Professional Documents

Culture Documents

DDECII To III-IV Conversion

DDECII To III-IV Conversion

Uploaded by

JOHN WrightOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

DDECII To III-IV Conversion

DDECII To III-IV Conversion

Uploaded by

JOHN WrightCopyright:

Available Formats

18SP546* Install DDEC II to DDEC IV Wire Harness and

Hardware Conversion Kit on 1991-1993 Series 60

On-Highway Manual Transmission Trucks

*Revision 12/14/04

6SE483 and the DDEC III/IV SECM Troubleshooting

Introduction Guide, 6SE497 for instructions on removing, installing,

and testing the other parts required for kit installation.

Service kit R23529490 permits conversion of a Detroit

Diesel Series 60 DDEC II engine to a DDEC IV DDEC II ECM Removal

configuration. The kit includes the items listed in

Table 1. Remove the ECM as follows:

Kit Part Number Qty. Description

R23519307 1 ECM

23512307 8 Isolator

23513558 1 Engine Harness PERSONAL INJURY

23517986 1 Power Harness Adaptor

23518358 1 Injector Harness, Jake To avoid injury from hot surfaces, wear

Brake protective gloves, or allow engine to cool

23520380 1 Coolant Level Sensor before removing any component.

(CLS)- 1/4 -18 NPTF

23520381 1 Coolant Level Sensor

(CLS) - 3/8-18 NPTF

23518206 1 Adaptor Module, Coolant

Level Sensor

23518359 1 Harness Asm., Coolant PERSONAL INJURY

Level Sensor Jumper

Liner To avoid injury from accidental startup

23515251 1 Coolant Temperature while servicing the engine, disconnect the

Sensor (CTS) - in. starting system.

brass

23519124 1 Heat Shield, Exh.

Manifold 1. With the engine at ambient temperature (cool to

23509744 3 Stud Bolt, M10, 1.5x120 the touch) and the starting system disconnected/

11506101 3 Nut, M10 disabled, disconnect the power harness from

23515250 1 Air Temperature Sensor vehicle batteries.

(ATS)

23517875 3 Intake Manifold Gasket 2. Loosen the wire harness connector hold-down

18SP546 1 Installation Instructions screws, and gently disengage the connectors

from ECM sockets.

Table 1 DDEC II to DDEC IV Conversion Kit,

P/N: 23529490 3. Remove the DDEC II injector and engine

sensor harness from the engine.

Following are instructions for installing the parts in the

kit. Refer to the current Series 60 Service Manual,

18SP546 (Rev) Page 1 of 8

4. Loosen the wire harness connector hold-down

screws, gently disengage connectors, and

remove DDEC II ECM from vehicle. PERSONAL INJURY

DDEC IV ECM Installation Diesel engine exhaust and some of its

constituents are known to the State of

Conversion kit components are listed in Table 1. Refer California to cause cancer, birth defects,

to the Series 60 Service Manual and install parts as and other reproductive harm.

follows: Always start and operate an engine in

a well ventilated area.

1. Install the Engine Sensor Harness (P/N: If operating an engine in an enclosed

23513558), included in the kit. See Figure 1. Refer area, vent the exhaust to the outside.

to Section 8.6 of Service Manual. Do not modify or tamper with the

exhaust system or emission control

2. Install the Injector/Jake Brake harness system.

(P/N: 23518358) included in the kit.

12. Reconnect starting power. Start the engine and

3. Install new Coolant Level Sensor (CLS) (either check for proper DDEC system operation.

P/N: 23520380 or 3/8 P/N; 23520381). Refer to

Section 2.34 of Service Manual.

4. Install the CLS adaptor module (P/N: 23518206)

and jumper adaptor (P/N: 23518359).

5. Install the Coolant Temperature Sensor (CTS)

(P/N: 23515251) at right rear of head. Refer to

Section 2.31 of Service Manual.

6. Install the heat shield (P/N: 23519124) using stud

bolts (P/N: 23509744) and nuts (P/N: 11506101).

a) If the engine has current exhaust manifold,

install heat shield as is.

b) If the engine has former style manifold, the heat Figure 1 DDEC IV ECM and Wiring Harness

shield may need to be altered prior to Locations

installation.

7. Remove the air intake manifold and discard old

gaskets.

8. Using a drill press and a 9/16 drill, drill and tap a

3/8 pipe port for the Air Temperature Sensor

(ATS), between #3 and #4 intake air ports in

manifold. See Figure 2.

9. Clean the air intake manifold thoroughly to remove

drill chaff.

10. Install ATS (P/N: 23515250). Torque to 11-16 Nm

(8-12 lbft).

Figure 2 Air Temperature Sensor Location

11. Using new gaskets (P/N: 23517875), install the air

intake manifold.

18SP546 (Rev) Page 2 of 8

NOTE:

Powernet Engine Order Entry, Vehicle speed sensors must be used for these two

Change Unit Information features to operate properly.

In order for the newly installed DDEC IV ECM to be For example, there is only one DDEC IV rating released

programmed, a mainframe file must be established. To for the 11 liter engines: 6N4D7275 is a 400/357 @

ensure that the ability to program the DDEC IV ECM is 1800/2100-1350 lbft.

established, the attached FAX form (See Figure 5) must

be filled out and sent to the DDC Customer Support To reduce the maximum torque from 1350 to 1250 lbft:

Center at (313) 592-5888. See Table 2 for the Set the low gear torque limit to 1250

appropriate 6N4D and 6N4M groups. Set the threshold to 0.1

Important Information Please read. To reduce the maximum rated speed from 2100 to

1800 rpm, set progressive shift as follows:

You must use the updated fax request in these LG1 rpm limit - 1800

instructions, or request the mainframe update to DDEC LG1 max rpm - 1800

IV, otherwise the wrong calibration could be assigned. LG1 max mph - 12

LG2 rpm limit - 1800

The DDEC IV ECM in this kit is only for use with LG2 max rpm - 1800

12-volt systems. LG2 max mph - 44

HG max rph - 1800

Within the ratings listed, you will find the original DDEC HG min mph - 45

II-III ratings and a cross-reference to the comparable

DDEC IV version.

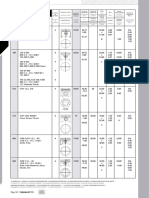

DDEC II to DDEC IV UPC groups are listed in Table 2.

With the following features now found within the DDEC To ensure that the engine is serviced properly after

system, it is possible to cover a wide variety of requests being converted from DDEC II to DDEC IV, and to

with fewer ratings: ensure that other modifications may be made, DDCs

Low gear torque limiting will modify the max. unit history file must be updated. If this is not done,

torque for the application. subsequent engine service and/or repair work might be

Progressive shift will limit the max RPM for the done using incorrect parts. Complete the attached FAX

user. form and send it to the DDC Customer Support Center.

See Figure 5.

18SP546 (Rev) Page 3 of 8

DDEC IV DDEC II/III CWC Rated @RPM Other @RPM FTLB @RPM Inj. P/N Inj. P/N

HP HP

6N4D-7275 6N4D-6309 5234935 5235605

N/A 6N4M-6149 235 350 1800 1250 1200

N/A 6N4M-6153 239 320 1800 1250 1200

N/A 6N4M-6167 354 320/350 1800 1250 1200

6N4D-7275 6N4D-6310 5234935 5235605

N/A 6N4M-6214 414 365 1800 1350 1200

N/A 6N4M-6215 413 350 1800 1350 1200

N/A 6N4M-6203 371 325 1800 1350 1200

N/A 6N4M-6216 415 325/350 1800 1350 1200

6N4D-7275 6N4D-6311 5234935 5235605

N/A 6N4M-6154 240 320 1800 1150 1200

N/A 6N4M-6157 243 285 1800 1150 1200

N/A 6N4M-6371 478 285/320 1800 1150 1200

6N4D-7275 6N4D-6312 5234935 5235605

N/A 6N4M-6148 234 320 2100 350 1800 1250 1200

6N4D-7275 6N4D-7127 5234935 5235605

6N4M-7815 6N4M-6916 1261 357 2100 400 1800 1350 1200

6N4D-7274 6N4D-6313 5234935 5235605

6N4M-7811 6N4M-6374 433 450 2100-1800 1450 1500-1200

6N4M-7812 6N4M-6211 416 430 2100-1800 1450 1500-1200

6N4M-7813 6N4M-6200 253 425 2100-1800 1450 1200

6N4M-7814 6N4M-6372 479 425/450 2100-1800 1450 1200

6N4D-7272 6N4D-6314 5234970 5235695

6N4M-7804 6N4M-6212 417 430 1800 1450 1500-1200

6N4M-7805 6N4M-6164 250 400 1800 1450 1200

6N4M-7806 6N4M-6166 252 365 1800 1450 1200

N/A 6N4M-6213 359 365/400 1800 1450 1200

6N4D-7272 6N4D-6315 5234940 5235600

6N4M-7804 6N4M-6212 417 430 1800 1450 1500-1200

6N4M-7805 6N4M-6164 250 400 1800 1450 1200

6N4M-7806 6N4M-6166 252 365 1800 1450 1200

6N4M-7807 6N4M-6213 418 365/430 1800 1450 1200

6N4D-7273 6N4D-6316 5234940 5235600

6N4M-7808 6N4M-6161 247 400 2100 425 1800 1450 1200

6N4M-7809 6N4M-6165 251 365 2100 1450 1200

6N4M-7810 6N4M-6202 373 365/400 2100 1450 1200

Table 2 1991-1993 Series 60 DDEC II to DDEC IV Conversion On-Highway Trucks with Manual

Transmissions

18SP546 (Rev) Page 4 of 8

DDEC II to DDEC IV Conversion Cruise Control

Switch Wiring Modifications

Figure 3 illustrates a typical DDEC II cruise control wiring

schematic. Wiring modifications to the Cruise Enable

Switch and the Set/Coast Switch are required whenever

a DDEC II to DDEC IV conversion is made on a vehicle

using the DDEC II cruise control feature.

Figure 4 Cruise Control Wiring Schematic after

Modification

Testing of Cruise Control Switch and Wiring

To speed up the testing of cruise control switches, quick

check tables have been developed. These tests are to

be run with the ignition ON, and the engine not running.

Figure 3 Typical DDEC II Cruise Control Wiring A DDR / DDDL must be plugged into the connector. All

Schematic three quick check tables must be completed to properly

check the cruise control wiring and switches.

Remove the wire identified as DDEC circuit #542 from See Tables 3, 4 and 5.

the Set/Coast Switch. At a convenient point, splice circuit

#542 into the cruise control switched ground circuit. NOTE:

Cruise control switched ground is the circuit that is When all tests pass, the unit is ready for road testing.

open when the Cruise Enable Switch is turned OFF

and grounded when the Cruise Enable Switch is turned

ON. If necessary, use a volt-ohm meter to verify the

circuit before splicing in circuit #542. Depending on the

application, the switched ground circuit may be identified

LOSS OF VEHICLE CONTROL

as DDEC circuit #558 or a branch of DDEC battery

ground, such as circuit #953A, #953B, or #953C, etc.

To avoid injury from the loss of vehicle control, do

See Figure 4.

Not use cruise control under these conditions:

When it is not possible to keep the

vehicle at a constant speed (on winding

roads, in heavy traffic, in traffic that varies

in speed, etc.)

On slippery roads (wet pavement, ice-or

snow-covered roads, loose gravel, etc.)

18SP546 (Rev) Page 5 of 8

Set/ Res/

Cruise Enable DDR/DDDL DDR/DDDL Okay

Step Coast Accel Go To

Switch Readout Display ?

Switch Switch

Off Yes

Cruise

1 Off Off Off Refer to Sec. 10.7 of DDEC

Enable On No

III/IV SECM TS Manual

Refer to Sec. 10.7 of DDEC

Cruise Off No

2 On Off Off III/IV SECM TS Manual

Enable

On Yes

Table 3 Cruise Control Quick Check Table, Testing Cruise Enable Switch and Wiring

Cruise Enable Brake Clutch DDR/DDDL DDR/DDDL Okay

Step Go To

Switch Pedal Pedal Readout Display ?

On Yes

Service

1 On Released Released Brake Refer to Sec. 10.7 of

Release Off No DDEC III/IV SECM

TS Manual

Refer to Sec. 10.7 of

Service

On No DDEC III/IV SECM

2 On Depressed Released Brake

TS Manual

Release

Off Yes

On Yes

Clutch Refer to Sec. 10.7 of

3 On Released Released

Release Off No DDEC III/IV SECM

TS Manual

Refer to Sec. 10.7 of

Clutch On No DDEC III/IV SECM

4 On Released Depressed

Release TS Manual

Off Yes

Table 4 Cruise Control Quick Check Table, Testing Brake and Clutch Switch and Wiring

Set/ Res/

Cruise Enable DDR/DDDL DDR/DDDL Okay

Step Coast Accel Go To

Switch Readout Display ?

Switch Switch

Off Yes

Set/Coast

1 On Off Off Refer to Sec. 10.7 of DDEC III/IV

On No

SECM TS Manual

Refer to Sec. 10.7 of DDEC III/IV

Set/Coast Off No

2 On On Off SECM TS Manual

On Yes

Off Yes

Res/Accel

3 On Off Off Refer to Sec. 10.7 of DDEC III/IV

On No

SECM TS Manual

Refer to Sec. 10.7 of DDEC III/IV

Res/Accel Off No

4 On Off On SECM TS Manual

On Yes

Table 5 Cruise Control Quick Check Table, Testing Set/Coast and Resume/Accel Switches and Wiring

18SP546 (Rev) Page 6 of 8

Figure 5

18SP546 (Rev) Page 7 of 8

Copyright 2004 Detroit Diesel Corporation. Detroit Diesel , DDC , Series 60 , and the spinning arrows design are registered trademarks of

Detroit Diesel Corporation. All other trademarks are the property of their respective owners.

18SP546 (Rev.) 0412 As technical advances continue, specifications will change. All rights reserved. Printed in U.S.A.

18SP546 (Rev) Page 8 of 8

You might also like

- DDEC II and III Wiring DiagramsDocument13 pagesDDEC II and III Wiring Diagramstwhiteman200682% (51)

- Detroit DieselDocument76 pagesDetroit DieselRonald Mario Kupa Anticona87% (47)

- Mercruiser Index Service ManualsDocument5 pagesMercruiser Index Service Manualsjitmarine100% (2)

- S60 Service ManualDocument2,117 pagesS60 Service ManualJustiniano Moreno95% (43)

- Williams Controls - Throttle Control CatalogDocument44 pagesWilliams Controls - Throttle Control Catalogjason_meyer_1467% (9)

- Service ManualDocument582 pagesService ManualBogdan Popescu100% (5)

- DDEC5 Witing Diagram1Document35 pagesDDEC5 Witing Diagram1Kilder Martinez100% (5)

- Detroit Diesel Serie 60 DDEC VIDocument925 pagesDetroit Diesel Serie 60 DDEC VILiamcito Gallagher96% (69)

- Holden VT 2000 Service TechlinesDocument177 pagesHolden VT 2000 Service Techlinescosky071% (7)

- SERVICE TOOL CATALOG Carrier TransicoldDocument98 pagesSERVICE TOOL CATALOG Carrier Transicoldgamagg100% (3)

- Ddec Iii - IvDocument540 pagesDdec Iii - IvNeil50% (2)

- Ddec IVDocument1 pageDdec IVJesus Almanzar SantosNo ratings yet

- Manual Detroit Serie 60Document1,669 pagesManual Detroit Serie 60Julian Mariño Pinilla95% (62)

- Ec - Engine Control System PDFDocument75 pagesEc - Engine Control System PDFMoaed Kanbar88% (8)

- Injector PressureDocument181 pagesInjector Pressureคุณชายธวัชชัย เจริญสุข89% (18)

- Accumulator Discharging and Charging Procedures (0738, 4263, 4264, 4331, 5077, 5077, 5081, 7474)Document24 pagesAccumulator Discharging and Charging Procedures (0738, 4263, 4264, 4331, 5077, 5077, 5081, 7474)Odai AlsaafinNo ratings yet

- Detroit Diesel - DDEC II To III-IV ConversionDocument8 pagesDetroit Diesel - DDEC II To III-IV ConversionValter MortaguaNo ratings yet

- DDECIV Multi-ECM Troubleshooting Manual PDFDocument943 pagesDDECIV Multi-ECM Troubleshooting Manual PDFJunior Lester100% (38)

- s60 ElectricDocument2 pagess60 Electricaup100% (5)

- All About EGR SERIE - 60pdfDocument114 pagesAll About EGR SERIE - 60pdfesteban euler100% (2)

- 18SP546 (Search-Manual-Online - Com) PDFDocument8 pages18SP546 (Search-Manual-Online - Com) PDFJesus Vega HummerNo ratings yet

- Foton Faw Shacman Sinotuck Howo Truck Spare Parts From Cinaautoparts GroupDocument284 pagesFoton Faw Shacman Sinotuck Howo Truck Spare Parts From Cinaautoparts GroupCINA auto partsNo ratings yet

- Detriot Desiel s60 SensorsDocument8 pagesDetriot Desiel s60 SensorsEdgar Gerve25% (4)

- Ddec VDocument30 pagesDdec Vllama90% (20)

- Ddec Master 2000 Current4-6Document234 pagesDdec Master 2000 Current4-6David O. Delgado91% (68)

- Ddec VDocument9 pagesDdec Vluiyel_net100% (3)

- Detroit Series 60 Service Manual - Vibratoare Seismice - 19-60-00aDocument20 pagesDetroit Series 60 Service Manual - Vibratoare Seismice - 19-60-00anguynthanhlongNo ratings yet

- 18SP546 (Search Manual Online - Com)Document8 pages18SP546 (Search Manual Online - Com)Jesus Vega HummerNo ratings yet

- Throttle Information Reference Guide PDFDocument24 pagesThrottle Information Reference Guide PDFJohn Rivera100% (1)

- Algebra Bald OrcDocument7 pagesAlgebra Bald OrcGilberto Morales CaldasNo ratings yet

- REHS4499 Testing The Refrigerant Compressor Protection ModuleDocument5 pagesREHS4499 Testing The Refrigerant Compressor Protection ModuleJuan Carlos Galarza CastilloNo ratings yet

- Prueba y Ajuste Presion de Valvula de Salida de ConvertidorDocument5 pagesPrueba y Ajuste Presion de Valvula de Salida de ConvertidorguayanecitroNo ratings yet

- 188-9901 Grupo de Valvula de Inversao Do VentiladorDocument29 pages188-9901 Grupo de Valvula de Inversao Do VentiladorGilson RodriguesNo ratings yet

- Si 1185Document6 pagesSi 1185user10002No ratings yet

- Bomba Inyeccion D5GDocument4 pagesBomba Inyeccion D5GjulianmatabajoyNo ratings yet

- Https 127.0.0.1 Sisweb Sisweb Techdoc Techdoc Print Page PDFDocument23 pagesHttps 127.0.0.1 Sisweb Sisweb Techdoc Techdoc Print Page PDFmiguelNo ratings yet

- 3406c Fuel Pump-Governor DriveDocument8 pages3406c Fuel Pump-Governor Driveharikrishnanpd3327No ratings yet

- 2.16 Ddec Iii/Iv Electronic Control ModuleDocument6 pages2.16 Ddec Iii/Iv Electronic Control Modulevictover100% (2)

- 1221 - 1010KVA DG Set SpecificationDocument36 pages1221 - 1010KVA DG Set SpecificationKhiem Le100% (1)

- Hydrostatic Test 5FZDocument26 pagesHydrostatic Test 5FZGuido Emanuel SteinbachNo ratings yet

- Motor de GiroDocument6 pagesMotor de GiroRigobertoOtinianoNo ratings yet

- Hydraulic Fan Drive System - Test and Adjust - (AAF1-200) (7PZ1-651)Document13 pagesHydraulic Fan Drive System - Test and Adjust - (AAF1-200) (7PZ1-651)Paulo FranciscoNo ratings yet

- Hydrostatic System - Test and Adjust: Pruebas y AjustesDocument22 pagesHydrostatic System - Test and Adjust: Pruebas y AjustesJose PichinteNo ratings yet

- Caterpillar Electronic TechnicianDocument11 pagesCaterpillar Electronic TechnicianJonathan Osses0% (1)

- Mejora Ventilador Dumper Caterpillar 730Document11 pagesMejora Ventilador Dumper Caterpillar 730Edwin VacaNo ratings yet

- Caterpillar Cat 226D SKID STEER LOADER (Prefix HRD) Service Repair Manual (HRD00001 and Up)Document26 pagesCaterpillar Cat 226D SKID STEER LOADER (Prefix HRD) Service Repair Manual (HRD00001 and Up)rpoy9396615No ratings yet

- Fuel System Pressure - TestDocument3 pagesFuel System Pressure - TestHAmir Alberto Mojica MojicaNo ratings yet

- DRBIII Release Notes - 56.0Document5 pagesDRBIII Release Notes - 56.0MarioNo ratings yet

- Service 1 Update Teleconference 0808Document6 pagesService 1 Update Teleconference 0808Garcia CruzNo ratings yet

- Lexus RX330 - 2004 - 3.3 - E PDFDocument22 pagesLexus RX330 - 2004 - 3.3 - E PDFDoDuyBacNo ratings yet

- Service BulletinDocument4 pagesService BulletinMR BEANo ratings yet

- D10T Full Landings PSA-D10T-FL+RHWW 240310Document41 pagesD10T Full Landings PSA-D10T-FL+RHWW 240310Эмиль ВалиевNo ratings yet

- Driver DFC MotorDocument24 pagesDriver DFC Motorda.dientuhnNo ratings yet

- Sevcon SC2000 Manual - With Calibrator Section PDFDocument58 pagesSevcon SC2000 Manual - With Calibrator Section PDFRicardo Marquez ValenciaNo ratings yet

- Installation of The Generator and Control Panel Components For Dynamic Gas BlendingDocument49 pagesInstallation of The Generator and Control Panel Components For Dynamic Gas Blendingالمهندسوليدالطويل100% (1)

- Service Manual Konica 1015Document24 pagesService Manual Konica 1015Colesniuc Alin50% (2)

- Installation Instructions: WarningDocument35 pagesInstallation Instructions: WarningwcuevasmNo ratings yet

- 325D and 325D L Excavator: Service Repair ManualDocument28 pages325D and 325D L Excavator: Service Repair ManualDana CarvajalNo ratings yet

- BC-244 NewDocument5 pagesBC-244 NewLuis Alberto Lopez100% (1)

- Caterpillar Cat 257D MULTI TERRAIN LOADER (Prefix EML) Service Repair Manual (EML00001 and Up)Document21 pagesCaterpillar Cat 257D MULTI TERRAIN LOADER (Prefix EML) Service Repair Manual (EML00001 and Up)rpoy9396615No ratings yet

- Off LeakDocument26 pagesOff LeakPatriciaH20No ratings yet

- Steering Pump - Test and Adjust: Shutdown SIS Previous ScreenDocument16 pagesSteering Pump - Test and Adjust: Shutdown SIS Previous Screenardan fadilahNo ratings yet

- LiftAire I and II Installation Manual 02-15-2013Document20 pagesLiftAire I and II Installation Manual 02-15-2013alanbrann0% (1)

- Remove and Install Fuel Injection LinesDocument2 pagesRemove and Install Fuel Injection LinesAnonymous cS9UMvhBqNo ratings yet

- Persan FiatDocument15 pagesPersan FiatAstrid PintoNo ratings yet

- Common Rail System (CRS) : Toyota 1Kd/2Kd EngineDocument31 pagesCommon Rail System (CRS) : Toyota 1Kd/2Kd Engine381tutNo ratings yet

- Diesel Engine ComponentsDocument33 pagesDiesel Engine ComponentsLuis Nunes100% (2)

- Kubota B6100EDocument128 pagesKubota B6100EPatty Elmore-DrakeNo ratings yet

- Fuel RailDocument27 pagesFuel RailJohn ValenzonaNo ratings yet

- M138 Engine SpecificationsDocument10 pagesM138 Engine SpecificationsWyattNo ratings yet

- Isuzu - Brosur - Print - NMR L + HDDocument2 pagesIsuzu - Brosur - Print - NMR L + HDJefa DanarNo ratings yet

- Turbo Fundamentals: How A Turbo WorksDocument5 pagesTurbo Fundamentals: How A Turbo WorksRajashekar Reddy Kandala100% (1)

- General Leaflet Compressors S8 S1 S1,5 S2, DrillAir v2Document4 pagesGeneral Leaflet Compressors S8 S1 S1,5 S2, DrillAir v2Giulio BelmondoNo ratings yet

- Gujarat Technological UniversityDocument1 pageGujarat Technological Universityfeyayel988No ratings yet

- Ecc230 12V DCDocument5 pagesEcc230 12V DCMilan NedeljkovicNo ratings yet

- Section: Engine MechanicalDocument60 pagesSection: Engine MechanicalStuart FerreiraNo ratings yet

- JeepDocument15 pagesJeepkenshinrk100% (1)

- My ScramjetDocument13 pagesMy ScramjetHimanshu GuptaNo ratings yet

- Toyota ECU ChartDocument8 pagesToyota ECU ChartChonseyNo ratings yet

- Aircraft Design Unit 3Document35 pagesAircraft Design Unit 3Vinoth AeroNo ratings yet

- Holley 1920 Carburetor ManualDocument41 pagesHolley 1920 Carburetor ManualeximiusconsultingwvNo ratings yet

- S250-M3 RockDrill 24x36 WallChart English Dec 2013 WebReady PDFDocument1 pageS250-M3 RockDrill 24x36 WallChart English Dec 2013 WebReady PDFJuan Mendoza100% (1)

- Design and Analysis of Muffler To Reduce The Back PressureDocument5 pagesDesign and Analysis of Muffler To Reduce The Back PressureijsretNo ratings yet

- PS 6100 PDFDocument22 pagesPS 6100 PDFampacpartsNo ratings yet

- Diesel Power PlantDocument28 pagesDiesel Power PlantIrvs SaiNo ratings yet

- 009-010-011-012 Service ManualDocument52 pages009-010-011-012 Service Manualhey_hop50% (4)

- Air Inlet and Exhaust Systems - Rafli D.A.SDocument3 pagesAir Inlet and Exhaust Systems - Rafli D.A.SBroCactusNo ratings yet

- Waukesha F18GL-GLD - S-7775-45Document10 pagesWaukesha F18GL-GLD - S-7775-45kman548No ratings yet

- Catalogo GLPDocument12 pagesCatalogo GLPJOEL APONTE ORTIZNo ratings yet

- CF34 10eDocument9 pagesCF34 10eJulia GarciaNo ratings yet