Professional Documents

Culture Documents

Technical Fact Sheet

Technical Fact Sheet

Uploaded by

vineetk007Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Technical Fact Sheet

Technical Fact Sheet

Uploaded by

vineetk007Copyright:

Available Formats

Ocean Thermal Energy Conversion (OTEC)

Technology

Ocean Thermal Energy Conversion (OTEC) is a technology for generating renewable energy that uses the

temperature differential between the deep cold and relatively warmer surface waters of the ocean to generate baseload

electricity. The technology is viable primarily in equatorial areas of the earth where the year round temperature

differential between the deep cold and warm surface ocean waters is greater than 20 C (36 F). An OTEC facility

continuously requires large volumes of both warm and cold water to generate electricity. A 100 megawatt (MW) OTEC

facility would likely require 10-20 billion of gallons of water per day. There are several types of OTEC systems; this

document describes the most likely initial commercial OTEC facility: an offshore, closed-cycle system.

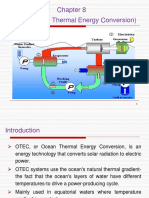

Closed-Cycle OTEC Power System:

OTEC is a heat engine system with a heat

source (i.e., warm water) and a heat sink (e.g., cold

water). The warm water passes through a heat

exchanger (i.e., evaporator) which is in contact with

a closed loop of working fluid (likely ammonia). The

warm water evaporates the working fluid into a

vapor which expands and drives a turbine. The

turbine, connected to a generator, is the source of

mechanical energy. The generator converts the

mechanical energy into electrical energy. After the

vaporized working fluid passes through the turbine

and generator it enters another heat exchanger

(i.e., condenser) which is in contact with the cold

water. The vaporized working fluid is condensed

back into a liquid which is then pumped back into

the evaporator to complete the cycle. Both the

cooled warm water and the warmed cold water are

discharged into the ocean after they have passed

through the heat exchangers. Figure 1 is a

schematic of the closed-cycle system.

Cold Water Pipe:

A unique feature of an OTEC facility is the

cold water pipe. The pipe must be able to

withstand the rigors of the marine environment in

order remain attached the OTEC platform. In order

Figure 1. Schematic of an offshore

to obtain the temperature differential required for

closed-cycle OTEC system

the system (20 C), the pipe must be able to

withdraw cold water at a depth of approximately 3300 feet (1000 meters). To accommodate the large cold water flows,

the size of the pipe for a 100 MW facility may be approximately 33 feet (10 meters) in diameter. The construction,

deployment, and installation of the cold water pipe have remained an engineering challenge.

Other System Features:

A surface platform is an integral part of the facility which is necessary to house the equipment required for the

OTEC system. A stationary OTEC platform would be held in place by mooring lines and anchors. An OTEC platform may

be visible from the shoreline. A power cable lying upon or beneath the ocean bottom would connect the electricity from

the off-shore facility to the electrical grid.

Other OTEC Products

OTEC technology has the potential to be integrated with other commercial systems (e.g., aquaculture and sea

water air conditioning) and products (e.g., potable water, ammonia, and hydrogen).

You might also like

- Ocean Thermal Energy ConversionDocument43 pagesOcean Thermal Energy ConversionMaitry DaveNo ratings yet

- Ptfe Seals Pde3354 enDocument196 pagesPtfe Seals Pde3354 enxuanphuong2710No ratings yet

- Renewable Energy Sources For Caribbean Territories and SIDS: OTECDocument40 pagesRenewable Energy Sources For Caribbean Territories and SIDS: OTECMouaamou AbdeljabbarNo ratings yet

- Ocean Thermal Energy ConversionDocument13 pagesOcean Thermal Energy ConversionRandroxRNo ratings yet

- Ams 5391 HDocument9 pagesAms 5391 HEhab HarbNo ratings yet

- Ocean Thermal Energy Conversion (OTEC)Document28 pagesOcean Thermal Energy Conversion (OTEC)Sehati FisikaNo ratings yet

- Annual Seminar 2015 PDFDocument196 pagesAnnual Seminar 2015 PDFWai TszYanNo ratings yet

- Design Calculation Sheet For Fire Lift Well Pressurisation S.NO. DescriptionDocument1 pageDesign Calculation Sheet For Fire Lift Well Pressurisation S.NO. DescriptionpsjjoshiNo ratings yet

- Ocean Thermal Energy Conversion Tide Current and Tide RangeDocument56 pagesOcean Thermal Energy Conversion Tide Current and Tide RangeSiddharth PatelNo ratings yet

- Otec Power Plant: NcercDocument22 pagesOtec Power Plant: NcercVimi WilsonNo ratings yet

- A Technical Paper Presentation On: Ocean Thermal Energy ConversionDocument20 pagesA Technical Paper Presentation On: Ocean Thermal Energy ConversionsaurabhNo ratings yet

- Module No 5a.ocean EnergyDocument15 pagesModule No 5a.ocean EnergyVaibhav Vithoba NaikNo ratings yet

- Ocean Thermal Energy ConversionDocument20 pagesOcean Thermal Energy ConversionAthisayaraj RajNo ratings yet

- CH 9 OTECDocument6 pagesCH 9 OTECscharichNo ratings yet

- Documenttopdf Trial Version, To Remove This Mark, Please Register This SoftwareDocument10 pagesDocumenttopdf Trial Version, To Remove This Mark, Please Register This Softwareranga247No ratings yet

- Documenttopdf Trial Version, To Remove This Mark, Please Register This SoftwareDocument11 pagesDocumenttopdf Trial Version, To Remove This Mark, Please Register This Softwareranga247No ratings yet

- Presentation ++Document15 pagesPresentation ++36.Praphull DesaleNo ratings yet

- Ocean Thermal Energy ConversionDocument14 pagesOcean Thermal Energy ConversionRahul Kumar YadavNo ratings yet

- Ocean Thermal Energy ConversionDocument10 pagesOcean Thermal Energy ConversionRaviteja RokzNo ratings yet

- Ocean Thermal Energy ConversionDocument15 pagesOcean Thermal Energy Conversion36.Praphull DesaleNo ratings yet

- Thermo OTECDocument15 pagesThermo OTECzikri annuurNo ratings yet

- Seminar Report On Ocean Thermal Energy ConversionDocument21 pagesSeminar Report On Ocean Thermal Energy ConversionHARENDRA BHINCHARNo ratings yet

- OTEC - Ocean Thermal Energy Conversion: by Maria Bechtel and Erik NetzDocument12 pagesOTEC - Ocean Thermal Energy Conversion: by Maria Bechtel and Erik NetzrodrigoflaNo ratings yet

- Otc 20340Document13 pagesOtc 20340Rasheed YusufNo ratings yet

- Ocean Thermal Wave Energy ConversionsDocument12 pagesOcean Thermal Wave Energy ConversionsJoseph Gil SalcedoNo ratings yet

- OTECDocument14 pagesOTECTALLURI LAKSHMI PRASANNANo ratings yet

- Vivek Chand OTECDocument20 pagesVivek Chand OTECvivek chand100% (1)

- Renewable Energy Sources For Caribbean Territories and SIDS: OTECDocument42 pagesRenewable Energy Sources For Caribbean Territories and SIDS: OTECVinay MaisuriyaNo ratings yet

- Chapter - 5 OTECDocument12 pagesChapter - 5 OTECsahitNo ratings yet

- RER Mod5@AzDOCUMENTS - inDocument13 pagesRER Mod5@AzDOCUMENTS - inMizan SalimNo ratings yet

- HereDocument3 pagesHereBilly Joe BreakfastNo ratings yet

- OTEC Summary Aug 2012Document33 pagesOTEC Summary Aug 2012Robie TrieoNo ratings yet

- Ocean Power: Ed Lemery, Brooke Scatchard, Nate TrachimowiczDocument19 pagesOcean Power: Ed Lemery, Brooke Scatchard, Nate TrachimowiczGanesh Kumar100% (1)

- Cean Hermal Nergy Onversion: O T E CDocument18 pagesCean Hermal Nergy Onversion: O T E CHappy PatelNo ratings yet

- Ocean Energy Conversion Methods: Arshad Babu. U M7B Roll No: 7457 TKMCE KollamDocument32 pagesOcean Energy Conversion Methods: Arshad Babu. U M7B Roll No: 7457 TKMCE KollamgaviNo ratings yet

- OotecDocument12 pagesOotecLouie Jay Gitgitin SalvañaNo ratings yet

- Close&Hybrid OTECDocument26 pagesClose&Hybrid OTECJohn Jay AbinalNo ratings yet

- Avery 2003Document38 pagesAvery 2003Neelesh SinghalNo ratings yet

- Ocean Thermal Energy Conversion (Otec)Document4 pagesOcean Thermal Energy Conversion (Otec)Sarvani ShettigarNo ratings yet

- Ocean Thermal Energy Conversion: By-Snehanshu Das 7 Sem, B.TechDocument20 pagesOcean Thermal Energy Conversion: By-Snehanshu Das 7 Sem, B.TechJeanNo ratings yet

- Nes Module IIIDocument12 pagesNes Module IIIVenuNo ratings yet

- Case Study Report On: Pyre 202 - Wind Energy, Tidal Energy and OtecDocument15 pagesCase Study Report On: Pyre 202 - Wind Energy, Tidal Energy and OtecsundarNo ratings yet

- 16eemme023 Seminar ReportDocument9 pages16eemme023 Seminar ReportShreya RathoreNo ratings yet

- OTEC (Ocean Thermal Energy Conversion)Document10 pagesOTEC (Ocean Thermal Energy Conversion)Farhan asifNo ratings yet

- Presentation On Ocean Thermal Energy ConvertionDocument23 pagesPresentation On Ocean Thermal Energy ConvertionAtal SahaNo ratings yet

- Ocean Thermal EnergyDocument14 pagesOcean Thermal EnergyRajat SinghNo ratings yet

- Ocean Thermal Energy: Submitted To DR - Harmeet KaurDocument19 pagesOcean Thermal Energy: Submitted To DR - Harmeet KaurAmitpal Singh CheemaNo ratings yet

- Ocean Thermal Energy Conversion (OTEC)Document8 pagesOcean Thermal Energy Conversion (OTEC)Vanne Jo PajoNo ratings yet

- Ocean Thermal Energy Conversion: UIS EGADocument33 pagesOcean Thermal Energy Conversion: UIS EGA1341131No ratings yet

- Ocean Thermal Energy Conversion - PPTX Neelu OtecDocument17 pagesOcean Thermal Energy Conversion - PPTX Neelu OtecrahulNo ratings yet

- Ocean Thermal Energy ConversionDocument1 pageOcean Thermal Energy Conversionyalamsravanthi_42503No ratings yet

- OTECDocument18 pagesOTECkss_sachinvarma12100% (2)

- Ocean Thermal Energy Conversion: ETB 10 Desember 2013Document35 pagesOcean Thermal Energy Conversion: ETB 10 Desember 2013Mohammad Hanri HardianNo ratings yet

- Ocean Thermal Energy ConversionDocument17 pagesOcean Thermal Energy ConversionVamsi Pelluru100% (1)

- Ocean Thermal Energy Conversion: HistoryDocument20 pagesOcean Thermal Energy Conversion: HistorySantosh PNo ratings yet

- Betck105e Mod4@Azdocuments - inDocument17 pagesBetck105e Mod4@Azdocuments - inswathiswathi7895467No ratings yet

- International Thermonuclear Experimental Reactor (ITER) Safety AnalysisDocument41 pagesInternational Thermonuclear Experimental Reactor (ITER) Safety Analysissatya_saraswat_1No ratings yet

- Otec SeminarDocument21 pagesOtec SeminarAbhishekSuman80% (5)

- Art 6Document5 pagesArt 6manjubd1No ratings yet

- JMI ESc OTECDocument16 pagesJMI ESc OTECAJKNo ratings yet

- Ocean Thermal Energy Conversion: Presented By:-Raj Ranjan GuptaDocument20 pagesOcean Thermal Energy Conversion: Presented By:-Raj Ranjan GuptagaviNo ratings yet

- Technical ReportDocument2 pagesTechnical ReportAyman Al-SabqiNo ratings yet

- Non Conventional Sources of EnergyDocument26 pagesNon Conventional Sources of EnergyVvn BhaskarNo ratings yet

- Mechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesFrom EverandMechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesNo ratings yet

- Homework Thermo2Document13 pagesHomework Thermo2Mia L. AyuningtyasNo ratings yet

- CFD Notes DetailsDocument2 pagesCFD Notes DetailsAnonymous drYNHeNo ratings yet

- Pipeline Pigging Handbook 11Document1 pagePipeline Pigging Handbook 11Bruno GonçalvesNo ratings yet

- PG M.sc. Chemistry 34431 Advanced Inorganic ChemistryDocument207 pagesPG M.sc. Chemistry 34431 Advanced Inorganic ChemistryinuperuvaikalaNo ratings yet

- Applying Finite Element Based Limit Load Analysis Methods To Structures Under Dynamic LoadsDocument5 pagesApplying Finite Element Based Limit Load Analysis Methods To Structures Under Dynamic LoadsM Afif HidayatNo ratings yet

- Model LB-C PDFDocument5 pagesModel LB-C PDFKarthikeyan Sankarrajan0% (1)

- History of FluorosDocument2 pagesHistory of FluorosEvi DianNo ratings yet

- Difference Between MAWP and Design PressureDocument3 pagesDifference Between MAWP and Design PressureAnonymous J1vjrU2No ratings yet

- Continuous-Flow Photochemistry A Need For Chemical EngineeringDocument14 pagesContinuous-Flow Photochemistry A Need For Chemical EngineeringAli TunaNo ratings yet

- Polymer MorphologyDocument4 pagesPolymer Morphologyrehrifat2000No ratings yet

- Ball Approval TestsDocument3 pagesBall Approval TestsCalidad CalidadNo ratings yet

- DonProof PRDocument4 pagesDonProof PRYousef HalasehNo ratings yet

- Electron and Quantum TheoryDocument14 pagesElectron and Quantum TheoryasNo ratings yet

- Viscose Fibres With New Functional QualitiesDocument6 pagesViscose Fibres With New Functional Qualitiesahmed samirNo ratings yet

- 3-69 ShigleyDocument3 pages3-69 ShigleyinivlaviNo ratings yet

- D 2295 - 96 R02 - RdiyotuDocument3 pagesD 2295 - 96 R02 - RdiyotuJorgeNo ratings yet

- Atomic Force Microscope Note PDFDocument7 pagesAtomic Force Microscope Note PDFPrasenjit NaskarNo ratings yet

- Vorticity PDFDocument16 pagesVorticity PDFrahpooye313No ratings yet

- CPKDocument2 pagesCPKMayank PatelNo ratings yet

- Chapter-4 Mechanical Testing 08-06-2014Document21 pagesChapter-4 Mechanical Testing 08-06-2014safeer ahmadNo ratings yet

- Richard Kilgo Enzyme Controlled Reactions WorksheetDocument4 pagesRichard Kilgo Enzyme Controlled Reactions Worksheetcraigkilgo100% (5)

- Thousand Tower & Sendai MTDocument7 pagesThousand Tower & Sendai MTAnastasia YesicaNo ratings yet

- Dew Point: Humidity and HygrometryDocument9 pagesDew Point: Humidity and HygrometryEndhy Wisnu NovindraNo ratings yet

- Side-Mount External Retaining Ring: 15-7 PH Stainless Steel, For 5/32" ODDocument2 pagesSide-Mount External Retaining Ring: 15-7 PH Stainless Steel, For 5/32" ODYossiNo ratings yet

- Optimization of Thermal Design of Heat Sinks A ReviewDocument25 pagesOptimization of Thermal Design of Heat Sinks A ReviewTiến MinhNo ratings yet

- Elias, M. B., Machado, R., & Canevarolo, S. V. (2000) - Journal of Thermal Analysis and CalorimetryDocument13 pagesElias, M. B., Machado, R., & Canevarolo, S. V. (2000) - Journal of Thermal Analysis and CalorimetryGeorgiana CrețuNo ratings yet