Professional Documents

Culture Documents

Loop Test Sheet PDF

Uploaded by

Trí NguyễnOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Loop Test Sheet PDF

Uploaded by

Trí NguyễnCopyright:

Available Formats

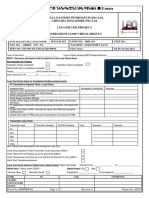

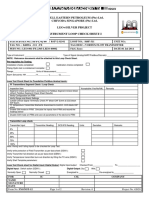

LOOP TEST SHEET

System:

Loop Number

Alarm Settings

Actual alarm values

Alarms needing reset

Post test statement

P&ID:

L=

L=

LL =

LL =

Project:

Description

H=

H=

Signed

The loop is installed as shown on the P&ID and loop

diagram

The loop will perform as designed

Field Labelling

Motor push buttons

Motors

Control/On-Off Valves

Instruments and cabel

Orifice Plates

Junction Box

Marshalling Cabinet

DCS/PLC Panel

Local Panels

General electrical wiring

Other

MCC Room

Starters and push buttons

Lighting suitable

Accessibility of terminations

Fuse/breaker lock box available

Heating adequate

Cooling adequate

Cabinet air fan acceptable?

Labels on cabinet door correct

Wires labeled

Cables labelled

Other

DCS and or I/O Room

DCS/PLC panels labelled

Termination panel access suitable

Termination drawing suitable

Fuse in place

HH =

HH =

YES

NO

YES

NO

OK N/A Instrument

Air Isolation correct

Accessible

Location correct per Loop diagram and P&ID

Input continuity check

Calibration

Range check with Control system

Loop direct/reverse action

Serial number correct

State change OK on control system

Control- On/Off valves

Position

0% =

Position

25% =

Position

50% =

Position

75% =

Position

100% =

mA =

mA =

mA =

mA =

mA =

Valve positioner operates correctly

State change OK on control system

Fail position checked

Interlock tested

Documentation

Interlock data on loop and P&ID correct

All loop diagram data correct

Master copy red lines for final mark up

Control room has copy until as built issued

Motor

Megged/rating

Rotation

State change OK on control system

Signed for Instrument/Control / Electrical

Signed for process

Date

Date

You might also like

- Icl 009 PLC PanelDocument2 pagesIcl 009 PLC Panelsamwel kariukiNo ratings yet

- I11c Instrument Close Loop Check PG 1Document1 pageI11c Instrument Close Loop Check PG 1Momo ItachiNo ratings yet

- MQDP4 instrument loop checkDocument2 pagesMQDP4 instrument loop checkshanks263100% (1)

- Instrument Loop CheckDocument3 pagesInstrument Loop Checknayum100% (1)

- DCS Commisioning StepsDocument7 pagesDCS Commisioning StepsJoven BabieraNo ratings yet

- Instrument Loop Check ProcedureDocument3 pagesInstrument Loop Check ProcedureMiko Quijano100% (1)

- Loop Check Sheet TransmitterDocument2 pagesLoop Check Sheet Transmittershanks263100% (1)

- Loop Test ReportDocument7 pagesLoop Test ReportAldeline Sungahid100% (1)

- Defining The Loop: - 20 Ma DC Is Coming From DCS or JB Want To Check. ThatDocument3 pagesDefining The Loop: - 20 Ma DC Is Coming From DCS or JB Want To Check. ThatNazeer Ahamad KhanNo ratings yet

- Loop Checking Basic ProcedureDocument4 pagesLoop Checking Basic ProcedureHamada Elsharawy100% (1)

- Loop Check PresentationDocument39 pagesLoop Check Presentationsaqib javaid100% (5)

- Instrumentation Job Interview Preparation GuideDocument11 pagesInstrumentation Job Interview Preparation GuideJignesh Banava100% (1)

- IAEA - CANDU I&C Lesson Explains InstrumentationDocument100 pagesIAEA - CANDU I&C Lesson Explains InstrumentationIonescu ViorelNo ratings yet

- Instrumentation Interview QuestionDocument35 pagesInstrumentation Interview Questionabbutalibb100% (1)

- Commissioning Issues and Solutions: Teo Puay Yong Pepperl+Fuchs Pte LTD SingaporeDocument52 pagesCommissioning Issues and Solutions: Teo Puay Yong Pepperl+Fuchs Pte LTD Singaporesolo AdoNo ratings yet

- Loop Check and ValveDocument1 pageLoop Check and ValveMohd A IshakNo ratings yet

- How To Do Loop Checks During Plant Pre-CommissioningDocument18 pagesHow To Do Loop Checks During Plant Pre-Commissioningtom2626No ratings yet

- Saudi Aramco Test Report: 30.apr.13 Inst SATR-J-6501 Instrument Loop - Inputs - Transmitter Circuit TestDocument4 pagesSaudi Aramco Test Report: 30.apr.13 Inst SATR-J-6501 Instrument Loop - Inputs - Transmitter Circuit TestRashid Arshad100% (1)

- I-007 DP Transmitter Calibration CheckDocument1 pageI-007 DP Transmitter Calibration CheckAr RahmanNo ratings yet

- Loop Checking and Field Instrument Testing ProcedureDocument7 pagesLoop Checking and Field Instrument Testing Procedurecharzree0% (1)

- Instrument Calibration ChecklistDocument11 pagesInstrument Calibration ChecklistMohd A IshakNo ratings yet

- DCS Commissioning StepsDocument14 pagesDCS Commissioning StepsElton Hove100% (1)

- Cold Loop CheckingDocument1 pageCold Loop CheckingZulkernain Omer TariqNo ratings yet

- Loop Check: Operator's GuideDocument21 pagesLoop Check: Operator's Guidemc_prayerNo ratings yet

- Loop Check Procedure PDFDocument8 pagesLoop Check Procedure PDFImran Nawaz Mehthal75% (4)

- SATR-J-6501 - Rev 0 PDFDocument5 pagesSATR-J-6501 - Rev 0 PDFAdel KlkNo ratings yet

- P-5000T - Loop Folder PDFDocument15 pagesP-5000T - Loop Folder PDFSrikant SuruNo ratings yet

- Instrumentation General Procedure-InstallationDocument23 pagesInstrumentation General Procedure-InstallationDewAngga Yudistira100% (7)

- C InstrumentationDocument12 pagesC InstrumentationabyzenNo ratings yet

- Flow & Level Calibration Notes: Differential Pressure Transmitter CalibrationDocument9 pagesFlow & Level Calibration Notes: Differential Pressure Transmitter Calibrationterio16100% (1)

- Project Quality Plan and Loop Testing ProceduresDocument3 pagesProject Quality Plan and Loop Testing ProceduresOwais MalikNo ratings yet

- Loop check procedure E1Document3 pagesLoop check procedure E1mc_prayer50% (2)

- J1525-HW1-010 SAT Procedure - Rev ADocument16 pagesJ1525-HW1-010 SAT Procedure - Rev Aluis HernandezNo ratings yet

- CVDocument5 pagesCVFenil ShingalaNo ratings yet

- SATR-J-6601 Rev 0 PDFDocument4 pagesSATR-J-6601 Rev 0 PDFAdel Klk100% (1)

- Hazira Site - Control Valve Calibration SheetDocument3 pagesHazira Site - Control Valve Calibration Sheet8103 Anshu Patil100% (1)

- A.S. A. Ap117: (Instrument & Control Engineer) & Spi (Intools) Specialist ObjectiveDocument5 pagesA.S. A. Ap117: (Instrument & Control Engineer) & Spi (Intools) Specialist ObjectiveAkoKhalediNo ratings yet

- FlowCheck User ManualDocument88 pagesFlowCheck User Manualrobercl51No ratings yet

- 639-2017 - Forms (ITP)Document9 pages639-2017 - Forms (ITP)george stanley paceteNo ratings yet

- Loop Checking Procedure IdeasDocument2 pagesLoop Checking Procedure IdeasJonatas13No ratings yet

- Control Valve Calibration FFDocument3 pagesControl Valve Calibration FFKram Alim VillonNo ratings yet

- Loop Test ProcedureDocument4 pagesLoop Test Procedureviddyadrian100% (2)

- D002 (I&C) Instrument and Calibration Procedure For Turbine & Boiler AreaDocument38 pagesD002 (I&C) Instrument and Calibration Procedure For Turbine & Boiler AreaSurya Darma100% (1)

- Symphony Plus DIN Operation GuideDocument58 pagesSymphony Plus DIN Operation Guideramses mantillaNo ratings yet

- Commissioning Methodology For Boiler-1Document17 pagesCommissioning Methodology For Boiler-1Subhankar ChaudhuriNo ratings yet

- KEI Wires & Cables - Instrumentation Cable ManufacturingDocument1 pageKEI Wires & Cables - Instrumentation Cable Manufacturingrobinknit2009No ratings yet

- Pre-Loop Check ProcedureDocument1 pagePre-Loop Check ProceduresithulibraNo ratings yet

- Loop Test Procedure 71259C-0100-PP-941 - OpenDocument40 pagesLoop Test Procedure 71259C-0100-PP-941 - Opensaid250009250No ratings yet

- Instrumentation Engineer 1expDocument4 pagesInstrumentation Engineer 1exppritiprakash1No ratings yet

- Field Instrumentation (Oil and Gas)Document4 pagesField Instrumentation (Oil and Gas)Mohamed RaeesNo ratings yet

- Calibration Procedure of A Control ValveDocument12 pagesCalibration Procedure of A Control ValveAbdNo ratings yet

- Offline SPI TrainingDocument2 pagesOffline SPI Trainingsmartravi222No ratings yet

- Standard Check List: Pressure TransmiterDocument3 pagesStandard Check List: Pressure TransmiterROUNAK MANDALNo ratings yet

- Instrument Check ListDocument19 pagesInstrument Check ListFarhan KhanNo ratings yet

- InstrumentationDocument8 pagesInstrumentationtingpaduNo ratings yet

- Model Work Place Check ListDocument5 pagesModel Work Place Check ListT S VirdiNo ratings yet

- Electrical and Instrumentation Specifications for Water Supply ProjectDocument36 pagesElectrical and Instrumentation Specifications for Water Supply ProjectPrashant MohokarNo ratings yet

- PLC Panel Check ListDocument6 pagesPLC Panel Check ListPATEL AKASHNo ratings yet

- JKR Acmv Ahu PDFDocument4 pagesJKR Acmv Ahu PDFHafiz Abdullah50% (2)

- Erroor Code SamsungDocument5 pagesErroor Code SamsungZdravko PeranNo ratings yet

- Advisor InstrumentDocument1 pageAdvisor InstrumentTrí NguyễnNo ratings yet

- Adjustable Speed Drives TutorialDocument13 pagesAdjustable Speed Drives Tutorialapi-3765150100% (2)

- OPC Security WP1Document39 pagesOPC Security WP1Gary8No ratings yet

- Electric Motor Controls TutorialDocument24 pagesElectric Motor Controls Tutorialvijai daniel100% (4)

- Instrumentation Training Tutorial Part1Document6 pagesInstrumentation Training Tutorial Part1Gary8100% (1)

- TroubleshootingDocument39 pagesTroubleshootingTrí NguyễnNo ratings yet

- Advisor InstrumentDocument1 pageAdvisor InstrumentTrí NguyễnNo ratings yet

- Sink or Source - PNP or NPN - Normally Open or Normally Closed - Instrumentation ToolsDocument5 pagesSink or Source - PNP or NPN - Normally Open or Normally Closed - Instrumentation ToolsTrí NguyễnNo ratings yet

- New PDFDocument12 pagesNew PDFChristopher GarciaNo ratings yet

- Flam GasDocument14 pagesFlam GasTrí NguyễnNo ratings yet

- 53ii 54ii Series ManualDocument26 pages53ii 54ii Series ManualTrí NguyễnNo ratings yet

- Instrument Cables SpecificationDocument12 pagesInstrument Cables Specificationdon121don121No ratings yet

- Understanding Instrument CablesDocument7 pagesUnderstanding Instrument CablesrjeceNo ratings yet

- Macurco CM6-FCK UserManualDocument4 pagesMacurco CM6-FCK UserManualTrí NguyễnNo ratings yet

- HippsDocument31 pagesHippsAjaykumar TiwariNo ratings yet

- L&T High Integrity Pressure Protection System HIPPSDocument8 pagesL&T High Integrity Pressure Protection System HIPPSvasan_andNo ratings yet

- Understanding ATEXDocument14 pagesUnderstanding ATEXFavas KvpNo ratings yet

- Control Loop Foundation OverviewDocument163 pagesControl Loop Foundation Overviewsubhu1981No ratings yet

- HippsDocument31 pagesHippsAjaykumar TiwariNo ratings yet

- Temperature MeasurementDocument33 pagesTemperature MeasurementTrí Nguyễn100% (1)

- High Integrity Protection Systems For Flare Load MitigationDocument8 pagesHigh Integrity Protection Systems For Flare Load MitigationKALPUSHNo ratings yet

- Hi Pps GarciaDocument20 pagesHi Pps GarciaTrí NguyễnNo ratings yet

- Ip Instrument Loop Diagram PDFDocument1 pageIp Instrument Loop Diagram PDFTrí NguyễnNo ratings yet

- Appendix F: Engineering Standards Manual ISD 341-2Document3 pagesAppendix F: Engineering Standards Manual ISD 341-2Trí NguyễnNo ratings yet

- Managing The Risk of Falls at WorkplacesDocument54 pagesManaging The Risk of Falls at Workplacesceliofsilva8993No ratings yet

- Ip Instrument Loop Diagram PDFDocument1 pageIp Instrument Loop Diagram PDFTrí NguyễnNo ratings yet

- Ergonomic Hazards FactsheetDocument12 pagesErgonomic Hazards FactsheetTrí NguyễnNo ratings yet

- Model 10K Bulletin - enDocument8 pagesModel 10K Bulletin - enTrí NguyễnNo ratings yet

- Planning and Designing Gas Detection ReferencesDocument4 pagesPlanning and Designing Gas Detection ReferencesAnonymous m4UHC60Y8No ratings yet