Professional Documents

Culture Documents

Performance Sheet Drill Pipe: Pipe Body: Tubular Assembly

Uploaded by

Garcia C L AlbertoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Performance Sheet Drill Pipe: Pipe Body: Tubular Assembly

Uploaded by

Garcia C L AlbertoCopyright:

Available Formats

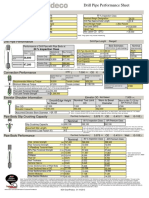

Drill Pipe Performance Sheet

Asset Number: WS42-18

Pipe Body:

Size and Weight: 5.875'' 23.40 ppf 0.361'' wall IEU

Grade: Z-140

Range: 2

Tool Joint: 7.000'' x 4.250'' XT57

Tubular Assembly:

Nominal

100% RBW

95% RBW

Ultra Class

90% RBW

Premium

80% RBW

5.875

0.361

5.153

5.839

0.343

5.153

5.803

0.325

5.153

5.731

0.289

5.153

Tensile Strength (lbs):

Torsional Strength (ft-lbs):

875,491

109,395

828,993

103,504

782,783

97,661

691,222

86,117

Burst Capacity (psi):

Collapse Capacity (psi):

15,054

11,023

16,345

9,771

15,485

8,504

13,764

6,296

OD (in):

Wall Thickness (in):

Nominal ID (in):

Adjusted Weight (lbs/ft): 28.17

Approximate Length (ft): 32.1

Box TJ Length (in): 17

Pin TJ Length (in): 12

Upset Type: IEU

Max Upset OD (in): 6.000

Drift Size (in): 4.125

Fluid Displacement (gal/ft): 0.43

Fluid Displacement (bblsl/ft): 0.0102

Fluid Capacity w/IPC (gal/ft): 1.03

Fluid Capacity w/IPC (bbls/ft): 0.0245

Fluid Capacity w/o IPC (gal/ft): 1.04

Fluid Capacity w/o IPC (bbls/ft): 0.0247

18

0

Notes: Body properties are calculated based on uniform OD and wall thickness.

Burst capacity for Nominal (100% RBW) based on 87.5% RBW per API.

Note: These are OEM values that may vary with actual values due to mill tolerances, IPC tolerances, OEM rounding, and other

factors. Pipe is purchased at a guaranteed 95% RBW. IPC is applied to a nominal thickness of 0.009''. Pipe will have an ID of

5.095'', which is smaller than pipe purchased at 87.5%.

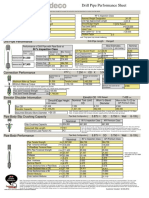

Connection: XT57

Elevator Shoulder:

TJ OD (in): 7.000

TJ ID (in): 4.250

MYS (ksi): 120

Maximum MUT (ft-lbs):

Tension at Shoulder Separation @ Max MUT (lbs):

Tension at Connection Yield @ Max MUT (lbs):

56,500

Tensile Limited

959,500

Minimum MUT (ft-lbs):

Tension at Shoulder Separation @ Min MUT (lbs):

Tension at Connection Yield @ Min MUT (lbs):

47,200

Tensile Limited

1,196,200

Smooth Edge Height (in): 3/32

Smooth Edge OD (in): 7.188

SE Elevator Shoulder Capacity (lbs): 1,223,100

Nominal TJ OD (in): 7.000

Nominal TJ OD Elevator Shoulder Capacity (lbs): 993,000

Assumed Elevator Bore (in): 6.125

N/A

N/A

Tool Joint Torsional Strength (ft-lbs): 94,200

Tool Joint Tensile Strength (lbs): 1,200,500

XT57 is a trademark of NOV Grant-Prideco.

Note: MUT values are based on a friction factor of 1.0. There is no published pressure rating for this connection.

Note: Elevator capacity based on assumed elevator bore, no wear factor, and contact stress of 110, 100 psi. An increased

elevator shoulder OD increases elevator capacity without affecting make-up torque.

The technical information containted herein, including the product performance sheet and other attached documents, has been extracted from information available from the manufacturer and is for reference only and not a recommendation. The user is fully responsible for the accuracy and suitability of use of the technical

information. Workstrings International cannot assume responsibility for the results obtained through the use of this material. No expressed or implied warranty is intended. Drill pipe assembly properties are calculated based on uniform OD and wall thickness. No safety factor is applied. The information provided for various

inspection classes and for various wear conditions (remaining body wall) is for information only and does not represent or imply acceptable operation limits. It is the responsibility of the customer and the end user to determine the appropriate performance ratings, acceptable use of the product, maintain safe operational practices,

and to apply a prudent safety factor suitable for the application. For API connections that have different pin and box IDs, tool joint ID refers to the pin ID. Per Chapter B, Section 4 VII of the IADC drilling manual, it is recommended that drilling torque should not exceed 80% of MUT.

www.workstringsinternational.com

Download the Workstrings International Pipe Specification App on the App Store or Google Play

08-Sep-15

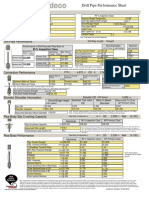

Operational Limits of Drill Pipe

Connection

Pipe Body

XT57

80 % Inspection Class

Tool Joint OD

(in)

7.000

Tool Joint ID

Pipe Body OD

(in)

5.875

Wall Thickness (in) 0.361

(in)

4.250

Tool Joint Specified Minimum

120,000

(psi)

Yield Strength

Pipe Body Grade

Z-140

(ft-lbs)

(lbs)

(ft-lbs)

0

2,600

5,100

7,700

10,200

12,800

15,300

17,900

20,500

23,000

25,600

28,100

30,700

33,300

35,800

38,400

40,900

43,500

46,000

48,600

691,200

690,900

690,000

688,500

686,400

683,500

680,200

676,100

671,400

666,100

660,000

653,400

645,800

637,500

628,700

618,700

608,300

596,600

584,300

570,600

(lbs)

(ft-lbs)

(ft-lbs)

(lbs)

(lbs)

(lbs)

(lbs)

691,200

959,500

691,200

691,200

1,196,200

690,900

959,500

2,000

691,000

691,000

1,196,200

690,000

959,500

4,100

690,400

690,400

1,196,200

688,500

959,500

6,100

689,500

689,500

1,196,200

686,400

959,500

8,100

688,200

688,200

1,196,200

686,400

686,400

1,196,200

684,300

684,300

1,196,200

681,800

681,800

1,196,200

678,700

678,700

1,196,200

675,400

675,400

1,196,200

1,196,200

683,500

680,200

676,100

671,400

666,100

660,000

653,400

645,800

637,500

628,700

618,700

608,300

596,600

584,300

570,600

10,200

959,500

12,200

959,500

14,200

959,500

16,300

959,500

18,300

959,500

959,500

20,300

671,700

671,700

959,500

22,400

667,400

667,400

1,196,200

959,500

24,400

662,900

662,900

1,196,200

959,500

26,400

657,900

657,900

1,196,200

959,500

28,500

652,300

652,300

1,196,200

959,500

30,500

646,400

646,400

1,196,200

959,500

32,500

640,100

640,100

1,196,200

959,500

34,600

633,000

633,000

1,196,200

959,500

36,600

625,700

625,700

1,196,200

959,500

38,600

617,700

617,700

1,196,200

Connection

Make-up Torque Range

(ft-lbs)

47,200

48,200

49,300

50,300

51,300

52,400

53,400

54,400

55,500

56,500

(lbs)

1,196,200

1,170,800

1,142,800

1,117,300

1,091,900

1,063,900

1,038,400

1,013,000

985,000

959,500

Note: Recommended MUT should always be used when possible. If not possible, MUT should be as close to Recommended MUT as possible.

Note: The technical information contained herein, including the product performance sheet and other attached documents, is for reference only and should not be construed as a recommendation. The user is fully responsible for the accuracy and

suitability of use of the technical information. NOV Grant Prideco cannot assume responsibility for the results obtained through the use of this material. No expressed or implied warranty is intended. Drill pipe assembly properties are calculated

based on uniform OD and wall thickness. No safety factor is applied. The information provided for various inspection classes and for various wear conditions (remaining body wall) is for information only and does not represent or imply acceptable

operating limits. It is the responsibility of the customer and the end user to determine the appropriate performance ratings, acceptable use of the product, maintain safe operational practices, and to apply a prudent safety factor suitable for the

application. For API connections that have different pin and box IDs, tool joint ID refers to the pin ID. Per Chapter B, Section 4 VII of the IADC drilling manual, it is recommended that drilling torque should not exceed 80% of MUT.

06-17-2015

You might also like

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsFrom EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsRating: 4.5 out of 5 stars4.5/5 (10)

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDocument2 pagesPerformance Sheet Drill Pipe: Pipe Body: Tubular AssemblyGarcia C L AlbertoNo ratings yet

- 5 7/8" VM-165 R2 Pipe SpecsDocument2 pages5 7/8" VM-165 R2 Pipe SpecsTiffany DacinoNo ratings yet

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDocument2 pagesPerformance Sheet Drill Pipe: Pipe Body: Tubular AssemblyGarcia C L AlbertoNo ratings yet

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDocument2 pagesPerformance Sheet Drill Pipe: Pipe Body: Tubular AssemblyGarcia C L AlbertoNo ratings yet

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDocument1 pagePerformance Sheet Drill Pipe: Pipe Body: Tubular AssemblyJohann ZabaletaNo ratings yet

- 5.000in 0.362wall IEU S135 NC50 (6.625 X 3.250 TJ) 9P 12BDocument3 pages5.000in 0.362wall IEU S135 NC50 (6.625 X 3.250 TJ) 9P 12BJeaneth HerreraNo ratings yet

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDocument1 pagePerformance Sheet Drill Pipe: Pipe Body: Tubular AssemblyGarcia C L AlbertoNo ratings yet

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDocument1 pagePerformance Sheet Drill Pipe: Pipe Body: Tubular Assemblymsm.ele2009No ratings yet

- LandingString, 80%, 5.875 OD, 0.750 Wall, IEU, S-135.. XT57 (7.250 X 3.500)Document3 pagesLandingString, 80%, 5.875 OD, 0.750 Wall, IEU, S-135.. XT57 (7.250 X 3.500)Garcia C L AlbertoNo ratings yet

- 4.000in 0.330wall IU CYX105-120 XT39 (4.875 X 2.688 TJ) 12P 15BDocument3 pages4.000in 0.330wall IU CYX105-120 XT39 (4.875 X 2.688 TJ) 12P 15BjohangomezruizNo ratings yet

- Drill Pipe Performance Sheet 5.875 XT57 G105Document3 pagesDrill Pipe Performance Sheet 5.875 XT57 G105Garcia C L AlbertoNo ratings yet

- DrillPipe, 80%, 5.875 OD, 0.750 Wall, IEU, G-105.. XT57 (7.250 X 3.500)Document3 pagesDrillPipe, 80%, 5.875 OD, 0.750 Wall, IEU, G-105.. XT57 (7.250 X 3.500)Garcia C L AlbertoNo ratings yet

- Landing String 6.625 .938 v150 FH Slip Proof 95rbw PDFDocument4 pagesLanding String 6.625 .938 v150 FH Slip Proof 95rbw PDFMarcelo VeronezNo ratings yet

- DrillPipe, 80%, 5.875 OD, 0.500 Wall, IEU, S-135.. XT57 (7.000 X 4.250)Document3 pagesDrillPipe, 80%, 5.875 OD, 0.500 Wall, IEU, S-135.. XT57 (7.000 X 4.250)Garcia C L AlbertoNo ratings yet

- Xt39 Spec SheetDocument3 pagesXt39 Spec SheetjdcomptonNo ratings yet

- Trispiral XT39Document1 pageTrispiral XT39Cerón Niño SantiagoNo ratings yet

- DrillPipe, 80%, 5.500 OD, 0.415 Wall, IEU, G-105.. XT57 (7.000 X 4.000)Document3 pagesDrillPipe, 80%, 5.500 OD, 0.415 Wall, IEU, G-105.. XT57 (7.000 X 4.000)Johann ZabaletaNo ratings yet

- DrillPipe, 80%, 5.000 OD, 0.500 Wall, IEU, S-135.. XT50 (6.625 X 3.750Document3 pagesDrillPipe, 80%, 5.000 OD, 0.500 Wall, IEU, S-135.. XT50 (6.625 X 3.750Инженер Луис А. ГарсиаNo ratings yet

- DrillPipe, 80%, 5.000 OD, 0.362 Wall, IEU, X-95.. XT50 (6.625 X 3.938)Document3 pagesDrillPipe, 80%, 5.000 OD, 0.362 Wall, IEU, X-95.. XT50 (6.625 X 3.938)Johann ZabaletaNo ratings yet

- Drill Pipe Configuration: 95 % Inspection ClassDocument3 pagesDrill Pipe Configuration: 95 % Inspection ClassSaurav SenguptaNo ratings yet

- DrillPipe, 80%, 4.000 OD, 0.330 Wall, IU, G-105.. XT39 (4.875 X 2.563)Document3 pagesDrillPipe, 80%, 4.000 OD, 0.330 Wall, IU, G-105.. XT39 (4.875 X 2.563)Johann ZabaletaNo ratings yet

- Drill Pipe Performance SheetDocument3 pagesDrill Pipe Performance Sheetjinyuan74No ratings yet

- HeavyWeight 3.5 25.58lbs NC-38Document3 pagesHeavyWeight 3.5 25.58lbs NC-38Инженер Луис А. ГарсиаNo ratings yet

- DrillPipe, 80%, 3.500 OD, 0.449 Wall, EU, G-105.. XT39 (4.938 X 2.563) PDFDocument3 pagesDrillPipe, 80%, 3.500 OD, 0.449 Wall, EU, G-105.. XT39 (4.938 X 2.563) PDFGarcia C L Alberto100% (1)

- Drill Pipe Performance SheetDocument3 pagesDrill Pipe Performance SheetGarcia C L AlbertoNo ratings yet

- 2.500 X 1.375 DC With MW20 SlickDocument1 page2.500 X 1.375 DC With MW20 SlickHadi Bapir SlemanNo ratings yet

- Tablas Tuberia XTDocument35 pagesTablas Tuberia XTArcadio Bahena100% (1)

- Drill CollarDocument1 pageDrill CollarGuillermo Rangel AvalosNo ratings yet

- Series 805YD Specification SheetDocument2 pagesSeries 805YD Specification SheetFEBCONo ratings yet

- WAW-600F Single Space Servo Universal Testing MachineDocument13 pagesWAW-600F Single Space Servo Universal Testing MachineXavier Kate GalvanNo ratings yet

- "Equipping The World For A Better Environment": Federal Supply ServiceDocument4 pages"Equipping The World For A Better Environment": Federal Supply ServiceAlberto CortezNo ratings yet

- Backflow PreventersDocument4 pagesBackflow PreventersSam WeberNo ratings yet

- HUT-A Hydraulic Universal Testing Machine 2018.6.26 PDFDocument6 pagesHUT-A Hydraulic Universal Testing Machine 2018.6.26 PDFSoup PongsakornNo ratings yet

- Monolithic Isolation Fittings: The Industry's "Dual O'Ring Seal"Document6 pagesMonolithic Isolation Fittings: The Industry's "Dual O'Ring Seal"chkzaNo ratings yet

- Burst Plug Tubing Drain - Technical DatasheetDocument8 pagesBurst Plug Tubing Drain - Technical DatasheetEvolution Oil ToolsNo ratings yet

- 2.875 N80 6.51ppf EUEDocument1 page2.875 N80 6.51ppf EUEANSARAKUNo ratings yet

- TB 00700001 eDocument9 pagesTB 00700001 eRicardo LopezNo ratings yet

- EUROPLUS New System TYPPR EN 2005-09Document12 pagesEUROPLUS New System TYPPR EN 2005-09Christian BenitezNo ratings yet

- Series 709 Specification SheetDocument4 pagesSeries 709 Specification SheetWattsNo ratings yet

- Series 008PCQT Specification SheetDocument2 pagesSeries 008PCQT Specification SheetWattsNo ratings yet

- Static Calculation For FansDocument4 pagesStatic Calculation For FansBadrul HishamNo ratings yet

- Apartarrayo Roser PolDocument16 pagesApartarrayo Roser PolMiguel Perez FloresNo ratings yet

- AA SPEC 371001 - Conveyor Pulleys and ShaftsDocument14 pagesAA SPEC 371001 - Conveyor Pulleys and Shaftsjonodo89No ratings yet

- Screen Sand ControlDocument20 pagesScreen Sand ControlsaptagunungNo ratings yet

- Datasheet For MUR1620Document6 pagesDatasheet For MUR1620WarungRobotika Milis100% (1)

- Brochure 3Document12 pagesBrochure 3Gohilakrishnan ThiagarajanNo ratings yet

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- Prevention of Valve Fugitive Emissions in the Oil and Gas IndustryFrom EverandPrevention of Valve Fugitive Emissions in the Oil and Gas IndustryNo ratings yet

- Contractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerFrom EverandContractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerRating: 5 out of 5 stars5/5 (1)

- Applied Process Design for Chemical and Petrochemical Plants: Volume 1From EverandApplied Process Design for Chemical and Petrochemical Plants: Volume 1Rating: 3.5 out of 5 stars3.5/5 (3)

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- Semi-Active Suspension Control Design for VehiclesFrom EverandSemi-Active Suspension Control Design for VehiclesRating: 5 out of 5 stars5/5 (1)

- 8035E Top Drive Spec SheetDocument2 pages8035E Top Drive Spec SheetTiffany DacinoNo ratings yet

- Beautiful Night Guitar TabDocument3 pagesBeautiful Night Guitar TabTiffany DacinoNo ratings yet

- Well Integrity / Well Plugging Guidelines (9.1 - 9.10)Document35 pagesWell Integrity / Well Plugging Guidelines (9.1 - 9.10)Tiffany DacinoNo ratings yet

- Snubbing GuidelinesDocument1 pageSnubbing GuidelinesTiffany DacinoNo ratings yet

- Calcium Chloride SolutionDocument5 pagesCalcium Chloride SolutionTiffany DacinoNo ratings yet

- Magnum ManualDocument2 pagesMagnum ManualTiffany DacinoNo ratings yet

- Otis R and RN Landing Nipples and Lock MandrelsDocument1 pageOtis R and RN Landing Nipples and Lock MandrelsTiffany DacinoNo ratings yet

- Free Body Diagram (FBD)Document1 pageFree Body Diagram (FBD)Tiffany DacinoNo ratings yet

- 1998 World Oil Rig FleetDocument62 pages1998 World Oil Rig FleetTiffany Dacino100% (2)

- Repair Manual MP 1Document11 pagesRepair Manual MP 1Tiffany DacinoNo ratings yet