100% found this document useful (1 vote)

4K views4 pagesAngle Grinder Checklist

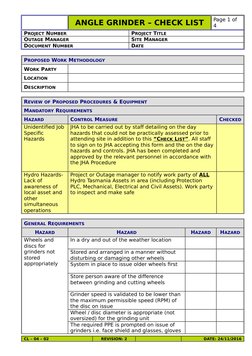

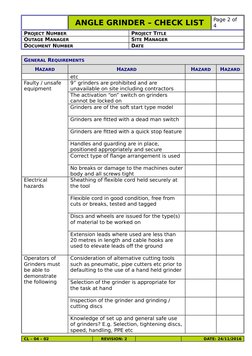

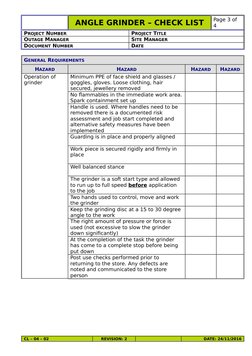

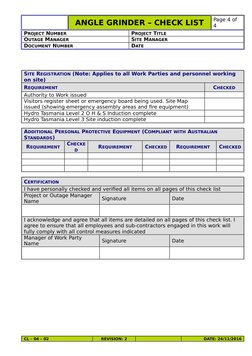

The document is a 4-page checklist for angle grinder use that outlines mandatory requirements and general requirements to be checked off. It includes checking for unidentified job hazards, awareness of local assets, proper storage and condition of grinding wheels and discs, inspection of grinding equipment for faults or damage, use of proper personal protective equipment, safe grinding practices, and site registration requirements. Operators must demonstrate knowledge of angle grinder setup, use, and completing post-use checks before returning equipment to storage. Both a project manager and work party manager must sign off to certify all items on the checklist have been reviewed and compliance will be ensured.

Uploaded by

shakti123456789Copyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOC, PDF, TXT or read online on Scribd

100% found this document useful (1 vote)

4K views4 pagesAngle Grinder Checklist

The document is a 4-page checklist for angle grinder use that outlines mandatory requirements and general requirements to be checked off. It includes checking for unidentified job hazards, awareness of local assets, proper storage and condition of grinding wheels and discs, inspection of grinding equipment for faults or damage, use of proper personal protective equipment, safe grinding practices, and site registration requirements. Operators must demonstrate knowledge of angle grinder setup, use, and completing post-use checks before returning equipment to storage. Both a project manager and work party manager must sign off to certify all items on the checklist have been reviewed and compliance will be ensured.

Uploaded by

shakti123456789Copyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOC, PDF, TXT or read online on Scribd