Professional Documents

Culture Documents

Tencel Fiber Properties Under 40 Characters

Uploaded by

nil006Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tencel Fiber Properties Under 40 Characters

Uploaded by

nil006Copyright:

Available Formats

Tencel is a cellulosic fiber regenerated from eucalyptus wood.

Tencel fibers have been claimed to be more absorbent than cotton, softer than silk

and cooler than linen.

Standard Tencel fibers have a cut length of 38 mm. However, these fibers are

available in cut lengths ranging from 12-58 mm depending on the ends use.

The linear density of standard Tencel fibers ranges from 1.3-2.2 dtex. Micro Tencel

may have a linear density of 0.9 dtex while some Tencel fibers used for filling or

technical textile may have linear density up to 6.7 dtex.

Tenacity of Tencel fibers is around 36-37 g/tex in dry state while 29-30 g/tex in wet

state.

Elongation at break of Tencel fibers is 14% in dry state while 16% in wet state.

Tencel fibers have excellent moisture management properties.

Tencel readily absorbs moisture and quickly releases it.

Due to smooth fiber surface, textiles made from Tencel feel very soft to the skin.

The growth of bacteria on Tencel fibers is extremely low as compared to synthetic

fibers and cotton. This is because no moisture layer is developed on the fiber surface

to sustain bacteria, due to quick transportation of the moisture to inside the fiber.

Moisture regain of Tencel fibers is around 13%. High moisture regain prevents

electrostatic charging.

Tencel fibers have excellent dye ability.

Tencel fabrics have good abrasion resistance and dimensional stability.

Unlike wool, Tencel is not attacked by moths.

Tencel fabrics crease less and are easier to iron as compared to cotton fabrics.

Tencel fabrics have good drape properties.

Tencel waddings offer better thermal insulation as compared to polyester fabrics.

You might also like

- Lecture Three Natural Bast FiberDocument46 pagesLecture Three Natural Bast FiberGemeda GebinoNo ratings yet

- SpandexDocument1 pageSpandexNavnath PingaleNo ratings yet

- Textile Fibre Yarn CountDocument30 pagesTextile Fibre Yarn CountSujit GulhaneNo ratings yet

- Lyocell: Lyocell Is A Regenerated Cellulose Fiber Made From Dissolving PulpDocument3 pagesLyocell: Lyocell Is A Regenerated Cellulose Fiber Made From Dissolving PulpMiraz HossainNo ratings yet

- Lyocell - One Fiber, Many Faces: HYG-5572-99 Joyce Ann Smith, PH.DDocument29 pagesLyocell - One Fiber, Many Faces: HYG-5572-99 Joyce Ann Smith, PH.DAbhi SheikhNo ratings yet

- Acrylic FiberDocument9 pagesAcrylic FiberNeeraj JainNo ratings yet

- A Report On Green Material - Jute FibresDocument7 pagesA Report On Green Material - Jute FibresvaibhavNo ratings yet

- Unit Ii: Count of The YarnDocument9 pagesUnit Ii: Count of The YarngowriNo ratings yet

- Textiles and Moisture 2Document5 pagesTextiles and Moisture 2Sajad AliNo ratings yet

- Synthetic FibreDocument6 pagesSynthetic FibreswaroophoppyNo ratings yet

- Application of Contemporary Fibers in Apparel - LyocellDocument5 pagesApplication of Contemporary Fibers in Apparel - LyocellVasant KothariNo ratings yet

- Textile ScienceDocument22 pagesTextile ScienceAbhinav VermaNo ratings yet

- Types of FiberDocument47 pagesTypes of FiberUmar MohammadNo ratings yet

- Unit 4-Cotton PDFDocument25 pagesUnit 4-Cotton PDFFuad HamidNo ratings yet

- Unconventional Fibre PlantsDocument18 pagesUnconventional Fibre PlantsRajendra Singh MeenaNo ratings yet

- Cotton, Polyester & Cotton Polyester BlendDocument4 pagesCotton, Polyester & Cotton Polyester BlendTanaji Santra100% (1)

- Study of Structure and Properties of Air Jet Textured YarnDocument15 pagesStudy of Structure and Properties of Air Jet Textured Yarnpraveen kumarNo ratings yet

- Cellulosic FibresDocument52 pagesCellulosic Fibresnitishkohli100% (1)

- Renewable Energy Resources: Textile ProcessingDocument17 pagesRenewable Energy Resources: Textile ProcessingrohithNo ratings yet

- Textile Proccessing - 1Document10 pagesTextile Proccessing - 1Shahzaib ButtNo ratings yet

- Project Technical TextilesDocument22 pagesProject Technical Textilesvijayabaskar777No ratings yet

- Modal FibreDocument10 pagesModal Fibresaran7ran100% (5)

- Processing TENCEL® LF / Cotton BlendsDocument32 pagesProcessing TENCEL® LF / Cotton Blendskona100% (1)

- UNIT - 1 FusingDocument8 pagesUNIT - 1 FusingMohamed SoudhNo ratings yet

- Bi ComponentDocument13 pagesBi ComponentA.K.M. Rashedul IslamNo ratings yet

- Fabric FinishesDocument31 pagesFabric FinishesDeepthi SonuNo ratings yet

- Friction SpinningDocument8 pagesFriction SpinningJoshi ParthNo ratings yet

- Sizing Ingredients AssignmentDocument34 pagesSizing Ingredients AssignmentMuhammad Asif Idrees100% (1)

- Development in Sizing Machine: By: Tanveer Malik, P.K.Roy & H.K.SinghDocument24 pagesDevelopment in Sizing Machine: By: Tanveer Malik, P.K.Roy & H.K.SinghAnonymous Pt7NHkat9No ratings yet

- Innovation in YarnDocument6 pagesInnovation in YarnDevendra VashisthNo ratings yet

- Polyester Fibers: Fig.1: Production of Polyethylene TerephthalateDocument12 pagesPolyester Fibers: Fig.1: Production of Polyethylene TerephthalateShailendra Mishra100% (1)

- Properties of Textile Fibres-LibreDocument31 pagesProperties of Textile Fibres-LibreJunaid AhmedNo ratings yet

- Ramie PDFDocument6 pagesRamie PDFkabir_ce06038No ratings yet

- Note Polyster FiberDocument16 pagesNote Polyster FiberMohammed Atiqul Hoque ChowdhuryNo ratings yet

- Steam Utilization in Textile InduastryDocument4 pagesSteam Utilization in Textile InduastryJonathan Fernandez0% (1)

- Study On Two For One Twisting PDFDocument11 pagesStudy On Two For One Twisting PDFGizachew ZelekeNo ratings yet

- Textile Industry - 01 LectureDocument40 pagesTextile Industry - 01 Lectureisabelism100% (1)

- Effect of First Heater Temperature Variations On The Polyester Yarn Properties of False Twist Texturing TechniquesDocument5 pagesEffect of First Heater Temperature Variations On The Polyester Yarn Properties of False Twist Texturing TechniquesIberê Cruz Freitas100% (1)

- Applications of Nanotechnology in Textiles (17070125113)Document9 pagesApplications of Nanotechnology in Textiles (17070125113)Sheron SisodiyaNo ratings yet

- Automobile TextileDocument45 pagesAutomobile TextileShamima akter100% (1)

- Mechanical Bonding 3Document53 pagesMechanical Bonding 3kavineshpraneetaNo ratings yet

- Warp Knitting Process and ApplicationsDocument21 pagesWarp Knitting Process and Applicationsmike workuNo ratings yet

- Wet II Presentation Group 3 Antimicrobial FinishDocument29 pagesWet II Presentation Group 3 Antimicrobial FinishZillur Rahman SaykatNo ratings yet

- Non Woven Home FurnishingsDocument6 pagesNon Woven Home FurnishingsMuhammad Farooq KokabNo ratings yet

- Airdye Technology Eliminates Water from Dyeing ProcessDocument7 pagesAirdye Technology Eliminates Water from Dyeing ProcessAnkita RajNo ratings yet

- Struto ProductDocument8 pagesStruto ProductMoniruzzaman MoNir100% (1)

- Fiber PropertiesDocument24 pagesFiber Propertiessatheeshpag12367% (3)

- Friction SpinningDocument8 pagesFriction SpinningVenkat Prasanna50% (2)

- Textile FinishesDocument12 pagesTextile FinishesFakrul Hasan KhanNo ratings yet

- MercerisationDocument18 pagesMercerisationVarun Mehrotra0% (1)

- LycraDocument7 pagesLycraFiaz juttNo ratings yet

- Textilelearner - Blogspot.ca-Rayon Fiber Characteristics of Rayon Fiber Manufacturing Process of Viscose Rayon End Uses of RayoDocument4 pagesTextilelearner - Blogspot.ca-Rayon Fiber Characteristics of Rayon Fiber Manufacturing Process of Viscose Rayon End Uses of Rayolyouf100% (1)

- STAPLE AND FILAMENT YARN SPINNINGDocument24 pagesSTAPLE AND FILAMENT YARN SPINNINGagga1111No ratings yet

- Textiles - DiplomaDocument9 pagesTextiles - DiplomamansiagrawalNo ratings yet

- Absorbency TestDocument30 pagesAbsorbency TestSalahuddin AzadNo ratings yet

- Vortex FDocument2 pagesVortex FNipu SenNo ratings yet

- Classification of DyesDocument60 pagesClassification of DyesAnkurVaidyaNo ratings yet

- Chiller Plant Efficiency ComputationDocument28 pagesChiller Plant Efficiency ComputationNeell RojasNo ratings yet

- How to Read a Psychrometric ChartDocument2 pagesHow to Read a Psychrometric ChartThomas JoseNo ratings yet

- Break Down Maintenance ReportDocument1 pageBreak Down Maintenance Reportnil006No ratings yet

- Machine Maintence CardDocument1 pageMachine Maintence Cardnil006No ratings yet

- Laptops/Y50 70 Notebook Lenovo/Downloads?Linktrack Footer:Support - DownloadsDocument1 pageLaptops/Y50 70 Notebook Lenovo/Downloads?Linktrack Footer:Support - Downloadsnil006No ratings yet

- Textile Mill Humidification GuideDocument5 pagesTextile Mill Humidification GuideRaman Ray100% (1)

- Chel QuafDocument1 pageChel Quafnil006No ratings yet

- Beam DiagramDocument1 pageBeam Diagramnil006No ratings yet

- Basic of Woven Fabric Finishing ProcessDocument7 pagesBasic of Woven Fabric Finishing ProcessFabric Club83% (6)

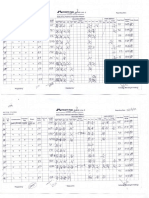

- Grey Inspection ReportDocument5 pagesGrey Inspection Reportnil006No ratings yet

- Sizing MachineDocument21 pagesSizing MachineKomol Kabir100% (2)

- Drop wire dimensions and weightDocument1 pageDrop wire dimensions and weightnil006No ratings yet

- M-RSLRSL Version 01 2017Document5 pagesM-RSLRSL Version 01 2017nil006No ratings yet

- 4 Points System:: Yards InspectionDocument1 page4 Points System:: Yards Inspectionnil006No ratings yet

- 4 Point SystemDocument6 pages4 Point Systemapi-2649455589% (9)

- IRC FormDocument1 pageIRC Formnil006No ratings yet

- What is an Intrapreneur? Definition and Role of an Inside EntrepreneurDocument1 pageWhat is an Intrapreneur? Definition and Role of an Inside Entrepreneurnil006No ratings yet

- Technology For Enzymatic Finishing of Fabrics Made of Tencel Fiber or Its Mixture With Other FibersDocument1 pageTechnology For Enzymatic Finishing of Fabrics Made of Tencel Fiber or Its Mixture With Other Fibersnil006No ratings yet

- Everything you need to know about modal fabricDocument1 pageEverything you need to know about modal fabricnil006No ratings yet

- Fleece FabricsDocument6 pagesFleece Fabricsnil006100% (11)

- Fabric Inspection Four-PointDocument6 pagesFabric Inspection Four-Pointramf2000lkNo ratings yet

- Medical Textile - BangladeshDocument16 pagesMedical Textile - Bangladeshnil00667% (3)

- Polyester YarnDocument6 pagesPolyester Yarnnil006100% (1)

- 08 Passage Rigid RapieDocument2 pages08 Passage Rigid Rapienil006No ratings yet

- 01 Cone Winding Study (Calculation)Document4 pages01 Cone Winding Study (Calculation)Hasan Istiaque Ahmed60% (5)

- Reasons of Slow Sizing Production & Production Loss Due To Yarn FaultDocument1 pageReasons of Slow Sizing Production & Production Loss Due To Yarn Faultnil006No ratings yet

- 05 Passage AirjetDocument2 pages05 Passage Airjetnil006No ratings yet

- Flannel & Brushed Fabric Spec SheetsDocument5 pagesFlannel & Brushed Fabric Spec SheetsHemel KhanNo ratings yet

- D2261 Tearing Strength: Can NumberDocument25 pagesD2261 Tearing Strength: Can NumberDoulat RamNo ratings yet

- Textile Interview Questions1Document65 pagesTextile Interview Questions1ErRajesh100% (1)

- Duvet SetDocument13 pagesDuvet SetyokeshNo ratings yet

- D1282 05 (Reapproved 2009)Document9 pagesD1282 05 (Reapproved 2009)Muhammad HugoNo ratings yet

- Comber: The Combing ProcessDocument21 pagesComber: The Combing ProcessAmir Shahzad100% (4)

- Vasant Kothari - Sourcing It RightDocument7 pagesVasant Kothari - Sourcing It RightsatexNo ratings yet

- Technical Guide On Textile Industry Internal AuditDocument110 pagesTechnical Guide On Textile Industry Internal AuditAbdullah Tabba67% (6)

- Yarn Specs - USTERDocument24 pagesYarn Specs - USTERZubairShafqat50% (2)

- Fiber MaturityDocument10 pagesFiber MaturityRajesh Dwivedi100% (7)

- List of HSN Codes at 4 DigitDocument19 pagesList of HSN Codes at 4 DigitsanjeevpithadiaNo ratings yet

- Interior Design PDFDocument69 pagesInterior Design PDFfevannesebido67% (93)

- Evince Textile Limited: Internship ExperienceDocument9 pagesEvince Textile Limited: Internship ExperienceAnik IslamNo ratings yet

- Garment Manufacturing Process Flow From Buyer To ShipmentDocument27 pagesGarment Manufacturing Process Flow From Buyer To Shipmenttallraj50% (2)

- ASTM Book of Standards (Print and CD-ROM) Volume 07.01, November 2004 Textiles (I) : D76 - D3218Document4 pagesASTM Book of Standards (Print and CD-ROM) Volume 07.01, November 2004 Textiles (I) : D76 - D3218Chandraditya Iman Firmansha100% (1)

- Product Analysis and Development: Submitted By-Harshita Tiwari KaarthikayaDocument15 pagesProduct Analysis and Development: Submitted By-Harshita Tiwari KaarthikayakaarthikayaNo ratings yet

- Mixing and blending cotton fibers in blow roomDocument6 pagesMixing and blending cotton fibers in blow roomakshay SinghNo ratings yet

- Twist in Yarns by Direct-Counting: Standard Test Method ForDocument7 pagesTwist in Yarns by Direct-Counting: Standard Test Method ForTuyên RùaNo ratings yet

- Grammar of Textile DesignDocument316 pagesGrammar of Textile DesignMarina ASNo ratings yet

- Image Processing of Fabric CharacteristicDocument5 pagesImage Processing of Fabric CharacteristicAndrian WijayonoNo ratings yet

- Pad Harshita Kartik PPT Assignment 1Document23 pagesPad Harshita Kartik PPT Assignment 1kaarthikayaNo ratings yet

- Study On The Effect of Bio-Polishing On CPI, WPI, Stitch Length, Yarn Count & GSM of Different Types of Knit FabricDocument40 pagesStudy On The Effect of Bio-Polishing On CPI, WPI, Stitch Length, Yarn Count & GSM of Different Types of Knit FabricMd Ifta Khairul AlamNo ratings yet

- Calculating fibre percentages in knitted fabricsDocument6 pagesCalculating fibre percentages in knitted fabricsMohammed Atiqul Hoque ChowdhuryNo ratings yet

- Fabric and Yarn Conversion ChartDocument6 pagesFabric and Yarn Conversion Chartpeeyush40No ratings yet

- Fibre IntroductionDocument18 pagesFibre IntroductionKunal SuvarnaNo ratings yet

- Tech Pack For QSN 1Document6 pagesTech Pack For QSN 1Yousuf AlaminNo ratings yet

- TexturingDocument25 pagesTexturingRtr Hasan MahmudNo ratings yet

- Card Setting A Factor For Controlling Sliver Quality and Yarn 2165 8064 1000246 PDFDocument3 pagesCard Setting A Factor For Controlling Sliver Quality and Yarn 2165 8064 1000246 PDFRajatNo ratings yet

- Sabit Adanur - Handbook of Weaving-CRC Press (2000) PDFDocument427 pagesSabit Adanur - Handbook of Weaving-CRC Press (2000) PDFAnjani Deevi50% (2)

- Fundamentals of Textile TestingDocument24 pagesFundamentals of Textile Testingirc.indusNo ratings yet

- Nuclear Energy in the 21st Century: World Nuclear University PressFrom EverandNuclear Energy in the 21st Century: World Nuclear University PressRating: 4.5 out of 5 stars4.5/5 (3)

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersFrom EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersNo ratings yet

- Process Plant Equipment: Operation, Control, and ReliabilityFrom EverandProcess Plant Equipment: Operation, Control, and ReliabilityRating: 5 out of 5 stars5/5 (1)

- Piping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationFrom EverandPiping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationRating: 4 out of 5 stars4/5 (18)

- Gas-Liquid And Liquid-Liquid SeparatorsFrom EverandGas-Liquid And Liquid-Liquid SeparatorsRating: 3.5 out of 5 stars3.5/5 (3)

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsFrom EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsNo ratings yet

- Pharmaceutical Blending and MixingFrom EverandPharmaceutical Blending and MixingP. J. CullenRating: 5 out of 5 stars5/5 (1)

- Guidelines for the Management of Change for Process SafetyFrom EverandGuidelines for the Management of Change for Process SafetyNo ratings yet

- Guidelines for Engineering Design for Process SafetyFrom EverandGuidelines for Engineering Design for Process SafetyNo ratings yet

- Physical and Chemical Equilibrium for Chemical EngineersFrom EverandPhysical and Chemical Equilibrium for Chemical EngineersRating: 5 out of 5 stars5/5 (1)

- Trevor Kletz Compendium: His Process Safety Wisdom Updated for a New GenerationFrom EverandTrevor Kletz Compendium: His Process Safety Wisdom Updated for a New GenerationNo ratings yet

- An Introduction to the Periodic Table of Elements : Chemistry Textbook Grade 8 | Children's Chemistry BooksFrom EverandAn Introduction to the Periodic Table of Elements : Chemistry Textbook Grade 8 | Children's Chemistry BooksRating: 5 out of 5 stars5/5 (1)

- Chemical Process Safety: Learning from Case HistoriesFrom EverandChemical Process Safety: Learning from Case HistoriesRating: 4 out of 5 stars4/5 (14)

- An Applied Guide to Water and Effluent Treatment Plant DesignFrom EverandAn Applied Guide to Water and Effluent Treatment Plant DesignRating: 5 out of 5 stars5/5 (4)

- Guidelines for Vapor Cloud Explosion, Pressure Vessel Burst, BLEVE, and Flash Fire HazardsFrom EverandGuidelines for Vapor Cloud Explosion, Pressure Vessel Burst, BLEVE, and Flash Fire HazardsNo ratings yet

- Operational Excellence: Journey to Creating Sustainable ValueFrom EverandOperational Excellence: Journey to Creating Sustainable ValueNo ratings yet

- Guidelines for Developing Quantitative Safety Risk CriteriaFrom EverandGuidelines for Developing Quantitative Safety Risk CriteriaNo ratings yet

- Pharmaceutical Excipients: Properties, Functionality, and Applications in Research and IndustryFrom EverandPharmaceutical Excipients: Properties, Functionality, and Applications in Research and IndustryOtilia M. Y. KooNo ratings yet

- Understanding Process Equipment for Operators and EngineersFrom EverandUnderstanding Process Equipment for Operators and EngineersRating: 4.5 out of 5 stars4.5/5 (3)

- Bow Ties in Risk Management: A Concept Book for Process SafetyFrom EverandBow Ties in Risk Management: A Concept Book for Process SafetyNo ratings yet

- Guidelines for Chemical Process Quantitative Risk AnalysisFrom EverandGuidelines for Chemical Process Quantitative Risk AnalysisRating: 5 out of 5 stars5/5 (1)

- The Periodic Table of Elements - Post-Transition Metals, Metalloids and Nonmetals | Children's Chemistry BookFrom EverandThe Periodic Table of Elements - Post-Transition Metals, Metalloids and Nonmetals | Children's Chemistry BookNo ratings yet

- Well Control for Completions and InterventionsFrom EverandWell Control for Completions and InterventionsRating: 4 out of 5 stars4/5 (10)