PROJECT :

CLIENT :

JOB NO. :

DATE :

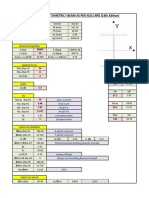

Tube / Pipe Column Design Based on AISC Manual 13th Edition (AISC 360-05)

INPUT DATA & DESIGN SUMMARY

COLUMN SECTION (Tube or Pipe)

HSS4X4X1/2

Tube

COLUMN YIELD STRESS

DIMENSION

Fy =

H=

46

14

ksi

ft

AXIAL LOAD, ASD

P=

kips

STRONG AXIS BENDING ? (1=Yes, 0=No)

UNIFORM LATERAL LOAD, ASD

CONCENTRATED LATERAL LOAD, ASD

=>

4

w = 0.15

0.1 kips at

F=

PAGE :

DESIGN BY :

REVIEW BY :

no, weak axis, y-y, bending.

k / ft

12

ft from bottom

THE DESIGN IS ADEQUATE.

ANALYSIS

CHECK COMBINED COMPRESSION AND BENDING CAPACITY (AISC 360-05, H1)

P r 8 M rx M ry

P c 9 M cx M cy

, for P r 0.2

Pc

P r M rx M ry

2 P c M cx M cy

, for P r 0.2

Pc

Where

KLx =

14

(KL / r)max =

Mrx =

0.00

Mry =

3.78

Pc = Pn / c =

0.26

<

<

200

1.0

KLy =

ft, for x-x axial load.

119

Pr =

[Satisfactory]

14

ft, for y-y axial load.

[Satisfactory]

kips

ft-kips, at 7.00 ft from bottom

106

/ 1.67 = 63.3737 kips, (AISC 360-05 Chapter E)

Pr

>

[Satisfactory]

Mcx = Mn / b =

29.5167 / 1.67 = 17.6747 ft-kips, (AISC 360-05 Chapter F)

Mrx

>

[Satisfactory]

Mcy = Mn / b =

29.5167 / 1.67 = 17.6747 ft-kips, (AISC 360-05 Chapter F)

Mry

>

[Satisfactory]

CHECK LATERAL DEFLECTION

max =

0.39

in, at 7.00 ft from bottom

<

Where

L/

Es =

29000

ksi

Ix =

11.9

in4

Iy =

11.9

in4

240

0.70

in

[Satisfactory]

�PROJECT :

CLIENT :

JOB NO. :

DATE :

WF Column Design Based on AISC Manual 13th Edition (AISC 360-05)

INPUT DATA & DESIGN SUMMARY

COLUMN SECTION

PAGE :

DESIGN BY :

REVIEW BY :

W10X49

COLUMN YIELD STRESS

DIMENSIONS

Fy =

H=

50

14

ksi

ft

AXIAL LOAD, ASD

P=

35

kips

STRONG AXIS BENDING ? (1=Yes, 0=No)

UNIFORM LATERAL LOAD, ASD

CONCENTRATED LATERAL LOAD, ASD

=>

0

w = 0.75

20

kips at

F=

no, weak axis, y-y, bending.

k / ft

11

ft from bottom

THE DESIGN IS ADEQUATE.

ANALYSIS

CHECK COMBINED COMPRESSION AND BENDING CAPACITY (AISC 360-05, H1)

P r 8 M rx M ry

P c 9 M cx M cy

, for P r 0.2

Pc

P r M rx M ry

2 P c M cx M cy

, for

Where

KLx =

14

(KL / r)max =

35

Mrx =

0.00

Mry =

59.52

Pc = Pn / c =

0.90

<

1.0

[Satisfactory]

Pr

0.2

Pc

KLy =

ft, for x-x axial load.

<

66

Pr =

200

14

ft, for y-y axial load.

[Satisfactory]

kips

ft-kips, at 11.00 ft from bottom

524

/ 1.67 = 313.645 kips, (AISC 360-05 Chapter E)

Pr

>

[Satisfactory]

Mcx = Mn / b =

231.233 / 1.67 = 138.463 ft-kips, (AISC 360-05 Chapter F)

Mrx

>

[Satisfactory]

Mcy = Mn / b =

117.917 / 1.67 = 70.6088 ft-kips, (AISC 360-05 Chapter F)

Mry

>

[Satisfactory]

CHECK LATERAL DEFLECTION

max =

0.68

in, at 7.40 ft from bottom

<

Where

L/

Es =

29000

ksi

Ix =

272

in4

Iy =

93.4

in4

240

0.70

in

[Satisfactory]

�ROJECT :

CLIENT :

JOB NO. :

PAGE :

DESIGN BY :

REVIEW BY :

DATE :

Plate Girder Design Based on AISC Manual 13th Edition (AISC 360-05)

INPUT DATA & DESIGN SUMMARY

STEEL YIELD STRESS

SIMPLY SUPPORTED SPAN

Fy =

50

ksi

S=

14

ft

SUPERIMPOSED UNIFORM DEAD LOAD

DL =

kips / ft

UNIFORM LIVE LOAD

LL =

PDL =

kips / ft

PLL =

kips

ft

POINT DEAD LOAD

POINT LIVE LOAD

DISTANCE POINT LOAD TO END

kips

TOP FLANGE WIDTH

c=

bf,top =

10

in

TOP FLANGE THICKNESS

tf,top =

0.56

in

BOTTOM FLANGE WIDTH

bf,bot =

10

in

BOTTOM FLANGE THICKNESS

tf,bot =

0.56

in

tw =

0.34

10

in

in

14

ft

WEB THICKNESS

BEAM DEPTH

d=

Lb =

UNBRACED LENGTH

Err:502

FLANGE TO WEB WELDING USE 1/4 in - 24 in @ 2683 in o.c.

THE GIRDER DESIGN IS ADEQUATE.

ANALYSIS

CHECK LIMITING WIDTH-THICKNESS RATIOS FOR WEB (AISC 365-05 Table B4.1)

h c / tw =

r =

<

26.12

137.27

<

p =

90.55

Compact Web

where

E=

29000

r = 5.7 (E / Fy)0.5 =

ksi

137.27

p = (hc / hp) (E / Fy)0.5 / (0.54 Mp / My -0.09)2 =

p = 3.76 (E / Fy)0.5 =

,for Af,top Af,bot

88.27

,for Af,top = Af,bot

90.55

hc =

8.88

in

hp =

9.41

in

Mp =

251.7

ft-kips

My =

227.5

ft-kips

CHECK LIMITING WIDTH-THICKNESS RATIOS FOR FLANGES (AISC 365-05 Table B4.1)

0.5 bf,top / tf,top =

r =

<

8.93

24.72

<

where

p =

9.15

Compact Flanges

r = 1.0 (kc E / FL)0.5 =

24.72

p = 0.38 (E / Fy)0.5 =

9.15

kc = Min [0.76 , Max (0.35 , 4 / (h / tw)0.5 )] =

0.74

Sxt =

55

in3

Sxc =

FL =

35

ksi, (AISC 360-05 Table note B4.1 & Eq F4-6)

55

in3

DETERMINE CRITERIA FOR ALLOWABLE FLEXURAL STRENGTH (AISC 365-05 Table F1.1)

Chapter F Sections

Required Conditions

F2

F3

Double Symmetric

Compact Web

Noncompact Web

F4

F5

x

Mallowable = Mn / b =

Slender Web

Compact Flanges

Noncompact Flanges

Slender Flanges

Applicable Section

138.5 ft-kips

( from following analysis)

ok

DETERMINE ALLOWABLE FLEXURAL STRENGTH , Mn / b , BASED ON AISC 365-05 Chapter F2

L p 1.76r y

L r 1.95r ts

where

ry =

E

Fy

E

0.7 F y

9.00

ft

S xh0

0.7 F y S x h 0

1 1 6.76

E

Jc

2.55

in

Jc

Sx =

55

r ts

in3

E

0.7 F y

31.63 ft

�h0 =

9.44

in

Iy =

93

in4

�(cont'd)

Cw = Iy h02 / 4 =

2080.8 , (AISC 365-05 F2.2)

J = [tw d (tw2 + d2)] / 12 =

28.3661 in4, (not applicable if taken web only, EIT Manual page 26)

(Use

rts =[( Iy Cw)0.5/ Sx)]0.5 =

c=

F cr

J=

1.39

in4 )

2.84

in

Cb =

1.0

C b 2E

1 0.078

L b

r ts

M

Jc L b

S x h 0 r ts

1.0

, (AISC Manual 13th Table 3-1, page 3-10)

107.861 ksi

for L b L p

L b L p

M n, F 2 Min C b M p M p 0.7 F y S x

L r L p

Min F cr S x , M p , for L r L b

Mallowable, F2 =Mn / b =

, M p

138.5 ft-kips

for L p L b L r

where

b =

1.67

231.2

ft-kips

, (AISC 365-05 F1)

DETERMINE ALLOWABLE FLEXURAL STRENGTH , Mn / b , BASED ON AISC 365-05 Chapter F3

<== Not Applicable.

pf

M p M p 0.7 F y S x

, for Noncompact Flanges

rf pf

M n, F 3

0.9 E k c S x

, for Slender Flanges

where

= bf / (2 tf) =

8.93

pf = p =

9.15

rf = r =

Mallowable, F3 =Min(Mn,F2 , Mn,F3) / b =

253.0 ft-kips

24.72

138.5 ft-kips

DETERMINE ALLOWABLE FLEXURAL STRENGTH , Mn / b , BASED ON AISC 365-05 Chapter F4

<== Not Applicable.

E

L p 1.1r t

Fy

L r 1.95r t

6.31

FL

S xch 0

ft

S h

1 1 6.76 F L xc 0

J

E

aw =hc tw/ (bfc tfc) =

where

rt

1

12 h 0 a w h

d

6

h

0d

2.86

Mp = Min [Zx Fy , 1.6Sxc Fy ] =

26.12

pw = p =

88.27

yc

R pc

31.83

ft

in

251.667 ft-kips

Myt = Sxt Fy =

227.5 ft-kips

= h c / tw =

0.54

b fc

Myc = Sxc Fy =

rw = r =

227.5 ft-kips

137.27

for h c / t w pw

Min M p M p 1

M yc M yc

pw

rw pw

C b 2E 1 0.078 J L b

F cr

2

S xc h 0 r t

L b

r t

M p

M yc

1.10623

for h c / t w pw

108.948 ksi, (for Iyc / Iy =

0.50

>

0.23, AISC 360-05 F4-5 )

R pc M yc , for L b L p

Lb L p

M n, F 4.2 Min C b R pc M yc R pc M yc F L S xc

L r L p

Min F cr S xc , R pc M yc , for L r L b

, R pc M yc

, for L p L b L r

223.8265 ft-kips

�(cont'd)

R pc M yc , for Compact Flanges

pf

R pc M yc R pc M yc F L S xc

rf pf

M n ,F 5.3

0.9 E k c S xc

, for Slender Flanges

yt

R pt

, for Noncompact Flanges

251.667 ft-kips

for h c / t w pw

Min M p M p 1

M yt M yt

pw

rw pw

M p

M yt

1.10623

for h c / t w pw

Mallowable, F4 = Min( Mn,F4.2 , Mn,F4.3, RptMyt) / b =

134.0

ft-kips

DETERMINE ALLOWABLE FLEXURAL STRENGTH , Mn / b , BASED ON AISC 365-05 Chapter F5

<== Not Applicable.

Lr r t

E

0.7 F y

21.55

for L b L p

Fy ,

ft

, F y

L b L p

Min C b F y 0.3F y

L r L p

F cr , F 5.2

C b

Min

2E

L b

r

t

for L p L b L r

, F y

42.4325 ksi

for L r L b

F y , for Compact Flanges

pf

, for Noncompact Flanges

F y 0.3F y

rf pf

F cr , F 5.3

0.9 E k c , for Slender Flanges

2

b f

2t f

hc

Min a w , 10

E

5.7

R pg Min 1

1200 300 Min a w , 10 t w

F y

, 1.0

50

ksi

Mallowable, F5 = Min( RpgFySxc , RpgFcr,F5.2Sxc , RpgFcr,F5.3Sxc , FySxt) / b =

115.6 ft-kips

DETERMINE ALLOWABLE SHEAR STRENGTH , Vn / v , BASED ON AISC 365-05 Chapter G2

h = d - tf,top - tf,bot =

13.7

a=

kv

a / h 2

h / tw =

in

Aw =

26

ft

3.40

in2

, for a / h 3

1.0 , for h / t w1.10 k vE

Fy

5.00

Cv

5 , for a / h 3

Vn = 0.6 FyAwCv =

102

1.10 k vE

E

E

, for 1.10 k v h / t w1.37 k v

Fy

Fy

h /tw F y

kips

Vallowable = Vn / v =

1.51E k v

E

, for 1.37 k v h / t w

Fy

h / t w 2 F y

v =

61.0778 kips

1.000

1.67

, (AISC 365-05 G1)

0.00

kips

TOTAL SUPERIMPOSED GRAVITY LOAD

w = DL + LL =

0.000

kips / ft

P = PDL + PLL =

CHECK EACH SECTION CAPACITIES

Section

Distance

d (in)

y (in)

Left

0

10

5

0.00 S

0.00

10

5

0.00 S

0.00

10

5

0.00 S

0.00

10

5

0.00 S

0.00

10

5

0.00 S

0.00

10

5

Point

0.00

10

5

0.17 S

2.33

10

5

0.33 S

4.67

10

5

0.50 S

7.00

10

5

0.67 S

9.33

10

5

0.83 S

11.67

10

5

Right

14.00

10

5

I (in4)

Wt (plf)

V (kips)

M (ft-k)

270

48.4

0.34

0

270

48.4

0.34

0

270

48.4

0.34

0

270

48.4

0.34

0

270

48.4

0.34

0

270

48.4

0.34

0

270

48.4

0.00

0

270

48.4

-0.23

1

270

48.4

-0.11

1

270

48.4

0.00

1

270

48.4

0.11

1

270

48.4

0.23

1

270

48.4

0.34

0

�Moments

(cont'd)

BENDING LOADS & CAPACITY

0

-20

-40

-60

-80

-100

-120

-140

-160

Length

Mmax = 1.185427 ft-kips @

< Mallowable =

7.00

ft, from heel.

138.463 ft-kips

S h ear F o rces

[Satisfactory]

SHEAR LOADS & CAPACITY

-59.50

-60.00

-60.50

-61.00

-61.50

-62.00

Length

Vmax =

0.34 kips

@

< Vallowable =

14.00 ft, from heel.

61.0778 kips

[Satisfactory]

DETERMINE DEFLECTION AT MID SPAN

DL

3/ 2

5wL 4

0.06415 Pb

L 2 b 2

384 EI

EIL

where

LL

0.01

in ( L / 31413 )

(for camber, self Wt included.)

E=

29000

ksi

w=

0.048

kips / ft

I=

b=

270

0.3

in4

ft

P=

L=

0

14.0

kips

ft

3/ 2

5w L 4

0.06415 Pb

L 2 b 2

384 EI

EIL

where

P=

0.00

kips

w=

#DIV/0!

0.000

kips / ft

DETERMINE FLANGE TO WEB WELDING (AISC 360-05 J2.4 )

w=

wmin =

wmax =

=

Vmax =

1/4

in

3/16

in, < w

4/16

2.0

in, > w

0.34

kips

Q = Af(d - y - 0.5 tf,top) =

vmax = Vmax Q / I =

A=

24

0.03

26

in3

kips / in

in

0.6 F EXX 0.707 w A

v max

2683

in. o.c.

USE 1/4 in - 24 in @ 2683 in o.c.

DESIGN STIFFENERS

1. BEARING STIFFENERS ARE REQUIRED AT EACH END SUPPORT. (AISC 360-05, J10.8)

2. CHECK LOCAL WEB YIELDING FOR THE CONCENTRATED LOAD. (AISC 360-05, J10.2)

R=P=

0.00

kips

N=

0

in, bearing length, point.

k = tf,top + w =

0.81

in

1.5

R

, for c d

t w N 5k

, for c d

t w N 2.5k

0.00

<

Fy /

[Satisfactory]

�(cont'd)

3. CHECK WEB CRIPPLING FOR THE CONCENTRATED LOAD. (AISC 360-05, J10.3)

2.0

2

0.80t w 1 3

Rn / 1 /

0.40t 2w 1 3

N t w

d t f

1.5

t w

t f

1.5

EF ywt f

tw

EF ywt f

tw

, for c 0.5d

71.46

>

[Satisfactory]

[Satisfactory]

, for c 0.5d

(Note : If item 2, local web yielding is Satisfactory, this item does not need to be checked.)

4. CHECK SIDESWAY WEB BUCKING FOR THE CONCENTRATED LOAD. (AISC 360-05, J10.4)

dc = d - 2k =

8.38

in

Cr =

960000

(dc / tw ) / (l / bf) =

ksi

1.47

1.76

3

C r t wt f 0.4 d c / t w

2

l /b f

C r t 3wt f

10.4 d c / t w

l /b f

h2

d

c / tw

2.3

P , for l /

bf

Rn / 1 /

/

, for d c t w 1.7

l /b f

3

, for 1.7

dc / tw

2.3

l /b f

192.30

>

(Note : If item 2, local web yielding is Satisfactory, this item does not need to be checked.)

5. DETERMINE STIFFENER SIZE.

tw =

in

1/3

bst / tw =

bst =

12.80

in

< 0.56 (E / Fy)0.5 , (AISC 360-05 Table B4.1)

[Satisfactory]

Ag =

3.89

in2

R=

c =

0.3

kips

1.67

, (AISC 365-05 E1)

Kl/r=

Cc =

Fe

I=

0.75 h / ( I / Aeff)0.5 =

3.4

4.71 (E/ Fy)0.5 =

113

2E

kl / r 2

15

in4

25099.40 ksi

F y

0.658 F e F y , for

R n / c A g / c

kl

0.877 F e , for r

kl

Cc

r

Cc

116.3

>

kips, (AISC 360-05 E2)

R

[Satisfactory]

Techincal Reference:

1. AISC: "Steel Construction Manual 13th Edition", American Institute of Steel Construction, 2005.