Professional Documents

Culture Documents

F560 Appendices

Uploaded by

LyteC123Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

F560 Appendices

Uploaded by

LyteC123Copyright:

Available Formats

APPENDIX A THEORY OF CALCULATIONS

Version 1.1 Rev October 2006

APPENDIX A.

THEORY OF CALCULATIONS

DATA PROCESSING AND CONVERSION

REACTION PROCESS AND MEASUREMENT POINTS

Measurements are taken at 9 second intervals over a 10 minute period. This results in

a maximum throughput of 400 photometric tests per hour. The F560 analyser has a 9

second cycle. During each cycle the system either adds sample, adds reagent, mixes

or takes a measurement. Measurements may be taken at one or two wavelengths,

depending on the assay specific chemistry parameters.

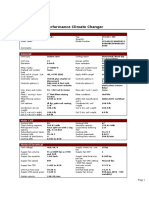

F560 Timeline

Measurement point

Time (seconds)

Measurement range 1

Measurement range 2

WATER BLANK

A water blank is performed on each cell during the washing process prior to R1

addition. This data is used to correct for cuvette variation and also to monitor the

degree of staining of the cuvettes.

ABSORBANCE DATA

Measurement details for each sample are defined on the Chemistry Parameters

menu (Parameter F6, Normal). Measurement conditions for each method are

different therefore samples should be corrected with a water blank.

W1: Water blank with primary wavelength

S1: Absorbance of sample with primary wavelength

W2: Water blank with secondary wavelength

S2: Absorbance of sample with secondary wavelength

Page 409

Operator Manual

APPENDIX A THEORY OF CALCULATIONS

Version 1.1 Rev October 2006

Absorbance of sample shows ABS1-68 for measurement points 1 to 68. The formula

for absorbance is as follows:

Primary wavelength: ABS1-68 = (S1-W1) 1-68

Secondary wavelength: ABS1-68 = (S2-W2) 1-68

Total wavelength: ABS1-68 = (S1-W1) 1-68 - (S2-W2) 1-68

MEASUREMENT PRINCIPLES

The system measures the standard sample, calculates absorbance differences

(ABS) from the reaction process (time course data), constructs the calibration curve

and converts to a concentration value based on the calibration curve data. Two assay

types are available, one is an end-point based method (END), the other is a ratebased method (RATE).

END-POINT METHOD (END)

The median value is calculated from the measurement range 1 and 2. The

absorbance value in the measurement points is shown as X.

If the number of values of n is odd:

X = X n +1

2

If the number of values of n is even:

X =

1

Xn + Xn

+1

2 2

2

The formula for ABS using an end-point method is as follows:

ABS = Median value of measurement points 2 - Median value of measurement point

1 (mABS)

Page 410

Operator Manual

APPENDIX A THEORY OF CALCULATIONS

Version 1.1 Rev October 2006

RATE METHOD

The variation of the reaction in a measurement point is approximated by primary

regression. Calculate the variation of the reaction between the measurement point 1

and measurement point 2.

The formula of the primary regression is as follows:

Y = a + bX

(Y: Absorbance X: Time a : Intercept b : Slope)

The formula of slope b if the number of data points is n is as follows:

n

n n

n xi yi xi yi

i =1 i =1

b = i =1

2

n

n

2

n xi xi

i =1

i =1

The formula of ABS for a rate-method is as follows:

ABS = The slope of measurement point 2 - The slope of measurement point 1

(the units are mABS/minute).

REAGENT BLANK CORRECTION

The reagent may have an inherent absorbance that may interfere with the calculation

of concentration from the absorbance values, this may vary slightly over time, or with

different reagent lots. Therefore a reagent blank measurement should be performed

on the first round of each day or after exchanging reagent bottles.

There are 3 methods for reagent blank measurement.

1. Reagent blank measurement without sample added

2. Reagent blank measurement with system water as sample

3. Reagent blank measurement with saline solution as a sample on the ASP tray

Page 411

Operator Manual

APPENDIX A THEORY OF CALCULATIONS

Version 1.1 Rev October 2006

For methods 1 and 2 above, time-course data for the reagent blank and cuvette blank

is saved for each method. These values will be used to offset the absorbance during

measurement of test samples.

Method 3 is used when a one point offset is performed using saline as S1.

ABSS1 - ABSS68= Time course of sample absorbance value

ABSSW

= Cuvette blank absorbance value during sample measurement

ABSR1 - ABSR68= Absorbance value of reagent blank time course

ABSRW

= Cuvette blank absorbance value during reagent blank measurement

Using the above definitions, the time course calculation used to obtain the change in

absorbance (ABS) will be as follows:

When a reagent blank is not used.

Time course absorbance value = (ABSS1 - ABSSW) - (ABSS68 - ABSSW)

When a reagent blank is used.

Time course absorbance value = ((ABSS1 -ABSSW) - (ABSR1- ABSRW)) - ((ABSS68ABSSW)-(ABSR68-ABSRW))

When method 3 is used (Reagent blank measurement with saline solution as a

sample on the ASP tray).

Time course absorbance value = (ABSS1- ABSSW) - (ABSS68 - ABSSW)

Page 412

Operator Manual

APPENDIX A THEORY OF CALCULATIONS

Version 1.1 Rev October 2006

EXAMPLES OF ENDPOINT ASSAY METHODS

END1: 1 POINT END METHOD

ABS = The median of the measurement range

For a single-shot, single reagent R1 assay:

ABS

measurement range

Time

For a two shot, 2 step R2 assay:

measurement range

ABS

dispensing of R2 Reagent

Time

Page 413

Operator Manual

APPENDIX A THEORY OF CALCULATIONS

Version 1.1 Rev October 2006

END2: 2 POINT END METHOD

ABS = The median value of measurement range 2 The median value of

measurement range 1

For a single shot, single reagent R1 assay:

ABS

measurement range 2

measurement range 1

without R2 reagent

Time

ABS = The median value of measurement range 2 The median value of

measurement range 1

* (S+R1/S+R1+R2)

S: Sample volume

R1: R1 volume

R2: R2 volume

For a two shot, 2 step R2 assay.

measurement range 2

ABS

measurement range 1

dispensing of R2 Reagent

Time

Page 414

Operator Manual

APPENDIX A THEORY OF CALCULATIONS

Version 1.1 Rev October 2006

EXAMPLES OF RATE BASED METHODS

RATE1: 1 POINT RATE-METHOD

ABS = The slope of the measurement range

For an R2, 2 shot assay method

ABS

measurement range

dispensing

of R2 Reagent

Time

For a single step one shot assay method.

ABS

measurement range

Time

RATE2: 2 POINT RATE METHOD

ABS = The slope of the measurement range 2 The slope of the measurement

range 1

ABS

measurement range 1

measurement range 2

Dispensing

of R2 reagent

Time

Page 415

Operator Manual

APPENDIX A THEORY OF CALCULATIONS

Version 1.1 Rev October 2006

MEASUREMENT RESULT CHECK

Before the conversion of absorbance values and calculation of the concentration, it is

possible to perform the following checks:

Linearity Check

Absorbance Limit Check

Prozone Check

Duplicate Limit Check

Sensitivity Limit Check

These limit checks can be set on the Parameter, Normal 2 screen.

LINEARITY CHECK

The linearity of kinetic assays (RATE method) is calculated by measuring the

deviation of the reaction curve from linear behaviour. If the specified value is

exceeded, the system will show a LIN flag attached to the result indicating that the

sample has failed the linearity check.

When the measurement range is set as 1 point, measurement range 2 will be

checked. When the measurement range is set as 2 point, measurement range 2 will

also be checked- Measurement range 1 will be ignored.

Range of measuring range 2 (measurement point number) = n (n is 4 or greater).

Absorbance of starting point of measurement range 2 = ABS1 (Reagent blank is

subtracted).

Absorbance of the last point of measurement range 2 = ABSn (Reagent blank is

subtracted).

Page 416

Operator Manual

APPENDIX A THEORY OF CALCULATIONS

Version 1.1 Rev October 2006

ABS1 + ABS2

Movingaverage1 = ---------------------------------------2

ABS2 + ABS3

Movingaverage2 = ---------------------------------------2

ABS ( n 1 ) + ABS ( n )

Movingaverage ( n 1 ) = ---------------------------------------------------------2

The slope of the moving average for points 1 to 3 will be calculated by regression

analysis.

This will be ABSfirst.

The slope of the moving average for the last 3 points (n-3) to (n-1) will be calculated

by regression analysis.

This will be ABSlast.

The slope of the moving average over the measurement range, 1 to (n-1) will be

calculated by regression analysis.

This will be ABSslope.

ABSlast- 100 %

LinearityLimit = ABSfirst

-------------------------------------------------------ABSslope

ABSslope

ABSlast

ABSfirst

1 1 2 3 4 5 6 7 8 9 10 11 12 13

34 14 15 16 17 18 19 20 21 22 23 24 25 26

68

Measurement range 1

Measurement range 2

Moving average

Page 417

Operator Manual

APPENDIX A THEORY OF CALCULATIONS

Version 1.1 Rev October 2006

A Linearity check will not be performed if:

a. The Linearity Limit has not been set on the Parameter Normal2 screen

b. The Rate method has not been selected.

c. The ABSslope check threshold (mABS/min).

d. The ABSfirst -ABSlast check threshold (mABS/min).

e. The number of measurement points for the measurement range 2 is less than 4

points.

f. A higher priority error than LIN has occurred.

ABSORBANCE LIMIT CHECK

If samples of high concentration or high activity are measured, it may cause

erroneous test results due to substrate depletion. In order to establish the validity of

results, the reaction limit at the primary wavelength is defined. Samples with

measured ABS values that exceed this limit will be output with an ABS flag.

FOR A DECREASING REACTION:

Reaction

Select decrease for a reaction with decreasing absorbance.

Limit

3500 mAbs/10

(Absorbance values which are less than

the limit value are not used)

ABS

Abs limit

Water blank value

Measuring range

Page 418

Operator Manual

APPENDIX A THEORY OF CALCULATIONS

Version 1.1 Rev October 2006

FOR AN INCREASING REACTION:

Reaction

Select increase for a reaction with increasing absorbance.

Limit

25000mAbs/10 (Absorbance values which are greater than

the limit value are not used)

ABS

Abs limit

Water blank value

Measuring Range

ABSORBANCE OF LIMIT CHECK FLAGS

Table: Absorbance Limit Check Flags

Number

Explanation

Flag

Result output

All the points in measuring

range of primary wavelength

are within the limit.

N/A

All points in

measuring range will

be used for

absorbance

calculation.

All points in

measuring range will

be used for

absorbance

calculation.

Points which are

within the limit will be

used for absorbance

calculation.

More than 8 points in

measuring range of primary

wavelength are within the limit.

N/A

Only 2 points in measuring

range of primary wavelength

are within the limit

AB2

Only 1 point in measuring

range of primary wavelength is

within the limit.

AB1

No result.

All the points in measuring

range are outside the limit.

AB1

No result.

Page 419

Operator Manual

APPENDIX A THEORY OF CALCULATIONS

Version 1.1 Rev October 2006

Set limit value

Water Blank

Measurement range

The reaction progress of normal and out of range reactions (labels 1-5: see

preceeding table).

PROZONE CHECK FOR RATE ASSAYS

The prozone check is used to detect a high dose Hook effect occurring in

turbidimetric immunoassays with excess antigen levels.

This has the effect that very high activity samples produce absorbance values

equivalent to low samples and therefore an incorrect result may be reported for rate

assays.

The formula for the prozone check value P:

( ABS SL 2 F ABS SL 2 S ) ( t SL 2 F t SL 2 S )

P = ---------------------------------------------------------------------------------------------------------------------( ABS SL 1 F ABS SL 1 S ) ( t SL 1 F t SL 1 S )

SL1-S

Slope range 1 Start

1 - 26

1st measuring point of slope

range 1

SL1-F

Slope range 1 End

1 - 26 (SL1-F > SL1-S)

Last measuring point of slope

range 1

SL2-S

Slope range 2 Start

1 - 26

1st measuring point of slope

range 2

SL2-F

Slope range 2 End

1 - 26 (SL2-F > SL2-S)

Last measuring point of slope

range 2

Page 420

Operator Manual

APPENDIX A THEORY OF CALCULATIONS

Version 1.1 Rev October 2006

If the specified value is exceeded, the system will output these results with a PRO

flag attached.

A Prozone check is not performed for control samples or for samples with values

below the specified Sensitivity Limit.

S = ( ABS SL 1 F ABS SL 1 S ) ( t SL 1 F t SL 1 S )

ACTUAL MEASUREMENT VALUE

The absorbance of measurement points for the Prozone check range SL1 and SL2 is

represented by X.

The value X is the measurement value for SL1 and SL2 ( ABSSL1 and ABSSL2 ) for

the prozone limit check.

If n is odd i.e the mid-point within the range

X = Xn + 1

-----------2

If n is even i.e. the average of the 2 midpoints within the range

1

X = --- ( X n + X n

)

2 ----- + 1

2

2

PROZONE CHECK FORMULA

Actual measurement value P is defined if the ranges SL1 and SL2 are defined.

P =ABSSL1-ABSSL2

Actual measurement value P is defined if the range SL1 is defined.

P = ABSSL1 - ABSwaterblank ( ABSreagent blank is not subtracted)

If Upper is selected

Error if P > Prozone value (Prozone value is defined on the display menu)

If Lower is selected

Error if P < Prozone value

(Prozone value is defined on the display menu)

Page 421

Operator Manual

APPENDIX A THEORY OF CALCULATIONS

Version 1.1 Rev October 2006

SENS CHECK FORMULA

The actual measurement value for S (Sens) is defined by the following formula

whether SL1 or SL1 and SL2 ranges are defined.

S = ABSSL1 - ABSwaterblank (ABSreagent blank is not subtracted)

When "S < Sens value", Prozone Limit Check is not performed.

(Sens value is defined on the display menu)

CALIBRATION

MEASUREMENT PRINCIPLES OF CALIBRATION

By measuring a set of calibrators with known concentrations and calculating the

ABS values, a calibration factor can be defined:

ABS calibrator = f ( concentration calibrator )

The unknown concentration of a sample can be determined from the factor in the

above equation.

concentration sample = f inverse ( ABS sample )

CALIBRATION CHECK

Standards and Calibrators are measured in duplicate or triplicate. The following

checks are carried out if the functions are enabled on the Parameters Normal2 menu.

DUPLICATE LIMIT (ALLOWABLE VARIATION LIMIT)

If a Standard sample is set to be measured 2 or 3 times and the absorbance

difference between the measurements is larger than the threshold value a Duplicate

Limit error flag is generated (DUP).

Page 422

Operator Manual

APPENDIX A THEORY OF CALCULATIONS

Version 1.1 Rev October 2006

The absorbance difference is calculated as follows:

Threshold value = Absorbance of first measurement - absorbance of second

measurement

Threshold value = Absorbance of second measurement - absorbance of third

measurement

Threshold value = Absorbance of third measurement - absorbance of first

measurement

The threshold value can be set on the Parameters, Normal2 menu screen within the

range 1 to 99999. An invalid result (*1) will not be included in the calculation. In the

case of triplicate measurements, a duplicate error (DUP) will be generated on every

invalid measurement. *1 Results with no error flag or an STB flag are valid. Results

with flags other than STB will be invalid.

Standard sample absorbance is measured as follows:

When all three measurement values are valid (*), the median value of three values

will be used.

When two measurement values are valid (*), the average of two values will be

used.

When only one measurement value is valid, or one reagent blank value is used for

one point offset, that one value will be used.

When there is no valid measurement value, a SEN limit error will be generated.

The threshold value can be set on the Parameters Normal2 screen within the range 1

to 99999. * Results with no error flag or STB flag are valid. Results with flags other

than STB will be invalid.

Under the following conditions a duplicate limit error flag will not be generated.

a. If the duplicate limit error check is disabled.

b. When S1 is the reagent blank and measured only once.

c. When a higher priority error than duplicate limit error occurs.

Page 423

Operator Manual

APPENDIX A THEORY OF CALCULATIONS

Version 1.1 Rev October 2006

SENSITIVITY (ALLOWABLE SENSITIVITY LIMIT)

If the difference in absorbance, ABS, between the first and last calibrators in a full

calibration is smaller than the specified value the last calibration value will be used.

CALIBRATION TYPE

FACTOR

ABS

10000

ABS

sample

ABS s1

S1

concentration sample

concentration

The formula of the calibration curve is defined as:

concentrationsample =

K

(ABS sample ABSs1 )

10000

ABSS1 is the actual measured value of standard S1, and S1 is the known

concentration.

The concentration of the sample after calibration is defined as:

1

concentration sample = --- ABS

b

sample

Page 424

Operator Manual

APPENDIX A THEORY OF CALCULATIONS

Version 1.1 Rev October 2006

LINEAR

ABS

Sn

S2

ABS sample

S1

concentration

concentration sample

The formula of the calibration curve is defined as:

ABS = a + b concentration

where the intercept a and slope b are calculated according to the least squares

method with:

yi b xi

i=1

i=1

a = --------------------------------------n

y i

xi

n

xi yi

i=1

i=1

i = 1 b = ---------------------------------------------------------------------n

n

2

2

n

xi

x i

i=1

i=1

xi and yi are pairs of corresponding values, i.e. ABS and known concentration of

calibrators i.

n is the number of calibrators, i.e. the values from 3 to 7.

Page 425

Operator Manual

APPENDIX A THEORY OF CALCULATIONS

Version 1.1 Rev October 2006

Concentration of the sample after calibration is defined as:

1

concentration sample = --- ( ABS sample a )

b

A correction of intercept a for a single calibrator Sx, using a 1point recalibration with

slope b remaining constant can be performed. Intercept anew will be defined after

correction as follows:

a new = ABS Sx ( b concentration Sx )

SPLINE

A non-linear calibration curve may be obtained from the measurement of 3-7

calibrators by spline interpolation. A Spline function is determined as cubic spline

under the following conditions:

1. A cubic equation for a small section.

2. Adapt a specified function value for both end points on a small section of the

curve.

3. Apply the derivatives to each of the following sections of the curve.

= Calibrator Point

ABS

AS5

A S4

Asample

AS3 AS2

AS1

CS1

concentration

CS2

CS4

sample

C

S3

C

CS5

Page 426

Operator Manual

APPENDIX A THEORY OF CALCULATIONS

Version 1.1 Rev October 2006

The formula for the calibration curve on each small section is defined as:

ABS = A * concentration 3 + B * concentration 2 + C * concentration + D

The procedure to convert the measured ABS to a concentration value is as follows:

1. Locate the section of the curve that fits the measured ABS.

2. Substitute the ABS into the cubic equation for that section, and convert it into a

concentration using either Cardano's formula or the Newton-Raphson method.

POINT TO POINT

In a Point to Point calibration each calibrator value, or point, is connected to the next

one by a straight line. For example, if there are 5 standards as shown below, the

calibration curve is composed of four straight lines (k1 to k4) between the 5 points.

= Calibrator Point

ABS

AS5

A S4

Asample

AS3 AS2

AS1

CS1

concentration

CS4

CS2

sample

C

S3

C

CS5

The formula for the point to point calibration curve may be obtained from the following

equation:

ABS = a + b concentration

a is derived as follows:

ABS Sk + 1 ABS Sk

a = ABS Sk ------------------------------------------------------------------------------------------------- concentration Sk ]

concentration Sk + 1 concentration Sk

Page 427

Operator Manual

APPENDIX A THEORY OF CALCULATIONS

Version 1.1 Rev October 2006

b is derived as follows:

ABS Sk + 1 ABS Sk

b = ------------------------------------------------------------------------------------------------concentration Sk + 1 concentration Sk

Therefore, the formula for calculating the concentration of the samples after

calibration is defined as:

1

concentration sample = --- ( ABS sample a )

b

LOG-LOGIT

= Calibrator Point

ABS

AS5 1

A S4

Asample

AS3 AS2

AS1

CS1

concentration

CS2

CS4

sample

CS3 C

CS5

In the case of a log-logit calibration type, in which there are 5 calibrators, the formula

for the calibration curve is given as follows:

ABS = k /( r + exp(ax 3 bx 2 cx d ) + 1)

Page 428

Operator Manual

APPENDIX A THEORY OF CALCULATIONS

Version 1.1 Rev October 2006

EXPONENTIAL

= Calibrator Point

ABS

AS5

AS4

A sample

AS3

A S2

AS1

CS1

concentration

CS4

CS2

sample

CS3 C

CS5

In the case of an exponential calibration, with 5 calibrators, the formula of the

calibration curve is given by:

ABS = A * concentration 3 + B * concentration 2 + C * concentration + D

Page 429

Operator Manual

APPENDIX A THEORY OF CALCULATIONS

Version 1.1 Rev October 2006

Page 430

Operator Manual

Operator Manual

APPENDIX B MAINTENANCE LOG SHEET

F560 Maintenance Log Sheet

Version 1.1 Rev October 2006

Page 431

APPENDIX B MAINTENANCE LOG SHEET

Operator Manual

Version 1.1 Rev October 2006

Page 432

APPENDIX C SOFTWARE UPGRADE PROCEDURE

Version 1.1 Rev October 2006

APPENDIX C.

SOFTWARE UPGRADE PROCEDURE

The software upgrading procedure for the F560 Clinical Chemistry Analyser PC

(running Windows XP operating system) is detailed as follows:

Materials required

ITEM

New Software

CD

DESCRIPTIONS

Software No. 25503281XX where "XX" denotes

2-digit version number.

To upgrade the software, follow procedures A to G as shown below.

A. Preparation for Software Upgrade

1. Terminate all programs running on the PC.

2. Terminate the user-interface software as follows:

(a) Hold down the CTRL key and the [.] (full stop) key and the following options will

be displayed:

Sleep

Power Off

Cancel

(b) Click on the POWER OFF button, to return to the Windows XP desktop.

3. Proceed to point B.

B. Backup of System Parameters

1. Start the existing user-interface software.

(Start Program (P), -> ca400, -> main)

2. Click on SYSTEM (F9) in the job menu.

3. Click on BACKUP in the tab menu.

Page 433

Operator Manual

APPENDIX C SOFTWARE UPGRADE PROCEDURE

Version 1.1 Rev October 2006

4. With the "Backup Operation" screen displayed, click on the Save box beside

Save Data in the "Data backup (HD)"section of the backup operation screen and

the following message will appear:

"Warning! Any existing data will be over written. OK?

5. Click on the OK button and the message "Backup in process" will appear.

6. When backup complete proceed to point C.

C. Termination of User-interface Software

1. Terminate the user-interface software as follows:

a) Hold down the CTRL key and the [.] (full stop) key. The following options will be

displayed:

Sleep

Power Off

Cancel

(b) Click on the POWER OFF button to return to the Windows XP desktop.

2. Proceed to point D

Page 434

Operator Manual

APPENDIX C SOFTWARE UPGRADE PROCEDURE

Version 1.1 Rev October 2006

D. Removal of Old User-interface Software

Remove the old user interface software as follows:

1. Click on the START button and select SETTINGS.

2. Click on CONTROL PANEL.

3. Double-click on ADD/REMOVE PROGRAMS.

4. Click on CA400 in the selection box and then click on the ADD/REMOVE button.

The installer/uninstaller "Install Shield Wizard" will start up.

5. Click on the NEXT> button, and the PROGRAM MAINTENANCE screen will

appear.

6. Select REMOVE and then click on the NEXT> button again. The Remove the

Program screen will appear.

7. Click on the REMOVE button. A bar-graph showing the degree of progress will

appear and the message "Install Shield Wizard Completed" will be displayed.

8. Click on the FINISH button, to return to the Windows XP desktop.

9. Proceed to point E.

E. Installation of New User-interface Software

1. Insert a new user software CD into the drive, and the following message will

appear:

"Welcome to the Install Shield Wizard "

2. Click on the NEXT> button, and the "Customer Information" screen will appear.

3. In the customer information screen enter the following details:

User Name: F560

Organization: Menarini

4. Click on the NEXT> button, and "Destination Folder" will appear.

5. Click on the NEXT> button again, and the message "Ready to Install the Program"

will appear.

6. Click on the INSTALL button, and a bar-graph showing the degree of progress will

appear. The following message will be displayed:

"Wait until Install Shield Wizard Completed"

Page 435

Operator Manual

APPENDIX C SOFTWARE UPGRADE PROCEDURE

Version 1.1 Rev October 2006

7. Click on the FINISH button to return to the Windows XP desktop.

8. Proceed to point F.

F. Restoration of System Parameters

1. Start the newly-installed user-interface software.

(Start Program (P) -> ca400 -> main)

2. Click on SYSTEM (F9) in the job menu.

3. Click on BACKUP in the tab menu and the Backup Operation screen will be

displayed.

4. Click on LOAD in the "Data backup (HD)" section of the Backup Operation screen

and the following message will appear:

"Warning! Retrieving the data will over write existing data. OK?

Select OK to proceed or CANCEL to return to existing data.

5. Click on the YES button, and a bar-graph showing the degree of progress will be

displayed.

6. Terminate the user-interface software as follows:

(a) Hold down the CTRL key and press the [.] (full stop) key. The following

options are displayed:

Sleep

Power Off

Cancel

(b) Click on the POWER OFF button, to return to the Windows XP desktop.

7. Proceed to point G.

G. Confirmation of Successful Software Upgrade

1. Perform the power shutdown procedure on the PC.

2. Turn the Clinical Chemistry Analyzer on.

3. Turn the PC on again to start the Windows XP.

4. The new user-interface software will start automatically.

(If it is does not start automatically: Start-> Program (P) -> ca400 -> main)

5. Click on SYSTEM (F9) in the job menu.

Page 436

Operator Manual

APPENDIX C SOFTWARE UPGRADE PROCEDURE

Version 1.1 Rev October 2006

6. Click on VERSIONS in the tab menu.

7. Make sure that the new PC version number (printed on the CD label) is displayed

on the upper-right section of the screen as shown below:

PC program version number

Program Version

UI

UI

UI

UI

Main:

UC:

PRT:

LIS:

25503281XX

25503291XX

25503301XX

25503311XX

Unit Main: 25503021XX

Unit LIQ: 25503041XX

Unit DTR: 25503031XX

NOTE: 2-digit Number "xx" Indicates A Program Version Number.

8. Click on MAINTE (F10) in the job menu.

9. Click on SEQUENCE in the tab menu and the "Sequence" screen will appear.

10. Click on the INITIALIZATION button to check that the operation has been

performed correctly.

PLEASE NOTE: It is advisable to make a backup copy of the new software on

the C drive of the computer in case the sofware needs to be reloaded and the

CD is lost or damaged.

Page 437

Operator Manual

APPENDIX C SOFTWARE UPGRADE PROCEDURE

Version 1.1 Rev October 2006

Page 438

Operator Manual

APPENDIX D GLOSSARY

Version 1.1 Rev October 2006

Appendix D: GLOSSARY

Job Menu

Permanent menu options located along the top of the screen.

This menu includes: Run Monitor, Chemistry Parameters,

Calibration, Quality Control (QC), System Parameters and

Maintenance.

Tab Menu

Additional menu options accessed within each Job Menu. The

Tab Menu is located down the right hand side of the screen.

Global Menu

Permanent menu options located at the bottom of the screen.

These options Include: START, EMERGENCY STOP, STAT

sample addition and ALARM.

FD

Floppy Disc drive

SPT

Sample Pipette Unit

RPT

Reagent Pipette Unit (RPT 1 and RPT2)

ISE

Ion Selective Electrode

IRU

Incubation Reaction Unit containing cuvettes.

ASP

Auto Sampler Unit

RCU

Reagent Container Unit

WPP

Water Pump Unit

WU

Wash Unit

SWU

Supply Water Unit

MIX

Mixing-Stirrer Unit (MIX-1 and MIX-2)

DTR

Detector Unit

RPP

Reagent Pump Unit

SPP

Sample Pump Unit

PID

Patient Identification Number.

SID

Sample Identification Number.

Pos

Autosampler unit (ASP) sample position number.

STAT

Emergency samples requiring immediate or priority

measurement.

Page 439

Operator Manual

APPENDIX D GLOSSARY

Version 1.1 Rev October 2006

RCU Scan

Scan of reagent barcodes on board the RCU to enable

registration of reagents.

BCR

Barcode Reader (this enables the barcode reading function for

management of samples, reagents and controls).

Profile

User defined selection of tests to be associated and performed

on a sample.

Multi-standard

Standard or Calibration details used for a number of tests.

Calculated Test

Method by which results are calculated using data obtained from

one or more selected tests.

Normal Range

The expected range of values for an analyte in a defined normal/

healthy population group.

Result Flag

Indication on a results printout to alert the operator that the result

is outside the normal or technical range.

Error Flag

Indication on a results printout to alert the operator that an error

has ocurred during processing or measurement of the sample.

Alarm Code

Alarm or error code generated by the analyser to indicate that a

fault has occured. Alarm code details can be accessed from the

Alarm (F4) button on either the Global menu or keyboard.

Prime

Pumps are activated to fill the fluid system and remove air which

would otherwise affect analyser performance.

Initialisation

System procedure to return the mechanical units (RPT 1 and 2,

SPT pipettes and mixers 1 and 2) to their home (original) position.

C1

C1 decontamination solution (contains Sodium Hyphochlorite)

used for cleaning.

Cal A

Calibrator A solution (Cal A bag) used as a wash, prime and

calibration solution for the ISE module.

Cal B

Calibrator B solution, used for calibration of the ISE module. Cal

B solution is placed in a user defined position in the ASP prior to

use.

Jig

A customised tool used in servicing/maintenance of the analyser

(e.g. nozzle cleaning jig).

Mosaic Plates

Removable panels located on the top work surface of the

analyser.

Page 440

Operator Manual

You might also like

- Method Validation Report Template 1Document6 pagesMethod Validation Report Template 1Abu Wildan100% (2)

- Callibration Curve PDFDocument12 pagesCallibration Curve PDFZARA ERFIDA100% (1)

- Kali Kaula A Manual of Tantric Magick HardbackDocument3 pagesKali Kaula A Manual of Tantric Magick Hardbackalintuta20% (1)

- Instrument Technology: Measurement of Pressure, Level, Flow and TemperatureFrom EverandInstrument Technology: Measurement of Pressure, Level, Flow and TemperatureRating: 4 out of 5 stars4/5 (1)

- 5200 Oxygen USPDocument33 pages5200 Oxygen USPJennie CardozoNo ratings yet

- An Introduction To Quality Assurance in Analytical Science: DR Irene Mueller-Harvey MR Richard Baker MR Brian WoodgetDocument25 pagesAn Introduction To Quality Assurance in Analytical Science: DR Irene Mueller-Harvey MR Richard Baker MR Brian Woodgetvrcom100% (1)

- Shattered Pixel Dungeon The Newb Adventurer's Guide: Chapter I: The BasicsDocument15 pagesShattered Pixel Dungeon The Newb Adventurer's Guide: Chapter I: The BasicsFishing ManiaNo ratings yet

- Analytical Method Validation Protocol For Pharmaceuticals - Pharmaceutical GuidelinesDocument7 pagesAnalytical Method Validation Protocol For Pharmaceuticals - Pharmaceutical GuidelinesMSL IndiaNo ratings yet

- Banking Financial InstitutionsDocument252 pagesBanking Financial Institutionspraise ferrerNo ratings yet

- Classes of ConatminationDocument36 pagesClasses of Conatminationsurfin_bumpkin100% (2)

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGFrom EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNo ratings yet

- Pressure Gauge Calibration TG13 Version 2 December 2017Document6 pagesPressure Gauge Calibration TG13 Version 2 December 2017iptNo ratings yet

- Calibrations and StandardizationDocument43 pagesCalibrations and StandardizationWaleed El-azabNo ratings yet

- 1-Introduction To Analytical ChemistryDocument181 pages1-Introduction To Analytical ChemistryFernando Dwi AgustiaNo ratings yet

- Experimentation, Validation, and Uncertainty Analysis for EngineersFrom EverandExperimentation, Validation, and Uncertainty Analysis for EngineersNo ratings yet

- ISO 8466-1 1990 PDF Version (En)Document12 pagesISO 8466-1 1990 PDF Version (En)Teresa Hernàndez100% (3)

- USEPA Hach Method 10267Document9 pagesUSEPA Hach Method 10267rezaNo ratings yet

- Sop17 15nov06Document5 pagesSop17 15nov06Ivancøvish Julian HuanccøNo ratings yet

- 0-Introduction Analytical ChemistryDocument181 pages0-Introduction Analytical ChemistryAmeyNo ratings yet

- CH 5 Measurement Procedures and Calculations in SpectrophotoDocument29 pagesCH 5 Measurement Procedures and Calculations in Spectrophototagele hunegnawNo ratings yet

- Method 6C - Determination of Sulfur Dioxide Emissions From Stationary Sources Applicability and PrincipleDocument5 pagesMethod 6C - Determination of Sulfur Dioxide Emissions From Stationary Sources Applicability and PrincipleMuksin SalehNo ratings yet

- EPA Document # EPA 815-B-01-001Document49 pagesEPA Document # EPA 815-B-01-001MojtabaNo ratings yet

- Validation of The Calibration Procedure in Atomic Absorption Spectrometric MethodsDocument10 pagesValidation of The Calibration Procedure in Atomic Absorption Spectrometric MethodsaureaborosNo ratings yet

- Experiment No. 2 UV-Vis AnalysisDocument3 pagesExperiment No. 2 UV-Vis AnalysisSIDDHARTH BHASNEYNo ratings yet

- CK-MB Via FactorDocument2 pagesCK-MB Via FactoryusringNo ratings yet

- TNTplus Ammonia EPA FormatDocument10 pagesTNTplus Ammonia EPA FormatYoyito JaenNo ratings yet

- Analytically ChemistryDocument24 pagesAnalytically ChemistryWaleed El-azab100% (1)

- Calibration Curves: Program Use/NeedsDocument8 pagesCalibration Curves: Program Use/NeedsJuan AntonioNo ratings yet

- 45095641Document12 pages45095641Pataki SandorNo ratings yet

- 2.2.58. Inductively Coupled Plasma-Mass SpectrometryDocument2 pages2.2.58. Inductively Coupled Plasma-Mass SpectrometryPablo ParraNo ratings yet

- Unceruianly Pressure GaugeDocument5 pagesUnceruianly Pressure GaugeMd HossainNo ratings yet

- NORDEST Incertidumbre y ValidaciónDocument5 pagesNORDEST Incertidumbre y ValidaciónNidia SuárezNo ratings yet

- Repeatability Standard DeviationDocument6 pagesRepeatability Standard DeviationBalram JiNo ratings yet

- AAC811S 2022 Chap 3Document68 pagesAAC811S 2022 Chap 3HUILE D’ORNo ratings yet

- Quantitative Chromatographic Analysis - The External Standard Method From Quantitative Chromatographic AnalysisDocument14 pagesQuantitative Chromatographic Analysis - The External Standard Method From Quantitative Chromatographic AnalysisAlexandraNo ratings yet

- Terminology Analytical Chemistry 3Document3 pagesTerminology Analytical Chemistry 3Aysha ElSkranNo ratings yet

- Application Data Calibrating Contacting Conductivity Sensors en 70580Document4 pagesApplication Data Calibrating Contacting Conductivity Sensors en 70580Yesid DiazNo ratings yet

- 〈209〉 Low Molecular Weight Heparin Molecular Weight DeterminationsDocument2 pages〈209〉 Low Molecular Weight Heparin Molecular Weight DeterminationsAvijit HazraNo ratings yet

- Introduction SPCDocument28 pagesIntroduction SPCmixarimNo ratings yet

- DiacereinDocument6 pagesDiacereinRikin ShahNo ratings yet

- Method 1 - Sample and Velocity Traverses For Stationary SourcesDocument12 pagesMethod 1 - Sample and Velocity Traverses For Stationary SourcesBenoitNo ratings yet

- 531 2Document38 pages531 2AlexSNo ratings yet

- Materiales de Referencia CCRMP (CANMET)Document5 pagesMateriales de Referencia CCRMP (CANMET)Erick Leonardo Valle MendozaNo ratings yet

- Capitulo 3 EPADocument29 pagesCapitulo 3 EPALady Andrea Fuertes RamirezNo ratings yet

- AN40986 Trace Contaminant Analysis in Brine Using An Icap 6000 Series Duo IcpDocument6 pagesAN40986 Trace Contaminant Analysis in Brine Using An Icap 6000 Series Duo IcpNitisha RathoreNo ratings yet

- Determination of Microcystins and Nodularin in Drinking Water EpaDocument40 pagesDetermination of Microcystins and Nodularin in Drinking Water Epamaria angel galéNo ratings yet

- Test PDFDocument4 pagesTest PDFferonika_cNo ratings yet

- Linearity: 2.2.23. Atomic Absorption SpectrometryDocument3 pagesLinearity: 2.2.23. Atomic Absorption SpectrometrynakitaNo ratings yet

- QuantDocument2 pagesQuantbooks1234No ratings yet

- TNTplus Ammonia EPA FormatDocument10 pagesTNTplus Ammonia EPA FormatOudah AliNo ratings yet

- Cadmium Nitrate Method 2019-1-0Document24 pagesCadmium Nitrate Method 2019-1-0aulia haniefNo ratings yet

- International Journal of Pharma Professional's ResearchDocument4 pagesInternational Journal of Pharma Professional's ResearchChichi FauziyahNo ratings yet

- Determination of Rate EquationDocument9 pagesDetermination of Rate EquationIsabella ThomasNo ratings yet

- Precision Statements in UOP MethodsDocument15 pagesPrecision Statements in UOP MethodsDavinNo ratings yet

- METHOD 314.0 Determination of Perchlorate in Drinking Water Using Ion ChromatographyDocument49 pagesMETHOD 314.0 Determination of Perchlorate in Drinking Water Using Ion ChromatographyAlexSNo ratings yet

- Method 300-1 1997Document40 pagesMethod 300-1 1997Sofy TaylorNo ratings yet

- MDL PDFDocument4 pagesMDL PDFnha vũNo ratings yet

- Complete Control ChartDocument54 pagesComplete Control Chartosama1928No ratings yet

- Comparison of Control Strategies For Dissolved Oxygen Control in Activated Sludge Wastewater Treatment ProcessDocument5 pagesComparison of Control Strategies For Dissolved Oxygen Control in Activated Sludge Wastewater Treatment ProcessAbderrahman MahiddiniNo ratings yet

- NIOSH 1003 Hidrokarbon Halogenated PDFDocument7 pagesNIOSH 1003 Hidrokarbon Halogenated PDFCaleb ConnerNo ratings yet

- Control Charts For Variables: HapterDocument71 pagesControl Charts For Variables: Haptervimal NegiNo ratings yet

- A New Concept for Tuning Design Weights in Survey Sampling: Jackknifing in Theory and PracticeFrom EverandA New Concept for Tuning Design Weights in Survey Sampling: Jackknifing in Theory and PracticeNo ratings yet

- D01659 - Insert ISE Calibrators GRDocument1 pageD01659 - Insert ISE Calibrators GRLyteC123No ratings yet

- Water Requirements ImolaDocument1 pageWater Requirements ImolaLyteC123No ratings yet

- Ech-E Fluidic Diagram A3Document1 pageEch-E Fluidic Diagram A3LyteC123No ratings yet

- RX Imola Installation: Site SurveyDocument10 pagesRX Imola Installation: Site SurveyLyteC123No ratings yet

- F360 Operator ManualDocument386 pagesF360 Operator ManualLyteC123No ratings yet

- C1 Wash Procedure Ver1.0Document3 pagesC1 Wash Procedure Ver1.0LyteC123No ratings yet

- Hp845c - Quick HelpDocument92 pagesHp845c - Quick HelpLyteC123No ratings yet

- Peh 12 Reviewer 3RD QuarterDocument12 pagesPeh 12 Reviewer 3RD QuarterRalph Louis RosarioNo ratings yet

- Vaccum FilterationDocument6 pagesVaccum FilterationAkshay bhuranNo ratings yet

- SP7 PDFDocument1,025 pagesSP7 PDFkushaljp8989No ratings yet

- Defence10 BookDocument58 pagesDefence10 BookYash ChanneNo ratings yet

- Wire Loops - PrecastDocument2 pagesWire Loops - PrecastkamakshiNo ratings yet

- Speech Analysis Guidelines: The ContentDocument1 pageSpeech Analysis Guidelines: The ContentChristian MorenoNo ratings yet

- Index of Appendices: Pmo - ConfidentialDocument149 pagesIndex of Appendices: Pmo - Confidentialonize mosesNo ratings yet

- AC405 Assignment R185840RDocument3 pagesAC405 Assignment R185840RDiatomspinalcordNo ratings yet

- Student Discussion Board (PHP) PDFDocument54 pagesStudent Discussion Board (PHP) PDFAman Kumar ChoubeyNo ratings yet

- Instant Download Principles of Virology Ebook PDF FREEDocument11 pagesInstant Download Principles of Virology Ebook PDF FREEwalter.penn362100% (51)

- SimNowUsersManual4 6 1Document271 pagesSimNowUsersManual4 6 1MichelleNo ratings yet

- Arch MLCDocument471 pagesArch MLCJoseNo ratings yet

- Did Tucson City Attorney Mike Rankin Commit A Half Million Dollar Fraud On Tucson Taxpayers?Document4 pagesDid Tucson City Attorney Mike Rankin Commit A Half Million Dollar Fraud On Tucson Taxpayers?Roy Warden50% (2)

- 2013 Red Sox Postseason GuideDocument267 pages2013 Red Sox Postseason Guidejen_rogers295100% (1)

- Dividido Trane 30 TonsDocument23 pagesDividido Trane 30 TonsairemexNo ratings yet

- Customized ListDocument6,024 pagesCustomized ListItiNo ratings yet

- Data Mining ToolsDocument9 pagesData Mining Toolspuneet0303No ratings yet

- Mechanisms of Nutrient Uptake of Plant Root Cells From SoilDocument47 pagesMechanisms of Nutrient Uptake of Plant Root Cells From SoilMaha ChaudharyNo ratings yet

- English Compulsory (1) PrintDocument15 pagesEnglish Compulsory (1) PrintZakir KhanNo ratings yet

- BD Interest Rate Matrix PDFDocument1 pageBD Interest Rate Matrix PDFMukaddes HossainNo ratings yet

- Helping Slides Pipelining Hazards SolutionsDocument55 pagesHelping Slides Pipelining Hazards SolutionsA NNo ratings yet

- Answers 1Document68 pagesAnswers 1Miguel Angel HernandezNo ratings yet

- Mvo 1965Document113 pagesMvo 1965younisNo ratings yet

- Induction Motor NotesDocument20 pagesInduction Motor NotesMani SaiNo ratings yet

- CLI Basics: Laboratory ExerciseDocument5 pagesCLI Basics: Laboratory ExerciseJhalen Shaq CarrascoNo ratings yet

- JD Pharmacy TechnologistDocument3 pagesJD Pharmacy Technologistpeter mulilaNo ratings yet

- اسئلة الهيئة السعودية- تمريضDocument39 pagesاسئلة الهيئة السعودية- تمريضlolo trabNo ratings yet