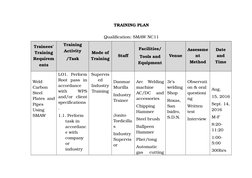

TRAINING PLAN

Qualification: SMAW NC11

Trainees

Training

Requirem

ents

Training

Activity

/Task

Mode of

Training

Facilities/

Staf

LO1. Perform Supervis

Root pass in

ed

Weld

Danmar

accordance

Industry

Carbon

Murilla

with

WPS

Training

Steel

Industry

Plates and and/or client

Trainer

specifications

Pipes

.

Using

Jonito

SMAW

1.1. Perform

Tordicilla

task in

s

accordanc

e with

Industry

company

Supervis

or

or

industry

Tools and

Equipment

Venue

Arc Welding

machine

AC/DC and

accessories

3rs

welding

Shop

Chipping

Hammer

Steel brush

Ballpeen

Hammer

Plier/tong

Automatic

gas

cutting

Roxas,

San

Isidro,

S.D.N.

Assessme

nt

Method

Observati

on & oral

questioni

ng

Written

test

Interview

Date

and

Time

Aug.

15, 2016

Sept. 14,

2016

M-F

8:2011:20

1:005:00

300hrs

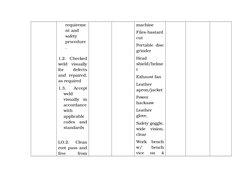

�requireme

nt and

safety

procedure

.

1.2. Checked

weld visually

for

defects

and repaired,

as required

1.3.

Accept

weld

visually in

accordance

with

applicable

codes and

standards

LO.2. Clean

root pass and

free

from

machine

Files-bastard

cut

Portable disc

grinder

Head

shield/helme

t

Exhaust fan

Leather

apron/jacket

Power

hacksaw

Leather

glove,

Safety goggle,

wide vision,

clear

Work bench

w/

bench

vice on 4

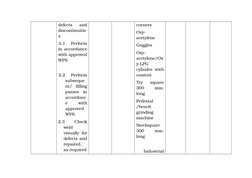

�defects

and

discontinuitie

s

corners

2.1 Perform

in accordance

with approved

WPS

Goggles

2.2

Perform

subseque

nt/ filling

passes in

accordanc

e

with

approved

WPS

2.3

Check

weld

visually for

defects and

repaired,

as required

Oxyacetylene

Oxyacetylene/Ox

y-LPG

cylinder with

content

Try

300

long

square

mm.

Pedestal

/bench

grinding

machine

Steelsquare

300

mm.

long

Industrial

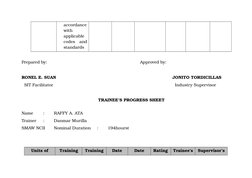

�2.4

Accept

weld

visually in

accordance

with

applicable

codes and

standards

LO3. Perform

capping in

accordance

with WPS

and/or

client

specificatio

ns

3.1

Check

weld

for

defects

and

repaired, as

required

3.2

Accept

weld

in

fan

Files-half

round

Fillet

gauge

�accordance

with

applicable

codes and

standards

Prepared by:

Approved by:

RONEL E. SUAN

JONITO TORDICILLAS

SIT Facilitator

Industry Supervisor

TRAINEES PROGRESS SHEET

Name

RAFFY A. ATA

Trainer

Danmar Murilla

SMAW NCII

Units of

Nominal Duration

Training

Training

194hourst

Date

Date

Rating

Trainees

Supervisors

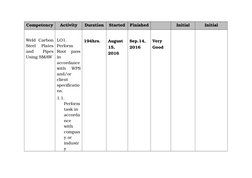

�Competency

Weld Carbon

Steel Plates

and

Pipes

Using SMAW

Activity

Duration

LO1.

194hrs.

Perform

Root pass

in

accordance

with WPS

and/or

client

specificatio

ns.

1.1.

Perform

task in

accorda

nce

with

compan

y or

industr

y

Started

Finished

August

15,

2016

Sep.14,

2016

Initial

Very

Good

Initial

�require

ment

and

safety

proced

ure.

1.2.

Checked

weld

visually for

defects and

repaired,

as required

1.3. Accept

weld

visually

in

accorda

nce with

applicab

le codes

and

�standar

ds

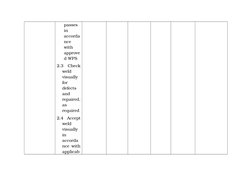

LO.2.

Clean root

pass

and

free

from

defects and

discontinui

ties

2.1

Perform in

accordance

with

approved

WPS

2.2

Perform

subseq

uent/

filling

�passes

in

accorda

nce

with

approve

d WPS

2.3 Check

weld

visually

for

defects

and

repaired,

as

required

2.4 Accept

weld

visually

in

accorda

nce with

applicab

�le codes

and

standar

ds

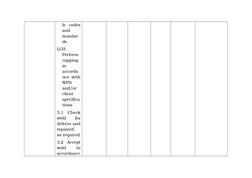

LO3.

Perform

capping

in

accorda

nce with

WPS

and/or

client

specifica

tions

3.1 Check

weld

for

defects and

repaired,

as required

3.2 Accept

weld

in

accordance

�with

applicable

codes and

standards

Total

Note: The trainee and the supervisor must have a copy of this form. The column for rating maybe used either

by giving a numerical rating or simply indicating competent or not yet competent. For purposes of analysis,

you may require industry supervisors to give a numerical rating for the performance of your trainees. Please

take note however that in TESDA, we do not use numerical ratings

�PREPARATION

1. Workshop layout

conforms with the

components of a CBT

workshop

2. Number of CBLM is

sufficient

3. Objectives of every

training session is well

explained

4. Expected

activities/outputs are

clarified

General Average

Average

�SUPERVISED INDUSTRY TRAINING OR ON THE JOB

TRAINING EVALUATION FORM

Dear Trainees:

The following questionnaire design to evaluate the effectiveness of

the Supervised Industry Training (SIT) or on the Job Training

9OJT) you had with the Industry Partners of ROXAS NATIONAL

HIGH SCHOOL. Please check ( ) the appropriate box

corresponding to your rating for each question asked. The

management of the SIT in ROXAS NHS to maximize the benefits

of the said program. Thank you for your cooperation.

Legend:

5-Outstanding

4-Very Good/Very Satisfactory

3-Good/Adequate

2-Fair/Satisfactory

1-Poor/Unsatisfactory

NA-not applicable

Ite

m

No.

Question

INSTITUTIONAL EVALUATION

Has Roxas National High School conducted an

orientation about the SIT/OJT program, the

requirements and preparations needed and its

expectations?

Has Roxas National High School the provided

necessary assistance such as referrals or

recommendations in finding the company for

your OJT?

Rating

1 2 3 4 5

N

A

�Has Roxas NHS showed coordination with the

3

Industry partner in the design & supervision of

your SIT/OJT?

Has your in-school training adequate to

4

undertake Industry partner assignment & its

challenge?

Has Roxas NHS monitored your progress in the

5

Industry?

Has the supervision been effective in achieving

6

your OJT objectives & providing feedbacks when

necessary?

Did Roxas NHS conduct assessment of your

7

SIT/OJT program upon completion?

Were you provided with the results of the

8

Industry & Roxas NHS assessment of your OJT?

Comments/Suggestions:

The school is the best place for learning, it is indeed where I mold &

trained to become a professional & skilled worker, teachers has different

character, perspective & ways on how they teach to students learns at

their very best venture. Therefore I commend that education must for all

& continue to pursue education & moreover, teachers also must be

trained & send to training & seminar to upgrade learning. And for

renewal of how to work with dedication in teaching students because

students learning most of the time lies in the hand of teachers.

�Ite

m

No.

Question

INDUSTRY PARTNER

1

2

3

6

7

9

10

Was the Industry partner appropriate for you

type of training required and/or desired?

Has the Industry partner designed training to

meet your objectives & expectations?

Has the Industry partner showed coordination

with Roxas NHS in the design and supervision of

the SIT/OJT?

Has the industry partner and its staff welcomed

you and treated you with respect and

understanding?

Has the Industry partner facilitated the training,

including the provision of the necessary

resources such as facilities and equipment

needed to achieve your OJT objectives?

Has the Industry partner assigned a supervisor

to oversee your work or training?

Was the supervisor effective in supervising you

through regular meetings, consultation &

advise?

Has the training provided you with the

necessary technical & administrative exposure of

real world problems & practices?

Has the training program allowed you to develop

self-confidence, self motivation & positive

attitudes towards work?

Has the experience improved your personal skills

and human relations?

Rating

1 2 3 4 5

N

A

�Are you satisfied with your training in the

Industry?

Comments/Suggestions:

11

In the part of On the Job Training, the time management

disciplined training is not much emphasized & it needs care & attention to

be strictly followed. Besides it needs more training design to be followed by

trainee in line with the new trend of technology. Furthermore, Equipments

& tools for safety must be strictly observed in order that the trainee feels

secure & safety. Finally, I am very much satisfied with my training despite

of little find fault explained above. I found myself belongs to skilled worker

now because of them that they make what have in my own now, a

knowledge & skills.

Signature:_________________________

Printed Name:Raffy A. Ata

Qualification: NCII

Host Industry Partner:3Rs Welding Shop

Supervisor: Jonito Tordicillas

Period of Training: August 20-Sep.22, 2016

Instructor: Danmar Murilla