Professional Documents

Culture Documents

Cinética de Muerte

Uploaded by

Clau Caroca RCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cinética de Muerte

Uploaded by

Clau Caroca RCopyright:

Available Formats

Reaction Kinetics of Thermal Death

page # 1

FScN 8312

MICROBIAL DEATH

KINETICS

Reaction Kinetics of Thermal Death

page # 2

1. First Order assumptions

a. general equation

dN

= kN

dt

E

A

N

ln = kt = ke R T t

No

plot ln N or log N vs time ---> straight line

pseudo first order with death rate constant k

2.3 * slope = k constant for death from semilog paper

Microbial Death Time Curve

10

6

240

243

250

cfu/gram

10 5

10 4

240F

10 3

243F

250F

10 2

0

Minutes

eg @ 250F k=2.3 min-1

in many cases lag time and non-linear due to

comeup time

Reaction Kinetics of Thermal Death

page # 3

spore clumping

population distribution

injury and pretreatment

some spores get activated at different temperatures

at long times also non-linear due to inaccuracy

Reaction Kinetics of Thermal Death

page # 4

b. D value

(1) definition

D = time when N = No/10

Bigelow Model

DRT = time to reduce population to 1/10 of original

population = D

D = DRT = t 0.1

N

0.1N o

ln = ln

= 2.3 kD

No

No

k = 2.3 D

Reaction Kinetics of Thermal Death

page # 5

read off semilog plot

from prior example D= 1 min @ 250F

D = 3 min @ 240 F

thus D inverse to k value

@ 250F k =2.3 = 2.3/D= 2.3/1 = 2.3

Example values

B. megaterium

C. botulinum

B stearothermophilis

B subtilus

A. niger

D100 = 10 min

D100 = 27 min

D130 = 20 min

D135 = 9 min

D100 = 10-5 min

Reaction Kinetics of Thermal Death

(2) effect of water activity

page # 6

Reaction Kinetics of Thermal Death

page # 7

2 . Z value - microbial temperature dependence

plot D value on semilog vs time

similar to shelf life plot - time to 90% reduction

Z Value Plot

DRT-Minutes

10

.1

230

240

250

260

270

280

temperature F

D = Do e bT

ln

for

0.1D1

= 0.1

D1

0.1D1

= ln 0.1 = bTz = bz

D1

z = C = Tz

b = 2.3 / Z = slope Z

define Z as temperature difference for one log difference in D value

Z is not a slope as stated in micro text books = inverse slope

above example Z = 22F= 12.2 C

Reaction Kinetics of Thermal Death

page # 8

similar to temperature sensitivity or activation energy

z=

T2 T1 250 T

=

D2

D

log

log

D1

D 250

above example

z=

T2 T1 114 102

=

= 12F

D2

10

log

log

D1

1

Z =6.7 C

Reaction Kinetics of Thermal Death

page # 9

Process times follow same format

eg meat cooking t=7 D for Salmonellae death

Listeria in eggs follows similar pattern

Salmonellae Z = 5.2F = 2.9 C

Effect of medium (Davies J. Food Tech 12:115 (1977)

TC

120

140

160

D water (min)

1000

2.45

0.22

D milk (min)

468

3.02

0.32

Q 10

Z

23.5

7.3C

8.9C

13.2

Reaction Kinetics of Thermal Death

page # 10

Process time plot for milk pasteurization from FDA vs E. coli death

FDA t140 = 30 min @140F

t 160= 15 sec @ 160F

Reaction Kinetics of Thermal Death

page # 11

3. Arrhenius relationship

ln k vs 1/T

or ln D vs 1/T

D = Do e

EA

RT

EA 1 1

T 2 T1

D2

R

=e

D1

=e

EA

R

T 2 T 1

T 2 T 1

0.1D1

D2

E T T1

E

= ln

= ln 0.1 = 2.3 = A 2

A

D1

D1

R T2 T1

R

2.3RT12 4.576T12

=

T K

z

EA

EA

ln

z1

T 2

1

Z decreases as EA increases - less F to cause 10 fold change

eg C. botulinum data

Reaction Kinetics of Thermal Death

z ~ 10C Q10= 10

page # 12

Reaction Kinetics of Thermal Death

page # 13

EA = 70.6 Kcal/mole @ 120C from equation

= 63.7 Kcal/mole @ 100C from equation

EA = 66.7 Kcal/mole from graph

suggests need to check paper to see how calculated

as can be slightly off

Reaction Kinetics of Thermal Death

page # 14

4. . Q10 , Z and EA relationship in C

(1) equations

ln Q10

2.3 logQ10 = 10b =

10 * 2.3

= 10b =

z

10 * 2.3

z

Q10 = 10

10

(2) typical values

Salmonellae

Z = 4.5C

Q10 = 167

EA = 113 Kcal/mole

yeast

Z=5 C

Q10=100

EA= 98 Kcal/mole

E. coli

Z = 6.1 C

Q10=43.6

EA= 83.2 Kcal/mole

S. aureus Z = 9 C

Q10 = 13Kcal/mole

EA = 56.4 Kcal/mole

C. bot spores

Z=10C

Q10 = 10

EA = 67 Kcal/mole

Reaction Kinetics of Thermal Death

page # 15

5. . F value for processing

a. equations for constant temperature

FT = time for process desired for x log cycle reduction

N

N

2.3

2.3

t=

Ft

ln = 2.3 log = kt =

N

N

D

D

o

o

N

F = D log

No

for T = constant

Fo = min at 250F for 12 log cycles reduction

Fo = D250. X 12 = ~ 2.3 minutes for C. botulinum

Reaction Kinetics of Thermal Death

page # 16

b. variable temperature process T = f(t)

N

ln = kt = k o e

No 0

0

t

E

RT (f (t ))

k t

i i

i =1

sum up time temperature sequence till equals value desired

eg if 12 log cycles desired then = 2.3 * 12 = 27.6

Reaction Kinetics of Thermal Death

page # 17

c. Area Under Curve Method - kinetic method

(1) measure time-temperature sequence at slowest point

of heating gives T=f(t)

2) then plot value of k for each temperature at given time

increment vs total time elapsed area under curve is sum of integral

(3). continue till reach value desired for area

gives process time

easy to do on computer for continuous

process

Reaction Kinetics of Thermal Death

page # 18

d. Lethality Method

set fo = 1 for desired process

N

N t 2.3

ln = 2.3 log =

t

No

N o 0 D (f (t ))

t

1

N

log o =

t=

(

(

))

N

D

f

t

0

ti

i = 1 Di

N

set x = log o

N

n

n

ti

t

f =

= i

i = 1 xD i

i = 1 LT i

1

1

=

= lethality rate

xD Lt

Reaction Kinetics of Thermal Death

page # 19

plot 1/lethal time for given x reduction vs time

or sum up on computer until Fo =1 area under curve

Reaction Kinetics of Thermal Death

page # 20

6. Canning Calculations

a. Unsteady State Heat transfer for object

2T

T

2T

2T

2

=T =

+

+

2

t

y 2 z 2

x

T Ti

ln T = ln out

= 2t

Tout T r

k

=

C p

a = thermal diffusivity = cm2/hr

r = characteristic thickness

Tout = retort temperature = TR

Ti = initial temperature

T = temperature @ time t

= unaccomplished temperature change

plot ln vs time ---> straight line to predict temperature

at any time

Reaction Kinetics of Thermal Death

page # 21

b. Temperature plot

ln[Tout

T ] = ln C 2 t

r

fH = F for 1 log cycle

Reaction Kinetics of Thermal Death

page # 22

d. Balls Formula

B = 0.42t cut + fH [log(JI ) log(g )]

JI = pseudo initial temperature [TR - TJ] after come

up time tcut

g = TR - TS where TS is temperature when cooling

starts obtained from Z and Fo values by trial and

error

time to turn off steam.

Reaction Kinetics of Thermal Death

page # 23

7 . Quality Loss in Thermal Processing

a. Equations

dN

= kN

dt

Nx

ln

= kt x

No

dA

= kA

dt

A

ln

= kt x

Ao

time is set for microbial death so quality loss depends on

quality rate function and temperature

Reaction Kinetics of Thermal Death

page # 24

b. Typical values for rate constants and EA in canning

Reference

Other

Gold and Weckel

(1959)

Blanched

Component

Medium

pH

Temp

Range

( F)

Ea

(KcalMole)

Chlorophyll

Pea puree

Nat2

240-280

16.1

14.0 min

do

do

do

do

12.1

13.9 do

D1211

Unblanced

Lenz and Lund

(1974)

Mackinney and

Joslyn (1941)

Chlorophyll

do

Pea puree

Spinach puree

6.5

6.5

175-280

do

22

19

113 min

166 do

Chlorophyll a

Chlorophyll b

Buffered soln

do

--

32-122

--

7.5

do

-9.0

--

Dietrich et al.

(1959)

Chlorophyll

Green beans

Nat2

190-212

12.0

10.1 min

Timerss (1971)

Color

Peas

Asparagus

Green beans

Whole kernel corn

Nat2

do

do

do

175-300

do

do

do

15.0

14.0

15.0

19.5

25.0 min

17.0 do

21.0 do

6.0 do

do

do

22.5

2.3 do

Whole green beans do

do

22.0

4.0 do

Time for

Whole peas

taste panel

to

judge 4.0/

9.0

compared

to

frozen

control.

Hermann (1970)

Chlorophyll a

Chlorophyll b

Maillard reaction

Nonenzymatic

browning

B-1

Spinach

Spinach

Apple juice

Nat2

do

do

212-266

do

100-266

12.5

10.0

27.0

34.1 min

48.3 do

4.52 hr

Apple juice

Pork

do

do

do

? - 250

20.7

19.5

4.75 hr

6.03 hr

Penting et al.

(1960)

Anthocyanin

Grape juice

Nat2

Boysenberry juice do

Strawberry juice

do

68-2250

do

do

28.0

20.0

19.0

17.8 min

102.5 do

110.3 do

Tanchev and

Joncheva (1973)

Cyanidin-3-rutinoside

Citrate buffer

Plum juice

Citrate buffer

Plum juice

170-225

do

do

do

23.7

23.1

26.2

22.1

28.5 min

41.6 do

21.6 do

27.7 do

Peonidin-3-rutinoside

4.5

4.5

4.5

4.5

Reaction Kinetics of Thermal Death

page # 25

Reference

Temp

Range

pH

Bendix et al. (1951)

Feliciotti and

Essselem (1957)

Mulley et al. (1974)

Gillespy (1962)

Garrett (1956)

Garrett (1956)

Davidek et al.

(1972)

Gupte et al. (1964)

Ramakrishnan and

Francis (1973)

von Elbe et al.

(1974)

Burton (1963)

Williams and Nelson

(1974)

Taira et al. (1966)

Mansfield (1974)

Component

Mole)

220-270

21.2

164 min

D1211

Thiamin

Whole peas

Nat

Thiamin

do

do

do

do

do

Carrot puree

Green bean do

Pea

do

Spinach do

Beef heart do

Beef liver

do

5.9

5.8

6.6

6.5

6.1

6.1

228-300

do

do

do

do

do

27

do

do

do

do

do

158 min

145 do

163 do

134 do

115 do

124 do

do

do

Thiamin

do

do

do

6.2

6.2

6.0

Nat2

do

do

do

250-280

do

do

do

do

29.4

27.5

27.4

120 do

157 do

156.8 min

246.9 do

254.2 do

do

-----

do

20.0

23.0

27.0

d-Pantothenic acid

C

B-12

Folic acid

A

Lamb

do

Pork

do

Phosphate buffer

Pea puree

Beef puree

Peas-in-brine

puree

--------Liquid multi

vitamin prep

do

do

do

Vitamin prep

do

3.2

do

do

do

3.2

do

39-158

do

do

do

30-158

do

26

21

23.1

23.1

16.8

14.6

Inosinic acid

(IMP)

(IMP)

Chlorophyll a

Chlorophyll b

Buffer soln

do

do

Spinach

do

3

4

5

6.5

5.5

140-208

do

do

260-300

260-300

34.0

30.4

28.1

15.5

7.5

------13.0 min

14.7 do

Carotensids

Paprika

Nat2

125-150

34.0

0.038 min

Betanin

do

Browning

do

Buffer

Beet juice

Goats milk

do

5.0

do

6.5-6.6

do

122-212

do

200-250

do

12.5

10.0

27.0

do

19.5 min

46.6 do

1.08 min

0..91 do

Methylmethionine

sulfonium

bromideDMS

Sodium-citrate

buffer

6.0

Sweet corn

6.9

Tomato

4.4

Soybean meal

--Peas

Nat2

Peas

Beets

Whole kernel corn

Broccoli

178-212

do

do

212-260

170-200

210-240

180-210

212-250

212-250

34.8

31.6

27.2

30.0

19.5

19.5

34.0

16.0

13.0

8.4 min

4.5 do

23.2 do

13.1 hr

1.4 min

2.5 do

2.0 do

2.4 do

4.4 do

Squash

Carrots

Green beans

Potato

182-240

176-240

182-240

161-240

25.0

38.0

41.0

27.5

1.5 do

1.4 do

1.0 do

1.2 do

Thiamin

Riboflavin

B-1 - HC1

Lysine

Texture

Overall cook quality

do

do

do

do

do

do

do

Hackler et al.

(1965)

Adams and Yawger

(1961)

Medium

Ea

(Kcal(F)

226.7 do

----1.35 days

4.46 do

1.12 do

1.94 do

1.95 days

12.4 do

Trypsin inhibitor

Soybean milk

---

200-250

18.5

13.3 min

Peroxidase

Whole peas

Nat2

230-280

16.0

3.0 min

Reaction Kinetics of Thermal Death

Reference

Licciardello et al.

(1967)

Read and Bradshaw

(1966)

Stumbo (1973)

Component

Medium

pH

Temp

Range

(F)

C. botulinum

toxin-type E

Growth

Media

do

6.2

do

do

125-135

26.4

135-140

57.4

1140-145 153.5

3.8 min

( ) 60C

Milk

6.4-6.6

210-260

25.9

9.4 min

Variety

do

>4.5

220- ?

do

64-82

53-82

Staphylococcus

enterotoxin B

C. botulinum spores

(type A and B)

B. stearothermophilus

D-value at 121C.

Indicates natural pH of the system.

page # 26

Ea

(KcalMole)

D1211

0.1-0.2 min

4.0-5.0 min

Reaction Kinetics of Thermal Death

page # 27

c. HTST processing effect

Example calculation for N/No = 10-7 or 7 log cycle destruction

k death B. stearothermophilis = 0.7 min-1 @ 125C

k thiamine = 0.014 min-1 at 102C

for each temperature calculate time for 7 D destruction

plug into quality equation for calculation of A/Ao

see plot next page

% Thiamine

TC 1000/T spores kD min-1

t for 7 D

100

110

120

130

140

150

2.681

2.611

2.545

2.481

2.421

2.364

0.002

0.017

0.16

1.3

9.6

62

8050

947

100

12.4

1.7

0.26

Amount loss

100

100

99.5

74.5

34

11

Reaction Kinetics of Thermal Death

example calculation plot

page # 28

Reaction Kinetics of Thermal Death

page # 29

8. Canned Food Storage

a. Modes of deterioration

microbial - only if > 40C

oxidation - little oxygen left

enzymes - should be inactivated

chemical - major reaction especially with container wall

texture - basically during processing

b. Shelf life test considerations

(1). MCCP - 2 weeks @ 80F

(2). FSIS test - 95F 2F

(a) 10 days

(b) 20 days high fat or > 3 lbs

(c) pH meat/sauce different - 30 days

c. temperature abuse conditions

1 year

70F

6 months 100F

3 months 120F

Reaction Kinetics of Thermal Death

page # 30

d. nutrient loss during storage

CANNED FOODS

Maximum Storage Temperatures F

for canned foods to assure not more than 10% loss of vitamin C, B1 ,

carotene, or riboflavin

(adapted from Feaster, 1960; Cecil and Woodroof, 1963)

__________

Ascorbic acid

(Vitamin C)

Thiamine

Carotene

(Vitamin B1) (Vitamin A pres

) (Vitamin B )

Riboflavin

Canned

product

12 mo 18 mo 24 mo

12 mo

18 mo

24 mo

12 mo 18 mo 24 mo

12 mo 18 mo

76

74

68

65

60

58

>32

45

--38

70

32

62

72

54

58

--45

-57

--50

60

45

32

57

45

32

---

---

---

57

50

74

60

45

>32

---

---

---

---

---

65

---

---

---

---

---

---

80+

80+

80+

---

71

60

50

64

58

53

75

66

58

70

---

---

---

56

47

41

---

---

---

---

60

45

32

---

---

---

---

---

---

---

65

50

40

84

80

76

70

40

32

---

74

66

52

62

56

50

72

58

45

55

---

---

---

---

---

---

80+

80+

80+

68

54

32

80

80

80

---

---

---

---

---

68

60

52

63

57

49

46

41

38

63

46

68

60

45

70

60

50

24 mo

Apricots

Asparagus

45

Beans, green

45

Beans, lima

32

Carrots

--Corn, sweet

48

Frankfurters

and beans

--Grapefruit

segments

--Peaches

--Peas

45

Plums

Pineapple

slices

--Spinach

32

Tomatoes

a

b

c

d

e

f

10% loss in 17 months - no temperature effect

20% loss in 12 months, 15% in 24 months, no temperature effect

No loss

10% loss - no time or temperature effect

8% loss in 12 months, 13% in 24 months, no temperature effect

20% loss, no time or temperature effect

40

--55

------50

f

Reaction Kinetics of Thermal Death

page # 31

e. Nutrient loss problems

(1). field variability

(2). choice of index of deterioration

(3). overpack and storage

(4) variation depending on level and test

Reaction Kinetics of Thermal Death

page # 32

D. Problem Set

1. (10 points) In a Study of the heat inactivation of Staphylococcal enterotoxin A

(Denny et al., J. Food Sci. 37:762, 1966), the procedure used was to grow the

organisms on special culture plates, isolate the endotoxin by dialysis and then use

TDT tubes for the heat inactivation studies. The heated extract was then injected into

each of five cats, a positive test, i.e., presence of toxin, being taken if one of the cats

reacted violently to the injection. The following data were obtained. Times are minutes

of heating at the given temperature. Initial toxin concentration was the same in all

cases.

-+ means at least one of five cats reacted (presence in all cases)

- means no reaction (i.e., all toxin destroyed)

(a) Prepare a graph that shows safe processing time as a function of temperature.

(b) What is the activation energy for heat inactivation of the staph enterotoxin?

State all assumptions that must be made in you analysis of the data.

Temperature F

Times min.

Cat reaction

210

95

80

60

+

30

+

220

60

50

40

30

+

230

50

40

30

20

+

240

40

30

20

15

+

10

+

8

+

250

12

11

10

9

+

Reaction Kinetics of Thermal Death

page # 33

2. (5 points) The following data (JFS 42:1224; 1977) have been found for the time to

reach 50 ug/g patulin on corn by Penicillium patulin M59 @ 75%RH.

51 days @ 5C

29 days @12 C

12.6 days @ 25C

(a) Write a general expression for the production of patulin as a function of time

(what order would you expect).

(b) What is the apparent activation energy for its production?

(c) The LD50 (lethal dose for a 50% chance of death) for mice is 40 mg/Kg body

weight. Mature wild mice eat about 6 g corn a day in their diet and weigh about 100 g.

How long would the corn have to sit at 22C to give a 50% probability of death, if the

corn gets contaminated with the mold? Assume that the mold immediately begins

growing at zero time and that the initial level is at least a factor of ten times under the

detection limit of 0.l ug/g food. The mouse in this problem eats the corn only once and

at the time when the patulin reaches a concentration that is 50% lethal to the mouse.

POOR MOUSE!

You might also like

- Libro 4 PDFDocument8 pagesLibro 4 PDFCynthia Jazmin Flores CisnerosNo ratings yet

- Chemical: List I List IIDocument6 pagesChemical: List I List IISudhanshu PandeyNo ratings yet

- Chapter 4Document36 pagesChapter 4siva sachaphibulkijNo ratings yet

- E T σ Q A A A T T ε ε ε ε σ: Visit us at: www.nodia.co.inDocument1 pageE T σ Q A A A T T ε ε ε ε σ: Visit us at: www.nodia.co.inSameerChauhanNo ratings yet

- Homework 5 - 2020 - 01 - v3 - YH (v3) - ALV (v2)Document5 pagesHomework 5 - 2020 - 01 - v3 - YH (v3) - ALV (v2)CARLOS DIDIER GÓMEZ ARCOSNo ratings yet

- Ln-8 Idle Mind Solutions: A 1 E A R 1 T 1 1 T 2Document22 pagesLn-8 Idle Mind Solutions: A 1 E A R 1 T 1 1 T 2aashulhedaNo ratings yet

- Chemical KineticsDocument7 pagesChemical Kineticsthinkiit100% (1)

- Kuliah Iv - B - Blok 9 - Stabilitas Obat Efek Suhu Media Dan PHDocument82 pagesKuliah Iv - B - Blok 9 - Stabilitas Obat Efek Suhu Media Dan PHnovita istiqomahNo ratings yet

- Heat Chap05 029Document20 pagesHeat Chap05 029Kerem GönceNo ratings yet

- Cooling Tower. Application - TreybalDocument89 pagesCooling Tower. Application - TreybalProcess TiglobalNo ratings yet

- Transient Conduction: The Lumped Capacitance MethodDocument11 pagesTransient Conduction: The Lumped Capacitance MethodBabak GHNo ratings yet

- Documentation of CCT Diagram CalculationDocument16 pagesDocumentation of CCT Diagram CalculationXimena Mercedez Palacios PortalNo ratings yet

- Chemical KineticsDocument8 pagesChemical KineticsSnehashis BoseNo ratings yet

- Transient or Unsteady State Heat ConductionDocument15 pagesTransient or Unsteady State Heat ConductionvdnsitNo ratings yet

- Exmn 3 TermoDocument7 pagesExmn 3 TermoJailene Gómez CollazoNo ratings yet

- Cooling Tower. Application - TreybalDocument89 pagesCooling Tower. Application - TreybalPinak ProjectsNo ratings yet

- Newtonian Cooling: Adam JohnsonDocument15 pagesNewtonian Cooling: Adam JohnsonmonstermuddyNo ratings yet

- CHE654 2012 Homework5 SolutionsDocument37 pagesCHE654 2012 Homework5 Solutionsmadithak100% (1)

- Masset - 2009 - LiCl DryingDocument3 pagesMasset - 2009 - LiCl Dryingdoidoi212001No ratings yet

- Topic 7Document6 pagesTopic 7Bert ManNo ratings yet

- Heat Transfer HWDocument12 pagesHeat Transfer HWrobert kasperNo ratings yet

- Fe310 Food Technology 3rd WeekDocument29 pagesFe310 Food Technology 3rd Weekirem emine demirNo ratings yet

- Chapter 9 Natural Convection: /s FT 10 222 - 0 F Btu/h.ft. 01692 - 0Document12 pagesChapter 9 Natural Convection: /s FT 10 222 - 0 F Btu/h.ft. 01692 - 0Emaan W KaNo ratings yet

- Assignment Typing (Recovered)Document11 pagesAssignment Typing (Recovered)Ibrahim ElgarhiNo ratings yet

- Module 1Document6 pagesModule 1gus brooks0% (1)

- 10 02 Parabolic PDE IntroDocument26 pages10 02 Parabolic PDE IntroJohn Bofarull GuixNo ratings yet

- K /K Against I Is Linear. Figure 8.5 Shows This PlotDocument6 pagesK /K Against I Is Linear. Figure 8.5 Shows This PlotDyah SukmaNo ratings yet

- 6-11 The Expression For The Heat Transfer Coefficient For Air Cooling of Some Fruits Is Given. The Initial RateDocument2 pages6-11 The Expression For The Heat Transfer Coefficient For Air Cooling of Some Fruits Is Given. The Initial RateBazli Faiq ZainiNo ratings yet

- FTFS Chap20 P032Document23 pagesFTFS Chap20 P032AbdulAbdulNo ratings yet

- Cross Sec AreaDocument3 pagesCross Sec AreaNoor GhazalNo ratings yet

- 1.5 Unsteady Heat ConductionDocument6 pages1.5 Unsteady Heat ConductionArvind ANo ratings yet

- FTFS Chap19 P032Document29 pagesFTFS Chap19 P032AbdulAbdulNo ratings yet

- Heat Chap13 032Document18 pagesHeat Chap13 032Kerem GönceNo ratings yet

- Lab Report R3 Batch ReactorDocument9 pagesLab Report R3 Batch Reactorzy_yf0% (1)

- Sol HW9Document6 pagesSol HW9Jao Wei KuangNo ratings yet

- One-Dimensional, Steady-State Conduction With Thermal Energy GenerationDocument35 pagesOne-Dimensional, Steady-State Conduction With Thermal Energy GenerationIvan PonceNo ratings yet

- Tutorial Session 3 2010 AnswersDocument8 pagesTutorial Session 3 2010 AnswersNatKrNo ratings yet

- Design of Shell Tube Heat Exchanger by Kern Method 2 57 Excel TemplateDocument2 pagesDesign of Shell Tube Heat Exchanger by Kern Method 2 57 Excel TemplateAbhishek SinglaNo ratings yet

- Final Exam Review ProblemsDocument9 pagesFinal Exam Review ProblemsalvinchuanNo ratings yet

- II IIT IRP Physics Worksheet - 13 Q + Soln - Heat Trans & Thermal RadiationDocument13 pagesII IIT IRP Physics Worksheet - 13 Q + Soln - Heat Trans & Thermal RadiationAshwin Kumar100% (1)

- Convection Heat Transfer Empirical RelationsDocument8 pagesConvection Heat Transfer Empirical Relationsbbfe89f31eNo ratings yet

- RAC Lecture 10 PDFDocument18 pagesRAC Lecture 10 PDFSalman KhanNo ratings yet

- RAC Lecture 10Document18 pagesRAC Lecture 10api-373446667% (3)

- Statistical Physics Solution ManualDocument105 pagesStatistical Physics Solution Manualgeorgeattack100% (4)

- Introduction To Statistical Physics Solution Manual: Kerson HuangDocument105 pagesIntroduction To Statistical Physics Solution Manual: Kerson Huangsumivrindavan100% (7)

- CRE Assignment Problems 1 4Document4 pagesCRE Assignment Problems 1 4Sarah SanchezNo ratings yet

- Natural Convection Lab ManualDocument12 pagesNatural Convection Lab Manualjohn paul.jaisonNo ratings yet

- Heat Lab Exp 1 PDFDocument12 pagesHeat Lab Exp 1 PDFjohn paul.jaisonNo ratings yet

- Paper Freezingtimeequation IJR1984Document9 pagesPaper Freezingtimeequation IJR1984Cherise TanNo ratings yet

- HW 8 SolutionDocument6 pagesHW 8 Solutionme395100% (1)

- A Modern Course in Statistical PhysicsFrom EverandA Modern Course in Statistical PhysicsRating: 3.5 out of 5 stars3.5/5 (2)

- Solution Manual for an Introduction to Equilibrium ThermodynamicsFrom EverandSolution Manual for an Introduction to Equilibrium ThermodynamicsNo ratings yet

- Review of The Best Available Techniques (BAT) Reference Document (BREF) For Waste IncinerationDocument4 pagesReview of The Best Available Techniques (BAT) Reference Document (BREF) For Waste IncinerationClau Caroca RNo ratings yet

- Deriving Waste Incineration: Under 21St Century LegislationDocument9 pagesDeriving Waste Incineration: Under 21St Century LegislationClau Caroca RNo ratings yet

- Waste Incineration Bref 0806Document638 pagesWaste Incineration Bref 0806Stullie100% (1)

- Extraccion de Los MetalesDocument19 pagesExtraccion de Los MetalesClau Caroca RNo ratings yet

- Energy and Mechanical EngineeringDocument1,059 pagesEnergy and Mechanical EngineeringClau Caroca RNo ratings yet

- Fundamentos de La Metalurgia ExtractivaDocument6 pagesFundamentos de La Metalurgia ExtractivaClau Caroca R100% (1)

- Bioleaching of CopperDocument23 pagesBioleaching of CopperClau Caroca RNo ratings yet

- 134 434 1 PBDocument13 pages134 434 1 PBClau Caroca RNo ratings yet

- C.L ThickningDocument9 pagesC.L ThickningashokpariseNo ratings yet

- Biochemical Engineering in BiotechnologyDocument20 pagesBiochemical Engineering in BiotechnologyClau Caroca RNo ratings yet

- BQ - Electrical Calibration Relay Bld803, NPBDocument2 pagesBQ - Electrical Calibration Relay Bld803, NPBKazuya KasumiNo ratings yet

- Method StatementDocument29 pagesMethod StatementZakwan Hisyam100% (1)

- DEIR Appendix LDocument224 pagesDEIR Appendix LL. A. PatersonNo ratings yet

- Ventricular Septal DefectDocument8 pagesVentricular Septal DefectWidelmark FarrelNo ratings yet

- NG Teng Fong Discharge DocumentsDocument14 pagesNG Teng Fong Discharge DocumentsAnonymous yGwMIPJRawNo ratings yet

- Those With MoonDocument1 pageThose With MoonRosee AldamaNo ratings yet

- Fill The Gaps With The Correct WordsDocument2 pagesFill The Gaps With The Correct WordsAlayza ChangNo ratings yet

- Village Survey Form For Project Gaon-Setu (Village Questionnaire)Document4 pagesVillage Survey Form For Project Gaon-Setu (Village Questionnaire)Yash Kotadiya100% (2)

- Outlook 2Document188 pagesOutlook 2Mafer Garces NeuhausNo ratings yet

- Leather & Polymer - Lec01.2k11Document11 pagesLeather & Polymer - Lec01.2k11Anik AlamNo ratings yet

- Sample SWMSDocument4 pagesSample SWMSJuma KavesuNo ratings yet

- Characteristics of Testable HypothesesDocument30 pagesCharacteristics of Testable HypothesesMarivic Diano67% (3)

- Castle 1-3K E ManualDocument26 pagesCastle 1-3K E ManualShami MudunkotuwaNo ratings yet

- Food Processing NC II - SAGDocument4 pagesFood Processing NC II - SAGNylmazdahr Sañeud DammahomNo ratings yet

- "Next Friend" and "Guardian Ad Litem" - Difference BetweenDocument1 page"Next Friend" and "Guardian Ad Litem" - Difference BetweenTeh Hong Xhe100% (2)

- 5SDD 71B0210Document4 pages5SDD 71B0210Merter TolunNo ratings yet

- Epicor Software India Private Limited: Brief Details of Your Form-16 Are As UnderDocument9 pagesEpicor Software India Private Limited: Brief Details of Your Form-16 Are As UndersudhadkNo ratings yet

- A Project Report On A Study On Amul Taste of India: Vikash Degree College Sambalpur University, OdishaDocument32 pagesA Project Report On A Study On Amul Taste of India: Vikash Degree College Sambalpur University, OdishaSonu PradhanNo ratings yet

- Care of Clients With Problems in OxygenationDocument5 pagesCare of Clients With Problems in OxygenationSkyla FiestaNo ratings yet

- Adsorbents and Adsorption Processes For Pollution ControlDocument30 pagesAdsorbents and Adsorption Processes For Pollution ControlJoao MinhoNo ratings yet

- Alugbati Plant Pigment Extraction As Natural Watercolor SourceDocument6 pagesAlugbati Plant Pigment Extraction As Natural Watercolor SourceMike Arvin Serrano100% (1)

- API 510 Practise Question Nov 07 Rev1Document200 pagesAPI 510 Practise Question Nov 07 Rev1TRAN THONG SINH100% (3)

- Global Talent MonitorDocument30 pagesGlobal Talent Monitornitinsoni807359No ratings yet

- GEC - ReviewerDocument23 pagesGEC - ReviewerGlycel BagabagonNo ratings yet

- University of Puerto Rico at PonceDocument16 pagesUniversity of Puerto Rico at Ponceapi-583167359No ratings yet

- Indian Standard (First Revision) : Method of Chemical Analysis of Hydraulic CementDocument44 pagesIndian Standard (First Revision) : Method of Chemical Analysis of Hydraulic CementArijit dasguptaNo ratings yet

- CBEU Service ConditionsDocument623 pagesCBEU Service ConditionsAtul ModiNo ratings yet

- Analysis of Pure Copper - A Comparison of Analytical MethodsDocument12 pagesAnalysis of Pure Copper - A Comparison of Analytical Methodsban bekasNo ratings yet

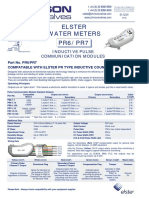

- Data Sheet No. 01.12.01 - PR6 - 7 Inductive Pulse ModuleDocument1 pageData Sheet No. 01.12.01 - PR6 - 7 Inductive Pulse ModuleThaynar BarbosaNo ratings yet

- United States v. Victor Vallin-Jauregui, 4th Cir. (2013)Document4 pagesUnited States v. Victor Vallin-Jauregui, 4th Cir. (2013)Scribd Government DocsNo ratings yet