Professional Documents

Culture Documents

Sample QAP of Steel Bridge Girder PDF

Sample QAP of Steel Bridge Girder PDF

Uploaded by

Adades Safede EfdOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sample QAP of Steel Bridge Girder PDF

Sample QAP of Steel Bridge Girder PDF

Uploaded by

Adades Safede EfdCopyright:

Available Formats

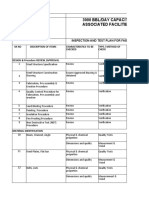

SAMPLE QUALITY ASSURANCE PLAN

30.5m Welded Open Web Girder (HM Loading-1995) as per RDSOs Drg. No. RDSO/B-11521

Name of project.....

Manufactured by .....

SN Component/ Characteristic Frequency Reference Fabricators Inspection details Type of Acceptance Remarks

Operations Check & type of Document Quality Record criteria

check Control Inspecting Extent of

Agency inspection

1 2 3 4 5 6 7 8 9 10 11

1.0 Raw Material

1.1 Steel Plates, Identification As per Mill Challan, Verification . 100% Fabricators Plates: IS

Structural Section and correlation T.C. and Mill T.C. of reference Railway record 2062-2006,

with Mill Test tests document Gr. E 250 B0,

Certificate from required by 12mm &

Supplier e.g., RDSO from above thick.

SAIL, TISCO, Govt./NABL Plates are fully

IISCO etc. approved lab killed &

normalized or

control cooled.

Sections IS

2062-2006,

Gr. E 250 A

Physical Visual - Complete 100% Fabricators IS 2062-2006 -

condition i.e., visual Railway Record

Pitting, rusting, inspection

straightness,

rolling defect,

etc.

Mechanical Test Lab Test at - Lab Test - - IS 2062-2006 Raw matl.

as per IS 2062- appvd. Report Railway Gr. E 250 B Clearance

2006 UTS, YS, Laboratory fully killed & shall be by

% El, Bend test, normalized or Zonal

control cooled Railway

Charpy test at -Do- - -Do- Heat/Cast - - -

0

0 C for plates of Railway no. section

thks. 12mm and wise as per

above IS 2062-

2006

Signature of Signature of Approval of RDSO

Fabricating Agency Railway Representative

SN Component/ Characteristic Frequency Reference Fabricators Inspection details Type of Acceptance Remarks

Operations Check & type of Document Quality Record criteria

check Control Inspecting Extent of

Agency inspection

1 2 3 4 5 6 7 8 9 10 11

Chemical -Do- - -Do- -Do- - Table 1, along

Analysis as per Railway with Note No.

IS 2062-2006 2 of IS 2062-

2006, Gr. E

250 B

Ultrasonic test By ASN - Lab Test 100% - IS 4225 or

for 12mm & Level II Report Railway ASTM SA

above thi. operator 435/435M

Plates, as per IS

4225 or ASTM-

SA 435/435M

Dimension Measurement Challan Measuremen 100% Fabricators

t of Railway Record &

Dimension Zonal Railway

Records

1.2 Revets, Bolts & a) Dimension Visual/ Challan Verification As per - For Rivet IS

Nuts Measurement of Reference Railway requirement 1148 For Bolt:

Document IS 1367(Part ii)

& property

classes as per

relevant Drg.

b) As per specn. Lab test at Manufactur -Do- -Do- -Do- -Do -Do

Mechanical & Govt. appvd. ers Test

Chemical Lab Certificate

1.3 Paints Verification of Visual Challan., Vefification ... Each Batch Manufacturers IS 102, Paints to be

Manufacturers Manufactur of Reference Railway Test Contract procured

Test Certificate, ers Test Document Certificate agreement from vendors

Inspection Certificate approved by

Certificate, RDSO

Challan

Tests as per Lab test at Challan., Verification . Random Lab. Test IS 102 -Do-

Specification Govt. Appvd. Manufactur of Reference Railway Report Contract

Lab ers Test Document agreement

Certificate

1.4 Welding As per Any test as Challan., Verification . As per Fabricators - Consumables

Consumables specification and required Manufactur of Reference Railway requirement Record should be of

as approved by ers Test Document RDSO appvd.

RDSO Certificate Brand

Signature of Signature of Approval of RDSO

Fabricating Agency Railway Representative

SN Component/ Characteristic Frequency Reference Fabricators Inspection details Type of Acceptance Remarks

Operations Check & type of Document Quality Record criteria

check Control Inspecting Extent of

Agency inspection

1 2 3 4 5 6 7 8 9 10 11

2.0 Manufacturing

Process

2.1 Lay out of Dimension Measuremen Approved Measuremen RDSO 100% Iinspection Relevant Clearance

Components & t with Drawing t of Report of IS/IRS Codes by RDSO

Joints calibrated Dimension Inspection & Approved

steel tape & Official Drawings

a) Normal gauges

b) Jigs & Dimension, Measuremen Approved Measuremen RDSO 100% Record of Jigs IRS B1-2001

Templates Intersection t with Drawing t of & fixtures as

lines, pitch, calibrated Dimension per proforma

gauge, dia. Of steel tape & issued by

Holes & No. of gauges RDSO

holes

c) Cutting, Dimension, Visual/ Inspection Visula & 100% Inspection IRS B1-2001,

Straightening, Freedom from Measuremen Report of Measuremen Railway Report of IS 1852-85

Edge preparation defect t Inspection t of Inspection

Official & dimension Official &

Fabricator Fabricators

s Record Record

3.0 Welding:

a) Submission of Review of Verification IRS B1- Verification RDSO 100% Fabricators IRS B1-2001 Only RDSO

WPSS WPSS 2001 IS of Reference Record IS 9595-96 certified

9595-96 Document WBC-2001 welders to

WBC-2001 be engaged

in the job.

b) WPQR Witnessing of Visual, DT & As per Verification RDSO 100% WPQR Sheet IS 7310(I)-74

established NDT at code of Reference to be recorded

WPSS approved lab requiremen Document in presence of

Witnessing of t RDSO Rep.

Welder

Qualification test

c) Preheating Measurement of Visual with As per Verification . Random Inspection IRS B1-2001

Temperature thermal approved of Reference Railway Report of

Chalk WPSS Document Inspection

Official &

Fabricators

Record

d) Baking of To have Visual Check As per Verification 100% Inspection IRS B1-2001

Electrode, Flux moisture free of Electrodes Manufactur of Reference Railway Report of

Electrode & Flux & beating es Document Inspection

Signature of Signature of Approval of RDSO

Fabricating Agency Railway Representative

SN Component/ Characteristic Frequency Reference Fabricators Inspection details Type of Acceptance Remarks

Operations Check & type of Document Quality Record criteria

check Control Inspecting Extent of

Agency inspection

1 2 3 4 5 6 7 8 9 10 11

recommen Officials &

dations Fabricators

Record

e) Selection of Reference to Visual As per Verification .. 100% Inspection As per list of

correct Electrodes WPSS, IRS approved of Reference Railway Report of vendors

& Flux Class, etc. WPSS Document inspection approved by

official & RDSO

Fabricators

Record

f) Current Condition Measurement of Visual with As per Verification Random Inspection IRS B1-2001

Amp. & Voltage Ammeter & approved of Reference Railway Report of

Voltmeter WPSS Document Inspection

Official &

Fabricators

Record

g) Sequence of To control Visual As per Verification . Random Inspection IRS B1-2001

Welding distortion approved of Reference Railway Report of

WPSS Document Inspection

Official &

Fabricators

Record

h) Provision of To avoid crater Visual As per IRS Verification . 100% Inspection

Run-on & Run off defects B1-2001 of Reference Railway Report of

Plates Document Inspection

Official &

Fabricators

Record

4.0 Inspection of a) For Fillet Visual, Approved Visual RDSO 100% Fabricators Relevant Clearance

Welding Welds: Visual, Gauge & Drg. & Inspection & Record IS/IRS Code, by RDSO

D.P.Test Fillet Macro WPSS Verification Approved Drg.

Size, Etching. of dimension & WBC-2001

Penetration, Leg by gauges

Length, Throat

thickness, etc.

5.0 Trial Assembly a) Camber on Jack Visual & Approved. Complete RDSO One Inspection IRS B1-2001 Clearance

b) Dead Load Dimensional Drg. dimensional complete Report of by RDSO

check of span Inspection

deflection

Control Official &

c) Dimension Assembly Fabricators

d) Fairness of Record

holes

Signature of Signature of Approval of RDSO

Fabricating Agency Railway Representative

SN Component/ Characteristic Frequency Reference Fabricators Inspection details Type of Acceptance Remarks

Operations Check & type of Document Quality Record criteria

check Control Inspecting Extent of

Agency inspection

1 2 3 4 5 6 7 8 9 10 11

e) Temporary

fasteners

f) Imfringement

g) Butting of

compression

edges

6.0 Final Clearance Component Visual Stage Verification RDSO Girder Inspection IRS B1-2001 Clearance

completeness Dimensional clearance of Stage fabrication Report of by RDSO

& Structural Record clearance with Inspection

Record approved Official &

Jigs-100% Fabricators

Record

Signature of Signature of Approval of RDSO

Fabricating Agency Railway Representative

You might also like

- Safe Erections WebDocument36 pagesSafe Erections Webuday64668No ratings yet

- Comparison of Tolerances - Is 7215 - AWS - MBMADocument1 pageComparison of Tolerances - Is 7215 - AWS - MBMASunil Pulikkal100% (2)

- Fabrication of Steel Giders IRS B1-2011Document33 pagesFabrication of Steel Giders IRS B1-2011Civil WorkNo ratings yet

- Quality Assurance PlanDocument3 pagesQuality Assurance PlanNESTOR YUMULNo ratings yet

- Fabrication-RNG 24.08Document230 pagesFabrication-RNG 24.08Habib Ur Rahman100% (1)

- Water Injection Manual (Preview)Document17 pagesWater Injection Manual (Preview)George Wiseman100% (1)

- QCF113 Structural Steel Pre-Fabrication CertificateDocument1 pageQCF113 Structural Steel Pre-Fabrication CertificateminhnnNo ratings yet

- QAP of Steel Bridge Girder PDFDocument6 pagesQAP of Steel Bridge Girder PDFVarun JainNo ratings yet

- VMware vSAN Network Design PDFDocument169 pagesVMware vSAN Network Design PDFFederico MiliaccaNo ratings yet

- Spacing Change Because Dia Not Avaiable On Site (In Slab)Document5 pagesSpacing Change Because Dia Not Avaiable On Site (In Slab)YASIRNo ratings yet

- Chqlist For Fabrication & InspectionDocument12 pagesChqlist For Fabrication & InspectionSuresh ShuklaNo ratings yet

- Effectiveness of Therapeutic Communication in Nursing StudentsDocument17 pagesEffectiveness of Therapeutic Communication in Nursing StudentsNamoAmitofouNo ratings yet

- Guidelines On Fabrication of Steel Structure ofDocument3 pagesGuidelines On Fabrication of Steel Structure ofsamirbendre1No ratings yet

- Thesis-Impulse Buying BehaviorDocument39 pagesThesis-Impulse Buying BehaviorDanish Ali100% (1)

- Material Inspection Report (Steel) FormDocument1 pageMaterial Inspection Report (Steel) FormAlfon TampubolonNo ratings yet

- Concrete Cube Test Report: Kokrajhar Under NCSM Cube Prepared at Site During Casting of Piles of Col. No.C3, C2&C14Document8 pagesConcrete Cube Test Report: Kokrajhar Under NCSM Cube Prepared at Site During Casting of Piles of Col. No.C3, C2&C14Pritam Jyoti GogoiNo ratings yet

- Field of VisionDocument286 pagesField of Visiondementia041296% (75)

- Qap & Inspection Test Plan (Itp) - SimplexDocument50 pagesQap & Inspection Test Plan (Itp) - SimplexN.Prabhu100% (1)

- Bar Bending Schedule & Quantity Estimation of Reinforcement SteelDocument19 pagesBar Bending Schedule & Quantity Estimation of Reinforcement Steelnaeem100% (1)

- Precast Segment ChecklistDocument1 pagePrecast Segment ChecklistRahul Chauhan100% (1)

- Qap PDFDocument11 pagesQap PDFNirajan MarwaitNo ratings yet

- Bs 110 (R) With A&c Guidelines For Fabrication of Steel Girder Procedure March 16Document57 pagesBs 110 (R) With A&c Guidelines For Fabrication of Steel Girder Procedure March 16Vvs RayuduNo ratings yet

- Itp For Structural Steel WorkDocument12 pagesItp For Structural Steel Worknguyen thangNo ratings yet

- Irs Welded Bridge CodeDocument32 pagesIrs Welded Bridge Codeamawauce67% (3)

- Sail 3502 Steel Chequered Plate ColisDocument1 pageSail 3502 Steel Chequered Plate Colisतरकश के तीर33% (3)

- 2022-03-24 ITP For Fabrication and Erection of StructuralDocument7 pages2022-03-24 ITP For Fabrication and Erection of StructuraljaymarNo ratings yet

- Sectional Testing of Pipe LineDocument2 pagesSectional Testing of Pipe LinesumitanuragNo ratings yet

- Qap PDFDocument2 pagesQap PDFJagjeet SinghNo ratings yet

- SAIL CatalogueDocument37 pagesSAIL Cataloguekoushikdey_20110% (1)

- Is - 6132-Part1Document13 pagesIs - 6132-Part1Rajendran NairNo ratings yet

- Int-UpperInt Placement Test PDFDocument3 pagesInt-UpperInt Placement Test PDFh1238709mNo ratings yet

- 4 Reading-PracticeDocument24 pages4 Reading-PracticeCườiLênNhéNo ratings yet

- RDSO Norms For Steel Girder FabricationDocument25 pagesRDSO Norms For Steel Girder FabricationSandip DasNo ratings yet

- Spec - WeldingDocument6 pagesSpec - Weldingprasad_kcpNo ratings yet

- QAP BridgeDocument23 pagesQAP BridgeBhawesh Ashu100% (2)

- PSC Girder Before Concreting MIPL CL 32Document2 pagesPSC Girder Before Concreting MIPL CL 32Rayudu VVS100% (1)

- Is 6623 High Strength Structural NutsDocument11 pagesIs 6623 High Strength Structural NutsprashantlingayatNo ratings yet

- Guidelines For Inspection & Maintenance of Bridge Bearings: BS-102 For Official Use OnlyDocument11 pagesGuidelines For Inspection & Maintenance of Bridge Bearings: BS-102 For Official Use OnlyAnirbanNo ratings yet

- Standard Specification Piping Fabrication and Installation Spec - 00 - P - 02Document12 pagesStandard Specification Piping Fabrication and Installation Spec - 00 - P - 02tsaigoneseNo ratings yet

- Reasoned Document IRS M-39-2020Document42 pagesReasoned Document IRS M-39-2020Metal deptNo ratings yet

- PQC Pour Card FormatDocument1 pagePQC Pour Card FormatChander MohanNo ratings yet

- L&T Quality Quiz-Sample 1Document3 pagesL&T Quality Quiz-Sample 1balaNo ratings yet

- Fire Fighting Building B O QDocument10 pagesFire Fighting Building B O QJurie_sk3608No ratings yet

- 0005 India Regulation On CoatingDocument33 pages0005 India Regulation On Coatingagustinusset100% (2)

- Inspection and Test Plan For Silos and HoppersDocument15 pagesInspection and Test Plan For Silos and HoppersHOMAYOUN KHADIVINo ratings yet

- Checklist For Bored Cast In-Situ Piles ConcretingDocument2 pagesChecklist For Bored Cast In-Situ Piles ConcretingHarlene Marie M. IlaganNo ratings yet

- British Universal Columns and BeamsDocument6 pagesBritish Universal Columns and BeamsjagvishaNo ratings yet

- IRS-B1 Correction Slips Upto 11Document41 pagesIRS-B1 Correction Slips Upto 11vishal agrawal100% (1)

- Typical QAPDocument4 pagesTypical QAPhemantmech09No ratings yet

- Project Work: Construction of Bridge No 352 (6 X 30.50M PSC Box Girder)Document44 pagesProject Work: Construction of Bridge No 352 (6 X 30.50M PSC Box Girder)shravan38No ratings yet

- Inspection and Test Plan: Activity: ITP For Inspection of Pile Load Test WorksDocument3 pagesInspection and Test Plan: Activity: ITP For Inspection of Pile Load Test WorksjitendraNo ratings yet

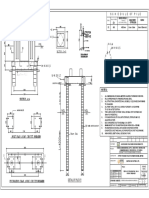

- DETAIL OF FOUNDATION 132 KV CIRCUIT BREAKERDocument1 pageDETAIL OF FOUNDATION 132 KV CIRCUIT BREAKERManas MondalNo ratings yet

- General Format For Girder Fabrication Check ListDocument4 pagesGeneral Format For Girder Fabrication Check ListBhanu Pratap ChoudhuryNo ratings yet

- Protocol Column AlignmentDocument9 pagesProtocol Column AlignmentManikandan elumalaiNo ratings yet

- SOR 8th Ed 2013Document467 pagesSOR 8th Ed 2013Durgesh Govil100% (3)

- Static Load TestDocument9 pagesStatic Load TestMuhunthan MurugananthanNo ratings yet

- Checklist For Fabrication & Erection of Structural Steel WorkDocument1 pageChecklist For Fabrication & Erection of Structural Steel Workbetelehem hailuNo ratings yet

- FINAL REPORT OF B KP ConstructionsDocument20 pagesFINAL REPORT OF B KP Constructionsboddu ramakrishnaNo ratings yet

- BHEL Tolerance For Column PDFDocument133 pagesBHEL Tolerance For Column PDFelangorenga0% (1)

- Fabrication Work For The Construction of Chenab Bridge Part IDocument2 pagesFabrication Work For The Construction of Chenab Bridge Part IIndra Mishra100% (2)

- Repairing Damaged Anchor Bolts - Ask The Expert (HTTPWWW - Portlandbolt.comtechnicalfaqscorrecting-Anchor-Bolt-Damage) PDFDocument3 pagesRepairing Damaged Anchor Bolts - Ask The Expert (HTTPWWW - Portlandbolt.comtechnicalfaqscorrecting-Anchor-Bolt-Damage) PDFahmedsabercgNo ratings yet

- TGN-BC-01 Tack Welding of Reinforcement BarDocument8 pagesTGN-BC-01 Tack Welding of Reinforcement Barnaseema1No ratings yet

- British StandardsDocument12 pagesBritish Standardsniginp67% (3)

- Pinos HexagonaisDocument32 pagesPinos HexagonaisAdriIaAnuUu CruzNo ratings yet

- DST200 UserManual v5Document66 pagesDST200 UserManual v5Jalberto SaldivarNo ratings yet

- SureFlowEquipmentInc - U S PDFDocument32 pagesSureFlowEquipmentInc - U S PDFM Alim Ur RahmanNo ratings yet

- Equipment InputsDocument5 pagesEquipment InputsMyint Myat NaingNo ratings yet

- GMCDocument122 pagesGMCramudo ZNo ratings yet

- AA Class Contractor As On 01.03.2016Document46 pagesAA Class Contractor As On 01.03.2016uday64668No ratings yet

- 8) Qap Itp For Gen Civil & RCC (10 Pages)Document10 pages8) Qap Itp For Gen Civil & RCC (10 Pages)uday64668No ratings yet

- List of Machines: S.No Description Specifications Unit CostDocument1 pageList of Machines: S.No Description Specifications Unit Costuday64668No ratings yet

- Qa Manual and QC May01Document70 pagesQa Manual and QC May01coli15No ratings yet

- Quality Plan and Inspection & Test Plan: Records Type To FrequencyDocument1 pageQuality Plan and Inspection & Test Plan: Records Type To Frequencyuday64668No ratings yet

- JCEPMS13002 Hyunjoo KimDocument9 pagesJCEPMS13002 Hyunjoo Kimuday64668No ratings yet

- Full Form of ITDocument4 pagesFull Form of ITsuryansh1234No ratings yet

- My ResumeDocument8 pagesMy ResumeShaikh Mohd ShahbazNo ratings yet

- PCC - Delhipolice.gov - in ViewStatus - AspxDocument2 pagesPCC - Delhipolice.gov - in ViewStatus - AspxMAAHI CYBER SOLUTIONNo ratings yet

- Ebook The Legal and Regulatory Environment of Business PDF Full Chapter PDFDocument63 pagesEbook The Legal and Regulatory Environment of Business PDF Full Chapter PDFsummer.stephens690100% (31)

- Between Empire and GlobalizationDocument5 pagesBetween Empire and Globalizationazert yuiopNo ratings yet

- GRP WRKDocument5 pagesGRP WRKrheaNo ratings yet

- Effects of Operating Parameters On Nitrogen Oxides Emissions For A Natural GasDocument9 pagesEffects of Operating Parameters On Nitrogen Oxides Emissions For A Natural GasMudhafar MudhafarNo ratings yet

- City of Manila v. Coca-Cola BottlersDocument17 pagesCity of Manila v. Coca-Cola BottlersRo CheNo ratings yet

- OcclusionDocument26 pagesOcclusionAbdelrahman GalalNo ratings yet

- Weld Overlay Cladding1Document3 pagesWeld Overlay Cladding1Yetkin ErdoğanNo ratings yet

- Manual Book of Kawasaki Ninja H2RDocument17 pagesManual Book of Kawasaki Ninja H2RAdit IndraNo ratings yet

- LETF (Tomas Fernandez Espada) : General InfoDocument3 pagesLETF (Tomas Fernandez Espada) : General InfoMiguel Angel MartinNo ratings yet

- This Is Me Part 2 Reading Comprehension For Adults Reading Comprehension Exercises - 8390Document3 pagesThis Is Me Part 2 Reading Comprehension For Adults Reading Comprehension Exercises - 8390Shalini RamNo ratings yet

- WeldingDocument23 pagesWeldingSuneel Kumar MeenaNo ratings yet

- Auto-Tuning of PID Controllers Via Extremum SeekingDocument6 pagesAuto-Tuning of PID Controllers Via Extremum SeekingjuliiojaiimesNo ratings yet

- C4B Unit16 HRMB V March2020 Task2 Report Shinan Solah 3855Document11 pagesC4B Unit16 HRMB V March2020 Task2 Report Shinan Solah 3855Athu KulhiNo ratings yet

- NBIMS-US V3 4.9 WSieDocument350 pagesNBIMS-US V3 4.9 WSiemahmoud mokhtarNo ratings yet

- Emesrt Section2 StandardsDocument4 pagesEmesrt Section2 StandardsNilson Alves de OliveiraNo ratings yet

- Assignment 2 - SolutionsDocument14 pagesAssignment 2 - Solutionshassaniqbal84No ratings yet

- PDF IRH GuidebookDocument121 pagesPDF IRH GuidebookReems LordNo ratings yet

- First FS - Audioscript - Test 1Document10 pagesFirst FS - Audioscript - Test 1Patrícia Faria0% (2)

- College of Health Sciences Cotabato City: Through An Interview, and To Set Contract With The FamilyDocument3 pagesCollege of Health Sciences Cotabato City: Through An Interview, and To Set Contract With The FamilyMarielle ChuaNo ratings yet

- Discipline CodeDocument29 pagesDiscipline CodeGolden SchoolNo ratings yet