Professional Documents

Culture Documents

Appendix C - Energy Savings Analysis: The User Should Input Project Specific Data Into The Yellow Shaded Cells

Uploaded by

amronkpjbOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Appendix C - Energy Savings Analysis: The User Should Input Project Specific Data Into The Yellow Shaded Cells

Uploaded by

amronkpjbCopyright:

Available Formats

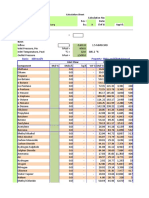

Appendix C - Energy Savings Analysis

Generic VFD Savings Calculation Spreadsheet

The user should input project specific data into the yellow shaded cells.

Cells in Row 23 describe the motor(s) being controlled in terms of HP, % loading at 100% output level for the process, and motor nominal efficiency.

Cell E29 is the power-to-speed reduction exponent. For closed systems where friction represents a high % of overall head, the exponent will be close to 3.0

and the input power with vfd will follow affinity laws (input power varies as the cube of % speed). For closed systems where total head is not predominantly

from friction losses, the exponent should be between 2.0 and 3.0. For open systems, or systems where friction head is negligible compared to overall head,

like a high pressure boiler feed water pump, the exponent will be close to 1.0. Please enter you best estimate of the exponent that is most appropriate for

your application.

Cell E30 and E31 should be populated with VFD manufacturers data.

Cell F33 represent the method of control that most closer describes the baseline situation.

Cells H35 and I35 represent the annual hours of operation for the baseline and the proposed case.

The range from cell B41:D53 should be used to describe the load shape of the operation. Inputs to this range should be supported by historical data, or

clearly explained.

Estimated Demand Total Demand

Description HP Quantity Efficiency

Load kW kW

Chilled Water Pump 25 1 70% 88.5% 14.8 14.8

Existing Process Pumps Demand 14.8 kW

VFD Parameters

Power-to-Speed Reduction Exponent 2.5 Range = 1.0 - 3.0

Safe Minimum Motor Speed 30%

Average VFD Efficiency Penalty at Full Speed 2.0%

IDENTIFY EXISTING METHOD OF CONTROL 2

1=No Control, 2=Fan/Blower Inlet Guide Vanes, 3=Pump Throttling or Fan/Blower Outlet Discharge Dampers

Existing Proposed

Annual Hours of Operation: 6,115 6115

Output Percent Estimated Existing Proposed Existing Proposed Energy

Load of full %Time at w/o VFD w/VFD w/o VFD w/VFD Savings

Level load speed Load kW kW kWh kWh kWh

100% 100% 15% 14.7 15.1 13,464 13,807 -344

95% 95% 15% 13.8 13.2 12,696 12,146 550

90% 90% 15% 13.0 11.6 11,967 10,610 1,357

85% 85% 15% 12.3 10.0 11,275 9,197 2,078

80% 80% 15% 11.6 8.6 10,622 7,904 2,718

75% 75% 15% 10.9 7.3 10,007 6,726 3,281

70% 70% 10% 10.3 6.2 6,286 3,774 2,513

65% 65% 10% 9.7 5.1 5,927 3,135 2,791

60% 60% 10% 9.1 4.2 5,593 2,567 3,026

55% 55% 0% 8.6 3.4 0 0 0

50% 50% 0% 8.2 2.7 0 0 0

45% 45% 0% 7.8 2.0 0 0 0

40% 40% 0% 7.4 1.5 0 0 0

120% TOTALS 87,836 69,866 17,970

C-1+1 energy & resource solutions

You might also like

- Length Power Dynamic Viscosity Heat FluxDocument14 pagesLength Power Dynamic Viscosity Heat FluxRJG0409No ratings yet

- Instruction Flowchart For Using The 2Phaserelief0000.Xls Worksheet (User Manual Is Also Available)Document14 pagesInstruction Flowchart For Using The 2Phaserelief0000.Xls Worksheet (User Manual Is Also Available)ChakerZagroubaNo ratings yet

- Values Highlighted in GREEN Are Calculated Values: Suction Fittings & ValvesDocument7 pagesValues Highlighted in GREEN Are Calculated Values: Suction Fittings & ValvesaltruismNo ratings yet

- LNG Versus CNG Versus HSDDocument7 pagesLNG Versus CNG Versus HSDUJJWALNo ratings yet

- Hydrogen IntroductionDocument39 pagesHydrogen IntroductionTalha ImtiazNo ratings yet

- Crude Oil Dalia AssayDocument4 pagesCrude Oil Dalia AssayPedro JoséNo ratings yet

- PinchDocument97 pagesPinchuxahidNo ratings yet

- Heat Conduction Pipe InsulationDocument1 pageHeat Conduction Pipe InsulationJogender DhayalNo ratings yet

- API 12j SizingDocument1 pageAPI 12j SizingAdewunmi OlufemiNo ratings yet

- Native File For Pump (Example)Document2 pagesNative File For Pump (Example)Venturindo SiteNo ratings yet

- Macro: This Worksheets Use Visual Basic Module Regarding ToDocument56 pagesMacro: This Worksheets Use Visual Basic Module Regarding ToOlumuyiwa FasehunNo ratings yet

- Pump Calc PranayDocument24 pagesPump Calc PranayNitin KurupNo ratings yet

- PDM-P-CS-002 - HP Prod SeparatorDocument5 pagesPDM-P-CS-002 - HP Prod Separatorfirman adiyantoNo ratings yet

- Cylindrical Horizontal Tank Volume CalculationDocument21 pagesCylindrical Horizontal Tank Volume CalculationashrafNo ratings yet

- 7 Natural Gas Transmission Pipelines and City Gas Distribution NetworksDocument2 pages7 Natural Gas Transmission Pipelines and City Gas Distribution NetworksJatin Vadhera VCSPNo ratings yet

- Air CompDocument1 pageAir CompHsein WangNo ratings yet

- Cooling Tower ComparisonDocument4 pagesCooling Tower ComparisonKiran DasNo ratings yet

- PFD Dme PlantDocument1 pagePFD Dme PlantSyamsul Rizal Abd ShukorNo ratings yet

- 5.5 Offshore Platform ProductionDocument14 pages5.5 Offshore Platform Productioneng20072007No ratings yet

- GPSA - Methanol Inhibition Rate RevisedDocument11 pagesGPSA - Methanol Inhibition Rate RevisedrmaganNo ratings yet

- 10.9. Gas Liquid Separators: Chemical EngineeringDocument6 pages10.9. Gas Liquid Separators: Chemical EngineeringsterlingNo ratings yet

- G LST 001 Ab Tank Farm in ProgressDocument270 pagesG LST 001 Ab Tank Farm in ProgressPhilippe AlexandreNo ratings yet

- Calculation Checklist: 002-000-PDF-566 (015311) EPF-0027 Rev 2 (5-Mar-07) Corporate Base Page 1 of 5Document5 pagesCalculation Checklist: 002-000-PDF-566 (015311) EPF-0027 Rev 2 (5-Mar-07) Corporate Base Page 1 of 5Amol JagtapNo ratings yet

- Basis: Basis: 100 Mol/h Property: GPSA and Elliott ManualDocument6 pagesBasis: Basis: 100 Mol/h Property: GPSA and Elliott ManualsterlingNo ratings yet

- Instructions For Using This WorksheetDocument11 pagesInstructions For Using This WorksheetMohanNo ratings yet

- Calculation Form CombustionDocument2 pagesCalculation Form CombustionKrishna KameshNo ratings yet

- Calculate Gas Heating Value From Gas CompositionDocument4 pagesCalculate Gas Heating Value From Gas CompositionAsad KhanNo ratings yet

- Calculation Title: Seagas Pipeline Design - MinervaDocument1 pageCalculation Title: Seagas Pipeline Design - Minerva秦东旺No ratings yet

- Hydroulics Calculation and Gas PropertiesDocument3 pagesHydroulics Calculation and Gas PropertiesSteve WanNo ratings yet

- FanSave53 RevDocument48 pagesFanSave53 RevHo Dac ThanhNo ratings yet

- Access Denied Your Page Is Blocked Due To A Security Policy That Prohibits Access To Category DefaultDocument87 pagesAccess Denied Your Page Is Blocked Due To A Security Policy That Prohibits Access To Category DefaultSahil PalNo ratings yet

- Charcoal Tower Sizing CalculationDocument5 pagesCharcoal Tower Sizing CalculationPrathmesh GujaratiNo ratings yet

- Eff FormulaDocument59 pagesEff FormulaVenkateswara Rao DoodalaNo ratings yet

- Kvaerner John Brown: Leff (Hor.) /H (Vert.)Document1 pageKvaerner John Brown: Leff (Hor.) /H (Vert.)bharathscdsNo ratings yet

- CNG Economics TrivandrumDocument7 pagesCNG Economics TrivandrumUJJWALNo ratings yet

- Heat Rate Calculation - JITPLDocument8 pagesHeat Rate Calculation - JITPLbnswain1No ratings yet

- Design Calculation For Gaseous SystemsDocument16 pagesDesign Calculation For Gaseous Systemsshashi ranjanNo ratings yet

- Test Gas CalculationDocument4 pagesTest Gas CalculationgrabettyNo ratings yet

- Plate Heat Exchanger PRDocument1 pagePlate Heat Exchanger PRRenzo BagacinaNo ratings yet

- Boiler-1 Aditya Cement Works Sept 21Document7 pagesBoiler-1 Aditya Cement Works Sept 21ameer meerNo ratings yet

- The FUEL OIL Calculation ProgramDocument2 pagesThe FUEL OIL Calculation ProgramAbdul AnisNo ratings yet

- Gujarat State Electricity Corporation Limited Sikka Thermal Power Station Performance Test of Unit No:-1 Estimating Thermal Efficiency of TurbineDocument14 pagesGujarat State Electricity Corporation Limited Sikka Thermal Power Station Performance Test of Unit No:-1 Estimating Thermal Efficiency of TurbinePunit BakulbhaiNo ratings yet

- Spray Nozzles Total STDDocument3 pagesSpray Nozzles Total STDDylan RamasamyNo ratings yet

- Proposal Wwme Ctfc150Document7 pagesProposal Wwme Ctfc150bahlakeNo ratings yet

- Curves and Correction Curves For Steam TurbineDocument18 pagesCurves and Correction Curves For Steam Turbinearunrajmech09No ratings yet

- Indiabulls Power Limited: SOP/OPNS/10 Operations DepartmentDocument2 pagesIndiabulls Power Limited: SOP/OPNS/10 Operations DepartmentAmit SoniNo ratings yet

- Pipeline Pigging Handbook 5Document1 pagePipeline Pigging Handbook 5engmecbruno5No ratings yet

- API-14E Gas CondensateDocument2 pagesAPI-14E Gas Condensatenwosu_dixonNo ratings yet

- Calculation and Specification of Bilge SystemDocument40 pagesCalculation and Specification of Bilge SystemTegar LanangNo ratings yet

- Reference: Chapter 2 Spread Sheet Made By: Himanshu Parikh Vadodara, Gujarat, IndiaDocument5 pagesReference: Chapter 2 Spread Sheet Made By: Himanshu Parikh Vadodara, Gujarat, IndiaHimanshu ParikhNo ratings yet

- LT Compressor Condensate Loading To The Road Tankers Through Buffer TankDocument2 pagesLT Compressor Condensate Loading To The Road Tankers Through Buffer TankMugesh KannaNo ratings yet

- 3-Phase Sparator Sizing (Vertical and Horizontal)Document30 pages3-Phase Sparator Sizing (Vertical and Horizontal)WickyNo ratings yet

- Counter Current Heat Exchanger CarnahanDocument4 pagesCounter Current Heat Exchanger CarnahancymyNo ratings yet

- Vent Dispersion CalcDocument9 pagesVent Dispersion CalcPeddy Nesa0% (1)

- KTPS V - Review of Forced Outages in Thermal Power PlantDocument24 pagesKTPS V - Review of Forced Outages in Thermal Power PlantNaveen ChodagiriNo ratings yet

- Control Valve: Instrument Datasheet Tag No. Process ConditionsDocument1 pageControl Valve: Instrument Datasheet Tag No. Process Conditionskrishna kumarNo ratings yet

- Antoine Equation Curve FittingDocument2 pagesAntoine Equation Curve FittingJM Flores De SilvaNo ratings yet

- Design Solution-4500wattDocument15 pagesDesign Solution-4500wattrofi azmanNo ratings yet

- Ch1.4o0.6 + 1.05 (O2 + 3.76N2) Co2 + 0.7h2o + 3.95N2Document4 pagesCh1.4o0.6 + 1.05 (O2 + 3.76N2) Co2 + 0.7h2o + 3.95N2kirankumar9898No ratings yet

- EIA NaturalGasPipelineProjectsDocument8 pagesEIA NaturalGasPipelineProjectsThanh Tung LeNo ratings yet