Lecture 6

Page 1 of 6

Lecture 6

BENDING

SHEET METAL PROCESSES

Bendingisoneverycommonsheetmetalformingoperationusednotonlytoformshapeslikeseams,corrugations,

andflangesbutalsotoprovidestiffnesstothepart(byincreasingitsmomentofinertia).

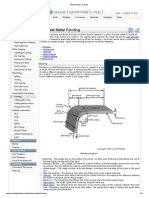

As a sheet metal is bent (Fig 6.1), its fibres experience a distortion such that those nearer its outside, convex

surfaceareforcedtostretchandcomeintension,whiletheinnerfibrescomeincompression.Somewhere,inthecross

section,thereisaplanewhichseparatesthetensionandcompressionzones.Thisplaneisparalleltothesurfacearound

which the sheet is bending, and is called neutral axis. The position of neutral axis depends on the radius and angle of

bend.Further,becauseofthePoisson'sratio,thewidthofthepartLintheouterregionissmaller,andintheinnerregionit

islarger,thantheinitialoriginalwidth.

Fig 6.1 Sheetmetalbending.Itmaybenotedthatthebendradiusismeasuredtotheinnersurfaceofthebentpart.

BEND ALLOWANCE

Itisthelengthoftheneutralaxisinthebend,Fig6.1.Thisdeterminestheblanklengthneededforabentpart.Itcan

beapproximatelyestimatedfromtherelation

Lb=a(R+kt)

where,Lb=bendallowance(mm)

a=bendangle(radian)

R=bendradius(mm)

t=thicknessofsheet(mm),and

k=constant,whosevaluemaybetakenas1/3whenR< 2t,andas1/2whenR 2t.

Example

A20mmwideand4mmthickC20steelsheetisrequiredtobebentat600atbendradius10mm.Determinethe

bendallowance.

Solution.

Here,bendradiusR=10mm

Sheetthicknesst=4mm

http://nptel.ac.in/courses/112107144/Metal%20Forming%20&%20Powder%20metallurgy 6/29/2016

�Lecture 6

Page 2 of 6

SinceR>2t,k=0.5

Bendallowance

MINIMUM BEND RADIUS

Astheratioofthebendradiustothethicknessofsheet(R/t)decreases,thetensilestrainontheouterfibresof

sheetincreases.IfR/tdecreasesbeyondacertainlimit,cracksstartappearingonthesurfaceofmaterial.Thislimitis

calledMinimum Bend Radius forthematerial.

Minimumbendradiusisgenerallyexpressedintermsofthethicknessofmaterial,suchas2t,3t,4t,etc.Table6.1

givestheminimumbendradiusallowedfordifferentmaterials.

Table6.1MinimumBendradiusforVariousMaterialsatRoomTemperature

Material

Aluminumalloys

Berylliumcopper

Brass,low-leaded

Magnesium

Soft

Condition

Hard

6t

2t

4t

5t

13t

0.5t

6t

0.7t

3t

Steels

Austeniticstainless

Low-carbon,low-alloy

Titanium

Titaniumalloys

0.5t

2.5t

4t

4t

Bending Force :

There are two general types of die bending : V die bending and wiping die bending. V die bending is used

expensivelyinbrakedieoperationsandstampingdieoperations.Thebendingforcecanbeestimatedfromthefollowing

simplerelation.

P=k.Y.L.t2/D

where P is bending force, g is the yield stress of the material, L is the bend length ( bend allowance ), t is the sheet

thickness,Disthedieopeningandkisaconstantwhosevaluecanbetakenas1.3foraV-dieand0.3forawipingdie.

Fig6.2showsvarioustypesofbendingdies.

http://nptel.ac.in/courses/112107144/Metal%20Forming%20&%20Powder%20metallurgy 6/29/2016

�Lecture 6

Page 3 of 6

Fig 6.2 Die-bendingoperations.

Bendingforcevariesasthepunchprogressesthroughthebendingoperation.Theforceiszerointhebeginning.It

risesandreachesthemaximumvalueasthepunchprogressesandreachesthebottomofthestroke.

Example:

A400mmlongand2.5mmthickpieceofcarbonsteelsheetisrequiredtobebentat900usingaVdie.Youmay

assumetheyieldstressofthematerialas500MPaandthedieopeningas10timesthematerialthickness.Estimatethe

forcerequiredfortheoperation.

Solution:Here,Y=500MPa

L=400mm

t=2.5mm

k=1.3(forVdie)

D=25mm

BendingforceP=k.Y.L.t2/D

=1.3x500x400x(2.5)2/25

=65KN

Example:

Ifthematerialasmentionedintheaboveexampleistobebentat900usingwipingdiewithradius=3.75mm,what

istheforcerequirement?

Solution:Here,Y=500MPa

http://nptel.ac.in/courses/112107144/Metal%20Forming%20&%20Powder%20metallurgy 6/29/2016

�Lecture 6

Page 4 of 6

L=400mm

t=2.5mm

k=0.3

D=2.5+3.75+3.75=10mm(seeFig6.3)

Fig 6.3

BendingforceP=k.Y.L.t2/D

=0.3x500x400x(2.5)2/10

=37.5KN

DRAWING

Itisaprocessofcoldformingaflatblankofsheetmetalintoahollowvesselwithoutmuchwrinkling,trimming,or

fracturing.Theprocessinvolvesforcingthesheetmetalblankintoadiecavitywithapunch.Thepunchexertssufficient

forceandthemetalisdrawnovertheedgeofthedieopeningandintothedie,Fig6.4.Informingacup,however,the

metalgoescompletelyintothedie,Fig6.5.

Fig 6.4 Drawingoperation.

http://nptel.ac.in/courses/112107144/Metal%20Forming%20&%20Powder%20metallurgy 6/29/2016

�Lecture 6

Page 5 of 6

Fig 6.5 Drawingoperation.

Themetalbeingdrawnmustpossessacombinationofductilityandstrengthsothatitdoesnotruptureinthecritical

area(wherethemetalblendsfromthepunchfacetotheverticalportionofthepunch).Themetalinthisareaissubjected

tostressthatoccurswhenthemetalispulledfromtheflatblankintothedie.

OPERATION . Asetupsimilartothatusedforblankingisusedfordrawingwiththedifferencethatthepunchanddieare

given necessary rounding at the corners to permit smooth flow of metal during drawing. The blank of appropriate

dimensionsisplacewithintheguidesonthedieplate.Thepunchdescendsslowlyontheblankandmetalisdrawninto

thedieandtheblankisformedintotheshapeofcupaspunchreachesthebottomofthedie.Whenthecupreachesthe

counterboredportionofthedie,thetopedgeofthecupformedaroundthepunchexpandsabitduetothespring back .

Onthereturnstrokeofthepunch,thecupisstrippedoffthepunchbythiscounterboredportion.

The term shallow drawing is used when the height of cup formed is less than half its diameter. When drawing

deepercup(heightgreaterthatdiameter)thechancesofexcessivewrinkleformationattheedgesofblankincreases.

Topreventthis,ablankholderisnormallyprovided,seeFig6.4.Asthedrawingprocessproceedstheblankholderstops

the blank from increasing in thickness beyond a limit and allows the metal to flow radially. The limiting thickness is

controlledbythegapbetweenthedieandtheblankholder,orbythespringpressureinthecaseofaspringloadedblank

holder.

Somelubricantisgenerallyusedoverthefaceoftheblanktoreducefrictionandhencedrawingload.

Blank Size

Itisgenerallydifficulttofindtheexactsizeoftheblankneededfordrawingagivencup,becauseofthinningand

thickeningofthemetalsheetduringthedrawingoperation.Thefollowingsimplerelationscanbeusedfordeterminethe

blankdiameterD:

whered=outsidediameterofcup

h=heightofcup

r=cornerradiusonpunch.

Drawing Force.

http://nptel.ac.in/courses/112107144/Metal%20Forming%20&%20Powder%20metallurgy 6/29/2016

�Lecture 6

Page 6 of 6

Fordrawingcylindricalshellshavingcircularcrosssection,themaximumdrawingforcePcanbedeterminedfrom

therelation

P=k.t.d.t.Y

whered=outsidediameterofcup

t=thicknessofmaterial

Y=yieldstrengthofmaterial

k=factorwhosevalueisapprox.equalto[D/d0.6]

D=blankdiameter

EMBOSSING

Embossingisanoperationinwhichsheetmetalisdrawntoshallowdepthswithmaleandfemalematchingdies,Fig

6.6.Theoperationiscarriedoutmostlyforthepurposeofstiffeningflatpanels.Theoperationisalsosometimesusedfor

makingdecorationitemslikenumberplatesornameplates,jewelry,etc.

Fig 6.6 Embossingoperationwithtwodies.Letters,numbersanddesignsonsheet-metalpartscanbeproducedbythis

operation.

COINING

Coiningisaseveremetalsqueezingoperationinwhichtheflowofmetaloccursonlyatthetoplayersofthematerial

andnotthroughoutthevalues.Theoperationiscarriedoutincloseddiesmainlyforthepurposeofproducingfinedetails

suchasneededinmintingcoins,andmedalorjewelrymaking.Theblankiskeptinthediecavityandpressuresashigh

as five to six times the strength of material are applied. Depending upon the details required to be coined on the part,

morethanonecoiningoperationsmaybeused.

Thedifferencebetweencoiningandembossingisthatthesamedesigniscreatedonbothsidesoftheworkpiecein

embossing(onesidedepressedandtheotherraised),whereasincoiningoperation,adifferentdesigniscreatedoneach

sideofworkpiece.

Goto Home

http://nptel.ac.in/courses/112107144/Metal%20Forming%20&%20Powder%20metallurgy 6/29/2016