Professional Documents

Culture Documents

Weld Group

Uploaded by

Jay PadamaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Weld Group

Uploaded by

Jay PadamaCopyright:

Available Formats

Design Considerations :

Roll Force , Fz (kN) =

Fy , (Mpa) =

ASF =

62010 N/mm

340 N/mm

1.33 AISC Allowable stress factor

Shear capacity of fillet welds

Allowalble weld strength ( Rn/ )

Rn =

fw x Aw

=

Fexx (Mpa) =

tweld =

Length of weld, Lw =

2.00

480

10

460

Mpa

mm

mm

( Total Weld Length )

fw x Aw /

x ASF

( Maximum Fx)

Rn /

* ASF =

fw =

fw =

Aw =

Aw =

0.60 Fexx

288 Mpa

0.707 x tw x Lw

3252.2

Lweld Required =

x Fx

fw x 0.707 x tw x ASF

Lweld Required =

45.80 mm

Ratio :

( Effective weld area)

0.10

VERIFIED

*Bending capacity of fillet weld*

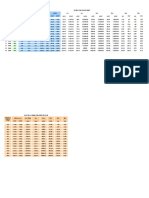

Weld Group design

Weld

Weld-1

Weld-2

Weld-3

Weld-4

Weld-5

Ref

Length

a-b

c-d

e-f

g-h

f-h

70

70

90

90

140

10

10

10

10

10

SUM

Xbar =

Ybar =

Area

70 mm

55.22 mm

c

d

g

494.9

494.9

636.3

636.3

989.8

3252.2

170

ybar =

Mz

h

f

xbar

Data :

Fz =

Moment Acting on weld, Mw =

60010 N

1950325 N-mm

AISC Table J2.5

AISC J2-3

x-centre

81

59

145

-5

70

Area*x

40086.9

29199.1

92263.5

-3181.5

69286

227654

Ixx

y-centre

3.15E+06

9.02E+06

1.02E+06

1.02E+06

2.89E+04

1.42E+07

135

135

40

40

-5

Area*y

66811.5

66811.5

25452

25452

-4949

179578

e=

e

mm

Iyy

2.62E+05

2.09E+05

1.38E+07

4.45E+05

6.47E+06

2.12E+07

32.5 mm

You might also like

- Steel Girder Comparison and Sensitivity AnalysisDocument6 pagesSteel Girder Comparison and Sensitivity AnalysisvinoraamNo ratings yet

- Design of MonorailDocument24 pagesDesign of MonorailSherwin PonsNo ratings yet

- ACI 318 deflection calculation sheet for reinforced concrete T-sectionsDocument8 pagesACI 318 deflection calculation sheet for reinforced concrete T-sectionsabdul khaderNo ratings yet

- Hyundai Master FileDocument81 pagesHyundai Master FilePHAM PHI HUNGNo ratings yet

- Gups For DL + LL Case Stress For DL + WL Case Stress For DL+LL+WL Case StressDocument36 pagesGups For DL + LL Case Stress For DL + WL Case Stress For DL+LL+WL Case StressraghavendraNo ratings yet

- UB UC Steel SectionsDocument10 pagesUB UC Steel SectionsMuhammad HasanNo ratings yet

- Sectional Propert Chart-NewDocument3 pagesSectional Propert Chart-Newrajeshmk2002No ratings yet

- M M P P For P M M P M M P P For P M M P: Angle Steel Member Capacity Based On AISC 360-10 Input Data & Design SummaryDocument1 pageM M P P For P M M P M M P P For P M M P: Angle Steel Member Capacity Based On AISC 360-10 Input Data & Design SummarysushilkumarNo ratings yet

- Beam Identity: GB-6 On Grid W.A1 Beam Data:: (Dead) (Live)Document12 pagesBeam Identity: GB-6 On Grid W.A1 Beam Data:: (Dead) (Live)redscorpion1No ratings yet

- 1532 Base PlanDocument1 page1532 Base PlanAnonymous qEPNPwA0% (1)

- Job No: CBSCL-102 0 Project: SEC Headquarters 1/9/16 Client: Shapoorji Pallonji Middle East Ltd. MA Podium Mosque-Built-Up RHS300x152x12 HNDocument3 pagesJob No: CBSCL-102 0 Project: SEC Headquarters 1/9/16 Client: Shapoorji Pallonji Middle East Ltd. MA Podium Mosque-Built-Up RHS300x152x12 HNvpjagannaathNo ratings yet

- 2.5m Wall - 2m SSHDocument15 pages2.5m Wall - 2m SSHSripara KrishnaNo ratings yet

- FootingDocument84 pagesFootingUma MaheshNo ratings yet

- CASTELLATED BEAM PropertiesDocument2 pagesCASTELLATED BEAM PropertiesHemant SonawadekarNo ratings yet

- Aci SHRDocument2 pagesAci SHRLove SemsemNo ratings yet

- Spreadsheets To BS 8110Document11 pagesSpreadsheets To BS 8110NitinShepurNo ratings yet

- Anchor Design for 219mm Pole SupportDocument1 pageAnchor Design for 219mm Pole SupportS A K ClostreNo ratings yet

- Pipe Schedule and WeightDocument1 pagePipe Schedule and WeightAffendiNo ratings yet

- ColumnDocument23 pagesColumnLong Live TauNo ratings yet

- Residential Beam Design OptimizationDocument8 pagesResidential Beam Design OptimizationTim AcostaNo ratings yet

- BEAMDocument3 pagesBEAMTano BahabobaNo ratings yet

- Bridge Design v1.1 enDocument186 pagesBridge Design v1.1 enGaurav GhaiNo ratings yet

- Tbeam SNO Load BM (Sag) BM (Hog) Sls1 Sls2 Sls3 Uls1Document3 pagesTbeam SNO Load BM (Sag) BM (Hog) Sls1 Sls2 Sls3 Uls1Venkat PalliNo ratings yet

- A) Shear Capacity of BoltsDocument30 pagesA) Shear Capacity of BoltsAjit JiNo ratings yet

- SCZ1 - 02 - NSB Toko - 0223Document200 pagesSCZ1 - 02 - NSB Toko - 0223Haaikal TrNo ratings yet

- Finite Element Method Task 2Document8 pagesFinite Element Method Task 2Christianto HsuNo ratings yet

- IRC Standard for Masonry Bridge ConstructionThe title "TITLE IRC Standard for Masonry Bridge ConstructionDocument52 pagesIRC Standard for Masonry Bridge ConstructionThe title "TITLE IRC Standard for Masonry Bridge ConstructionNorendro KangjamNo ratings yet

- Column Design: 3 Design of Column Subjected To Biaxial Bending (With Reinforcement Equally OnDocument11 pagesColumn Design: 3 Design of Column Subjected To Biaxial Bending (With Reinforcement Equally OnmukhleshNo ratings yet

- RCC Rect Col-Dsn Kns 176Document7 pagesRCC Rect Col-Dsn Kns 176nvnrevNo ratings yet

- P-Delta - Stability Coefficient CalculationDocument46 pagesP-Delta - Stability Coefficient Calculationnitin400No ratings yet

- Cell K11 1 Cell K11 0.5 For F 0, For F 0Document9 pagesCell K11 1 Cell K11 0.5 For F 0, For F 0HaymanAHMEDNo ratings yet

- Rectangular Column Design by IS CodeDocument72 pagesRectangular Column Design by IS CodeStructural SpreadsheetsNo ratings yet

- Chapter8 - Design Theory & Procedure PDFDocument407 pagesChapter8 - Design Theory & Procedure PDFJunwhan KimNo ratings yet

- Indian Steel Weight Calculator FreeDocument1 pageIndian Steel Weight Calculator Freeparth shahNo ratings yet

- Bearing Strength of Concrete Vu Area Required For Baseplate AreaDocument5 pagesBearing Strength of Concrete Vu Area Required For Baseplate AreaSunidhi ItagiNo ratings yet

- G EOTECHNICAL CAPACITY OF R. C. C PILEDocument1 pageG EOTECHNICAL CAPACITY OF R. C. C PILEChowdhury PriodeepNo ratings yet

- Eccentrically Loaded Weld Group Analysis: Company Name Sample Calculations YP and Address 8/1/21 C-Shape WeldDocument9 pagesEccentrically Loaded Weld Group Analysis: Company Name Sample Calculations YP and Address 8/1/21 C-Shape WeldDesign explorer olomizanaNo ratings yet

- Weld Group Under Shear and BendingDocument4 pagesWeld Group Under Shear and Bendingangelica abanesNo ratings yet

- Bridge RulesDocument21 pagesBridge Rulesraghuveer11No ratings yet

- 2B Calc PDFDocument12 pages2B Calc PDFFerdie TolosaNo ratings yet

- Bi Material BeamDocument22 pagesBi Material BeamPraveen KumaarNo ratings yet

- HILTI ExBar Rebar Design Soft WareDocument45 pagesHILTI ExBar Rebar Design Soft WareAc2140No ratings yet

- DESIGN FLOOR JOISTS SPECIFICATIONSDocument7 pagesDESIGN FLOOR JOISTS SPECIFICATIONSTalen Marzan-LelisNo ratings yet

- CK 1 y Ys: - . Strength Ratio: M / M 1.188 1.000....... ReinforcementDocument2 pagesCK 1 y Ys: - . Strength Ratio: M / M 1.188 1.000....... ReinforcementVeva Santi DNo ratings yet

- Load CalculationDocument13 pagesLoad CalculationJahidul IslamNo ratings yet

- Appendix A: Derived Formulae: Flexure: Beams and SlabsDocument5 pagesAppendix A: Derived Formulae: Flexure: Beams and SlabsAbdul Hameed HatemNo ratings yet

- Base Plate - Connection Plate Design-B401 - 12.08.2019Document12 pagesBase Plate - Connection Plate Design-B401 - 12.08.2019Siddharth TiwariNo ratings yet

- Disclosure To Promote The Right To InformationDocument16 pagesDisclosure To Promote The Right To InformationCristian WalkerNo ratings yet

- Session 8 SteelDocument11 pagesSession 8 SteelAlec Christopher MagnoNo ratings yet

- Binder 1Document40 pagesBinder 1Aftub Uz ZamanNo ratings yet

- Connection Design SheetDocument47 pagesConnection Design SheetStephen James100% (1)

- End Plate-Splice ConnectionDocument76 pagesEnd Plate-Splice ConnectionHemant Ramesh Narkar100% (6)

- Gusset Plate Design for Cleveland Clinic Abu DhabiDocument4 pagesGusset Plate Design for Cleveland Clinic Abu Dhabikalpanaadhi75% (4)

- Shear Stress in BeamsDocument11 pagesShear Stress in Beamsangelica abanesNo ratings yet

- Cleat Connection For PlatformsDocument29 pagesCleat Connection For PlatformsRajveer SinghNo ratings yet

- TB1Document7 pagesTB1Feliciano Esteban DominguezNo ratings yet

- BS5950 End Plate DesignDocument4 pagesBS5950 End Plate DesignSimon Lsm67% (3)

- Column Base Plate DesignDocument4 pagesColumn Base Plate Design_jessecaNo ratings yet

- TEDDS calculation summaryDocument5 pagesTEDDS calculation summaryIvan DimitrovNo ratings yet

- Large Moment ExampleDocument5 pagesLarge Moment ExampleAmro Ahmad AliNo ratings yet

- Eur Ocode Design Factor S and Limits: Horizontal DeflectionsDocument1 pageEur Ocode Design Factor S and Limits: Horizontal DeflectionsJay PadamaNo ratings yet

- Murugesan-reddiar-Thesis - Kent and Park ModelDocument2 pagesMurugesan-reddiar-Thesis - Kent and Park ModelJay PadamaNo ratings yet

- New Replaceable Coupling Beams For Shear Wall Structures: Yun ChenDocument10 pagesNew Replaceable Coupling Beams For Shear Wall Structures: Yun ChenFrancisco GarridoNo ratings yet

- Course SyllabusDocument2 pagesCourse SyllabusJay PadamaNo ratings yet

- Aci 374.1-05Document9 pagesAci 374.1-05Arshadahc100% (2)

- Dong 2003 Thesis (1) - TheSISDocument380 pagesDong 2003 Thesis (1) - TheSISJay PadamaNo ratings yet

- Course SyllabusDocument2 pagesCourse SyllabusJay PadamaNo ratings yet

- Cyclic Behavior of Steel Shear Links Used in Replaceable Coupling BeamsDocument11 pagesCyclic Behavior of Steel Shear Links Used in Replaceable Coupling BeamsJay PadamaNo ratings yet

- Reinforced-Concrete-Tilt-Up-Wall-Panel-Analysis-Design-ACI551 - Structure Point PDFDocument18 pagesReinforced-Concrete-Tilt-Up-Wall-Panel-Analysis-Design-ACI551 - Structure Point PDFDivy JainNo ratings yet

- (MSC) A Finite Element Approach To Reinforced Concrete Slab DesignDocument170 pages(MSC) A Finite Element Approach To Reinforced Concrete Slab DesignAbera MamoNo ratings yet

- Behaviour of A Precast Concrete Beam-Column Connection: Sergio M Alcocer, Rene Carranza and David Perez-NavarreteDocument8 pagesBehaviour of A Precast Concrete Beam-Column Connection: Sergio M Alcocer, Rene Carranza and David Perez-NavarreteAbdul HafeezNo ratings yet

- Precast ConnectionDocument108 pagesPrecast ConnectionFreddie Koo100% (2)

- Masters CostDocument1 pageMasters CostJay PadamaNo ratings yet

- Sustainability 11 00867 v2 PDFDocument22 pagesSustainability 11 00867 v2 PDFMatías Pino YáñezNo ratings yet

- Behaviour of A Precast Concrete Beam-Column Connection: Sergio M Alcocer, Rene Carranza and David Perez-NavarreteDocument8 pagesBehaviour of A Precast Concrete Beam-Column Connection: Sergio M Alcocer, Rene Carranza and David Perez-NavarreteAbdul HafeezNo ratings yet

- Analytical Investigation Between, Precast and In-Situ Concrete Under Seismic ConditionDocument16 pagesAnalytical Investigation Between, Precast and In-Situ Concrete Under Seismic ConditionJay PadamaNo ratings yet

- BLASRDocument10 pagesBLASRJay PadamaNo ratings yet

- Precast ConnectionDocument108 pagesPrecast ConnectionFreddie Koo100% (2)

- 2014 OlmatiTrasborgNaitoBontempiIJCritInf DraftDocument17 pages2014 OlmatiTrasborgNaitoBontempiIJCritInf DraftJay PadamaNo ratings yet

- 2014 OlmatiTrasborgNaitoBontempiIJCritInf DraftDocument17 pages2014 OlmatiTrasborgNaitoBontempiIJCritInf DraftJay PadamaNo ratings yet

- Analytical Investigation Between, Precast and In-Situ Concrete Under Seismic ConditionDocument16 pagesAnalytical Investigation Between, Precast and In-Situ Concrete Under Seismic ConditionJay PadamaNo ratings yet

- Numerical FE Modelling of Occupant Injury in Soil Vehicle Blast InteractionDocument14 pagesNumerical FE Modelling of Occupant Injury in Soil Vehicle Blast InteractionJay PadamaNo ratings yet

- SSI and Influence Factors in An Underground Electrical SubstationDocument23 pagesSSI and Influence Factors in An Underground Electrical SubstationYorman LPNo ratings yet

- Ch3 Bearing Capacity of Shallow FoundationsDocument53 pagesCh3 Bearing Capacity of Shallow FoundationsBilal MzhrNo ratings yet

- Lec17 Bearing CapacityDocument57 pagesLec17 Bearing CapacityMuhammad EhtshamNo ratings yet

- Seismic Design of Reinforced Concrete Special Moment FramesDocument31 pagesSeismic Design of Reinforced Concrete Special Moment FrameswilfredNo ratings yet

- Evaluation and Prediction of Common Stock Prices - A StatisticalDocument66 pagesEvaluation and Prediction of Common Stock Prices - A StatisticalJay PadamaNo ratings yet

- Blast Resistant DesignDocument6 pagesBlast Resistant DesignKumaraavel ViswanathanNo ratings yet

- Gs Recommendation-Manila PDFDocument2 pagesGs Recommendation-Manila PDFJay PadamaNo ratings yet

- Gs Recommendation-Manila PDFDocument2 pagesGs Recommendation-Manila PDFJay PadamaNo ratings yet