Professional Documents

Culture Documents

Velocity of Water in Pipe

Uploaded by

abidch143Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Velocity of Water in Pipe

Uploaded by

abidch143Copyright:

Available Formats

106 COMPONENTS

Figure 5-12. Two-way valve controlling hot water circuit.

Figure 5-13. Three-way valve controlling chilled-water circuit.

the coil, varies the volume of water flowing through the coil and

diverts flow around the coil as the coil flow is decreased.

The application of valves to air-and-water systems is treated in

Chapter 7; their application to all-water systems is treated in Section 8.7.

5.7 PIPING

The design of piping systems is described in the Pipe Sizing chapter in the ASHRAE HandbookFundamentals, while

physical pipe sizes are given in the ASHRAE HandbookHVAC

AIR-CONDITIONING SYSTEM DESIGN MANUAL107

Systems and Equipment. Assume a value of C = 100 for old or

dirty pipe (i.e., in open systems), 140 for new steel pipe, and 150

for plastic or copper tube/pipe in the Hazen-Williams equation.

Friction loss in hydronic systems is usually between 1 and 5 ft per

100 ft of pipe [10 to 50 kPa per 100 m], with an average of 2.5 ft

per 100 ft [25 kPa per 100 m]. Typically, add 50% to the friction

loss from the straight length of piping to account for fittings. The

following rule is often used to account for the pressure drop in

elbows: the equivalent straight length of pipe (in feet) for an

elbow equals twice the nominal pipe diameter (in inches). Thus, a

1 in. [25 mm] elbow causes the same friction loss as 2 ft [[0.6 m]

of straight 1 in. [25 mm] pipe. Pumping power (for water, with a

specific gravity of 1) is estimated from

bhp = (gpm) (head of water, ft) / (3960) (pump efficiency) (5-14)

[kW = (L/s) (head of water, kPa) / (1002) (pump efficiency)]

with pump efficiencies ranging from 0.40 to 0.60 for small pump

capacities and from 0.70 to 0.85 for larger pumps.

To calculate the appropriate size of compression/expansion

tanks, use the table in the Hydronic Heating and Cooling System

Design chapter in the ASHRAE HandbookHVAC Systems and

Equipmentt that lists volumes in gallons per foot of pipe [L per m].

The water volumes in chillers, coils, heat exchangers, etc., must be

added to those volumes.

Approximate parameters for air control expansion tanks are

16% of total water volume for chilled water;

20% of total water volume for hot water under standard sea

level conditions and 30 to 40 ft [90 to 120 kPa] static head;

12 psig [83 kPa] fill pressure, 30 psig [207 kPa] relief valve; and

200F [93C] hot water, 44F [6.7C] chilled water.

Tank sizes as estimated above can usually be cut in half if compression tanks, which contain a diaphragm that maintains separation between the air cushion and the water, are used.

If antifreeze liquids are used, the reduced thermal capacity

(specific heat) and increased viscosity of these liquids compared to

water (see the Secondary Coolants (Brines) chapter in the

ASHRAE HandbookFundamentals) must be considered. For

example, the flow resistance of a 30% glycol aqueous solution is

15% greater than that of water. Drag-reducing agents may be able

to offset these conditions.

108 COMPONENTS

The following velocities are recommended for closed (pressurized) piping systems:

Service

Pump discharge

Pump suction

Drain line

Header

Riser

General service

City water

Velocity Range, fps [m/s]

8 to 12 [2.5 to 3.7]

4 to 7 [1.2 to 2.1]

4 to 7 [1.2 to 2.1]

4 to 12 [1.2 to 3.7]

3 to 10 [0.9 to 3.1]

5 to 10 [1.5 to 3.1]

3 to 7 [0.9 to 2.1]

Maximum recommended water velocities to minimize erosion

are as follows:

Normal Annual Operating Hours

1500

2000

3000

4000

5000

8000

Maximum Recommended

Water Velocity, fps [m/s]

12 [3.7]

11.5 [3.5]

11 [3.4]

10 [3.1]

9 [2.7]

8 [2.4]

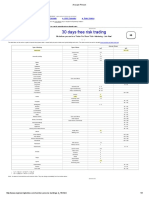

Pressure drop calculations for a typical 10,000 ft2 [930 m2]

low-rise office building are shown in Table 5-2. The information is

based upon manufacturers data, except where noted. Both pressurized and open systems are considered.

5.7.1 Air Control and Venting

If air and other gases are not eliminated from a hydronic piping

circuit, they may cause air binding in terminal heat transfer elements and noise and/or reduction in flow in the piping circuit. Piping can be run level, provided flow velocities in excess of 1.5 fps

[0.5 m/s] are maintained. Otherwise, piping should pitch up in the

direction of flow to a high point containing an air vent or a runout to

a room terminal unit. Vent high points in piping systems and terminal units with manual or automatic air vents. As automatic air vents

may malfunction, provide valves at each vent to permit servicing

without draining the system. Pipe the discharge of each vent to a

point where water can be wasted into a drain or container to prevent

damage to the surroundings. If a standard compression or expansion tank is used, free air contained in the circulating water can be

AIR-CONDITIONING SYSTEM DESIGN MANUAL109

Table 5-2. Sample Pressure Drop Calculations

Pressurized System

Item

Boiler (assume 20 gpm [1.3 L/s])

Pump tree

Strainer (in tree)

Supply piping

Return piping

Three-way valve

Total

Pressure Drop, ft of water [kPa]

1.0 [3.0]

6.0 [17.9] (from calculations)

8.0 [23.9]

12.0 [35.9] (from calculations,

assume 400 ft [122 m] at 3 ft/100

ft [0.3 kPa/m])

12.0 [35.9] (from calculations,

assume 400 ft [122 m] at 3 ft/100

ft [0.3 kPa/m])

12.0 [35.9] (assume 50% of loop)

51.0 [152.5]

Space heating hot water pump:

bhp = (20 gpm) (51 ft) / (3960) (0.75) = 0.34 bhp

[kW = (1.3 L/s) (152.5 kPa) / (1002) (0.75) = 0.26 kW]

Open System

Item

Cooling tower return pipe

Indoor retention tank

Basket strainer (3.5 psi [24 kPa])

Pump tree

Chiller

Cooling tower supply pipe

Three-way modulating valve

Cooling tower nozzle

Lift to tower nozzle

Total

Pressure Drop, ft of water [kPa]

1.5 [4.5] (from calculations)

0.5 [1.5]

7.0 [20.9]

6.0 [17.9] (from calculations)

6.0 [17.9]

1.5 [4.5] (from calculations)

3.0 [8.9]

12.0 [35.9]

12.0 [35.9] (from building plans)

49.5 [147.9]

Condenser water pump:

bhp = (3 gpm per ton) (49.5 ft) / (3960) (0.75) = 0.05 bhp/ton

[kW = (0.0538 L/s per kW) (147.9 kPa) / (1002) (0.75) = 0.0106 kW/kW]

removed from the piping circuit and trapped in the expansion tank

by air-separation devices. If a diaphragm-type tank is used, vent all

air from the system.

You might also like

- Selection Sheet - 30XA452 Screw ChillerDocument1 pageSelection Sheet - 30XA452 Screw Chillercalvin.bloodaxe4478No ratings yet

- DBR-HVAC Rev 0Document16 pagesDBR-HVAC Rev 0psjjoshiNo ratings yet

- Modification & Repair of Gantry Control Room: Doc No. 2838-CAL-001 Revision No. 0 Calculation For Room PressurizationDocument1 pageModification & Repair of Gantry Control Room: Doc No. 2838-CAL-001 Revision No. 0 Calculation For Room Pressurizationazhar islamNo ratings yet

- Decoupler RecommendationsDocument1 pageDecoupler RecommendationsWaleed FathiNo ratings yet

- System Design Manual-DPCVDocument29 pagesSystem Design Manual-DPCVrama_easNo ratings yet

- Equipment Selection & Design - 2Document5 pagesEquipment Selection & Design - 2Nabeel SiddiqueNo ratings yet

- Duct DesignDocument49 pagesDuct DesignabianshbaralNo ratings yet

- 2 Way & 3 Way Modulating Valve Selection ProcedureDocument5 pages2 Way & 3 Way Modulating Valve Selection ProcedureJuan Altamirano RojasNo ratings yet

- Final - District Cooling System Design MENA - July2021Document220 pagesFinal - District Cooling System Design MENA - July2021Mubashir KhanNo ratings yet

- CP13 - 1999 MV and AC in BuildingDocument56 pagesCP13 - 1999 MV and AC in Buildingbozow bozowlNo ratings yet

- Tyco Pre Action LimitsDocument13 pagesTyco Pre Action LimitsGrbayern Munchen100% (2)

- DecouplerDocument1 pageDecouplersyedahmedsabir100% (2)

- Net Positive Suction HeadDocument7 pagesNet Positive Suction HeadNenad MutavdzicNo ratings yet

- HVACDocument9 pagesHVACMailisa FitriaNo ratings yet

- CTI Test Summary Report (Advent IT Park) T43A 178 16A 2016Document9 pagesCTI Test Summary Report (Advent IT Park) T43A 178 16A 2016nagrajuNo ratings yet

- Pharmaceutical Facility DesignDocument27 pagesPharmaceutical Facility Designmdalt9180No ratings yet

- تقرير تدريب صيفي لواء الدين مظفرDocument23 pagesتقرير تدريب صيفي لواء الدين مظفرlalaNo ratings yet

- Chilled Water FlowDocument1 pageChilled Water FlowKarthikeyan Sankarrajan100% (1)

- The Good Ventilation of Switchgear and Transformer RoomsDocument8 pagesThe Good Ventilation of Switchgear and Transformer RoomsjayamenggalaNo ratings yet

- Hvac Oil GasDocument8 pagesHvac Oil GasManuelNo ratings yet

- Condensate TrapsDocument3 pagesCondensate Trapsalamdar321No ratings yet

- 4 ACMV SystemsDocument293 pages4 ACMV SystemsMorgan HengNo ratings yet

- Expansion Tank Calculation (Chilled Water)Document5 pagesExpansion Tank Calculation (Chilled Water)Ahmed AliNo ratings yet

- Carrier Recommended Minimum CW Fluid Loop VolumeDocument1 pageCarrier Recommended Minimum CW Fluid Loop VolumeRyan Carter100% (2)

- Chiller StorageDocument2 pagesChiller Storageأنين خاطرةNo ratings yet

- Ishrae Variable Volume Pumping SystemDocument14 pagesIshrae Variable Volume Pumping SystemAidrus AliNo ratings yet

- AC-300 - Water Cooled Liquid ChillerDocument11 pagesAC-300 - Water Cooled Liquid Chillerjames_chan2178No ratings yet

- AHU Drain CalculationDocument1 pageAHU Drain Calculationeldosrajan100% (1)

- Acoustic Calculation of Ventilation SystemsDocument49 pagesAcoustic Calculation of Ventilation SystemsHari Babu DharmavarapuNo ratings yet

- Cartridge FiltersDocument7 pagesCartridge FiltersMohamed TallyNo ratings yet

- Chiller PDFDocument20 pagesChiller PDFredaNo ratings yet

- NBC vs. NFPADocument12 pagesNBC vs. NFPAMGHIRBI HAYKELNo ratings yet

- Variable Primary FlowDocument58 pagesVariable Primary FlowAlfredo Merizalde Aviles100% (2)

- Design Calculation Sheet: Water Demand & Drainage FlowDocument5 pagesDesign Calculation Sheet: Water Demand & Drainage FlowAhmadNo ratings yet

- Fcu PipingDocument20 pagesFcu PipingRamadan RashadNo ratings yet

- ASHRAE Journal - Tips To Reduce Chilled Water Plant Costs - TaylorDocument6 pagesASHRAE Journal - Tips To Reduce Chilled Water Plant Costs - TaylorsajuhereNo ratings yet

- Sizing and Selection Guide of ASME Bladder Type Expansion Tanks For Chilled Water SystemsDocument4 pagesSizing and Selection Guide of ASME Bladder Type Expansion Tanks For Chilled Water SystemsAntonio LebrunNo ratings yet

- Ahu 6 Alternate ArrangementDocument4 pagesAhu 6 Alternate Arrangementnaresh100% (1)

- IA Compressor PKG - OptimizedDocument7 pagesIA Compressor PKG - OptimizedJetul PatelNo ratings yet

- Spec - Chiller Lắp Đặt ChillerDocument42 pagesSpec - Chiller Lắp Đặt ChillerBay MưaNo ratings yet

- HVAC Psychrometric Analysis To Avoid Moisture ProblemsDocument30 pagesHVAC Psychrometric Analysis To Avoid Moisture ProblemsmohdrashidNo ratings yet

- Double Regulating ValveDocument24 pagesDouble Regulating ValveMohamed Rady33% (3)

- Ashrae ChartDocument1 pageAshrae Chartalone160162lNo ratings yet

- Air Changes Per Hour - University of LiverpoolDocument2 pagesAir Changes Per Hour - University of LiverpoolminiongskyNo ratings yet

- Pipe Pressure Drope ASEREHDocument3 pagesPipe Pressure Drope ASEREHSenghou MeasNo ratings yet

- Chiller Diversity FactorDocument3 pagesChiller Diversity FactoraadsamudNo ratings yet

- A Theoretical and Practical Guide To The Basics of Designing Air Flow SystemsDocument3 pagesA Theoretical and Practical Guide To The Basics of Designing Air Flow Systemsmarcoo8No ratings yet

- Chiller System Design and Control1Document11 pagesChiller System Design and Control1حيدر محمدNo ratings yet

- High Delta T Chilled Water SystemDocument13 pagesHigh Delta T Chilled Water SystemShivraj Sawant100% (3)

- Pump Room Submersible Pumps CalcDocument1 pagePump Room Submersible Pumps CalcMohamed Adel ElBazNo ratings yet

- Ventilation - Electrical Rooms PDFDocument4 pagesVentilation - Electrical Rooms PDFvalentinlupascu33No ratings yet

- ESP CAlDocument1 pageESP CAlMohammed Sayeem ShabuddinNo ratings yet

- Carrier HAP Systems Design ReportDocument30 pagesCarrier HAP Systems Design ReportEngineering WavesNo ratings yet

- Dedicated Outdoor Air Systems (Doas) : Indoor Air Quality + Energy Recovery + Humidity ControlDocument39 pagesDedicated Outdoor Air Systems (Doas) : Indoor Air Quality + Energy Recovery + Humidity Controlhtanh100% (1)

- Technical YKDocument16 pagesTechnical YKnairam2003No ratings yet

- Run Around Coil Loop Heat RecoveryDocument3 pagesRun Around Coil Loop Heat RecoveryesagcojrNo ratings yet

- Piping Eveporative COndensersDocument12 pagesPiping Eveporative COndensersscribd99190No ratings yet

- 131A Piping BrochureDocument12 pages131A Piping Brochuredeanewing11No ratings yet

- All Code Jurisdictions Have Maximum Allowable Turnover Times For FiltrationDocument13 pagesAll Code Jurisdictions Have Maximum Allowable Turnover Times For FiltrationCamilo RochaNo ratings yet

- 3.0 Water Lines Preface: Bechtel ConfidentialDocument6 pages3.0 Water Lines Preface: Bechtel ConfidentialCristhianNo ratings yet

- Air Curtain PDFDocument8 pagesAir Curtain PDFabidch143No ratings yet

- CLimate DEsign Condition - ASHRAEDocument1 pageCLimate DEsign Condition - ASHRAEabidch143No ratings yet

- Schedule QDocument31 pagesSchedule Qabidch143100% (9)

- Kitchen Hoods GeneralDocument55 pagesKitchen Hoods Generalabidch143No ratings yet

- 3 Ways To Align A Centrifugal Pump PDFDocument4 pages3 Ways To Align A Centrifugal Pump PDFabidch143No ratings yet

- Design of Air Conditioning DuctsDocument15 pagesDesign of Air Conditioning Ductsabidch143No ratings yet

- National Factory 3 Way DiffusersDocument16 pagesNational Factory 3 Way Diffusersabidch143No ratings yet

- Fire Rated Door CertificateDocument1 pageFire Rated Door Certificateabidch143No ratings yet

- Heatexchanger TestDocument6 pagesHeatexchanger Testabidch143No ratings yet

- Ceiling DiffuserDocument2 pagesCeiling Diffuserabidch143No ratings yet

- Moisture Barrier On Metal Jacketing & Kraft PaperDocument2 pagesMoisture Barrier On Metal Jacketing & Kraft Paperabidch143No ratings yet

- SBC 601 2007 - Saudi Building Code (Energy Conservation)Document13 pagesSBC 601 2007 - Saudi Building Code (Energy Conservation)abidch143No ratings yet

- Saep 1150Document50 pagesSaep 1150abidch14383% (54)

- admissible: لوبق لباق یدنب گنج cease fireDocument1 pageadmissible: لوبق لباق یدنب گنج cease fireabidch143No ratings yet

- Ventilation & Exhaust CalculationDocument4 pagesVentilation & Exhaust Calculationabidch143100% (1)

- Area Per PersonDocument5 pagesArea Per Personabidch143No ratings yet

- Ashrae 1.1Document4 pagesAshrae 1.1abidch143No ratings yet

- Installation Instructions For Fire Dampers: in Drywall Type Construction 1 Hour and 2 Hour RatedDocument4 pagesInstallation Instructions For Fire Dampers: in Drywall Type Construction 1 Hour and 2 Hour Ratedabidch143No ratings yet

- Saep 14Document53 pagesSaep 14abidch143100% (1)

- Chiller CompressorDocument41 pagesChiller Compressorabidch143No ratings yet

- XU-CSG Cabinet Minutes of Meeting - April 4Document5 pagesXU-CSG Cabinet Minutes of Meeting - April 4Harold John LaborteNo ratings yet

- Case Study On Goodearth Financial Services LTDDocument15 pagesCase Study On Goodearth Financial Services LTDEkta Luciferisious Sharma0% (1)

- Case Study To Find Tank Bulging, Radial Growth and Tank Settlement Using API 650Document15 pagesCase Study To Find Tank Bulging, Radial Growth and Tank Settlement Using API 650Jafer SayedNo ratings yet

- Jurnal Vol. IV No.1 JANUARI 2013 - SupanjiDocument11 pagesJurnal Vol. IV No.1 JANUARI 2013 - SupanjiIchsan SetiadiNo ratings yet

- Sanskrit Lessons: �丘��恆� � by Bhikshuni Heng HsienDocument4 pagesSanskrit Lessons: �丘��恆� � by Bhikshuni Heng HsiendysphunctionalNo ratings yet

- 2432 - Test Solutions - Tsol - 2432 - 21702Document5 pages2432 - Test Solutions - Tsol - 2432 - 21702Anmol PanchalNo ratings yet

- Atom SDDocument5 pagesAtom SDatomsa shiferaNo ratings yet

- Controlled DemolitionDocument3 pagesControlled DemolitionJim FrancoNo ratings yet

- University Fees Structure (Himalayan Garhwal University) - UttarakhandDocument1 pageUniversity Fees Structure (Himalayan Garhwal University) - UttarakhandabhaybaranwalNo ratings yet

- Assignment-For-Final of-Supply-Chain - Management of Courses PSC 545 & 565 PDFDocument18 pagesAssignment-For-Final of-Supply-Chain - Management of Courses PSC 545 & 565 PDFRAKIB HOWLADERNo ratings yet

- Smart Plug Installation GuideDocument9 pagesSmart Plug Installation GuideFrancisco GuerreroNo ratings yet

- Caso Estudio: Reliability Analysis of Power Distribution System. A Case StudyDocument6 pagesCaso Estudio: Reliability Analysis of Power Distribution System. A Case StudyCarlos HernandezNo ratings yet

- Dept & Sem: Subject Name: Course Code: Unit: Prepared byDocument75 pagesDept & Sem: Subject Name: Course Code: Unit: Prepared by474 likithkumarreddy1No ratings yet

- Saif Powertec Limited Project "Standard Operating Process" As-Is DocumentDocument7 pagesSaif Powertec Limited Project "Standard Operating Process" As-Is DocumentAbhishekChowdhuryNo ratings yet

- Ankle Injury EvaluationDocument7 pagesAnkle Injury EvaluationManiDeep ReddyNo ratings yet

- MQXUSBDEVAPIDocument32 pagesMQXUSBDEVAPIwonderxNo ratings yet

- Asu 2019-12Document49 pagesAsu 2019-12janineNo ratings yet

- Model Answer Winter 2015Document38 pagesModel Answer Winter 2015Vivek MalwadeNo ratings yet

- KiSoft Sort & Pack Work Station (User Manual)Document41 pagesKiSoft Sort & Pack Work Station (User Manual)Matthew RookeNo ratings yet

- Junos ErrorsDocument2 pagesJunos ErrorsrashidsharafatNo ratings yet

- SodiumBenzoate PDFDocument3 pagesSodiumBenzoate PDFyotta024No ratings yet

- VLSI Implementation of Floating Point AdderDocument46 pagesVLSI Implementation of Floating Point AdderParamesh Waran100% (1)

- Chapter 13Document15 pagesChapter 13anormal08No ratings yet

- Assessment 4 PDFDocument10 pagesAssessment 4 PDFAboud Hawrechz MacalilayNo ratings yet

- Percentage and Profit & Loss: Aptitude AdvancedDocument8 pagesPercentage and Profit & Loss: Aptitude AdvancedshreyaNo ratings yet

- Bathinda - Wikipedia, The Free EncyclopediaDocument4 pagesBathinda - Wikipedia, The Free EncyclopediaBhuwan GargNo ratings yet

- What Are Some of The Best Books On Computer ScienceDocument9 pagesWhat Are Some of The Best Books On Computer ScienceSarthak ShahNo ratings yet

- Transposable Elements - Annotated - 2020Document39 pagesTransposable Elements - Annotated - 2020Monisha vNo ratings yet

- Reproduction in PlantsDocument12 pagesReproduction in PlantsAnand Philip PrasadNo ratings yet

- Design Practical Eden Swithenbank Graded PeDocument7 pagesDesign Practical Eden Swithenbank Graded Peapi-429329398No ratings yet