Professional Documents

Culture Documents

Common Mode Suppression Chokes: EV/EH Series

Uploaded by

Nattanapong KongtrakulOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Common Mode Suppression Chokes: EV/EH Series

Uploaded by

Nattanapong KongtrakulCopyright:

Available Formats

RFI suppression chokes

EV/EH series

Common mode suppression chokes

Current rating up to 5A

Broadband attenuation characteristics

Low magnetic leakage flux

UL rated materials

RoHS compliant

By March 2005

Environmental ratings

Maximum continuous operating voltage:

Power operating frequency:

Overcurrent:

High potential test voltage

winding-to-winding @ 25C:

Temperature range (operation and storage):

Climatic class per IEC68:

Flammability corresponding to:

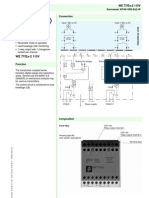

Typical electrical schematic

250V @ 50C

dc to 400Hz @ 50C

1.5x Inominal for 1 minute, once per hour

3000VAC, 60sec, guaranteed

2000V, 50Hz, 2sec, factory test

-250C to +1000C

25/100/21

UL94-V0

Test conditions

Measuring frequency:

Resistance:

Electrical characteristics:

10kHz; 5mA < 16H;

500A > 16H < 160H;

50A > 160H < 16mH;

50mV > 16mH < 160mH;

inductance tolerance 30%

Tolerance max. 15% @ 25C; 20m, 1A;

> 20m 200m 100mA; > 200m 2V 10mA

@ 25C 2C

Features and benefits

Typical applications

Common mode suppression chokes are

Current rating up to 5A

Input filters for switch mode power

mainly used to filter noise on AC power lines.

Compact and light weight

supplies

Noise on commercial power lines could enter

Low magnetic leakage flux

Filters to reduce leaking noise

the equipment and disturb the proper function.

Sectional winding

TVs, VCRs, multimedia and audio

Noise generated by the equipment for example

Standard foot print

equipment

from switch mode power supplies need to be

Broad range of available inductances and

Office automation, communications

filtered and the spread of such generated

current ratings

and other electronic devices

noise need to be suppressed. Common mode

Custom specific versions

Electric ballast

suppression chokes together with line bypass

Schaffner offers you also EMI measurement

AC/AC converters

capacitors building an AC EMI suppression

service to verify that your design will pass

filter device.

the required safety standards.

> Components > EV/EH series

Choke selection table

EV Choke

EV

EV

EV

EV

EV

EV

EV

EV

EV

EV

EV

EV

EV

EV

EV

EV

EV

EV

EV

EV

EV

EV

EV

EV

EV

20-0.3-02-33M

20-0.5-02-18M

20-0.8-02-5M6

20-1.0-02-3M9

20-1.2-02-3M3

20-1.5-02-1M8

20-2.0-02-0M8

24-0.5-02-44M

24-0.8-02-18M

24-1.0-02-10M

24-1.5-02-4M5

24-2.0-02-2M5

24-3.0-02-1M2

24-4.0-02-0M5

28-1.0-02-36M

28-1.5-02-20M

28-2.0-02-11M

28-3.0-02-5M0

28-4.0-02-2M3

28-5.0-02-1M1

35-1.0-02-90M

35-2.0-02-20M

35-3.0-02-10M

35-4.0-02-5M0

35-5.0-02-3M6

EH Choke

EH

EH

EH

EH

EH

EH

EH

EH

EH

EH

EH

EH

EH

EH

EH

EH

EH

EH

EH

EH

EH

EH

EH

EH

EH

20-0.3-02-33M

20-0.5-02-18M

20-0.8-02-5M6

20-1.0-02-3M9

20-1.2-02-3M3

20-1.5-02-1M8

20-2.0-02-0M8

24-0.5-02-44M

24-0.8-02-18M

24-1.0-02-10M

24-1.5-02-4M5

24-2.0-02-2M5

24-3.0-02-1M2

24-4.0-02-0M5

28-1.0-02-36M

28-1.5-02-20M

28-2.0-02-11M

28-3.0-02-5M0

28-4.0-02-2M3

28-5.0-02-1M1

35-1.0-02-90M

35-2.0-02-20M

35-3.0-02-10M

35-4.0-02-5M0

35-5.0-02-3M6

Lnominal

(30%)

DC resistance

R

Rated current

I (50C)

Weight

[mH]

[m]

[A]

[g]

33

18

5.6

3.9

3.3

1.8

0.82

44

18

10

4.5

2.5

1.2

0.5

36

20

11

5

2.3

1.1

90

20

10

5

3.6

1780

725

245

168

127

72

38

1250

438

244

116

62

29

16

591

282

162

79

40

27

628

150

72

53

33

0.3

0.5

0.8

1.0

1.2

1.5

2.0

0.5

0.8

1.0

1.5

2.0

3.0

4.0

1.0

1.5

2.0

3.0

4.0

5.0

1.0

2.0

3.0

4.0

5.0

10

10

10

10

10

10

10

18

18

18

18

18

18

18

31

31

31

31

31

31

70

70

70

70

70

All wires rated 130C or higher

Typical choke attenuation

Per CISPR 17; 50/50 asym

EV/EH 20 types

EV/EH 24 types

EV/EH 28 types

EV/EH 35 types

A = 33mH

A = 44mH

A = 36mH

A = 90mH

B = 18mH

B = 18mH

B = 20mH

B = 20mH

C = 5.6mH

C = 10mH

C = 11mH

C = 10mH

D = 3.9mH

D = 4.5mH

D = 5mH

D = 5mH

E = 3.3mH

E = 2.5mH

E = 2.3mH

E = 3.6mH

F = 1.8mH

F = 1.2mH

F = 1.1mH

G = 0.8mH

G = 0.5mH

> Components > EV/EH series

Mechanical Data

EV 24, EV 28

EV 20

1

4

1

B

2

3

A

D

E

E

F

EV 35

EH 20 to EH 35

1

B

B

A

2

3

A

C

C

E

F

E D

F

Dimensions

EV 20

EV 24

EV 28

EV 35

EH 20

EH 24

EH 28

EH 35

21.0

24.6

29.2

36.0

21.0

24.0

28.0

36.0

16.0

17.4

21.0

24.5

21.0

24.0

28.0

36.0

25.0

29.1

34.7

42.7

17.8

20.0

22.9

27.7

4.0

4.0

4.0

4.0

4.0

4.0

4.0

4.0

0.8

0.8

0.8

1.2

0.8

0.8

0.8

1.0

13.0

13.0

13.0

21.0

13.0

21.0

24.0

30.0

10.0

10.0

10.0

15.0

10.0

15.0

20.0

25.0

All dimensions in mm; 1 inch = 25.4mm

Tolerances according: ISO2768 / EN22768

Your local partner: To find your local partner within Schaffners global network, please go to www.schaffner.com

March 2005

You might also like

- Analog Circuit Design: A Tutorial Guide to Applications and SolutionsFrom EverandAnalog Circuit Design: A Tutorial Guide to Applications and SolutionsRating: 3.5 out of 5 stars3.5/5 (6)

- Cirucit Breakers VCB y VCSDocument0 pagesCirucit Breakers VCB y VCSNelson Garvizu0% (1)

- Thermo Scientific Emcpro Plus: Advanced EMC Test System For Compliance Testing To IEC/EN StandardsDocument4 pagesThermo Scientific Emcpro Plus: Advanced EMC Test System For Compliance Testing To IEC/EN StandardsluizsameNo ratings yet

- A Compilation by Virendra SahdevDocument108 pagesA Compilation by Virendra SahdevVirendra Sahdev100% (1)

- 7PA27 30 en-AuxiliaryRelayDocument5 pages7PA27 30 en-AuxiliaryRelayLê Văn Phú100% (1)

- Delivery Programme: Soft Starter DS6, 22kW Part No. DS6-340-22K-MX Article No. 103086Document3 pagesDelivery Programme: Soft Starter DS6, 22kW Part No. DS6-340-22K-MX Article No. 103086Willians RodriguesNo ratings yet

- Datos Tecnicos Leroy Sommer Lsa40Document12 pagesDatos Tecnicos Leroy Sommer Lsa40caprit_her_771605No ratings yet

- Sa60 Stadspec 05112008Document2 pagesSa60 Stadspec 05112008Norbert SteffensNo ratings yet

- MFA160 :: ROAL Living EnergyDocument5 pagesMFA160 :: ROAL Living EnergyroalscribdNo ratings yet

- User Manual Sepam 20-1Document78 pagesUser Manual Sepam 20-1Ursula JohnsonNo ratings yet

- Protect 3-pole 3A-4A thermomagnetic circuit breakerDocument2 pagesProtect 3-pole 3A-4A thermomagnetic circuit breakerOliver TaimbudNo ratings yet

- SCR/SCRF Series: Industry's First Choice For Time-Tested Proven ReliabilityDocument8 pagesSCR/SCRF Series: Industry's First Choice For Time-Tested Proven ReliabilityAdrian M FahriNo ratings yet

- MFA160 :: ROAL Living EnergyDocument5 pagesMFA160 :: ROAL Living EnergyroalscribdNo ratings yet

- 7SG117 Argus 7: Answers For EnergyDocument10 pages7SG117 Argus 7: Answers For EnergygovindarulNo ratings yet

- 6.3kA PerformanceDocument36 pages6.3kA PerformanceedgarcooNo ratings yet

- MFA160 :: ROAL Living EnergyDocument4 pagesMFA160 :: ROAL Living EnergyroalscribdNo ratings yet

- Kepco Gives You Zero-Up Programmability in An Affordable Power ModuleDocument6 pagesKepco Gives You Zero-Up Programmability in An Affordable Power ModulerrebollarNo ratings yet

- Zelio Time Re11rmmwDocument2 pagesZelio Time Re11rmmwleanhhaievn_95463721No ratings yet

- Vacuum ContactorDocument4 pagesVacuum ContactorArun Kumar0% (1)

- DC/DC Converters: FeaturesDocument4 pagesDC/DC Converters: FeatureskhoshnamaNo ratings yet

- Power Supply: 1 LED Constant Current Water-Proof Switching Power SupplyDocument10 pagesPower Supply: 1 LED Constant Current Water-Proof Switching Power Supplybacuoc.nguyen356No ratings yet

- RCB600 :: ROAL Living EnergyDocument10 pagesRCB600 :: ROAL Living EnergyroalscribdNo ratings yet

- RM 35 TF 30Document2 pagesRM 35 TF 30Marco GrijalbaNo ratings yet

- Zelio Control RM35LM33MWDocument6 pagesZelio Control RM35LM33MWZainul FananiNo ratings yet

- Zelio Control RM22UA33MRDocument7 pagesZelio Control RM22UA33MRArief SetyawanNo ratings yet

- Componentes LSDocument52 pagesComponentes LSrhusseinpos4765No ratings yet

- Excelitas Analog Optical Isolators 07 PDFDocument2 pagesExcelitas Analog Optical Isolators 07 PDFRamin FarzanehNo ratings yet

- Test Equipment and Accessories for Circuit Breaker ApplicationsDocument5 pagesTest Equipment and Accessories for Circuit Breaker ApplicationsParichay GuptoNo ratings yet

- Ac500 XCDocument2 pagesAc500 XCthlsatheeshNo ratings yet

- We77 Ex2Document2 pagesWe77 Ex2melkote_1985No ratings yet

- SCH2936 SinglePhaseInverter v3-1Document2 pagesSCH2936 SinglePhaseInverter v3-1KybernetikumNo ratings yet

- AXOS5 Compact Immunity Test SystemDocument8 pagesAXOS5 Compact Immunity Test Systemanon_181944212No ratings yet

- 19.2kW -48V 400A Modular Power SystemDocument2 pages19.2kW -48V 400A Modular Power SystemPhillip SmithNo ratings yet

- ABB S203-C20 - Miniature Circuit Breakers MCBs - Modular DIN Rail ProductsDocument4 pagesABB S203-C20 - Miniature Circuit Breakers MCBs - Modular DIN Rail Productsvs.prasannaNo ratings yet

- SFA350 :: ROAL Living EnergyDocument6 pagesSFA350 :: ROAL Living EnergyroalscribdNo ratings yet

- E RelayDocument8 pagesE RelayRadhakrishnan VgNo ratings yet

- Introduction To EMC: Electronic ComponentsDocument26 pagesIntroduction To EMC: Electronic ComponentsLakshitha Prabath WijesingheNo ratings yet

- EMC For Dummies e News FinalDocument26 pagesEMC For Dummies e News FinalWilson MartinezNo ratings yet

- MFA160 :: ROAL Living EnergyDocument5 pagesMFA160 :: ROAL Living EnergyroalscribdNo ratings yet

- HEC 7S - RuDocument6 pagesHEC 7S - Rut_syamprasadNo ratings yet

- Zelio Control RM35LM33MWDocument6 pagesZelio Control RM35LM33MWOgreson OgreNo ratings yet

- Ceramic Transient Voltage Suppressors, CTVS: Protection Standards For Electromagnetic Compatibility (EMC)Document9 pagesCeramic Transient Voltage Suppressors, CTVS: Protection Standards For Electromagnetic Compatibility (EMC)vspuriNo ratings yet

- 61573268231Document2 pages61573268231MxgxxngNo ratings yet

- Data Sheet: Analogue Meters With Moving - Iron MovementDocument4 pagesData Sheet: Analogue Meters With Moving - Iron MovementKali MuthuNo ratings yet

- EMI EMC Test ParametersDocument2 pagesEMI EMC Test ParametersSravan CholeteNo ratings yet

- ABB T1maxDocument6 pagesABB T1maxharrisvasNo ratings yet

- Rugged Multimeters for Electrical TestingDocument2 pagesRugged Multimeters for Electrical TestingKosong SudahanNo ratings yet

- Telemecanique ContactorDocument26 pagesTelemecanique ContactorgeoghoNo ratings yet

- V Series Rectifier 102407 PDFDocument6 pagesV Series Rectifier 102407 PDFchiquilin2No ratings yet

- RE11RCMUDocument5 pagesRE11RCMUbogdy0073No ratings yet

- Zelio Control Relays - RM4UB35Document8 pagesZelio Control Relays - RM4UB35Variya DharmeshNo ratings yet

- RM22TR31 Product Data SheetDocument7 pagesRM22TR31 Product Data SheetAbdul Majeed SurmawalaNo ratings yet

- Smr50rh Spec en 15.11Document4 pagesSmr50rh Spec en 15.11cartimon1No ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- TestDocument1 pageTestNattanapong KongtrakulNo ratings yet

- Advance English Conversation 51-100Document79 pagesAdvance English Conversation 51-100Nattanapong KongtrakulNo ratings yet

- Alstom in Thailand: 40 Years of Contribution To Transport and Energy InfrastructuresDocument5 pagesAlstom in Thailand: 40 Years of Contribution To Transport and Energy InfrastructuresNattanapong KongtrakulNo ratings yet

- Thailand FactsheetDocument5 pagesThailand FactsheetNattanapong KongtrakulNo ratings yet

- Lightning Observation Station at The Rzeszow University of Technology, PolandDocument2 pagesLightning Observation Station at The Rzeszow University of Technology, PolandNattanapong KongtrakulNo ratings yet

- E. Part 1Document3 pagesE. Part 1Nattanapong KongtrakulNo ratings yet

- E. Part 2Document6 pagesE. Part 2Nattanapong KongtrakulNo ratings yet

- Cattareya CHAAllDocument190 pagesCattareya CHAAllNattanapong KongtrakulNo ratings yet

- Understanding Machine Learning Theory AlgorithmsDocument449 pagesUnderstanding Machine Learning Theory AlgorithmsHigor EduardoNo ratings yet

- 00293729Document6 pages00293729Nattanapong KongtrakulNo ratings yet

- Cascaded TransformersDocument3 pagesCascaded TransformersGiovanni SatriaNo ratings yet

- Advance English Conversation 51-100Document79 pagesAdvance English Conversation 51-100Nattanapong KongtrakulNo ratings yet

- MaxwellSV ElectrostaticDocument80 pagesMaxwellSV Electrostaticravijat12No ratings yet

- Understanding Machine Learning Theory AlgorithmsDocument449 pagesUnderstanding Machine Learning Theory AlgorithmsHigor EduardoNo ratings yet

- TI HF Antenna CookbookDocument29 pagesTI HF Antenna CookbookmikcomiNo ratings yet

- Understanding Ferrite BeadDocument3 pagesUnderstanding Ferrite BeadLaercio MarquesNo ratings yet

- Asian Development Tour 2015: Date LocationDocument10 pagesAsian Development Tour 2015: Date LocationNattanapong KongtrakulNo ratings yet

- APC MGE Galaxy 3500 Operation_Manual (EN)Document48 pagesAPC MGE Galaxy 3500 Operation_Manual (EN)Neto SantosNo ratings yet

- Transistor MD 1802Document11 pagesTransistor MD 1802Chilukuri RajeshNo ratings yet

- Asynchronous MachineDocument15 pagesAsynchronous MachineboumedienNo ratings yet

- Singel State TransistorDocument7 pagesSingel State Transistorkaran007_mNo ratings yet

- EM 6400 ManualDocument80 pagesEM 6400 Manualraj_ritu_aNo ratings yet

- Bernal Power FlowDocument7 pagesBernal Power FlowGS AshishNo ratings yet

- Tutorial CH 2 SolutionDocument6 pagesTutorial CH 2 SolutionRandy Marzan100% (1)

- Battery Replacement GuideDocument4 pagesBattery Replacement Guidest_vasuNo ratings yet

- Question Bank M& I FinalDocument4 pagesQuestion Bank M& I FinalVel MuruganNo ratings yet

- Product Specifications Product Specifications: Cellmax Cellmax - O O - Cpuse CpuseDocument2 pagesProduct Specifications Product Specifications: Cellmax Cellmax - O O - Cpuse CpuseВадим ЧеховскийNo ratings yet

- Electronic Shop PracticeDocument6 pagesElectronic Shop PracticeAbid TonmoyNo ratings yet

- 11 kV, 22 kV or 33 kV Air-Insulated Switchgear SpecificationDocument29 pages11 kV, 22 kV or 33 kV Air-Insulated Switchgear SpecificationAnoop Ks0% (1)

- MagnetismDocument73 pagesMagnetismjohnNo ratings yet

- SP Singhania University B.Tech Electrical Engineering Comprehensive Viva Voce QuizDocument5 pagesSP Singhania University B.Tech Electrical Engineering Comprehensive Viva Voce QuizViru JaiNo ratings yet

- Digital Coin TosserDocument15 pagesDigital Coin TosserDayo BalogunNo ratings yet

- UNIT II - Multi Core ArchitectureDocument102 pagesUNIT II - Multi Core ArchitectureVivek DubeyNo ratings yet

- 703 01Document124 pages703 01123adpNo ratings yet

- Short Circuit Analysis of DFIGDocument13 pagesShort Circuit Analysis of DFIGjigsaiNo ratings yet

- Analog VLSI Design: Nguyen Cao QuiDocument72 pagesAnalog VLSI Design: Nguyen Cao QuiKhuong LamborghiniNo ratings yet

- CENTRAL WAREHOUSING CORPORATION ONLINE EXAMDocument15 pagesCENTRAL WAREHOUSING CORPORATION ONLINE EXAMRaja RamboNo ratings yet

- JHS 182 Service ManualDocument168 pagesJHS 182 Service Manualbg2tt100% (5)

- Lab 11 DAC and ADC Full PackageDocument5 pagesLab 11 DAC and ADC Full PackageLoveWorldCanadaNo ratings yet

- Thermocouple Wire Size and Resistance TableDocument1 pageThermocouple Wire Size and Resistance TablePeter PlumNo ratings yet

- Especificaciones Motores de ArranqueDocument19 pagesEspecificaciones Motores de ArranqueVictor LuqueNo ratings yet

- Introduction to Laser PhysicsDocument27 pagesIntroduction to Laser PhysicsVijay Krishna KanthNo ratings yet

- ITYS-E 6-10kVA MSMITYTWXX31-GB 00Document24 pagesITYS-E 6-10kVA MSMITYTWXX31-GB 00Anuradhe ThilakarathnaNo ratings yet

- Ese ABB PDFDocument4 pagesEse ABB PDFJatinBatraNo ratings yet