Professional Documents

Culture Documents

Battery Charger Sizing Guide

Uploaded by

Priambudi PujihatmaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Battery Charger Sizing Guide

Uploaded by

Priambudi PujihatmaCopyright:

Available Formats

Battery and Charger Sizing

CONTENTS

SECTION

DESCRIPTION

1.0

PURPOSE

2.0

CODES & STANDARDS

3.0

DESIGN INPUTS

4.0

ASSUMPTIONS / CONSIDERATIONS

5.0

RESULTS

6.0

BATTERY LOAD CYCLE

7.0

BATTERY LOAD CURVE

8.0

DETERMINATION OF NO. OF CELLS

9.0

DETERMINATION OF AH RATING OF BATTERY

10.0

277266699.xls (Index)

DETERMINATION OF RATING OF BATTERY CHARGER

Page 1 of 17

Battery and Charger Sizing

1.0 PURPOSE :

The purpose of this calculation is (a) to establish Battery load Cycle, (b) to calculate the no. of cells required for

220 V DC, (c) to calculate AH rating of 220 V DC Battery for ststion auxiliary loads, and the rating of Battery

Charger for 2 X 15 MW Muri, Co-Generation Plant, Jharkhand, India.

2.0 CODES & STANDARDS

(a) IEEE-485, 1997 - IEEE Recommended Practice for Sizing of Lead Acid Batteries for Stationary Applications

(b) IEEE-946 - IEEE Recommended Practice for the Design of DC Auxiliary Power Systems for Generating Stations

3.0 DESIGN INPUTS

(a) 1 x 100 % Battery and 2 x 100 % Battery Charger are considered for 220V DC system.

(b) Plante type Lead Acid station batteries are considered.

(c) The End Cell Voltage (ECV) is considered as 1.85 V/cell in the battery

(d) Battery is sized for maximum one (1) hour of duty as per specification

(e) Temperature correction factor shall be calculated based on minimum site temperature 5 degC with respect to

the standard temeperatute 27 degC.

(f) A design margin of 10% has been considered for unforeseen additions and future growth.

(g) An aging factor of 1.00 has been considered in sizing the battery as per IEEE : 485 - 1997, cl. no. 6.2.3

(h) Cell voltage required for float charging is taken as 2.15 V/Cell as per specification.

4.0 ASSUMPTIONS / CONSIDERATIONS

(a) Breaker tripping coil loads have been considered as 1 minute duration loads (Duty Cycle: 0-1 min.) as per

standard engineering practice

(b) Breaker closing coil and spring charging motor loads have been considered as 1 minute duration loads

(Duty Cycle: 59-60 min.) as per standard engineering practice.

(c) Emergency DC lighting load has been considered as continuous load ( Duty cycle : 0 - 60 min.)

(d) Local LED indications, protective relays, trip relays, timers, other aux. Relays, control panel supply and

emergency lube oil pump, have been considered as continuous loads (Duty Cycle: 0-60 min.) as per standard

engineering practice and system requirements.

(e) For emergency lube oil pump, motor have been considered with 85% efficiency. The starting current has been

been considered 2 times of respective full load current.

(f) The value of K factor has been considered as per Vendors data.

(g) The rated current of each battery charger will be such that it is capable of supplying the continuous load

current and re-charging a fully discharged battery at eight (8) hour.

(h) The duty cycle does not include any spare capacity as this is accounted for by the design margin .

i)

The percentage change of capacity on discharge with temperature for PLANTE' type battery has been

considered as 0.9 as per reputed manufacturer's data.

5.0 RESULTS

(a) Rating of each station battery is 645 AH (Minimum) (Refer note-1)

(b) The no. of cell of each battery is 102

(c) Rating of each station battery charger is 175 Amp

Note:

1)

Aging factor 1.00 has been considered as per IEEE-485. However, if Manufacturer recommends aging factor, the

uncorrected AH capacity shall be multiplied by Aging factor 1.25 to get the final AH capacity of the battery.

277266699.xls (General)

Page 2 of 17

Battery and Charger Sizing

ith respect to

per standard

rent has been

aging factor, the

277266699.xls (General)

Page 3 of 17

Battery and Charger Sizing

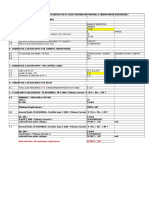

6.0 BATTERY LOAD CYCLE

Sl.

No.

Load

Description

Turbine Auxiliaries

Emergency Oil Pump (12 kW)

Generator

Generator Excitation

System(Assumed)

Generator Protection Panel (Assumed)

CO2 System

11 kV Switchgear

Spring charging motor of 11 kV

Breaker

( 250 W)

1

2

Closing coil of 11 kV Breaker (250 W)

Tripping of 11 kV Breaker ( 500 W)

4

D

1

Control supply, indication circuit and

protective relays for 15 nos breakers

@ 0.3 A each for 11 kV switchgear

6.6 kV Station Switchgear

Spring charging motor of 6.6 kV

Breaker

( 220 W)

Closing coil of 6.6 kV Breaker (440 W)

Tripping of 6.6 kV Breaker (440 W)

4

E

1

Control supply, indication circuit and

protective relays for 8 nos breakers @

0.3 A each for 6.6 kV switchgear

415 V Station Switchgear

Spring charging motor of 415 V

Breaker ( 220 W)

Closing coil of 415 V Breaker (110 W)

Tripping of 415 V Breaker (110 W)

Control supply, indication circuit and

protective relays for 18 nos breakers

@ 0.3 A each for 415 V switchgear

415 V Boiler MCC#1

Spring charging motor of 415V

Breaker

(200 W)

Closing coil of 415 V Breaker (110 W)

Tripping of 415 V Breaker (110 W)

Control supply, indication circuit and

protective relays for 3 nos breakers @

0.3 A each for 415 V switchgear

415 V Boiler MCC#2

Spring charging motor of 415V

Breaker

(200 W)

Closing coil of 415 V Breaker (110 W)

Tripping of 415 V Breaker (110 W)

Control supply, indication circuit and

protective relays for 3 nos breakers @

0.3 A each for 415 V switchgear

415 V Boiler MCC#3

277266699.xls (LoadCycle)

BATTERY LOAD CYCLE: 220V DC BATTERY

No. of

From

To

From

Total Simultaneou

0

1

1

Nos.

s

Operation Minute load (A) Minute load (A)

Type

of

Load

Unit

Load

(A)

Continuou

s

64.17

256.68

128.34

1.00

2.00

2.00

1.00

2.00

2.00

2.00

4.00

4.00

1.14

15

1.14

15

2.27

15

15

34.09

0.30

15

15

4.50

1.00

2.00

2.00

12.00

0.30

2.40

1.00

18

0.50

18

0.50

18

13

6.50

0.30

18

18

5.40

0.91

0.50

0.50

1.00

0.30

0.90

0.91

0.50

0.50

1.00

0.30

0.90

Continuou

s

Continuou

s

Continuou

s

Momentar

y

Momentar

y

Momentar

y

Continuou

s

Momentar

y

Momentar

y

Momentar

y

Continuou

s

Momentar

y

Momentar

y

Momentar

y

Continuou

s

Momentar

y

Momentar

y

Momentar

y

Continuou

s

Momentar

y

Momentar

y

Momentar

y

Continuou

s

4.50

2.40

5.40

0.90

0.90

Page 4 of 17

Battery and Charger Sizing

Sl.

No.

Load

Description

Spring charging motor of 415V

Breaker

(200 W)

Closing coil of 415 V Breaker (110 W)

Tripping of 415 V Breaker (110 W)

Control supply, indication circuit and

protective relays for 3 nos breakers @

0.3 A each for 415 V switchgear

415 V Water MCC

Spring charging motor of 415V

Breaker

(200 W)

Closing coil of 415 V Breaker (110 W)

Tripping of 415 V Breaker (110 W)

Control supply, indication circuit and

protective relays for 2 nos breakers @

0.3 A each for 415 V switchgear

415 V ESP MCC

Spring charging motor of 415V

Breaker

(200 W)

Closing coil of 415 V Breaker (110 W)

Tripping of 415 V Breaker (110 W)

Control supply, indication circuit and

protective relays for 2 nos breakers @

0.3 A each for 415 V switchgear

415 V Ash Handling MCC

Spring charging motor of 415V

Breaker

(200 W)

Closing coil of 415 V Breaker (110 W)

Tripping of 415 V Breaker (110 W)

Control supply, indication circuit and

protective relays for 2 nos breakers @

0.3 A each for 415 V switchgear

415 V STG MCC#1

Spring charging motor of 415V

Breaker

(200 W)

Closing coil of 415 V Breaker (110 W)

Tripping of 415 V Breaker (110 W)

Control supply, indication circuit and

protective relays for 3 nos breakers @

0.3 A each for 415 V switchgear

415 V STG MCC#2

Spring charging motor of 415V

Breaker

(200 W)

Closing coil of 415 V Breaker (110 W)

Tripping of 415 V Breaker (110 W)

Control supply, indication circuit and

protective relays for 3 nos breakers @

0.3 A each for 415 V switchgear

415 V BOP MCC

277266699.xls (LoadCycle)

Type

of

Load

Momentar

y

Momentar

y

Momentar

y

Continuou

s

Momentar

y

Momentar

y

Momentar

y

Continuou

s

Momentar

y

Momentar

y

Momentar

y

Continuou

s

Momentar

y

Momentar

y

Momentar

y

Continuou

s

Momentar

y

Momentar

y

Momentar

y

Continuou

s

Momentar

y

Momentar

y

Momentar

y

Continuou

s

BATTERY LOAD CYCLE: 220V DC BATTERY

No. of

From

To

From

Total Simultaneou

0

1

1

Nos.

s

Minute

load

(A)

Minute

load (A)

Operation

Unit

Load

(A)

0.91

0.50

0.50

1.00

0.30

0.90

0.91

0.50

0.50

0.50

0.30

0.60

0.91

0.50

0.50

0.50

0.30

0.60

0.91

0.50

0.50

0.50

0.30

0.60

0.91

0.50

0.50

1.00

0.30

0.90

0.91

0.50

0.50

1.00

0.30

0.90

0.90

0.60

0.60

0.60

0.90

0.90

Page 5 of 17

Battery and Charger Sizing

Sl.

No.

Load

Description

Spring charging motor of 415V

Breaker

(200 W)

Closing coil of 415 V Breaker (110 W)

Tripping of 415 V Breaker (110 W)

Control supply, indication circuit and

protective relays for 2 nos breakers @

0.3 A each for 415 V switchgear

Intercommunication

Emergency Lighting

Miscellaneous Loads

Total load in Amps.

277266699.xls (LoadCycle)

Type

of

Load

Momentar

y

Momentar

y

Momentar

y

Continuou

s

Continuou

s

Continuou

s

Continuou

s

BATTERY LOAD CYCLE: 220V DC BATTERY

No. of

From

To

From

Total Simultaneou

0

1

1

Nos.

s

Minute

load

(A)

Minute

load (A)

Operation

Unit

Load

(A)

0.91

0.50

0.50

0.50

0.30

0.60

0.60

5.00

5.00

5.00

20.00

20.00

20.00

10.00

10.00

10.00

378.48

190.54

Page 6 of 17

Battery and Charger Sizing

TERY

To

59

From

59

To

60

Continuous

Load (A)

Remarks

Minute load (A) Minute load (A)

128.34

128.34

2.00

2.00

2.00

2.00

2.00

2.00

4.00

4.00

4.00

1.14

1.14

4.50

4.50

4.50

1.00

2.00

2.40

2.40

2.40

1.00

0.50

5.40

5.40

5.40

0.91

0.50

0.90

0.90

0.90

0.91

0.50

0.90

0.90

277266699.xls (LoadCycle)

0.90

Page 7 of 17

Battery and Charger Sizing

TERY

To

59

From

59

To

60

Continuous

Load (A)

Remarks

Minute load (A) Minute load (A)

0.91

0.50

0.90

0.90

0.90

0.91

0.50

0.60

0.60

0.60

0.91

0.50

0.60

0.60

0.60

0.91

0.50

0.60

0.60

0.60

0.91

0.50

0.90

0.90

0.90

0.91

0.50

0.90

0.90

277266699.xls (LoadCycle)

0.90

Page 8 of 17

Battery and Charger Sizing

TERY

To

59

From

59

To

60

Continuous

Load (A)

Remarks

Minute load (A) Minute load (A)

0.91

0.50

0.60

0.60

0.60

5.00

5.00

5.00

20.00

20.00

10.00

10.00

190.54

210.00

277266699.xls (LoadCycle)

32.20

Page 9 of 17

Battery and Charger Sizing

time

CURRENT IN AMP

0

0

1

1400

59

59

60350

60

0

0300

0

0

0250

0

0

0200

current

0

378.4754

378.4754

190.5422

190.5422

209.9968

209.9968

0

0

0

0

0

0

0

0

0

SEC : 7 -BATTERY LOAD CYCLE

150

100

50

0

0

20

40

60

80

TIME IN MIN

277266699.xls (Loadcurve)

Page 10 of 17

Battery and Charger Sizing

LE

60

277266699.xls (Loadcurve)

80

Page 11 of 17

Battery and Charger Sizing

8.0

DETERMINATION OF NUMBER OF CELLS

Nominal cell voltage

2 volts

Nominal battery voltage

220 volts

Float voltage

2.15 volts

End cell voltage

1.85 volts

System DC voltage variation

Boost voltage

(as per reputed manufacturer's catalogue)

(as per reputed manufacturer's catalogue)

220V, + 10% to - 15%

242.00 volts to

2.75 volts

187.00

volts

(as per reputed manufacturer's catalogue)

Number of cells determined considering the minimum system voltage and end cell voltage =

Minimum System Voltage

End Cell Voltage

=187/1.85 =

101.08

..(i)

Number of cells determined considering the maximum system voltage and float voltage =

Maximum System Voltage

Float Charging Voltage

=242/2.15=

112.56 ..(ii)

Number of cells chosen is lower of the values as per eq (i) & (ii) =

###

=

102

Taken

Maximum system voltage considering 102 cells and float voltage of 2.15 volts =

102 x 2.15

=

<

219.3

242.00

volts

volts

Minimum system voltage considering 102 cells and end cell voltage of 1.85 volts =

102 x 1.85

=

>

188.7

187.00

volts

volts

Hence, selection of 102 cells is justified.

9.0 DETERMINATION OF AH RATING OF BATTERY

9.1 CORRECTION FACTORS FOR BATTERY SIZING

For arriving at the battery AH capacity, the following correction factors have been considered:

a) Temperature derating factor at minimum site temperature 5 deg C ( From reputed manufacturer' data)

Standard temperture in deg C =

Minimimum site/ electrolyte temperature in deg C =

% change of capacity on discharge with temperature for PLANTE' type battery

Temperature correction factor = 1 + 0.9/100(27-5) =

277266699.xls (Cell)

27

5

0.9

1.198

Page 12 of 17

Battery and Charger Sizing

b) Capacity Factor (KT) with end cell voltage of 1.85 V/ cell) ( From reputed manufacturer's

catalogue )

Duration (min.)

Temperature derating factor, Tt

Capacity Factor (KT)

1.00

1.198

1.25

58.00

1.198

1.893

59.00

1.198

1.897

60.00

1.198

1.90

277266699.xls (Cell)

Page 13 of 17

Battery and Charger Sizing

9.2 BATTERY SIZING CALCULATION

End Cell Voltage : 1.85 volts

Minimum Site Temperature : 5 Deg. C

Battery Nominal Voltage : 220 V

Nominal cell voltage : 2.0V per cell

Cell type : Plante' type Lead Acid Battery

Total Duration : 60 Min.

Load Details :

A1 =

378.5

Amp

A2 =

190.5

Amp

A3 =

210.0

Amp

[1]

[2]

[3]

[4]

[5]

[6]

Period

Load

Change in

Load

Duration Of

Period

Time End of Section

Capacity Factor

at t Min. rate (KT)

Section 1: First Period Only - if A2 is greater than A1, go to Section 2

1 A1=

378.5

378.5 M1=1

t=M1=1

1.250

Section 1

Section 2: First Two Periods Only- If A3 is greater than A2, go to Section 3

1 A1=

378.5

378.5 M1= 1

t= M1 + M2 =59

2 A2=

190.5

-187.9 M2 = 58

t= M2 = 58

1.897

1.893

Section 2

Section 3 : First Three Periods Only - if A4 is greater than A3, go to Section 4

1 A1=

378.5

378.5 M1 = 1

t= M1 + M2 + M3 = 60

2 A2=

190.5

-187.9 M2 = 58

t=M2 + M3 = 59

3 A3=

210.0

19.5 M3 = 1

t = M3 = 1

1.900

1.897

1.250

Section 3

Uncorrected Cell Size = Maximum Section Size =

Design Margin =

Aging Factor =

566.8

10%

1.00

623.4

Cell Size (Uncorrected Cell Size) * (Design Margin) * (Aging Factor) =

Minimum AH rating of Battery selected

645

10.0 DETERMINATION OF RATING OF BATTERY CHARGER

Each station battery charger has been sized in accordance with the following formulas :

I1 = LC + 1.1 AH / T ------------ (1)

I2 = LC + Ln ------------------------(2)

where

I1 = the minimum required charger rated output ( Amp)

I3 = the recommended charger rated output ( Amp); I.e, the larger of I 1 or I2

LC = the continuous DC load ( Amp ), including future load growth

40.25

Ln = the largest combination of noncontinuous loads that would likely be connected to

the bus simultaneously during normal plant operation. (Amp)

128.34

1.1 = Battery Inefficiency Factor (for Lead Acid batteries)

AH = The ampere-hours discharged from battery.

645.00

T = the time to recharge the battery to approximately 95% of capacity ( in hours)

8.00

277266699.xls (Charger)

Page 14 of 17

Battery and Charger Sizing

I1 =

40.25 + [ 1.1 x 645 /8 ] =

128.94

(Amp)

From eq. No. (1),

I2 =

40.25 +128.342 =

168.59

(Amp)

From eq. No. (2),

I3 = Recommended charger out put, larger of I 1 or I2 =

168.59

(Amp)

Charger Rating Selected at 220 V DC

175 Amp

277266699.xls (Charger)

Page 15 of 17

Battery and Charger Sizing

[7]

[8]

Temp Derating

Factor for t Min. (Tt)

Required Section Size =

(3)x(6)x(7) = Rated AH.

Pos. Values

Neg. Values

1.198

Total (AH)

566.8

566.8

1.198

1.198

Sub. Total

Total (AH)

1.198

1.198

1.198

Sub. Total

Total

861.5

-427.1

29.1

890.6

463.5

-427.1

AH

Considering 25% design margin

(Assumed)

277266699.xls (Charger)

Page 16 of 17

Battery and Charger Sizing

277266699.xls (Charger)

Page 17 of 17

You might also like

- CYMCAP Basic Web TrainingDocument5 pagesCYMCAP Basic Web TrainingĐÀM TRỌNG CHÍNHNo ratings yet

- Battery Sizing CalculationDocument11 pagesBattery Sizing Calculationyasser5100% (1)

- Battery Sizing CalculationDocument7 pagesBattery Sizing CalculationThirumalNo ratings yet

- 110V Battery SizingDocument21 pages110V Battery SizingHassenL100% (3)

- Cable Sizing CalculationDocument15 pagesCable Sizing CalculationKhairul AshrafNo ratings yet

- Cable Impedance CalculationsDocument4 pagesCable Impedance CalculationsJoseph PoplingerNo ratings yet

- Data Sheet For Power TransformerDocument3 pagesData Sheet For Power TransformerNakkolopNo ratings yet

- Battery Charger SizingDocument10 pagesBattery Charger SizingAlam ArjunoNo ratings yet

- CT SizingDocument34 pagesCT SizingBijaya Kumar MohantyNo ratings yet

- 220 V DC Battery Sizing 220 KV Main Station 1Document25 pages220 V DC Battery Sizing 220 KV Main Station 1Madhu BTNo ratings yet

- ACT6000 User Guide 1.18Document38 pagesACT6000 User Guide 1.18sefovaraja100% (1)

- I-Test Wallem-Tanker-Chief Eng-2Document11 pagesI-Test Wallem-Tanker-Chief Eng-2Anonymous T54y2W100% (7)

- Battery Charger Sizing SS 1, Rev 03Document15 pagesBattery Charger Sizing SS 1, Rev 03Pramod B.Wankhade100% (1)

- Battery SizingDocument7 pagesBattery SizingAchint Kumar100% (2)

- 110V DC Battery Sizing Calculation For 132/11kV Primary Substation For Tender Purpose OnlyDocument10 pages110V DC Battery Sizing Calculation For 132/11kV Primary Substation For Tender Purpose OnlyDundikumarNo ratings yet

- Battery Sizing Design Basis TCEDocument85 pagesBattery Sizing Design Basis TCEjigyesh80% (5)

- Design Guide - Battery SizingDocument11 pagesDesign Guide - Battery Sizingrahulnegi191792% (12)

- Sizing switchgear batteries by handDocument9 pagesSizing switchgear batteries by handpcsamyNo ratings yet

- Arar-battery&Battery Charger 26.10.2004 CalDocument22 pagesArar-battery&Battery Charger 26.10.2004 Calsrigirisetty208No ratings yet

- Sizing Calculation of Battery ChargerDocument15 pagesSizing Calculation of Battery ChargerRavi Chandar83% (6)

- Capacity Calculation For VRLA Type (NMST) 2 V Cells:: ConsiderationsDocument9 pagesCapacity Calculation For VRLA Type (NMST) 2 V Cells:: ConsiderationsPramod B.Wankhade100% (4)

- AC UPS battery sizing and rack dimensionsDocument12 pagesAC UPS battery sizing and rack dimensionscherif yahyaoui100% (1)

- UPS & Battery SizingDocument0 pagesUPS & Battery SizingShrikant Kajale100% (1)

- Battery & Battery Charger Calculation RevADocument27 pagesBattery & Battery Charger Calculation RevAhosein30No ratings yet

- Transformer Sizing CalculationDocument9 pagesTransformer Sizing CalculationMirko Yanque TomasevichNo ratings yet

- Battery Sizing Calculation KPD 981 Com E4 005 p0Document16 pagesBattery Sizing Calculation KPD 981 Com E4 005 p0drawler0% (1)

- Section 6 Battery SizingDocument54 pagesSection 6 Battery SizingAca ChchNo ratings yet

- Power and Distribution Transformers Sizing Calculations 8Document20 pagesPower and Distribution Transformers Sizing Calculations 8hashimelecNo ratings yet

- Cal-Mn Dastur T2117 Rev 2Document4 pagesCal-Mn Dastur T2117 Rev 2Shubham BaderiyaNo ratings yet

- Relay CoordinationDocument68 pagesRelay CoordinationrajuNo ratings yet

- SIZING TRANSFORMERS FOR LARGE MOTOR LOADSDocument20 pagesSIZING TRANSFORMERS FOR LARGE MOTOR LOADSserban_el100% (1)

- Transformer & DG SizingDocument10 pagesTransformer & DG Sizingvinaynagvanshi5No ratings yet

- Sizing Transformers With Large Motor LoadsDocument6 pagesSizing Transformers With Large Motor LoadsRajendra Prasad Shukla50% (2)

- Battery Bank CalculationDocument3 pagesBattery Bank CalculationJoshua Cm100% (1)

- Sizing Power Cables for Circuit Breaker Feeders (Part 1Document25 pagesSizing Power Cables for Circuit Breaker Feeders (Part 1akash_ing7683100% (1)

- SEO-Optimized Lighting Transformer TitleDocument8 pagesSEO-Optimized Lighting Transformer TitleShrikant KajaleNo ratings yet

- Cable Thermal Analysis Short Circuits EADocument19 pagesCable Thermal Analysis Short Circuits EAErsiAgoNo ratings yet

- Battery SizingDocument9 pagesBattery Sizingsitifarhani100% (1)

- 2 X 660MWNCC POWER PROJECT UPS SIZING CALCULATIONDocument5 pages2 X 660MWNCC POWER PROJECT UPS SIZING CALCULATIONkkumar_717405No ratings yet

- UPS Sizing CalcDocument2 pagesUPS Sizing CalcNagoor MeeranNo ratings yet

- Saudi Electricity Company: Eastern Operating Area Dammam, Saudi ArabiaDocument17 pagesSaudi Electricity Company: Eastern Operating Area Dammam, Saudi Arabiasrigirisetty208No ratings yet

- Datasheet-160MVA Generator Transformer PDFDocument16 pagesDatasheet-160MVA Generator Transformer PDFOm EliasNo ratings yet

- Sizing Calculation: Selection of UPS 3 Phase or 1 PhaseDocument18 pagesSizing Calculation: Selection of UPS 3 Phase or 1 PhasedhruvNo ratings yet

- HT Cable Sizing Selection Criteriafor 5Document9 pagesHT Cable Sizing Selection Criteriafor 5maheshNo ratings yet

- ALCAD Battery Size CalculationDocument3 pagesALCAD Battery Size CalculationmrtabiehNo ratings yet

- Ieee-485 Sizing Program (Ver.1, 7-22-11, Ms2003)Document8 pagesIeee-485 Sizing Program (Ver.1, 7-22-11, Ms2003)Ann DodsonNo ratings yet

- 06 - Short Circuit - ANSI PDFDocument50 pages06 - Short Circuit - ANSI PDFÁlvaro Alarcón MolinaNo ratings yet

- Battery Charger CalculationDocument7 pagesBattery Charger CalculationBimoBrillianta100% (2)

- Calculate Voltage Drop and Select Cable SizeDocument31 pagesCalculate Voltage Drop and Select Cable SizeCharlotte WilkinsonNo ratings yet

- Cable SizingDocument14 pagesCable SizingAnupam0103No ratings yet

- CT Sizing For MalawiDocument2 pagesCT Sizing For MalawiDharmenderSinghChoudharyNo ratings yet

- 5-Power & Control Cables PDFDocument11 pages5-Power & Control Cables PDFAnonymous ufMAGXcskMNo ratings yet

- 22 Ts 110v Battery ChargerDocument22 pages22 Ts 110v Battery ChargerRamesh AnanthanarayananNo ratings yet

- Design of Earthing System For 230 KV High Voltage Substation by ETAP 12.6 SoftwareDocument4 pagesDesign of Earthing System For 230 KV High Voltage Substation by ETAP 12.6 SoftwareEditor IJTSRD100% (1)

- Transformer and DG Set SelectionDocument3 pagesTransformer and DG Set SelectionZIPDASHNo ratings yet

- ACSR Conductor SizingDocument13 pagesACSR Conductor SizingraghuvarmaNo ratings yet

- NGR sizing calculationsDocument4 pagesNGR sizing calculationsYogesh Mittal100% (1)

- Battery Sizing TemplateDocument15 pagesBattery Sizing TemplateJAY PARIKHNo ratings yet

- Training Programme For Assistant Engineers (2009-10) : Topic: DC Batteries and Battery ChargersDocument3 pagesTraining Programme For Assistant Engineers (2009-10) : Topic: DC Batteries and Battery ChargersashokNo ratings yet

- Tech Spec PQR-2021-11-08-12 29 10Document79 pagesTech Spec PQR-2021-11-08-12 29 10patilshailesh123No ratings yet

- 125 VDC Power Supply System for TermoCentro Combined Cycle ProjectDocument9 pages125 VDC Power Supply System for TermoCentro Combined Cycle ProjectLuis Angel PatiñoNo ratings yet

- DigSilent Training ModuleDocument18 pagesDigSilent Training Moduletosikur rahmanNo ratings yet

- GE Multilin Relay Selection GuideDocument40 pagesGE Multilin Relay Selection GuideSaravanan Natarajan100% (1)

- Oil Circuit Breakers PF TestDocument35 pagesOil Circuit Breakers PF TestPriambudi Pujihatma100% (1)

- Taylor SeriesDocument4 pagesTaylor SeriesPriambudi PujihatmaNo ratings yet

- MCMTopsis PDFDocument7 pagesMCMTopsis PDFPriambudi PujihatmaNo ratings yet

- Batt SizingDocument58 pagesBatt SizingPriambudi PujihatmaNo ratings yet

- Curve DesginationDocument3 pagesCurve DesginationJavier Valencia MurilloNo ratings yet

- Brayton CycleDocument4 pagesBrayton CyclePriambudi Pujihatma0% (1)

- Gas Turbine PrincipleDocument16 pagesGas Turbine PrinciplePriambudi PujihatmaNo ratings yet

- AGC Model Using Matlab SimulinkDocument12 pagesAGC Model Using Matlab SimulinkEléctrico IngenieríaNo ratings yet

- CP (T) DT: AIR FuelDocument3 pagesCP (T) DT: AIR FuelPriambudi PujihatmaNo ratings yet

- ArresterFacts 013 - Understanding Arrester Discharge VoltageDocument8 pagesArresterFacts 013 - Understanding Arrester Discharge VoltagePriambudi PujihatmaNo ratings yet

- Sanford (UW)Document12 pagesSanford (UW)Priambudi PujihatmaNo ratings yet

- Weibull ApplicationDocument10 pagesWeibull ApplicationPriambudi PujihatmaNo ratings yet

- KX TG6461 Service ManualDocument48 pagesKX TG6461 Service ManualAk OraNo ratings yet

- Hi-Target Qmini ManualDocument32 pagesHi-Target Qmini Manualtheengineer3100% (1)

- Conversion of Internal Combustion Car Into Electric CarDocument15 pagesConversion of Internal Combustion Car Into Electric CarRoha AdnanNo ratings yet

- The Supply Chain For Electric Vehicle BatteriesDocument21 pagesThe Supply Chain For Electric Vehicle BatteriesProbonogoya Erawan Sastroredjo100% (2)

- Batteries and Primitive Survival E Book 2008Document333 pagesBatteries and Primitive Survival E Book 2008MoreMoseySpeedNo ratings yet

- Olympus - Delta Test Stand Guide PDFDocument8 pagesOlympus - Delta Test Stand Guide PDFEduardo ArdilesNo ratings yet

- 5 Secret Tips To Maintain Your Beauty: Peeling Ion Treatment Light TherapyDocument2 pages5 Secret Tips To Maintain Your Beauty: Peeling Ion Treatment Light TherapyNicole WeatherleyNo ratings yet

- Heavy Vehicle Electrical Wiring CodeofpracDocument20 pagesHeavy Vehicle Electrical Wiring Codeofpracsantiagoest100% (1)

- Isl 88732Document2 pagesIsl 88732MasUd MzNo ratings yet

- Ia - Automotive Servicing NC Ii PDFDocument36 pagesIa - Automotive Servicing NC Ii PDFEagle ZartNo ratings yet

- AlternatorDocument33 pagesAlternatorG Sandeep KumarNo ratings yet

- Generator, Starter, Battery and Spark Plug Repair InstructionsDocument10 pagesGenerator, Starter, Battery and Spark Plug Repair InstructionsSoporte Tecnico AutoMotrixNo ratings yet

- Caterpillar XQ1250G Containerized Gas Generator SetDocument6 pagesCaterpillar XQ1250G Containerized Gas Generator SetMacAllister MachineryNo ratings yet

- King Gu100is Qt2a 4520 60 240 3FNDocument2 pagesKing Gu100is Qt2a 4520 60 240 3FNAdrian DivitaNo ratings yet

- Invacare Lynx L-3 and L-4 Owner's ManualDocument52 pagesInvacare Lynx L-3 and L-4 Owner's ManualJustin RenbergNo ratings yet

- Hoppecke RTM2-RPM2 Ficha (Cargador) (Ingles 2017) PDFDocument2 pagesHoppecke RTM2-RPM2 Ficha (Cargador) (Ingles 2017) PDFJuan Carlos Rubio Fresco0% (1)

- BL-104 Portable X-Ray User ManualDocument15 pagesBL-104 Portable X-Ray User ManualEng.yahya tawiliNo ratings yet

- GC 02 Datasheet v01 190314 English A4Document2 pagesGC 02 Datasheet v01 190314 English A4zaporoyets1No ratings yet

- Mil e 7016FDocument48 pagesMil e 7016Fgustavojorge12No ratings yet

- Cat C32 SubmittalDocument68 pagesCat C32 SubmittalAnh VuNo ratings yet

- Manual Recognoil 2015 ENGDocument29 pagesManual Recognoil 2015 ENGGoranNo ratings yet

- Automotive Electronics SolutionsDocument36 pagesAutomotive Electronics Solutionssorteabhay6877No ratings yet

- UPS Project NewDocument34 pagesUPS Project NewKrishna RajNo ratings yet

- Portable Mobile Charger Presentation OutlineDocument11 pagesPortable Mobile Charger Presentation OutlineAbirami Mani57% (7)

- Geopro 10 Ground Penetrating Radar Manual-2022Document48 pagesGeopro 10 Ground Penetrating Radar Manual-2022Nur Hidayat NurdinNo ratings yet

- ROTALIGN-Ultra Operating-Instructions ALI-209.855!01!09 2.06 GDocument165 pagesROTALIGN-Ultra Operating-Instructions ALI-209.855!01!09 2.06 GDon Freeman100% (1)

- Scrubbers CatalogDocument64 pagesScrubbers CatalogNewVersion_FacilityManagementNo ratings yet

- WWW - Usbr.gov Power Data Fist Fist4 1b Fist4 1b PDFDocument67 pagesWWW - Usbr.gov Power Data Fist Fist4 1b Fist4 1b PDFടോണി തോമസ്No ratings yet