Professional Documents

Culture Documents

Engineer's Digest PDF

Engineer's Digest PDF

Uploaded by

Ganesh Prabu0 ratings0% found this document useful (0 votes)

39 views55 pagesOriginal Title

Engineer's Digest.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

39 views55 pagesEngineer's Digest PDF

Engineer's Digest PDF

Uploaded by

Ganesh PrabuCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 55

; PEW 2 GUIS

(VOLUME - 1)

(FOR INTERNAL CIRCULATION ONLY)

rN

ECC

LARSEN & TOUBRO LIMITED

ECC DIVISION

CHENNAI

Se

1

This remarkable book of palm size emerged from

« the compilation of technical information sourced

from vorious rare references. The book was very

: poputor under its tric! use to our CMPC engineers.

: The book contoins everything neces to carryout

the field design of conventional rks in steel

or concrete or timber, in addit’=- to voluable

technical information related to co ction.

| toke the pleosure in introducing th vriceless book

7 ‘as a quick reference for our en :ers both at

& jobsites ond offices. :

( With worm regords

(GE # -Sd-

« SEPTEMBER - 2000 R, VENKATESH

v

ey

a US

INIT R

LENGTH

1 in = 254 cm Tem = 0.3937 in

vt = 30.48 cm tom = 0.0328 ft

1 yord = 09146 m

1 mile = 1609.30 m

1 noutical mile = 1853.27 m

= 6.4516 Sq. cm

1 Sq. t= 0.0929 Sq, m

1 dere = 4045.86 Sq. m

1 Sq. mile = 2.590 Sq. km

VOLUME & CAPACITY

1 Cu in = 16.3871 Cu.cm 1 Cu, cm = 0.061 Cu. in

1 Cu = 0.0285 Cu. m 1 Cu. m = 35.315 Cu ft

= 0.7645 Cu. m

1 Kiogram = 2.2045 Pound (Avie)

Mr = 1000 kilogram

Var = 19,684 Hundred weight

(Cnt. Be)

wut = 0.9862 Tons

MATHEMATICAL AND TRIGONOMETRICAL FUNCTIONS

[TRIGoNOMETRICAL FORE SSSSSSOSC~— ane a ,

{convex ond conical

tces combined) SPHERICAL

| = SEGMENT arm renee - 1/3) a

RIGHT CIRCULAR arch ren

‘CYLINDER

1

‘HOLLOW

CYUNDER awh)

poaeeee a

i 2 92) na

any 1 a

y PARABOLOD ale a “ay <

i

i getn a

cme - HYPERBOLOID ee

{

) 2 { 7

eee 15

GEOMETRICAL PROPERTIES OF PLANE SECTIONS. 2

3

POSITION OF] MOMENT OF 2

SECTION arta ENTROD ah SECTION MODULI é

ca ° x= bh? /36. tex §

- : yan) /AB bose=bh?/12 F:

; a [he w2| ees an epex-bh2/24 .

iL NL,

: bb=bh8/12 Uys? /24

eS ir a a

a . 9

sh tt | eee dexsbd2/6

STP Ty | ae be | ee v2 meet e ,

zl Bele teo=bd2/3 a

4 tae Bee

g bid? ote?

ie B(b% 42) 5(P* a

GEOMETRICAL PROPERTIES OF PLANE SECTIONS

MOMENT OF

INERTIA SECTON MODUL

SECTION AREA

RECTANGLE

3 boxe bys st/12 Tex=Zyy283/6

le = 8/12 5"

ao tx = fe

3 tn o2atb) fix = do? +4ob+b?) we

| A= dlots)/2 Sor) elev) | ‘(two values)

E * adcbotorarhe) yy = 2

| eB

a J

=

GEOMETRICAL PROPERTIES OF PLANE SECTIONS a) Fs

5

POSITION OF] MOMENT OF

SECTION area SRO ne SECTION MODULI 5

te =

Ee i Hpstaeyoa-snas)| 2 = 3

six wor 7 ? ose = i/e, £

s ie a sah &

i) correo | Brgy. Se

sing ¢in28)|

wen |

: 4 ee

8 angele sin? (9/2)(4r4/9) ‘centre = bx/e,

se Pn pratense) | com = infer,

14 (0/180 Ty = 2 yc

*

JU. vo

inx = by = 0.0549r4l "

Fi a » snes en

Bra x Be = 01968 | ay = Zyy = 109589

www = 007144 qe aioe

A tw = a.0384r! Iw = 0.0643

QR

: . : '

GEOMETRICAL PROPERTIES OF PLANE SECTIONS

POSTON OF] MOMENT OF

wen OETA SECTION MODUL

Minirum Valves

aan 077% thx = hy = 0.00764

ey = 02i6d 2 70% . Bw = 00178

S| i Sette erat Iw = 0.00793

Ey ye eae

x ai ae ee Tex = 0.785400?

a Ree mh Tye orasaend | day = 0785406?

=

IZ Y tx = 0.10980 5

Ss = tate [tax - bose = 0.2587 5

>| z 7? [ny = 0397700? | Zax-crown = 0.190700" 2

is bese Tagse = 0.992703 | Zyy = 0.592700? 3

5 2

i

fe GEOMETRICAL PROPERTIES OF PLANE SECTIONS

POSITION OF | _WOWENT OF PADS OF

oe AREA |" cenrrowo | werTia aBout xx | SECTON MODULI | Greation

©) ) fy *o.7071 (e?-a7)} 0.48204, | a.0ssa(ai-a/) ooess(“*) 0.2376/(6?+49)

|OCTAGONAL CELL

=

: " TN ag?-ra) | yr toe-ba) ij

TT) Foe-nay | | 2 econ

rz] 4 J+ a.o4ar (bem) somse(inel) a A\ babi

Howow ELUPSE

bd 4 bob de?

muda | |e 7

H(t =)

PRP P| oto? : oa : i “ | 7 =)

|HOULOW SQ. ON = 0.1 n(n)

coe, b

i

GEOMETRICAL PROPERTIES OF PLANE SECTIONS

POSTION OF | MOMENT OF RADUS OF

SECTION | AREA eno | enna secur xx [CM MOON Stn

re en ee oo

HOLLOW CIRCLE

Xe ya ten | ota

Re (0.28292 R2{Re -Ri aie (1)

x ruta set spe oh, alt= aN Re +R Y IG)

X05 (Re-Ri RI fee fae

| -

Ik fy *o.sags (42-a9)| 12 a,= 0.43300, | — 0338(64-¢,') corso (=) | ozzsryiereed]

7 a

IEXAGONAL CELL He

Lan mf

= Be = 04338" pert o.o1a0s* 0.03135? 0.20415 |

5

GEOMETRICAL PROPERTIES OF SECTIONS e

Distonces to ‘Moment of inert Section | RO || =

A UP Pee arte |ll

y ond yy seh 17% 3

sit f

mages 5 rt pide mobgotr'y LEE

Earn Es 1200 ope of longen(o-s) +e(hi)x(ort)a1/6 for stndord. section

Test 1 tad 1 tt

FE as See to

+i | teeter) ie w a + Ee

+ fassiope of Hongem(al-s) + Ua(naI}H{b-t)=1/8 for stondord sections: a

ie

tegen d wrzma | tradable? 1

i EE | wekeed Fen Stang al +\£

t foesces of Nongen(a-s)+Ua(raIPHO-U=1/6 for slonders sections

mai

GEOMETRICAL PROPERTIES OF SECTIONS

Distonces to a (Section | Rowe

er Exteeme Fibres eee ere et

y ond yy : Sov |

2dtocaue Porto, 2ily-g2te-anya? | 7

bvormong > BEeraletecatee sh) Porta P| | Le

wer

coe 1 ad Lofty)

z Fee Lolly

ae

7

erzekoed)

fp=s0pe of flongen(al-s) + te(n-i}:{0-1)=1/6 lor stoners sections!

SVINNYOS TWOLVAGHLVA

ois

a

DIAGRAMS FOR PROBLEMS ON AREAS: :

(Shaded portion is enclosed area)

4, Curve: y= x, x22 y

1, Curve: One arch of

hen = Seana

2. Curve: y = «2

= sin ox

a

°

wean 6 itnonds

nfo

nf/2

rae = 26 a

3. Curve: 2 Gal

10. Curve: y2= br

y

Volume of solid got

fon revolving OLS

round X axis

2

Volume = WG be x

2 y2

Scere

zs

uM ae

curve: “> +

Volume of solid got

‘on revolving A'OAB

‘around X oxis

042

Vol = 219 Sota

| (Shaded portion is enclosed volume)

12. Curve: 2

y

72

Volume of solid got orf

revolving OAB oround

IX oxis

a

13. Curve one arc of

y = sin 2c

7. Curve: y= 4ox | 8. curves: y2= 4ox 19.

Gow: y=me Lotus rectum: x = 0

y

Sh

x

OK fo/

4o/mt

deo = (Ch i-mai (2041)

folume of solid got on|

lrevolving OAB oround

IK axis

Vol. = woh 2x de

14. Curve: y = log x

Y

*

a

Volume of solid got on

revolving ALB oround

X axis

vol © 1G fg wan

15. Curve: y= (Ta?

Volume of solid got or

Jrevolving OACB oround

IX axis

4

Vel = BG

@

aa

3

| MATHEMATICAL FORMULAE. MATHEMATICAL FORMULAE

——

LIMENSION CALCULATION

T

7

i P Pas

| & 7

eee fife # : many

WHEN ANGLE TOUCHES “AC a T

ag

. coe Z

B44

z fe

% *

Ls (oe

i

wen wes mes 1 ¢ « 228 ee em

coe ay :

x

4

4

& ee

é i

“ u :

574 , oer

~ ge ean, ier

ed ; werner woes c= | OT a

where, M = my +m g¢my ten ‘eee z

i ae r

(18 x 2+ 10% 5 48x 7)Tm E ‘

oe

(18+10+8)T wh

“ag . x 4 .

We w. Gary

a Cae

- xn Axis a AlsBY Y iz

: norma ones e+ HE | aS Ne aa ee

. epee |? 7

coe

C 37

g Se] povrenit ont out lod)

2 3 i Ie rr 1

3) BE ta Eee

2/8

|e eeeceeseecoe when 1 Odd, Max * (02 ~1)PL/ga : ae"

when is 1 Max = 1.5 So fe

B [lc ur =2P/5 Nyce 31/5] ert ® OA Moe are 3) ner ree

Co, i 8

Rs 8 —= Ra=w(ntl) 2/20,

uw, — ae W(LtN)(L-A)

g a 1/2 % : arf nW/t a

FH] R= Rg= WP fet

ence wen nis odd, a : 6: 10, consider the food uniformly dstibuted. The reoction ot the te | tn wowed cetecton ot 0. See

‘supports ='W/2, but the max. SF. ot the ends of the beom 2) Mo = Ma/L. Mp = M/L

= W(n=1)/2n = AW, The volue of the maximum bending moment = CML 3 Wae—eN2/2 2 a

The vob of the deflection ot the cenre of the spon = + ME s Paeeeseee crea Ma

voue of a] A | C (0/4K-See2n2) Wy = A n= 0.08460,

[when 1=0.67)

Mae -20)/0. co

a \y,=45(9-20m2) pH Fs ay

Rua BCa? site) 8 eee

Rg S(22-sasted j ;

w w/z W/2

‘SHEAR

we dg= AEtG-1a047H2-o8)

Magy PP yat 2-4?)

DEFLECTION SHEAR MOMENT LOADING [DEFLECTION SHEAR MOMENT LOADING

DEFLECTION SHEAR MOMENT LOADING | DEFLECTION

|

Rooms

wy=- 2M ye

unt Reale ns ‘ra =0.05968 ne Ey encsen

rare 00d gre te sire E tom vain) | {orem 10200]

support roca forthe boom —— Ig

(Upbeing considered positive) ot a-¥ ere a te ag

mea a

= 9.0047" = 900375

Seen? wren ean | Aran’

BM,SF_& 2 - FORMULAE FOR BEAMS BM,SF_& 2 - FORMULAE FOR BEAMS

SSS

‘PROPPED CANTILEVERS

Wen(L+o) Wan

a US,

PS, UR act

LOADING

e Wc= PL/9 p= 21/9 My==19PL/S2 pet 7PL/S4

B| wge-wo2/2 Mys-w{ -202)/8 | Mge-24y>-w0?/2 : ye -PYS ; Me=33PL/128

8 Mex =¥12(36p8 -289249)/128 | p = oft —_——,, ‘>,

wen As8-HM| gq = dA Rye 4P/3. Ry= 2°/3 © 630/32 Rye350/32"

Rf ps, | No Re 0423. e a

| % | Ra=w(S/8-392/4) Ras Swop/4 } : ‘

& | ggan(So?4p+5/8) Ryzwol+3p/4) Gyan" 0.015250 m= 0.020955

7

ep PP Pop PP

nit | tia

gr BE UAEH No te)-2041 | dye HEL GorORt6*04]

ke ys ct 6 i: alrakat Bey

we | wee

DEFLECTION SHEAR MOMENT LOADING | DEFLECTION SHEAR - MOMENT LOADING

S ‘ owe? Wy=T9PL/4B Mye2IPL/96 | M =-SPL/S Mes 9PL/25.

Slee Bhlamtea setae] | toe =F i wees |

& ‘C3, Ney

ieee RprSIP/AB ReeS3P/AB Rust3P/5 —Rge7P/5

s/he Fe (15-18F. (s2ap-1569+33]| -

non ores

X Ey AG :

: sean

DEFLECTION

‘SHEAR MOMENT

LOADING

JOEFLECTION SHEAR ‘MOMENT LOADING

ae

[SREC'D=x VaYA"MERO'O= A+

(wc puoe- yur) =n

HE

z

Q

i

everON HN BED NY

(ox. goon conet sor) 2 ay

SP cnn

oS

DEFLECTION

‘SHEAR MOMENT

DEFLECTION SHEAR MOMENT LOADING

"3x0 uoyal

Xi

S

eee. (coe porv+9 72+ 3) SHEE ol

at

WL

i un

i

:

z

5

{Ce-wsr +,

SHY

hI

fre Serie

ii

ne =p

Tei Mez—Te)K- =

‘otis

BMSF & 2 - FORMULAE FOR BEAMS BMSF_& A. — FORMULAE FOR BEAMS

(ace

(f ‘BUILT-IN BEANS 1) ‘BUILT-IN BEANS ))

a os P

g Vote oad) ovina 2| 3 —, =

3 : 3 ue oy

wa ee,

5 uy 8) woes, |S .

Z Wy=lg=—W1/20 S| years fee ae _

- ay “{—|___.

g — = |e

5 tan Rye w2 oe erent x io

5 pes} §) pe} poe

8 a 8 ian = AEBS See” F531-20)

5 rea. = “ite & en.* Eber jinen x = 12/(SL-20)

i : i) Reet | eo

3 ot —l 3 ° Fe 0 ‘wean vs

$F cre =

z por ea 3] = Ma

a Peer yrs aera ay Bfrdge PAD eatgsPo2/t] Me -Y/T6 Mey P/IB

sangha R het caal

——,

3 RasRyzalpe of moment Gagiom 3 wstgee jatgep LF

; efi Tess, 5 : :

3 t 7 t 3

5 hen = 3 3

E ne ato | me ~e

| epee Ais the oreo of the fang For anticlockwise moments reverse 8 ln

moment diogrom the deflections a

TE NE

eae eee eee Pee eee ee eee

CONTINUOUS BEAMS: SHEARS FROM EQUAL LOADS

ON EQUAL SPANS ‘ALL SPANS LOADED IMPOSED LOAD(SEQUENCE

Loa E.G.DEAD LOAD) OF LOADED SPANS TO

Loan Abk SPANS LOADED IMPOSED LOAD(SEQ— : ; GIVE “MAX. SHEAR FORCE

(E.G.DEAD LOAD) | UENCE OF LOADED 0575 0625 438 0.525

SPANS TO GIVE : Kai Taro

MAX. SHEAR FORCE 4 z

Sy | geoo_oso0_ason

O313_0.688 WS 0.60080 500% 0.4008

5 nf mea SY] |= EB | 0393 0556 asst osor 0445 0.803 0571 0621

: iret i ||) S [Fcsomoetoss ome = | Aoartos7Pom® one

4 Fo.ss0050080.3504

2 0. 7 0.395 0526 0500 0.474 0605 | 0.447 0598 0591 0576 0.

B | | 0339 0554 0.046 0.661 ‘

S| | £0.66 ose ose ose

5 0.544 0.856

é 20847 0656 a5 0678 Sasso

“067 051 06s 0647 0.42%

a ee 3 0375 _0500_0.625

3 Aosesosoot 0.754

8

0.333 0867 0867 EG | Pie 20 pass os

2 «fos ost “6% ose e M

& 0.367_0.500_ 0.633. 0.433_0.611 0.656 i

E—| |*ososootos6r Ao ssetosi ROA

3__| | 0387 0st 9452 9803 0.429 0857 0585 0.661 cera soya

3 Seta aar ace fee

g FOO FROM AOE AE.

Eg, Fan 05. COED At CENT, o

‘TWO -SPAN BEAM 1S (0.625-0:5}(1+0.5- 15=0.656.

a, =

\ASF_& 2 = FORMULAE FOR BEAMS: BM,SF_& & ORMULAE FOR BEAMS

Trea eee eee

CONTINUOUS BEAMS: MOMENTS FROM EQUAL LOADS CONTINUOUS BEAMS: MOMENTS FROM EQUAL LOADS

ON EQUAL SPANS ON EQUAL SPANS

ALL SPANS LOADED] !MPOSED LOAD(SEQ-| || ‘ALL SPANS LOADED| IMPOSED LOAD(SEQ-

LOAD} "(E.G.DEAD LOAD) | UENCE OF LOADED LOAD] “"(E.G.0EAD LOAD) | UENCE OF LOADED

SPANS TO GIVE MAX, SPANS TO GIVE MAX.

BENDING MOMENT) BENDING MOMENT)

0.155 : 0.188

0.155 0.188 kenikom*

Soia7F0.1774 Kois6@0.1564 '0.203"0.203"

‘oon ton 0.5 0.145 eae 0175 0.75

0124 0124 SouwFonmztoisee 5 0190 0.150, Ose THORTS

£o107%0.040%0.1074 {0.155} {o.89) [0.135] _ 1 *o7540.10080.175" 107 (0.161)

(0.14) (0133) (0144) 3 ) (0.1%)

0.135 0089 0133 z

*o0s*0054*0054%0.105" ;

{0.151} 0.098] [0.098] [0.131]

0.131 0098 0.098 0.131 8

Ayoetnostcoocsctac] Ov) Gm) CIS) Oo)

70.156, 0.167

os Ko.03s4 2

i x

|. 0.125 0.125 2 0.133 0.153

a 7 j08%0.04240.1084 ES | Aniztoosstorz {0.143} {0.095} [0.143],

3 (0.185) (0.143) (0.1

0134 0.089 0.134 z 0.143 _0.085_0.143

FT I04F 095640 05680:106%, i

‘

i

é

;

E

a fi

= - =

hoe clk

22 SI mn

oe s|E aI

ay d

He * € F

bole le

ij sete harmed teed

t Ae ae

| ab ale aiv

| Baie, zh,

Oz1S

7

= F

¢ ois

ap 7E

Alp

ale

a

ue

wre = OH = My

oh hata + = One

25

pag

S3WVaL BOs BINDS = Wa

‘S3NVUS UOJ IVINNNOS - 4S FP NG

JM_& SF ~ FORMULAE FOR FRAMES

8M _& SF - FORMULAE FOR FRAMES

1 er unt eight

ee

Constants: X= ag Movseherte-e) faye #2, Hoeedenioes

= . wr

2 K{164156)+62 2

we. = m2, {0+90)-7

ge ae +s Shy ye SE Hesse ae a

Me Ky MQ X23 Mee HK) Mm Katy, We Ky ge Apt (B- x

Mee -mysty Moe t= (MB es

wee Eo Kym ea “(

2

ver = Ee ryamty

wpe

antes) 25

Wwe ier = +

ween meee

: ath Ae

gots A : fee

/ Hs = (ott)

|

! & ae

£

7

Th 8 0

7 7 Pl P.

c i

tE Ui

t

8B D A, E

2 Pp

ich

lj +4 9 cate 12 ee

Constonts : 0, 0/h, bj =b/n Wye = Wer 2 - Hye = Hee =P

Y =Pef20? (1-302 J] Yq =Pe{0+(S03-1)k) Pp FRAME ~ Il]

c

sips 2H

Macys t c S

| 8 o \ '

- t

ates tact i ee A ey

Mon Me

My =yHye pally Hed % %

Puedes +8) Pum

Hate Ve ynlne -

ves FE aye Wye Yee 72 ts Hee tA

4

& 8 Dp) a 3

BM_& SF - FORMULAE FOR FRAMES BM_& SF — FORMULAE FOR FRAMES

My =Po Mord

Hys-tga-P

Po

Woke

Moment ot loads = £ Po

Se nee ese es)

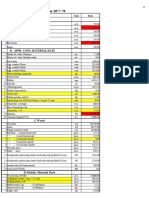

FORMWORK V_ANAND

WALL 02 x 25 x 3.0m HIGH

Ie Di

|e = 70 © |e = 70 kN /m?

Probable mesimam pomp presses Wichnict pugs - 5.00 W/m?

Preamote pers = 0.70 N/mm?

100.

|

— FORMWORK

CONCRETE PRESSURE DATA »)

CONCRETE PRESSURE DATA

EXAMPLES DESIGN PRESSURE DISTRIBUTION

WALL 0.5 x 10.0 x 6.0 m. HIGH Paz = D(C, + CeKJA-C; TR] or Dh kN /M?

OPC concrete with retarder whichever is smolier

Concrete temperature ot plocing,: 10°C] S| where,

Rote of rise = 3 m/n * ©, = coefficient dependent on the size ond shape of

Pa = 91 N/m? slat formwork (see Tobie 1 for voiues), [mmf

"3.50 m = 91/26 = | Boo 94 f/m?

COLUMN 0.5 x 1.75 x 10.0 m. HIGH

(OPC concrete without retorder -

Concrete temperature of plocing : 10°C] g| 3

Rote of rise = 10 m/h 3

Prox = 158 kN/m?

6.08 m = 158/26 L

| Pas = 194 = 156 EN/m?

T= concrete lemperotore ot plocing, °C

where, CyaR > H, the tid pressure (Oh) should be

token os the design pressure.

of rise, All the effect

‘odmintures. ond concrete

the term.

OKI R

1) OF, RFC & SC stu caries

2) OF, REC SC ath ony sors,

‘exagh 0 elder

ty weUrc, PFC, PTAC or vis conta |

Nemes TOR pao AOR plo wth e

—

2) Bene cvcig re en 7 9

ot pe

hie o toe teh)

Tie of fe

BOOooooG

EER

ae

waa nH A a

70 704 Tot 104

8 toe 18

a

*

7 107 a se

005 19

7 eNO

EEE

o es

a ak

a

ae

104 io Joe

72 164 104

e518 8 1

te 6

Ts 17 16

Tae

om

150 10

ma

16a

*Plon dimensions in both the orthogonal directions within 2m

=>

‘assumed as column

©

rk Pressures (In_kN/sg.m) for WALLS*

Design For

TOR, Ree © SPE wo ite

Do pee o arto oy soncon

cone meee

fy oF, wee a SC who rrr

B} PSF, POF, PIC wr tends cnn ks

han POR gis or AO pla tnd ees

WORE, PIF, PAC ar Mande cvs et

thon TOR gis oF 40% pla wih ary ost

mein «tr.

1) Wer, PaFC, POAC or aes canting

sean POE por AO ple wth

mate

fy Barts caning more than 70K gts

ot pe

SI eee Tae oe Tete oes (al)

Lon asfocfos] oJ] 20[ a] so] ol e2 Jos Ja Jos [v0 fis fro fsa [so Po [oa]osfer]os] a] v3] 20] s0] 50] 0

aa 2a ae Teusuuvapavave sas

oa se a ee Ce |

s eC) ee RC

Ce) ao Ww To as 1 fs OS eS He

= Soe Bee Ta Ba fs eo LT

a

2 “O82 29 2 Sle oH ARR 2 2

FI a ee |

@ Sea ne wee 8 seo

3 Rod os ae Te O_O He

e we ea oa ve fie om Ton TG VBE TST

[Av AS eee ea DE ee a Slew

i]s a we eo aL we es lee oe sO Ow

» [iio es en poe 6 eS se | ae

(ae es eo Ae a ss ee wl 8 Oe

Ce RY

*Pian dimension in ony of the orthogonal directions exceeding 2m => assumed os woll

SHOMAHOS

es

’OMANOd

2RMWORK

‘curing is done, following striking period may deem to solisfy.

TYPE OF FORMWORK MN, PERIOD BEFORE

‘STRIKING FORMWORK

5 16-24 h

16

x4 3 doys

6

8 immediately ofter removal of formwork) 7 doys

d) Props to siobs:

1) Spomting up to 4.5m 7 doys

2) Spanning over 4.5m 14. doys,

GRAIN OF —_ THE GRAN OF ) Props to beoms and orches:

& OUTER PLIES THE OUTER PUES _ i 14 cays

a 0.9m 1.25m 21 days

mON 1.65m_ 2.15 ints ond lower temper sre, the stripping lime recommended

PROMS 255m 330m

sizes and disposition be

pt 225 N/mm? 325 W/m? such a8 to be oble lo safely full dead of the slob, beam or

‘arch os the cose may be together with ony fe ‘kely to occur during

PER 4000 N/mm? —— 8000 N/mm? a ‘curing or further construction.

NOTE: Te sun of the lense sents both Grecfons shal be al les thon 60.0 N/m? Where the shope of the eleme ork has re~entrant

yet wine ary plat coatng or subi omy maybe Dent to i saber ‘angles, the fort asile otter the concrete

a5 by sooking in cold ot hot woler (temperature vp to 70°C) before fing. hhos set, to ovoid shrinkage cracking occurring due w the festroint imposed. 2

108 JS eA at

- = ——

>

AOADNG ATA

‘WELDED FRAME | WELDED FRAME

MODEL M45 | MODEL M=52

T. FOR SINGLE TER LOAD APPLE 450 WT 34 MT

‘ON VERTICAL LEGS. PER LEG PER LEG

7% FOR 2 TER LOAD APPLED ‘375 MI 27 MI

ON VERTICAL LEGS. PER LEG PER LEG

‘3. FOR 3 THER LOAD APPLIED 36 MT 22 WI

(ON VERTICAL LEGS. PER LEG PER LEG

© FOR 4 TER LOAD APPLED 32M 18 WI

OW VERTICAL LEGS. PER LEG PER LEG

2

Ee

38, ne.20

1215

TE:

IF USED AS A SCAFFOLDING

OF MORE THAN 2 TIERS

HEIGHT FASTEN THE SYSTEM

TO A STABLE STRUCTURE

LUKE A BUILDING AT EVERY

2nd, TIER.

a

as 1219

120. HGH UNIT

ap e/ =a

7 SEenON 8 = 8 copie cs

sae, AMER]

0 CT POLE

Sori0 ue PATE DS ret eome| 100

o12 nce FOR 10 BOT

tsi6 tk PATE ZS to wma | 100

7Ox3.15 th, PLATE, 70

/50x3.15 tk. PLATE 390,

oss POE 50

is 1 PAE Ta00

2008.15 PE

DESERIPTION

ar x a @ fo ‘SECIION C =

Tot wee = 30.80 Xo.

NOTES :

1. ALL DIMENSIONS ARE IN MM,

aiNFORCED_CONCRETE

REINFORCED CONCRETE

7

MODERATE:

‘surfoces sheltered from severe rain or freezing

exposed to condensation ond rain

continuously under water

fe contact oF buried under non-oggressive soil/ground water.

Concrete surtoces sheltered trom saturated soll oir in coostol oreo,

SEVERE:

Concrete surfaces exposed to severe rain, alternate wetting ond drying

‘Surfoce of members in tidal zone,

Members in direct contoct with fiquid/aotd — chamicols.

y PI INS _F

Trade of | Total @ Proportion of | uonlity of

concrete | of dry aggregates fine oggregote | woter per

by moss per 50 kg | to coorse 50 kg of

of cement, 0 be oggregote coment, mox

Token 08 the sum of | (by mass) Litres

the indviduo! mosses

of fine ond coorse

‘aggregates, kg (mox.)

ws

Mrs

M10

Mas

M20

concrete

2

ue

x

us

ve

REINFORCED CONCRETE

in, cement [mex. free woter |min. grade of

content kg/eum. | cement ratio

ass

050

as

0s

00

3

#81 lelelele

Sey lal sla]

i

;

3

Byeyieieiaiel:

Ho

Ble lal

sé :

NOTE: The proportion

)

EXPOSURE

sw

No.

IES

moves token inlo account do nat exceed the Knit of pozzolona and siog spied in 1S 1489 (part 1) ond 455 respective,

The odétions such es lly osh oF ground grenulted Dost fumoce slog may be token into eccount in the concrete composition

sth respect to the cement content ond woler-cement rolio i the suitably i estebished end os ong os the maimuo

douse $2 1 496 ~ 2000,

1. Cement content prescribed in this table & especie of the grades of cement ond i i indsie of odsiions mentioned in

2. Visirum grade for pin conerele under ld exposure conston is not specified

REINFORCED CONCRETE

e =) '

oan poeryaeat tea FLEXURE - REINFORCEMENT PERCENTAGES )

Ce ee ore FOR DOUBLY REINFORCED SECTIONS

feck = 25 N/mm? : fek= 20 N/mm?

fy = 415 N/mm?

Mu/oa? Wu/od? | ty = we srg? #142005 df= 010 dfs 018 d/8 5 020

2 415. N/mm? nym? Te Pe me! Tm Pe!

oat 0.958 = 0.002 0.958 0.002 0.003 0.959 = 0.003

0.01) 0968 0.012 0013 0.969

‘Oa

0.069 1.008

0064 1.036

019 1.073

0082 0998

1.108

SINFORCED CONCRETE REINFORCED CONCRETE

C PERMISSIBLE SHEAR STRESS IN FLAT SLAB i) (en tt ft tte sc

(Reler clouse: 31.6.3. of 1S:456-2000) fees Me = cos - 43 7 a

Si

y

(a - 16)

te method of design, ond 0.16 Ter

method of design.

For the cose ol puraly exel compression, the points poled on the y-oxis of the

Totows: EOC DR COMED A LOAD AO BNA. BENING

Sa aee men

ss a

eae Beal. Ps 10 "ay = mre ty ti

Ta 0” OMS * Top Tey Use Wah Mgt =

Oa Gy = I (Pu/Puz)

a mrs os iy cn idk 9 ot cae

chorts oe oblsined 03 folors.

(cee Ne

2 thon 08 On is 20.

is

125

= . —S

6.2 BENDING STRESSES

6.2.1 Maximum Bending Stresses - The maximum bending stress ia lenson

(ip, exi) o in compression (Te, eat) ia extreme fire colcuited on the

ttlectve section of 0 beom shail not exceed the maximum permiasble bending

stress in tension (Bet) or in compression (Ope) obicined ox folows noe the

voles specified in 6.2.2, 6.2.3, 6.25 ond 626, of S 800-1964 os opproprale:

Tot or Doe = 0.66 fy

6.2.2.1 In TABLES 6.18 (page No: 137, 138 & 139)

0 = overall depth of beam;

dy = i) For the web of o beom without horizontal slilleners-the cléor distonce

Hlonges, neglecting filles or the clear distance between

cof the flange ongles os oppropriate,

ith horizontol stilfeners-the cleor distance

et ond the tension flange, neglecting

1 tension flonge angles os appropriate

1 = effective length of compression flonge where eoch end of the simply

supported beom ond girder is restroined agoinst torsion shall be token

ends of compression anges unrestrained ageinst fleral

bending. 1 = span

b) With ends of compression flanges partially restreined against lateral

bending | = 0.85 x spon

‘c) With ends of compression flanges fully restrained ogoinst lateral

bending | = 0.7 x spon

fy = radius of gyration of the section about is axis of minimum

strength (y-y axis);

T= mean thickness of the compression flange, is equal to the oreo

cof horizontal portion of flange divided by width;

For rolied sections, the mean thickness is that given in appropriate

Indien standards.

t= wed thickness,

(CLUASE 6.2.3 of 1S: 800 - 1984)

fey - ty

Oboe = 066 —

ere, Fear ay”

fep = elastic cfiticol stress in bensing in MPa

fy = yet stress of the sleet m9; ond

n= @ factor assumed os 1.4.

g

fey = ky (Xt)

: area ofboth Hanges ot the point of lest BM

ky is HY) Y= “Jeo both flanges ot the point Tmax, BM

‘ny of compression flanges of the point of mox. BM

ik. is f(w) =

25 1) w= Sr compresinttenion“cirs atthe point of mex. M

= 108

26.5 * 10 “

Y=

We)

cy. cz = respectively the lesser ond groter distances from the section

neutral oxis to the extreme fibres. (cy = ¢2 For equal flange beams)

6.2.4:1 Volues of fep shall be increosed by 20 percent when T/t is

not greater thon 2.0 and ¢;/t is not greoter than 1544/JTy where dj is as

defined in poge No: 128 ond "Y’ the thickness of web.

128

uv 129

STRUCTURAL STEEL, RAILS, TUBES AND PIPES

STRUCTURAL STEEL, RAILS, TUBES AND PIPES ________

13 SYMBOLS ~ Te sme: tin 7 ‘ond 7.1.2 shall hove the following

oe, col = my ce ‘viol compressive stress

Tot. cok. = cokeuloted average oxil tensile stress

The, col. = cokcuoted bending compressive stress in extreme bre

Ti, col. = colevoled bending lensie stress in extreme fibre

Toc ‘= permissible oxicl compressive stress in the member subjected

{0 oxi! compressive fod only

Tat = permissible oxio! tensile siress in the member subjecled to oxiol

lensie ood ony

Ode = permissible bending compressive stress in extreme libre

Tet = permissible bending tensie. stress in extreme fre

m

me

fee = elostc critical stress in compression = LE

x

) = sme fn pe

t whose volue sholl be token cs follows:

‘members in fromes where side swoy is nol prevented:

Cm = 085

(©) For members in fromes where side swoy is prevented ond

ol subjected to trngverse foding belween ther supports

inthe plane of bending:

4b 2 04

‘af smaer to the larger

3 portion of the unbroced

‘member in the plone of bending under consideration,

Bis positive when the member is bent in

everse curvature ond negative when itis bent in singe

curvature,

(©) For members in fromes where side swoy i prevented in the

plane of looding and subjected to transverse looting bebween

theic supports; the vaive of Crymay be determined by

ralionat onolysis. In the obsence of such onolysis, the

folowing, values ‘moy be used:

For members whose ‘ends ore restroined agcinst rotation

Cm = 085

For members whose ends ore urvestcined ogeinst rotolion

Cm = 1.00

132

in 7.1.4.1. shall not exceed the volue: Oe

Te = maximum permissible equiva

TAA The equivolent stress Te, col, is obtoir. from the following formula:

z i teererecenmgiacs

Ge, cot = Vf Orzcan + 3 xvme cot oF Ober col + 3 wm’ col

718. Combined Bending, Bearing ond Sheor Sire - Where o bearing stress

is combined with lensile or compressive, bendin shear stresses

‘most unfavourable condition of loading, the eq —*t stress Te, cal,

from the fobowing forme, shal not exceed Ge = 09 f,

= 0.

‘TABLE 8.1 MAXIMUM PERMISSIBLE STRESS IN BOLTS

Description of Fasteners | Axio! Tension Tu | Shears xm ] Be0ring: Opt

- - Po. Po.

[Close Tolerance ond

turned botts

[Gots in cleoronee holes

Under combined sheor ond tension

)wed tH 5) Olea < Ot ond + ue

ow

Jove

STRUCTURAL SICEL, RAILS, TUBES AND PIPES

‘STRUCTURAL STEEL, "RAILS, TUBES AND PIPES SIRUCTURAL SIECL, RAILS, IUGES ANU Fite

COLUMNS WITH_BATTENS

FORCES IN BATTEN:

V/2N | =V/2N

The number of battens shat! be such that

Ue member i vided into not less thon

tree ports longitcinaty.

3

3

8

1 VAN v/2N=— & =

icone! & 2

i 1), a =z

o $4 8)—

: g2 wl 8

SPACING OF BATTEN: (Batters be placed opposite to each other) ‘ £2 sl

Senderness of the componen! witin the alten spacing it 32 2 |_8

" 2

owe ake 28.21

ey aaa aie ee gese

- enn g3 5/8

fa = minimum rods of gyrotion of each of the component of the member os? gu-l—s

The design consideration is Bae (=

Ae £7 Ay oF 50 seog\ ec

rn + most unfavorable siendemess roto af the member os 0 whole (ob! is x) See

Tri BATTEN (tn): . 2 =

en be any ofthe role sections or pes coe of oes baer, 23 be

the thichness should be at leest one-fiieth of innermost connecting tine of weil. g5 =| —

‘CONSTRAINTS AL BATTEN CONNECTION: eee le

2) Elective depth (dg) of intermediote botten pltes 2 0.75 3 >

lop >4ty limes the distance between the centroxd of moin members. wy

2 \

Wy

oi

slotes be less thon twice the contoet width of one member

in the piene of betten,

136 137

Ss

x

=] wip

rlee

=

Sis

F\KEB

=

Sleek

=e

a

= (0

a

~I6B

E| Re

r

B

el f&

<

3

z=

§

eee

on"

| 1 1150.01] 17 [149.0]f 33 |143.6]] 49 [132.6 |] 65 117.0] 81 | 99.7 || 97| 83.3

7 1150.0|) 18 [148.8 || 34 [143.1 [| 50 [151.7 |) 66 115.9 || 82 | 98.6 || 98] 82.3

J (150.011 19 [148.6] 35 [142.6 [| 51 |150.8 || 67 |114.8 83 | 97.6 || 99| 81.4

1150.0{] 20 /148.4 || 36 [142.0|] 52 [129.9 |] 68 |115.8 84 | 96.5 |] 100| 80.5

5 i500 |f 21 [148.1 |] 37 [141.4 ][ 53 [129.0 || 69 [112.7 85 | 95.4 || 101} 79.5

6 |149.9|| 22 (147.9 ] 38 [140.8]! 54 [128.1 || 70 711.6 || 86 | 94.4 || 102] 78.6 | -

7

8

9

749.9 | 23 1147.6] 39 [140.2 || 55 [127.1 |] 71 [110.5 |] 87 93.3 |] 103] 77.7

749.9 || 24 [147.3] 40 [139.5 |] 56 1126.1 |[ 72 [109.4 || 68 92.3 || 104) 76.8

749.81] 25 [147.01] 41 |138.8|[ 57 |125.2|[ 73 [108.4|| 89 | 91 3 |{ 105

70 149.8] 26 [146.7 || 42 [138.1 || 58 [124.2 || 74 [107.5 90 | 90.3 |] 106] 75.0

Ti [149.7 || 27 [146.3|| 43 [137-4 |] 59 [123.2 [| 75 [106.2] 91 89.2 || 107] 74.1

72 1149.6 |] 28 (145.9 |) 44 [136.6 || 60 [122.2] 76 [105.1 92 | 88.2 || 108] 73.3

13 [149.5]| 29 |145.5|[ 45 [135.8]] 61 [121.1 || 77 104.0 |[ 93 | 87.2 |[ 109] 72.4

14 1149-411 30 1145.1 || 46 [135.1 || 62 [120.1 || 78 [102.9 || 94 86.2 || 110] 71.6

75 1149.3|| 31 1144.6) 47 [154.2 |[ 63 [119.1][ 79 [101.8 95 [85.2 ff 111] 70.7

16 1149.1|| 32 [144.1 || 48 [133.4 || 64 [118.0 |] 80 100.8 |] 96 | 84.3 |] 112] 69.9

RMI ts IN Mi JON (N/mm2) FOR ST

TH TF = ‘mm? :

Iki/*] Foc |[KL/r| Foe |IKL/e] Foc |IKL/r| Foe eae IKi/r} Foc |iKL/r} Fee

113] 69.1 {1129 57-4 41145 | 47.9 [[ 161] 40.4 |[177| 34.3 [[193] 29.4 || 209] 25.5

Tid | 68.3 ||130| 56.7 [1146 | 47.4 || 162] 39.9 |/178] 34.0 |] 194 | 29.2 |[ 210] 25.3,

115] 67.5 ||131 | 56.1 [147 | 46.9 [| 163] 39.5 [[179 33.6 [[195 | 28.9 |] 211 | 25.0

116] 66.7 ||132| 55.4 1148 | 46.4 || 164| 39.1 ||180| 33.3 |} 196 | 28.6 [| 212] 24.8

Ov

a

&

DQ

Sidid ONY S3BNL ‘Sve “1331S TWaNk

| Ti7] 65.9 [1133 | 54.8 ||149 | 45.9 |] 165! 38.7 |/181 | 33.0 [[ 197) 28.4 |] 213] 24.6

| 118] 65.2 {|134| 54.2 (1150 | 45.4 |] 166] 38.3 |[182| 52.7 [198] 28.1 || 214! 24.4

135) 53.6 ||151 | 44.9 |] 167] 37.9 |]183] 32.4 1199) 27.9 1215 242 |

216] 24.0

| 217| 23.8

122) 190 | DLO rvs ww Tie | = 2.0 1188] 31-4 [202 | 27.1 [1218] 23.6

723] 61.5 [139] 512 |/155| 43.0 [171 | 36.4 |[187] 31.1 [[203| 26.9 |/219| 23.4

124} 60.8 |[140| 50.7 [1156 | 42.6 |[172 36.1 || 188] 30.9 |]204| 26.6 || 220] 25.2

tet

oS

gz)

120 | 63.7 |}136 | 53.0 1/152

7 ae

[126] 59.4 ||142| 49.5 [[158 41.7 || 174] 35.4 ||190| 30.5 ||206 | 26.2 [[ 222] 22.8

127 | 587 || 143) 49.0 |[159 | 41.2 |[175] 35.0 [1191 | 3000 [207 | 25.9 || 225] 22.6

128 | 58.0 ||144| 48.5 |/160 | 40.8 |} 176 | 34.7 |] 192 29.7 ||208 | 25.7 ||224 | 22.4

Sadid ONY S38N1 “Sia “T331S Wanlonyls

IZES AND PROPERTIES OF STEEL TUBES FOR STRUCT Pi

pee rranans 05213) (OORT WITEIZOND wi g/m NBFO (00.269) (1.38/04) 98/0) 7

NoMI-[ OUTSIDE MoMENT[ MODULUS | RADIUS | SO. OF

nat OK | crags [THICK] we | A) OF OF OF | RADIUS OF

BORE | METER NESS INERTIA | SECTION |GYRATION] GYRATION

mm | mm mm |Kg/mlem?| cmt | cm? | cm cm?

Bb 33.7 | UCHT 2.60 1.98 | 2.54] 3.09 1.83 110 at

wepum | 320 | 241 | 3.06) 3.61 24 1.08 eases tee

. ‘HEAWY 4.00 293 | 3.73) 4.19 248 1.05, wat 2 z

32] 424° | UGHT 2.60 | 254 | 325) 6.47 305 14 1.98 ™ HM

MEOIUM ‘3.20 3.10 | 3.94] 7.62 359 1.39 1.93 le

‘HEAVY 4.00 ‘3.79 | 4.82] 8.99 424 1.36. 1.86 2/2

xz] 0 48.3 | UCHT 290 3.23 | 4.13} 10.70 443, 1.61 2.59 if :

* weoum | 320 | 356 | 4.53) 11.59 4.80 1.59 254 LR

‘HEAVY 4.00 4.37 | 5.56] 13.77 5.70 157 247 s iC

50 60.3 | UGHT 2:90 4.08 | 5.23) 21.59 7.16 2.03 4d oe

MEDIUM 3.60 5.03 | 6.41) 25.88 8.58 2.00 4.02

HEAVY 450 6.19 | 7.88) 30.90 10.20 1.98 392

65 764 UCHT 3.20 S71 | 7.32] 48.79 1282 258 6.66

‘MEDIUM 3.60 6.42 | 8.20) 54.02 4.20 287 6.60

‘HEAVY 4590 793 [10.10] 65.12 7.10 254 6.43

80 889 | LICHT 3.20 6.72 | 861| 79.23 17.82 3.03 9.19

‘MEDIUM 4.00 B36 |10.70) 96.36 21.68 3.00 9.00

4.80 142.52 Ls 8.88

i PERTIES OF STI TR PURP

NOMI-| OUTSIDE THICK- JMOMENT | MODULUS | RADIUS SQ. OF

na 0K | crass [CK] we] A | OF OF OF | RADIUS OF

BORE | METER INERTIA | SECTION |GYRATION | CYRATION:

mm | mm mm |Kg/mlem?| cmt | em’ | em i

90 | 1016 [uc | 360 | 870 {ivi0] 13527 | 2623 | 347 1203

weouw | 400 | 963 [12.30] 14832 | 2880 | 345 nist

weary | 480 | 11.50 [14.60] 17144 | 3375 | 343 1178 7

too | 143 [ucer |] 360 | 975 |1250] 19203 | 3360 392 15.36 2

; weouw | 450 | 1220 |1550] 23630 | 41.00 | 349 15.10 5

i. veavr | 540 | 1450 [1850] 27450 | 4800 | 3.85 14.86 Ss

} H&P uo [1270 fucu [aso | 136/173) 3253 4 433 1878 =

weouM | 4.80 | 145 | 184] 34458} 2927 4.32 18.69 a

: ver | 540 | 162 | 206] 3820 430 1852 fp

is | 1307 [usu | 450 | 150 [191] 4372 “75 [2287 2

weoum | 480 | 159 | 203) 463.44 am | 2276 a

rear | 540 | 179 | 228] 5145 47s | 2258 ies

135 | 1524 | uGHT 450 | 164 [209] 5722 oa | Bar iS

weoum | 4.80 | 175°] 222] 606.92 522 27.25 fa

ea | $40 | 19.6 | 25.0] 674.5 $20 | 27.05 z

a

S__UCTURAL STEEL, RAILS, TUBES AND PIPES STRUCTURAL STEEL, RAILS, TUBES AND PIPES

as TRAPEZOI ING PROFI

(FOR COMPOSITE FLOORS & PERMANENT ‘SHUTTERING) (FOR COMPOSITE FLOORS & PERMANE, SHUTTERING)

|

f |

Ist [THICKNESS SPAN IN METRES

jNo.| mm. 1.00 | 1.20|1.40|1.50 }1.60} 1.70 /2.00 |2.50]3.00|3.:

vp ss oo wal ae) wf

2] one 0 | arf 2] so

ts tao wee) are] 09 [2

| mae ze] azo! sno ye | ns

sae ves | e20| 720[ ae 37

o | 200 waar] sia] ove] cor | a2

| {fsores:

|. The properties given. are for one metre width of the profile.

| conforms to 1S: 513 (0) quality. / 1S 10748-1995 gr.2.

ction is token es spon / 150.

. Allowable loads ore applicr

ni iinimum of four supprts ore

Su) paceness [ur m. | MOMENT OF |” SECTON:

No.| mm. | kg/sam, ‘crn ‘em 6. Above allowable loads may b= multiplied by o factor of 0.80

7 B43 2.03 9.557 i for sheets sponning over 2 or 3 supports.

2 B16 26.70 12.137 i

3 10:20 33.38 15.171

: waa] | ant

3

n

wae | 5347 24278

oao_| e877] 30351 {

M49

STRUCTURAL STEEL, RAILS, TUBES AND PIPES STRUCTURAL STEEL, RAILS, TUBES ANDO PIPES

f

ae . i

Avget om 134

80x 80x 9.29) 45] 20 eS

80x 80x 8 5] 20 her

80x 80x11 “| 20 be a

Soe SOetz $5} 20 3081 30e 6 [159 Sail S26] 136 #0 |

Sos $0 6 B2}108 2 {50} 20 97! 405] 640} 165 i2s7{ 431/80] 20 | |

90x 90x 8108/1358 ( 251 oe fies [azo] 2.75 0 [50] 20 as oo set Srofaol 20"

90x 90x10]13.4/17.0 | 259 f127 [zoe [51.6] 2.75 19.8 [50]: 20 : faa eas} asst a0 ees

[ 90x 90x12)15.8|202 | 2.66 [148 235 [soo] a7 233 [50] 20 0x180a10 1228 G5e[ 10) ze «66 [587 fase! seal so

POO 6 927 | 267 Pay h7a lea] 308 152 {60 20 150K150x12 [27.5 7746/1190] 306| 4.63 {5.84/2.97 90!

hoox100% 15.4 | 2.76 [145 [232 [sea] 3.07 20.0 [60] 20 sauieacia [iam Toate

(00x100x10/14.9/19.0 | 284 77 [eer |ria| 3.05 247 [60] 20 cereal alias

hiooxt00e12\17.7|22.6 | 292 p07 [see [ear] 3.05 292 [60] 20 Fote200.12 Le raed

‘ 200%200x16 |48.5 [2370|5760|

f200x200220 [60.0 [2880|4570}

po0x200325 [735] 941] 5.90 [3470

STRUCTURAL STEEL, RAILS, TUBES AND PIPES STRUCTURAL STEEL, RAILS, TUBES AND PIPES :

ge] 2. al 8

in SE Bi 2.

Dilek i 1g! gis: !

Seleislzjaisisjaiels 2

ars = S/3/R eSBs 818)

alesis ‘

Si 8|#|8)8/2/=lalsielelala,

SSBHEEBREIEEE |

wea) al el2 slSlalelels

BH) -s)8/3)6/S[R| s/o) 3/2) 3/5 i

ZITSTSfste [CHAANELS Moss} 0.) tx[ i

8/8 /8]2 2]s|z1s|s [2/38 BE [osowes| fs | | ent tt

> 75x 80[iSwC_75| 1428] 182/157] 15652

O-s|8/sisigielgleigis

ul : mee 3 5 a 3 g g 100x100 /1SMC 100) 19.12| 24.4! 384] 345.51

Gloss 2/2] -lelelalalalsis 125x150] SMC 125| 26.2 | 334] B50] 615.65)

wl se 150x150] tSwC 150| 33.6 | 42.6 | 1576|1402.63| 187.02/ 6.

io I E(RIR [S/S )3 [2 ) 8/513 )3]3 175x150 ISMC_175| 38.2 | 49.8 | 2480/ 1648.17) 219.76)

BIE els(sialalela/2/s/si3l3 [ooxisofisuc 200] 446 | 57.0| 360° ~s.13 251.08)

t/eS/a/s/s/2/2]e/slaislsi3 [225x160 |ISMC 225] 52.2 | 666| 547 25 316.53]

TES ls/sieieislstalsis . | HIzsoxt60tswc 250] 612 [780] 7 369.53

ee tats 8/8818] 818 500x180 |1SMC300| 72.6 | 92.6 | 12640] 524.6737.

i By) FRR RRS s\sis 350x200 [ISM 350| 85.4 | 108.8 | 20000| | .31]1142.86] 708.65 |13:56|807|

Ba se] | x | 2] 2 2] 2] |e D5 [400x200 | SMC 400|100.2 {127.6 | 30400 |e 1.44|1520 [34.74 [15.43] 8.09

é lelsieislelslegigigis

Bee leo lect

a

156 i

ome, ‘ce fsoenni|spenassoxour|soeous|

pec sz] stows] 60 | 8 | 10 | 120 | 10

‘ar met | ‘mm’ | ‘mat | ‘mnt | “own? | “et

We a, cc

we 30 3)

17 373 a

ve a 391

i ry 1

7 as zs

nz 38 a

z 3 aH

Ewa 7a) Tat

+ 7a TH

evi ‘os a

+ a6 coy Ta

3 339 a3 TR.

+ aa7, aay, 7a,

cs an SE

a cy ap ae | 69 | af a

oH oe. an [a fa Pa | me [ee

w e_ |r a0) se | aes Pas an [ae

i os |r a9 | 8 [via me | soe | esr

w os [ i270] 1995, ae ae

2 os |r ie 9 | me |

a os [ ast 1.

# ae Ra

x 128

a Tw

= 1

Es 129

mE 127

x 12,

191

S3did ONY S38N1 ‘Ste ‘1331S TWwUnlonels

Sidid ONY S3AN) “Siwy VAD© WN ane

STRUCTURAL STEEL, RAILS, TUBES AND PIPES:

STRUCTURAL . SEL, RAILS, IUBES AND PIPES

ee

APPENODI A

(CLAUSES 0.3 AND 8.3)

SUPPLEMENTARY LIST OF CRANE RAIL SECTIONS

(A = 1, THE DIMENSIONS OF 22, 30, 32, 43, 45, 52A, 528, 57, 67, 74, 75, 101

‘AND 125 kg/m CRANE RAL SECTIONS ARE GVEN IN TABLE 6

AND FIG. 2 TO B. THE SECTIONAL PROPERTIES ARE GIVEN IN TABLE 5.

TABLE - 5 (1S:3443~1980)

SECTIONAL PROPERTIES OF NON-METRIC CRANE RAIL SECTIONS

DESIGNATION AREA WEKGHT MOMENT © SECTION RADIUS Lasse hehe ed

OF wooues OF

INERTIA GYRATION vane re,

ix Tex tee xs

0) 2 @ 6 ©) ” ®

ig/m cm? kg/m cm com> em cm

an ws m2 ms 1m a ES

» Bo BB a Me 48 G2

2 07 0 wo "21 3 WES

oe Se Se ny Ul AM UES

6567S 1 2 818 G3

st 660 Sz 1204 aT m4

522 68S 5221200 wea BAS ros

7 Rl MB 8 9 «28 80D

7 BA DOS ee) ros

” MB ThA 88S (307 sz 67

is ose 2 am mo 3058

wm 420 mo 38 8S

me 24g) roe

—— ee

C Seana

5

g i

oo i Hi

Siete iets ecient se

sé i

ert

Se

a? |e ok

aie... .-8 ag

hr lL

[ie ue

3 d af §

é - | ae

252 # ge 8

eo giata . is

z a8 |

eae acu)

OESIG~

NATION

(1)

1ScR 50

WSCR 60 105 105.655 60 275 24

WScR 80 130 150 87 BO 35 32

SCR 100 150 150 108 100 40 38

SCR 120 170 17

1SCR 140 170 170 150 140 50 60

9. FREEDOM FROM DEFECTS

9.1 THE RALS SHOULD BE. REASONABLY FREE FROM TWIST.AND THE CAMBER SHALL

NOT EXCEED 0.2 PERCENTAGE OF THE LENGTH.

9.2 THE ASYMMETRY OF THE RAL CROSS SECTION WITH RESPECT TO THE VERTICAL AXIS

SHALL NOT EXCEED 2 mm AND 0.6 mm IN THE RAL FLANGE AND HEAD

RESPECTIVELY.

9 120 45 44

45 kg/m

Fig. 3

30 kg/m

CRANE RAIL SECTIONS BASED ON IS 3443-1980

Fig. 2

ALL DIMENSIONS ARE IN MILLIMETRES

Wis

SUIATIN HR SHOSNANN TY

ees

ee

z_isgj_ er see]

j

'

i

Zz

- e | i

o

ee ~

8 x |

& Ss

$ &

ee 3

Ye 2F

a a

z z

8 8

3 3

s

2

‘ ,

INT: It 1 RICATION

DETAIL 00s DONT'S

| NO ACCESS

! t

i

BEAMS TO

WALLS 1 4 a

i : +=. E ==.

3 i +

i 1

1 as ‘SACRIFICIAL iad

WEATHER PLATE.

| use PUTE pty ALUMINUM ease PUT: ALUMINIUM |

INSULATION ~ CORROSION

euerauc | —— STEEL STEEL BIMETALLIC

‘CORROSION H CORROSION

|

BOLTS WITH SLEEVES ‘SULT

Hi AND INSULATION WASHERS, paca

US WaNInUls

Sdid ONY S38M1 ‘Sive

eis

F————-

FP ener ee eer

IN_STRUCT! TI FABRICATION

ai

DETAIL 005 DONT'S REMARKS, :

1 3 E

= a8 3 fF

HO. BOUIS 8 ss aa4 a :

, ak

\ root 4p. anus

be E

NOMINAL DESIRABLE 5

ee | seg [ow (Ousties WoO E

>) JOINT [ees ‘STE PROBLEM -

TS_IN FABRICATION

‘DETAL 00's DONT'S REMARKS

HOLES. REQUIRING a

TOLERANCE e.g.

FOR EXPANSION LARGE OUAWETER: “a ‘HOLE

on wweRE iE ra oe

TOLERANCE 10 Sy losaovavtaces:

‘BE ACCOMMODATED a 1, TOLERANCE IM ONLY ONE DIRECTION

2. SLOT HOLES EXPENSE

. (3. CORROSION TRAP

4 a ea ee

fesse: | MAINTENANCE

# OE) Co fs

0/6 OR

ara

CHANNELS:

a f (as fan, SM | croson

eae ESCAPE HOLE =

“UNAVOIDABLE

DEL-SHACKLES AND ROFES. DEE-SHACKLES AND ROPES

(G ‘GENERAL ENGINEERING ROPES

RQUND STRAND 6 x 19 (12/6/1) FIBRE CORE

TOLE- | APPROX. | MINIMUM BREAKING LOAD OF THE ROPE CORRESPON~

rR} RANCE | MASS DING TO TENSILE DESIGNATION OF THE WIRES OF

160. kgf/mm? 180 kgi/mm? | 200 kgf/mm?

OR OR OR

Metres | 1570 N/mm? 1770 N/men? 1960 N/mm?

103 igh] KN 1103 kot] KN [103 Kgl) KN

4 5 6 8

3.10 0.44 43 0.50 49 | 055 540

5.50, 0.79 WwW 0.90 87 | 0.98 9.60

= [aso 123 [120 [139 [136 [150 | 1500

45-1] 1240 4a? Wa 2.00 19.6 | 2.20 | 21.50

. 17.00 2.40 235, 272 27.0 | 3.00 | 29.50

+4 = 1] 22.00 35 30 356 35.0 | 3.90 | 3850

isi 28,00 4.00 39.0 450 44.0 | 5.00 | 48.80

00 | «90 | «80 $58] ss 610 | 6020

(EXTRACTS FROM 15:6132 (PART-1)-1972)

'2|e|ajajele|s|e|s|S

a] )er)so] 518 [ss ) 3]

1S_1367 PART I~ 1991 € ITION/ISO:_ 898-1; 1988 (uecHanica, PROPERTIS OF HJ. STEEL)

PROPERTY CLASS

weconwical PROPERY TS eT 45] aa] se | 5a | oa |f%|88,| 98 |r09|129 fume

ae] Sa Ba aa ome _| S| TS LTRs we cope a

BS ese an [sr [a [oy set we ened

Step

ee

A ae a

fr i

. peels a

eC ae

[ae | ae a

oe 7: 7

2 =T

Min | CARBON | MANGANESE | PHOSPHORUS

=> | a

a cs

we [ew [ts ewe

= [es | te

ee

= | om ry ale

=| se [ee

= [ces [en a) =

Cam 190 os 12 LT an

= [ex [86 tee

=e pe eof eie

Teeth SUR AACS COREPOOG G4 SRF. 70 PT=2 «18D

a ear ‘BUNS (meres) Se as

| six sinc =

[Pfo.r5-cifo75-nt[a.75-1] 025]

25-01] 25-m1

3-01] s-nil

2,01] 8m

15-0] 5-m

sol sia sts tes

| eel Fs esha am eh atl el

vaca oe | rea Pre an

[feo-eon 138 ° [as

TAA) WIaade.

wis

SPECIAL TOPICS

(IRIE 120 6, town UC 4 Mon, BO MOT WER

OIE AL OMRON AE a,

(PANEL = 8)

(SCNE 1:15)

F_TRESTLE

THIN PIPES AND CYLINDERS: (t/m) < (1/10)

THICK PIPES AND CYLINDERS: (t/tm) 2 (1/10)

an eee

eo Hoop: stress, sec.m—m,

Sev DL. ¢.wO

R ey Ray eR (0)

5 Longitudinal stress, sec.a-n.

3

2 wt 2)

eee en ace (b)

= W=unit interno! pressure.

& Both Hoop ond

longitudinal stresses ore

independant of the form of

the ends.

f~ = Meon radius

Longitudinal ter le stress

wo?

fy eo

(b*-

Tensile stress | 20p

fe ;

fin = — +) (mox. @ r=0!

Deca Naaee

Radiol compr 2 stress

2

eee - 2) (mex. © #0)

fa , re

- 0

internal pressure. f= Mean rodius

189 )

Oris

| 1 Fees eae

1 |

j FLOATING BODIES

|| c

fa) e (b)

e xg, faimcl |

wy. |

P

| | —— & ee d

| |A

ORR LOO ONG LFTING/LONERNG = (25/100) « CWMCTERSTC FMLAG LOO t

B. PHYSICAL, PARAMBTERES PONTOON §

\ To vat Pars Sree Ls fom area

= eR =e Te hepa Meloceniric = Bu = WV

Fut NUTS [ROM IGRSE AS Tm [ee | ob ale | «is | = Moment plane about AB/CD axis.

fat woes OE oars fen | afm [ost = V = Volume of fquid displaced

iB |_| vo fie [aa i WETACENTRIC HEIGHT = GM = ‘GM - 8) > 0,

conus Pe epee Steet FOR BOTH THE CASES OF MO! ABO'!T 48 & CD AXES |

sc omset____Tm [18 aletere | FOR STABILITY OF PONTOON,

DYWIDAG Bonded Single Bar Tendons | MINIMUM METACENTRIC. HEIGHT = 52 oF DRAFT |

‘ow. [SOOT BAR THREADER When moment is obout AB axis, t = Pontoon length

reac yay MOL | RY] sr wayne | |} wot is also obout AB ie, 1 = be°/12 i

= ee | : =

ee — eS et be | || When moment is about CD oxis, 5). 7 = Specific wt. of liquid

jana oa we [re [sa a [on Po WOI is also about CD ie. 1 = £b°/12

[veto LOW yo. ® ww | on | vom | oo [on | oso | ses | 868 | 1009 R= angle bet

[FAnGUE STRESS ANCE ANGLE OF TILT QUE BM OF _M:

Ise cys asyan — |w/met| 20 | 20 m0 20 1

leita OR nioed| on | oe 2 n 8= V7 (Gu)

[NOM CROSS SECTIONAL AREA mont | woe | rors | soi | aoe | sore | sox [aoe | i018 1 a

wma. we wwe | esr [ro | aot [et far [aes [a ' sasholl be 1:10 (5.7) or less with ;

some oe Tm [sta tat etal st ste i eboard of zer0 or more :

92 | 193

eee ee eke oe a

ooo

SPECIAL TOPICS

WELDING DETAILS FOR

[Binders placed closely

Lop welded pace:

Bars (>20mm) oO

: Dio

sanss Seca Acces SE

2-024,

SS 4 eg

re, e024

eae 3 10 Som ¥

ve soe = 1

=. 16

|

En

Le

Ue som = TE 2

‘STE OF BAR IN mm ‘SIZE OF ELECTRODE (Mi) IN ene

‘WF 0 AMD WOLUONG 6 | 15

OER 6 UP TO MO RELUDNG 10 20

(OER 10 UP TO MO CLONE 14 25

(OR 14 UP TO AO WOWORG 20 MS

‘OAR 20 «0

sors

1. 6013 ELECTRODE SNL. BE USED F THE CAREDN CONTENT OF REAR IS UPTO 0.25%

44. BUTT-WED 1S NORUALY ADOPTED TO JOM BARS OF DWETER NORE THAK 20mm,

SPECIAL TOPICS

TENSION (T) = Fy (1416074 ton?a + 80tona )'

| 197

SPECIAL TOPICS

nee | ‘DESCRIPTION

Tiord rock without Tomsnalion ond defects eg qronite,

lrop and diovte.

8 Tominated rocks in sound condition eg. sond slone

Residual deposits of shollered ond broken bed rock

Geovel, sand ond

resistonce to penetration when excavated by tool.)

Goorse sond, compact ond ory

Medium sand, compoct ond doy

Fine sand, sit (ary lumps eosiy pulerised by the Fingers)

Loose grovel or sond grovel mixture; loose coorse to

medium sond, dry

NON-COHESNE SOUS

Fine sand, loose ond dry

Konkor

‘Sond with clay

‘Solt shale, hard or still clay in deep bed, ory

Wedium lay, readily indented with o thumb nail

Walsh coy ond sand coy mixture which con be indented

with strong thuimb_pressure

| Medium coy, eodily indented wih ee

Soll coy indented with moderate thumb pressure

Very soll coy which can be penelrated several inches:

vsith the thumb.

‘Block colton soil oF olher shvinkoble soit or exponsive

cay in dey condition (SOX soturtion)

COHESWE SOLS

Red eorth

‘Auwviol soi

‘Aiwal toorn|

Peat

Fils or made up ground (consotdated)

as

a0e

You might also like

- Circular Slab Estimation of SteelDocument3 pagesCircular Slab Estimation of SteelGaddam Padmaja ReddyNo ratings yet

- Maintenance & EstimateDocument40 pagesMaintenance & EstimatePerkresht PawarNo ratings yet

- Estimation ManualDocument33 pagesEstimation Manualmerreik100% (1)

- Thumb RulesDocument25 pagesThumb RulesSagar Baravkar100% (1)

- Basic Thumb Rules Used in Construction by Civil EngineersDocument7 pagesBasic Thumb Rules Used in Construction by Civil Engineersearth one100% (1)

- COMPOUND WALL-ModelDocument1 pageCOMPOUND WALL-ModelEr Mansoor HussainNo ratings yet

- Thumb RuleDocument6 pagesThumb RuleVivek ShuklaNo ratings yet

- Cost Estimation DraftDocument3 pagesCost Estimation DraftYeontanNo ratings yet

- Cost Analysis For Brick WorkDocument14 pagesCost Analysis For Brick WorkVittal Kumar50% (2)

- Estimate Table 2 SheetsDocument4 pagesEstimate Table 2 SheetsBernardNo ratings yet

- GP Build Karlapalem 01.03.17Document63 pagesGP Build Karlapalem 01.03.17Thota RevanthNo ratings yet

- Detailed Estimate of Measurement and Quantity CalculationDocument4 pagesDetailed Estimate of Measurement and Quantity CalculationHossen Ali MollahNo ratings yet

- Geodetic Equivalents SepharialDocument30 pagesGeodetic Equivalents Sepharialottuser100% (4)

- EstimateDocument24 pagesEstimateKamal Kumar MallikarjunaNo ratings yet

- Thumb Rules FormulaDocument13 pagesThumb Rules FormulaRamesh MehraNo ratings yet

- Rate AnalysisDocument1,986 pagesRate AnalysisHamid NaveedNo ratings yet

- Brief Rate AnalysisDocument15 pagesBrief Rate AnalysisSaroj AcharyaNo ratings yet

- Furnish Details in A Separate Sheet)Document4 pagesFurnish Details in A Separate Sheet)Parasuram BonangiNo ratings yet

- Comparision Between PT and Conventional SlabDocument5 pagesComparision Between PT and Conventional SlabSheik Mohamed Liakath50% (2)

- What Are The Labour Output Constants For Every Building Works - PDFDocument11 pagesWhat Are The Labour Output Constants For Every Building Works - PDFadkNo ratings yet

- Analysis of RatesDocument32 pagesAnalysis of Ratesgsaty29No ratings yet

- Rate Analysis and Estimate: Brick Work With 1:6 Cement Sand MortarDocument6 pagesRate Analysis and Estimate: Brick Work With 1:6 Cement Sand MortarBaskaran SeetharamanNo ratings yet

- Building SSR 2019-20Document333 pagesBuilding SSR 2019-20NagabhushanamNo ratings yet

- Sreevatsa Real Estate Sreevatsa Global Village, Coimbatore Cement Adequacy S.No Description Adequacy Units RemarksDocument2 pagesSreevatsa Real Estate Sreevatsa Global Village, Coimbatore Cement Adequacy S.No Description Adequacy Units RemarkssivabuvanaNo ratings yet

- Sump Estimate APRSCL 15-4-2011Document102 pagesSump Estimate APRSCL 15-4-2011pandu123456No ratings yet

- Quantity of Shuttering With ExampleDocument2 pagesQuantity of Shuttering With Examplesri projectssNo ratings yet

- Rate Analysis - P$CDocument557 pagesRate Analysis - P$CHemant Dhaked0% (1)

- Estimating and Costing MaterialDocument42 pagesEstimating and Costing MaterialQuestion paperNo ratings yet

- Planning EstimateDocument41 pagesPlanning EstimateImee LignesNo ratings yet

- Estg Part2 - CalculationDocument90 pagesEstg Part2 - CalculationDaphne Tan 丽文No ratings yet

- Building EstimateDocument36 pagesBuilding EstimatesamNo ratings yet

- Cost Civil Works of Building Per Sq. FT Area / Build Up AreaDocument2 pagesCost Civil Works of Building Per Sq. FT Area / Build Up AreaHossen Ali MollahNo ratings yet

- Network Security Essentials-William StallingsDocument204 pagesNetwork Security Essentials-William StallingsHarpreet Kaur100% (1)

- Rate 2077-2078Document63 pagesRate 2077-2078क्षितिज चौलागाईंNo ratings yet

- Rate AnalysisDocument8 pagesRate AnalysisGopal SudhirNo ratings yet

- Material Consumption PDFDocument10 pagesMaterial Consumption PDFShyamontika Choudhury ChakrabartiNo ratings yet

- (RATE ANALYSIS) Site Engineers Data PART 2Document16 pages(RATE ANALYSIS) Site Engineers Data PART 2dolceudayNo ratings yet

- New Analysis of Rate + EstimatesDocument447 pagesNew Analysis of Rate + Estimatesmanas-sahu8053No ratings yet

- PWD Schedule Rate AnalysisDocument196 pagesPWD Schedule Rate AnalysisSachin Chivate50% (2)

- Estimate Note Upto Rate Analysis by Roshan KarkiDocument189 pagesEstimate Note Upto Rate Analysis by Roshan KarkiAnuj ChaliseNo ratings yet

- 2business Center-Section-2 Sanitary & Plumbing PPDocument43 pages2business Center-Section-2 Sanitary & Plumbing PPSourov SamadderNo ratings yet

- E. S. T. I. M. A. T. I. O. N.: by Mohamad L. NaloDocument45 pagesE. S. T. I. M. A. T. I. O. N.: by Mohamad L. NaloMohamad NaloNo ratings yet

- Clovis Moura - Dialética Racial No Brasil Negro PDFDocument125 pagesClovis Moura - Dialética Racial No Brasil Negro PDFRayane Lula AndradeNo ratings yet

- Pneumetic Roller: Item No. Per 13.14 1 Cum Cum 40 Mm. Th. Premix Carpet Asphalt Concrete Per SQMDocument4 pagesPneumetic Roller: Item No. Per 13.14 1 Cum Cum 40 Mm. Th. Premix Carpet Asphalt Concrete Per SQMslashNo ratings yet

- RCC SLAB 11-12 Rate AnalysisDocument2 pagesRCC SLAB 11-12 Rate AnalysisRiazahemad B Jagadal0% (1)

- Quantitynotes 180816020109 PDFDocument73 pagesQuantitynotes 180816020109 PDFOm Krish RamNo ratings yet

- Acfrogdqwmeslskvqklrdq8wbbv7 Pt3p5q4 N Mbvijr8q8evymkkpjn2 Mhloeijuvdzws0mkhfj2fy4mg4xd56fpalrrqyfwyfkiwzdfwbvgu8cto8vqtrjg1psgDocument2 pagesAcfrogdqwmeslskvqklrdq8wbbv7 Pt3p5q4 N Mbvijr8q8evymkkpjn2 Mhloeijuvdzws0mkhfj2fy4mg4xd56fpalrrqyfwyfkiwzdfwbvgu8cto8vqtrjg1psgSrinivas SukhavasiNo ratings yet

- Basics of Quantity Surveying: Business DiagnosticsDocument25 pagesBasics of Quantity Surveying: Business DiagnosticsJay Badiyani100% (1)

- Boundary Wall ConstrctDocument6 pagesBoundary Wall ConstrctSyed Adnan AqibNo ratings yet

- Sub Contractor AgreementDocument3 pagesSub Contractor AgreementNavam NanthanNo ratings yet

- BIWTA - Narayanganj - Estimates 2020.09.04Document1,056 pagesBIWTA - Narayanganj - Estimates 2020.09.04Anand PandeyNo ratings yet

- Civil Engg Basic Knowledge PDFDocument3 pagesCivil Engg Basic Knowledge PDFASHUTOSH GUPTA100% (5)

- Ggps Sandasar Qasim, Battgram OF STEEL REINFORCEMENT (Upto 2nd Bill) S.No Sheet # Part of Building Remarks Steel Used (LBS)Document7 pagesGgps Sandasar Qasim, Battgram OF STEEL REINFORCEMENT (Upto 2nd Bill) S.No Sheet # Part of Building Remarks Steel Used (LBS)syukNo ratings yet

- Rate Analysis of PCC: (Plain Cement Concrete)Document5 pagesRate Analysis of PCC: (Plain Cement Concrete)rahul nagare100% (1)

- Rate-Analysis GHFDocument64 pagesRate-Analysis GHFSandeep VishwakarmaNo ratings yet

- Amway Spring Catalogue 2011Document13 pagesAmway Spring Catalogue 2011Juned AnsariNo ratings yet

- Piping GuideDocument257 pagesPiping Guideveluchamymuthukumar100% (2)

- Luban PlozzaDocument5 pagesLuban PlozzaAnca ZamoraNo ratings yet

- Canguilhem Ideology & Rationality 1Document18 pagesCanguilhem Ideology & Rationality 1edifyingNo ratings yet

- Clóvis Moura - Dialética Radical Do Brasil Negro - Literatura SocialistaDocument125 pagesClóvis Moura - Dialética Radical Do Brasil Negro - Literatura SocialistaMatheus NunesNo ratings yet