of the ki nemati c

vi scosi ty i s better than 3.0%. The resul ts were correl ated

as a functi on of temperature. The standard devi ati on and

the maxi mum devi ati on of the experi mental resul ts from

the equati on are 0.5% and 1.3%.

Literature Cited

(1) Wang, H. Experi mental and Theoreti cal Studi es on Performance

and Combusti on Characteri sti cs of Di rect I njecti on Di esel Engi ne

Fuel ed Wi th DME. Ph.D. Thesi s, Xi an Ji aotong Uni versi ty, Xi an,

2000.

(2) Wakeham, W. A.; Nagashi ma, A.; Sengers, J. V. Experimental

Thermodynamics Vol. 3: Measurement of theTransport Properties

of Fluids; Bl ackwel l Sci enti fi c Publ i cati ons: Oxford, 1991.

(3) Cannon, M. R.; Manni ng, R. M.; Bel l , J. D. Vi scosi ty measurement

the ki neti c energy correcti on and new vi scometer. Anal. Chem.

1960, 32, 355.

(4) Lv, P. Theoreti cal Study on Vi scosi ty of Ethane Cl uster Freon

and Measurement of Vi scosi ty of Saturated HFC--152a and

HCFC-133a Li qui d. Master Thesi s, Xi an Ji aotong Uni versi ty,

Xi an, 1996.

(5) Wu, J. T.; Li u, Z. G.; Huang, H. H.; Pan, J.; Zhao, X. M.; He, M.

G. Devel opment of New Hi gh Accuracy PVTx Measurement

Experi mental System. J . Xian J iaotong Univ. 2003, 37, 5-9.

(6) The I nternati onal Associ ati on for the Properti es of Water and

Steam. Revised Release on the I APS Formulation 1995 for the

viscosity of Ordinary Water Substance; The I nternati onal As-

soci ati on for the Properti es of Water and Steam: Erl angen, 1997.

(7) Ci bul ka, I . Saturated l i qui d densi ti es of 1-al kanol s from c1 to c10

and n-al kanes from c5 to c16: a cri ti cal eval uati on of experi mental

data. Fluid PhaseEquilib. 1993, 89, 1-18.

(8) Assael , M. J.; Pol i mati dou, S. K. Measurements of the Vi scosi ty

of Al cohol s i n the Temperature Range 290-340 K at Pressures

up to 30 MPa. I nt. J . Thermophys. 1994, 15, 94-107.

(9) Assael , M. J.; Dal aouti , N. K.; Gi al ou, K. E. Vi scosi ty and thermal

conducti vi ty of methane, ethane and propane hal ogenated refri g-

erants. Fluid PhaseEquilib. 2000, 174, 203-211.

(10) Sato, H.; Hi gashi , Y.; Okada, M. J ARef HFCs and HCFCs Version

1.0; Japanese Associ ati on of Refri gerati on: Japan, 1994.

(11) Yaws, C. L. Chemical PropertiesHandbook; McGraw-Hi l l : Bei ji ng,

1999.

Recei ved for revi ew September 30, 2002. Accepted January 1, 2003.

Thi s research i s supported by the Nati onal Natural Sci ence

Foundati on of Chi na (Grant No. 59976030) and the Nati onal Basi c

Research Pri ori ti es Program of the Mi ni stry of Sci ence and

Technol ogy of Chi na (973 Project, Grant No. 2001CB209208).

JE0256232

J ournal of Chemical and Engineering Data, Vol. 48, No. 2, 2003 429

http://www.paper.edu.cn

You might also like

- Recommended Reference Materials for Realization of Physicochemical Properties: Pressure–Volume–Temperature RelationshipsFrom EverandRecommended Reference Materials for Realization of Physicochemical Properties: Pressure–Volume–Temperature RelationshipsE. F. G. HeringtonNo ratings yet

- Thermometric Titrimetry: International Series of Monographs in Analytical ChemistryFrom EverandThermometric Titrimetry: International Series of Monographs in Analytical ChemistryNo ratings yet

- Of Lo of of 15.0: Chosgsnc Been A N D A Piemure Mxtin An& Llou Thsrer Lta Aa&$&niodDocument19 pagesOf Lo of of 15.0: Chosgsnc Been A N D A Piemure Mxtin An& Llou Thsrer Lta Aa&$&niodBhaskar GiriNo ratings yet

- Pressão de Vapor Da ÁguaDocument33 pagesPressão de Vapor Da ÁguaPaulo HenriqueNo ratings yet

- Aic 690170119Document6 pagesAic 690170119Tiên PhạmNo ratings yet

- A Nomograph For Correction of Boiling Points: Kent State University, KentDocument2 pagesA Nomograph For Correction of Boiling Points: Kent State University, Kentthrowaway456456No ratings yet

- Hartman1968 PaperDocument11 pagesHartman1968 PaperwpgurgelNo ratings yet

- Dashuk Et Al., 1980Document5 pagesDashuk Et Al., 1980Tu LENo ratings yet

- A Cautionary Note On The Use of The Evans Method For Magnetic MeasurementsDocument1 pageA Cautionary Note On The Use of The Evans Method For Magnetic MeasurementskawtherahmedNo ratings yet

- Oxidation-Reduction Potential of The Ferro-Ferricyanide System in Buffer SolutionsDocument7 pagesOxidation-Reduction Potential of The Ferro-Ferricyanide System in Buffer SolutionsscribedbioaNo ratings yet

- Coal Pyrolysis ModelingDocument12 pagesCoal Pyrolysis Modelinganon_990649048No ratings yet

- Were Or: ONE D. BDocument12 pagesWere Or: ONE D. BAhmad Al MataanyNo ratings yet

- Solubility of Water in Hydrocarbons - Hibbard & SchallaDocument27 pagesSolubility of Water in Hydrocarbons - Hibbard & SchallarschirtNo ratings yet

- Vapor Pressure of A Pure LiquidDocument6 pagesVapor Pressure of A Pure LiquidAndres Zuma PhillipsNo ratings yet

- IgnitionDocument9 pagesIgnitionEska Putra DwitamaNo ratings yet

- A Kinetic Model of Steady State Ethylene Epoxidation Over A Supported Silver CatalystDocument17 pagesA Kinetic Model of Steady State Ethylene Epoxidation Over A Supported Silver CatalystFrank LordNo ratings yet

- A High Performance Ethanol Gas Sensor Based 0 N C 0-Fe, O3 1 (3 EM1 C ND Uctin Mater ADocument4 pagesA High Performance Ethanol Gas Sensor Based 0 N C 0-Fe, O3 1 (3 EM1 C ND Uctin Mater AVigneshwaran MuruganNo ratings yet

- Experiment 4Document12 pagesExperiment 4jamiecfraser08No ratings yet

- 12 - 3 - Atlantic City - 09-68 - 0019Document13 pages12 - 3 - Atlantic City - 09-68 - 0019Lucyana AngelNo ratings yet

- Correlation For Boiling Heat Transfer T O Saturated Fluids in Convective FlowDocument8 pagesCorrelation For Boiling Heat Transfer T O Saturated Fluids in Convective FlowbarelihbNo ratings yet

- Experimental Determination of Absolute Zero (Celsius) Using The Ideal Gas LawDocument4 pagesExperimental Determination of Absolute Zero (Celsius) Using The Ideal Gas Lawsr20fd3stNo ratings yet

- Case Studies in Thermal Engineering: J.M. Gorman, E.M. Sparrow, J.P. AbrahamDocument4 pagesCase Studies in Thermal Engineering: J.M. Gorman, E.M. Sparrow, J.P. AbrahamAdiKurdiNo ratings yet

- PRO-II Thermodynamic Model SelectionDocument79 pagesPRO-II Thermodynamic Model Selectionchemsac2100% (1)

- Theoretical Analysis of The Thermal Resistance of Non-Uniform Fouling On Cross-Flow Heat Exchanger TubesDocument8 pagesTheoretical Analysis of The Thermal Resistance of Non-Uniform Fouling On Cross-Flow Heat Exchanger TubesShalehAhmadNo ratings yet

- Holdup-Charge Ratio in Istillation: 1480 Industrial and Engineering Chemistry No. 6Document7 pagesHoldup-Charge Ratio in Istillation: 1480 Industrial and Engineering Chemistry No. 6Anonymous ee5dOjNo ratings yet

- Kinetics of Hydroformylation of Ethylene in A Homogeneous Medium: Comparison in Organic and Aqueous SystemsDocument6 pagesKinetics of Hydroformylation of Ethylene in A Homogeneous Medium: Comparison in Organic and Aqueous SystemsKide SilveNo ratings yet

- Viscosity of Liquid Water in The Range 8 °C To 150 °C: Articles You May Be Interested inDocument9 pagesViscosity of Liquid Water in The Range 8 °C To 150 °C: Articles You May Be Interested inAnandhu Mohan MNo ratings yet

- Reynolds Vs Heat Transfer CoeffDocument15 pagesReynolds Vs Heat Transfer CoeffquantumfeelingNo ratings yet

- BF 00411718Document30 pagesBF 00411718st.shenppNo ratings yet

- Elison HR J Chem Educ 2005 82 1086Document3 pagesElison HR J Chem Educ 2005 82 1086Daniel ButlerNo ratings yet

- Vapor-Liquid Equilibrium Data for Ethanol-Water and 2-Propanol-Water SystemsDocument15 pagesVapor-Liquid Equilibrium Data for Ethanol-Water and 2-Propanol-Water SystemsJCKARLNo ratings yet

- 16 4 Boston 04-72 0079 PDFDocument9 pages16 4 Boston 04-72 0079 PDFtespakNo ratings yet

- Cyclic Voltammetry Experiment: JamesDocument5 pagesCyclic Voltammetry Experiment: Jameshongluc1991100% (1)

- Sca1994 28Document10 pagesSca1994 28Rosa K Chang HNo ratings yet

- A Method of Estimating High Temperature Low CycleDocument28 pagesA Method of Estimating High Temperature Low Cycleaemis2010No ratings yet

- Free Radical Suspension Polymerization Kinetics of Styrene Up To High ConversionDocument19 pagesFree Radical Suspension Polymerization Kinetics of Styrene Up To High ConversionAntoine ValdezNo ratings yet

- Lab Report FinalDocument13 pagesLab Report Finalidyllic20No ratings yet

- Research and Technical Notes: Specific Heat of Wakefield Thermal Compound From 2 To 40 KDocument2 pagesResearch and Technical Notes: Specific Heat of Wakefield Thermal Compound From 2 To 40 KJosemarPereiradaSilvaNo ratings yet

- Determination of Mass Transfer CoefficientDocument5 pagesDetermination of Mass Transfer CoefficientgalojlNo ratings yet

- Thermal Conductivity of NaCl SolutionsDocument25 pagesThermal Conductivity of NaCl SolutionslinhNo ratings yet

- Exp1 Result ReportDocument10 pagesExp1 Result Report성제박No ratings yet

- SPE 84226 A Mechanistic Heat Transfer Model For Vertical Two-Phase FlowDocument10 pagesSPE 84226 A Mechanistic Heat Transfer Model For Vertical Two-Phase FlowEduardo FloresNo ratings yet

- Recovery of Platinum from Brine by ElectrodepositionDocument27 pagesRecovery of Platinum from Brine by ElectrodepositionGmmmm123No ratings yet

- Heat Transfer QBDocument10 pagesHeat Transfer QBBanu KarthiNo ratings yet

- The Surface Tension of Mixtures of Methanol Acetonitrile Tetrahydrofuran Isopropanol Tertiary Butanol and Dimethyl Sulfoxide With Water at 25 C PDFDocument22 pagesThe Surface Tension of Mixtures of Methanol Acetonitrile Tetrahydrofuran Isopropanol Tertiary Butanol and Dimethyl Sulfoxide With Water at 25 C PDFKatipot InkongNo ratings yet

- Pressure-Volume-Temperature Data For Oxygen: by Cyril HDocument10 pagesPressure-Volume-Temperature Data For Oxygen: by Cyril HAhmed Mohamed HassanNo ratings yet

- Chemistry Lab-Enthalpy of Vaporization of Water Discussion and AnalysisDocument4 pagesChemistry Lab-Enthalpy of Vaporization of Water Discussion and Analysislanichung100% (2)

- L-08 (SS) (Ia&c) ( (Ee) Nptel)Document11 pagesL-08 (SS) (Ia&c) ( (Ee) Nptel)Marvin BayanayNo ratings yet

- Critical Temperatures, Pressures, and Volumes of Hydrogen, Deuterium, and Hydrogen DeuterideDocument5 pagesCritical Temperatures, Pressures, and Volumes of Hydrogen, Deuterium, and Hydrogen DeuterideMaria AngelinNo ratings yet

- Thermodynamics of H2O2 DecompositionDocument5 pagesThermodynamics of H2O2 DecompositionLuis LozadaNo ratings yet

- Thermodynamics Lab Guide PDFDocument5 pagesThermodynamics Lab Guide PDFCarlos Andres Quesada DiazNo ratings yet

- 1 s2.0 0009250964850922 MainDocument12 pages1 s2.0 0009250964850922 MainPedro SiscatoNo ratings yet

- Spe 125413 MSDocument14 pagesSpe 125413 MStruth sayer100% (1)

- Solid State Ionics Volume 8 Issue 2 1983 (Doi 10.1016/0167-2738 (83) 90079-6) D.P. Almond G.K. Duncan A.R. West - The Determination of Hopping Rates and Carrier Concentrations in Ionic ConductoDocument6 pagesSolid State Ionics Volume 8 Issue 2 1983 (Doi 10.1016/0167-2738 (83) 90079-6) D.P. Almond G.K. Duncan A.R. West - The Determination of Hopping Rates and Carrier Concentrations in Ionic ConductoZulhadi RadziNo ratings yet

- Charles' LawDocument5 pagesCharles' LawSuganya BaabuNo ratings yet

- Adiabatic Expansion Determines Heat Capacity RatiosDocument7 pagesAdiabatic Expansion Determines Heat Capacity RatiosVereneNo ratings yet

- Mona SCH YfytitycDocument7 pagesMona SCH YfytitycJeevananthan S P KannanNo ratings yet

- Trifon Ov Ivanov 2003Document5 pagesTrifon Ov Ivanov 2003ArnoldoNo ratings yet

- 1 s2.0 S1004954106600840 Main PDFDocument7 pages1 s2.0 S1004954106600840 Main PDFWaheed ZebNo ratings yet

- Exp.2-Principles of Saturation Pressure MeasurementDocument65 pagesExp.2-Principles of Saturation Pressure MeasurementAmir Hamzah25% (4)

- November 7, 2015Document3 pagesNovember 7, 2015saifu2No ratings yet

- Hamad Bin Khalifa University College of Science and EngineeringDocument3 pagesHamad Bin Khalifa University College of Science and Engineeringsaifu2No ratings yet

- Moisture content and drying rate of solid samplesDocument1 pageMoisture content and drying rate of solid samplessaifu2No ratings yet

- AMU. B.tech DetailsDocument11 pagesAMU. B.tech Detailssaifu2No ratings yet

- Creeping Flow 1Document11 pagesCreeping Flow 1radwaelhadadNo ratings yet

- IOCL, Mathura Refinery Training ReportDocument26 pagesIOCL, Mathura Refinery Training ReportNamishaAgarwalNo ratings yet

- Journal Japan Petrol InstitueDocument0 pagesJournal Japan Petrol Instituesaifu2No ratings yet

- Autoscan P12 04 16 enDocument12 pagesAutoscan P12 04 16 enCouscoussiere GrandgazNo ratings yet

- Despiese Bomba de Direccion D8TDocument3 pagesDespiese Bomba de Direccion D8TEliecer godoyNo ratings yet

- Ansys Fluent Simulation ReportDocument7 pagesAnsys Fluent Simulation Reportsaitharun reddy.munthaNo ratings yet

- McCormick X60 Series (2011-2014) - RP67 - X60.50 Tractor Service Repair Manual PDFDocument25 pagesMcCormick X60 Series (2011-2014) - RP67 - X60.50 Tractor Service Repair Manual PDFfjkkekmdmNo ratings yet

- Assingment 2Document1 pageAssingment 2Aliaa TarekNo ratings yet

- MT 2010Document8 pagesMT 2010kokonunezNo ratings yet

- ADAMS Lecture 1 Introduction To ADAMSDocument19 pagesADAMS Lecture 1 Introduction To ADAMSAneesh KalraNo ratings yet

- Sheet Metal Forming: Deep Drawing of Rectangular and Asymmetric PartsDocument17 pagesSheet Metal Forming: Deep Drawing of Rectangular and Asymmetric PartsBachLeCaoNo ratings yet

- AMP Summer Question Paper (Msbte Study Resources)Document4 pagesAMP Summer Question Paper (Msbte Study Resources)Varad DateNo ratings yet

- Wei Gong Lattice Tower Design of Offshore Wind Turbine Support Structures v0Document135 pagesWei Gong Lattice Tower Design of Offshore Wind Turbine Support Structures v0Sachin Sithik50% (2)

- STB S19 00 Datenblatt - Scalpac - EN - v01 PDFDocument2 pagesSTB S19 00 Datenblatt - Scalpac - EN - v01 PDFAnastasia PošaracNo ratings yet

- Article DetailDocument78 pagesArticle Detailandi_lb9453No ratings yet

- Mechanism and Robot Kinematics: Anirvan DasguptaDocument122 pagesMechanism and Robot Kinematics: Anirvan Dasguptaसुमित शर्माNo ratings yet

- Carta Psicrometrica PDFDocument1 pageCarta Psicrometrica PDFFederico Ferreira LopezNo ratings yet

- EJOT ASYST Component System Flyer 10.17Document5 pagesEJOT ASYST Component System Flyer 10.17Eren GülayNo ratings yet

- Heat Flow Calculations Made Using The V C: Ventilation Test InstrumentsDocument6 pagesHeat Flow Calculations Made Using The V C: Ventilation Test Instrumentsretrospect1000No ratings yet

- pc200 7 Main Pump Test MethodDocument26 pagespc200 7 Main Pump Test Methodalfred100% (1)

- Shubham Gaikwad 163014 Seminar ReportDocument21 pagesShubham Gaikwad 163014 Seminar ReportShubham GaikwadNo ratings yet

- Hadeel Al-Kurdi Lab Report 1Document10 pagesHadeel Al-Kurdi Lab Report 1Haidy T. SakrNo ratings yet

- Certificado - Flange Adapter 125MM - XindaDocument3 pagesCertificado - Flange Adapter 125MM - XindaGR CarlosNo ratings yet

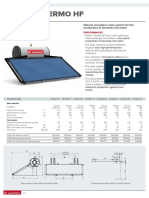

- Kairos Thermo HF Natural Circulation Solar System for Domestic Hot Water ProductionDocument4 pagesKairos Thermo HF Natural Circulation Solar System for Domestic Hot Water ProductionFILID MADNo ratings yet

- EC7 - Peat Negative Skin FrictionDocument14 pagesEC7 - Peat Negative Skin FrictionKelvin bongNo ratings yet

- Akron Brass CatalogDocument236 pagesAkron Brass CatalogDaniel RodasNo ratings yet

- Atlas Copco QES RangeDocument8 pagesAtlas Copco QES RangeDave WallaceNo ratings yet

- SSC JE Mains Test Series ProblemsDocument6 pagesSSC JE Mains Test Series ProblemsAble KuriakoseNo ratings yet

- INSTRUMENTED PILE LOAD TEST REPORTDocument24 pagesINSTRUMENTED PILE LOAD TEST REPORTsandrock92No ratings yet

- TM 5-811-6 Generator and Electrical Facilities DesignDocument26 pagesTM 5-811-6 Generator and Electrical Facilities DesignrockclaudiuNo ratings yet

- Linearschwingsieb enDocument12 pagesLinearschwingsieb enBrunoNo ratings yet

- Metsec Engineering Forms the FutureDocument24 pagesMetsec Engineering Forms the Futureshashank adigaNo ratings yet

- Die Casting Machines Core Pins & Ejector PinsDocument1 pageDie Casting Machines Core Pins & Ejector PinsJayden BarnesNo ratings yet