Professional Documents

Culture Documents

Everything you need to know about modal fabric

Uploaded by

nil006Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Everything you need to know about modal fabric

Uploaded by

nil006Copyright:

Available Formats

Description

A generic name for a modified rayon fiber that has high tenacity and high wet modulus. Modal

fibers were initially developed in the 1930's for industrial uses in tires, conveyor belts and hose

pipes. Changes in the rayon processing, such as the spin conditions, chemical solutions and

stretching sequences, produced rayon fibers with increased crystalline and thus, greater

strength. Additional developments in Japan in 1951 by S. Tachikawa lead to the production of

rayon with a high wet modulus. These specific types of modal fibers are called polynosic fibers.

Modal fibers are dimensionally stable and do not shrink or get pulled out of shape when wet like

many rayon. They are also wear resistant and strong while maintaining a soft, silky feel. Modal

fibers have found a wide variety of uses in clothing, outwear and household furnishings. They are

often blended with cotton, wool or synthetic fibers.

Modal is type of viscose. Modal fabric has softness, good drape and is comfortable for

wearing. Modal fabric has good moisture regain and air permissibility which is often

considered better than cotton fabric, it is a good material for exercise clothing and health suit,

which can serve to benefit physiology circulation and health of the body. Modal fabric

has level up surface, fine and smooth and velvet, which have the effect of natural silk. The yarn

has the character of high strength. The fabric has good softness and brilliant luster. The effect

of the finished Modal garment is very good, and the form is steady. The garment maintains

anti-crease properties and has relatively easy care.

Modal is a bio-based fiber made by spinning (Spinning is the process of creating yarn (or

thread, rope, cable) from various raw fiber materials.)

reconstructed cellulose (Cellulose (C6H10O5)n is a long-

chain polymeric polysaccharide carbohydrate, of beta-glucose. It forms the primary structural

component of green plants. The primary cell wall of green plants is made primarily of cellulose;

the secondary wall contains cellulose with variable amounts of lignin. Lignin and cellulose,

considered together, are termed lignocellulose, which (as wood) is the most

common biopolymer on Earth. Only one group of animals, the tunicates, have evolved the ability

to create and use cellulose.) from beech trees. It is about 50% more hygroscopic, or water-

absorbent, per unit volume than cotton is. It is designed to dye just like cotton, and is color-fast

when washed in warm water. Modal is essentially a variety of rayon.

Textiles made from Modal do not fibrillate, or pill, like cotton does, and are resistant to shrinkage

and fading. They are smooth and soft, more so than even mercerized cotton, to the point where

mineral deposits from hard water, such as lime, do not stick to the fabric surface. Like pure

cotton, modal needs to be ironed after washing.

You might also like

- Application of Contemporary Fibres in Apparel - ModalDocument4 pagesApplication of Contemporary Fibres in Apparel - ModalVasant KothariNo ratings yet

- CottonDocument6 pagesCottonrim3lNo ratings yet

- Modal Rayon Lyocell Rayon: Cuproamonium Rayon Acetate RayonDocument18 pagesModal Rayon Lyocell Rayon: Cuproamonium Rayon Acetate RayonHrs Shihab100% (1)

- Properties and uses of cotton fibreDocument20 pagesProperties and uses of cotton fibreAlen Jose ThomasNo ratings yet

- Lyocell Fibre DocumentDocument4 pagesLyocell Fibre DocumentHossain RsfaNo ratings yet

- ModalDocument2 pagesModalaparnimaNo ratings yet

- Lyocell - One Fiber, Many Faces: HYG-5572-99 Joyce Ann Smith, PH.DDocument29 pagesLyocell - One Fiber, Many Faces: HYG-5572-99 Joyce Ann Smith, PH.DAbhi SheikhNo ratings yet

- Modal FabricDocument30 pagesModal FabricGillian Faye LechocoNo ratings yet

- RafaDocument8 pagesRafaMD.MAHABUB ALOM REFAETNo ratings yet

- Classification of FibresDocument9 pagesClassification of Fibres01917473787No ratings yet

- LECTURE SERIES ON NATURAL TEXTILE FIBRESDocument98 pagesLECTURE SERIES ON NATURAL TEXTILE FIBRESPrathmesh Bharuka100% (1)

- Classification of FibresDocument12 pagesClassification of FibresARYAN RATHORENo ratings yet

- Training Report On Textile Wet ProcessingDocument38 pagesTraining Report On Textile Wet ProcessingMunazza SohailNo ratings yet

- Properties of Bamboo, PLA and SPF FibresDocument2 pagesProperties of Bamboo, PLA and SPF FibresDorin VladNo ratings yet

- FibresDocument5 pagesFibresu92445622No ratings yet

- 38 Character Title for Organdy Fabric DocumentDocument6 pages38 Character Title for Organdy Fabric DocumentShivendu BhadauriaNo ratings yet

- FlexDocument4 pagesFlexmdfazle165No ratings yet

- Submitted by Sakshi Singh Himadri VyasDocument39 pagesSubmitted by Sakshi Singh Himadri VyasSakshi SinghNo ratings yet

- Properties Natural FibresDocument46 pagesProperties Natural FibresanishaNo ratings yet

- New Fibres For Home Textile Lyocell FibreDocument5 pagesNew Fibres For Home Textile Lyocell FibreVasant KothariNo ratings yet

- Relations Between Fiber Structure and PropertiesDocument7 pagesRelations Between Fiber Structure and PropertiesChikam BuraNo ratings yet

- Fabric Powerpoint 19Document55 pagesFabric Powerpoint 19Japhet GatchoNo ratings yet

- Cotton FibreDocument5 pagesCotton FibreSieed HassanNo ratings yet

- Textile Industry - 01 LectureDocument40 pagesTextile Industry - 01 Lectureisabelism100% (1)

- FKM 1Document13 pagesFKM 1itee0510No ratings yet

- What Are Natural FibersDocument2 pagesWhat Are Natural FibersCathy BiasettiNo ratings yet

- Solution of Mulberry Bark Pulp and Gummy RubberDocument10 pagesSolution of Mulberry Bark Pulp and Gummy RubberT. TNo ratings yet

- Cotton FiberDocument10 pagesCotton Fibermalikarslanali621No ratings yet

- Guide to Common Textile FibresDocument34 pagesGuide to Common Textile FibresmehrasunilNo ratings yet

- Bamboo Fabric Products and UsesDocument7 pagesBamboo Fabric Products and UsesDorin VladNo ratings yet

- Introduction To FiberDocument12 pagesIntroduction To FiberTowfic Aziz KanonNo ratings yet

- Chapter 1:-Sportswear: IntroductionDocument6 pagesChapter 1:-Sportswear: IntroductionTejaswini SinghNo ratings yet

- Advancements and Modifications in Conventional Fiber and Yarn Manufacturing ProcessesDocument33 pagesAdvancements and Modifications in Conventional Fiber and Yarn Manufacturing ProcessesShahan AkhtarNo ratings yet

- Natural FibreDocument11 pagesNatural FibreArj VirkNo ratings yet

- Textile Technology 1 CourseDocument6 pagesTextile Technology 1 Coursefatima hussainNo ratings yet

- Preparation of Rayon ThreadDocument20 pagesPreparation of Rayon ThreadAkshaya SuruthiNo ratings yet

- Rayon: Purvisha NadkarniDocument20 pagesRayon: Purvisha NadkarniChristopherGunawanNo ratings yet

- Airlaid & Spunlace NonwovenDocument5 pagesAirlaid & Spunlace NonwovenRonak JoshiNo ratings yet

- Scheme of The EvaluationDocument6 pagesScheme of The EvaluationSabihanaz InamdarNo ratings yet

- Textile Fibers GuideDocument49 pagesTextile Fibers GuideAnonymous 51N3PEzjNo ratings yet

- Sustainable Fabrics & Fairtrade CraftsDocument48 pagesSustainable Fabrics & Fairtrade CraftsBright Mariya100% (1)

- By B.TECH (Final Year) Roll No.-0804462029 Man Made Fibre TechnologyDocument10 pagesBy B.TECH (Final Year) Roll No.-0804462029 Man Made Fibre TechnologySanjeev SinghNo ratings yet

- Assignment On Coir Fiber. Discuss About The Polymeric Structrue of Different Cellulosic Fiber.Document12 pagesAssignment On Coir Fiber. Discuss About The Polymeric Structrue of Different Cellulosic Fiber.Md. Mozammel Haque ShakibNo ratings yet

- Bamboo FabricDocument12 pagesBamboo FabricSweta Saha100% (1)

- Kehe 105Document16 pagesKehe 105Saisab AhmedNo ratings yet

- Study The Effect of Acids and Bases On The Tensile Strength of A FibreDocument15 pagesStudy The Effect of Acids and Bases On The Tensile Strength of A FibreHiaderKhokhawala75% (67)

- Fundamentals of Textile Engineering: Che - 436 Lecture-1Document16 pagesFundamentals of Textile Engineering: Che - 436 Lecture-1Nirban SahaNo ratings yet

- Report On Rayon FibresDocument7 pagesReport On Rayon FibresMomin ShahNo ratings yet

- Clothing Material FST-503 and 053: by Gurumurthy.B.R E-MailDocument103 pagesClothing Material FST-503 and 053: by Gurumurthy.B.R E-MailGurumurthy B RNo ratings yet

- Title: Pre-Treatment of PC Blended FabricsDocument12 pagesTitle: Pre-Treatment of PC Blended FabricsFahad HussainNo ratings yet

- Fibres, Sutures andDocument82 pagesFibres, Sutures andSara Rafique100% (2)

- Prepared By: Aryan Shandilya Roll - No.03 Subject: Chemistry Submitted To: Umesh PandeyDocument16 pagesPrepared By: Aryan Shandilya Roll - No.03 Subject: Chemistry Submitted To: Umesh PandeyTHE TALKIESNo ratings yet

- Grade 6 Fibre To Fabric Sample QuestionsDocument3 pagesGrade 6 Fibre To Fabric Sample Questionsmohamedaahil12318No ratings yet

- Chemistry Project (Draft 1)Document8 pagesChemistry Project (Draft 1)Aadi AthreyaNo ratings yet

- Textile Fibres Classification PPT 1Document43 pagesTextile Fibres Classification PPT 1tutu1990100% (4)

- Terry Knit Fabric Production ProcessDocument45 pagesTerry Knit Fabric Production ProcessSaumya KharyaNo ratings yet

- "Triple Gold Medalist": by M.E. Textile EnggDocument46 pages"Triple Gold Medalist": by M.E. Textile EnggFouzia MirzaNo ratings yet

- Fibre ScienceDocument29 pagesFibre ScienceEngr Mujahid MehdiNo ratings yet

- Break Down Maintenance ReportDocument1 pageBreak Down Maintenance Reportnil006No ratings yet

- How to Read a Psychrometric ChartDocument2 pagesHow to Read a Psychrometric ChartThomas JoseNo ratings yet

- Textile Mill Humidification GuideDocument5 pagesTextile Mill Humidification GuideRaman Ray100% (1)

- Machine Maintence CardDocument1 pageMachine Maintence Cardnil006No ratings yet

- Basic of Woven Fabric Finishing ProcessDocument7 pagesBasic of Woven Fabric Finishing ProcessFabric Club83% (6)

- Laptops/Y50 70 Notebook Lenovo/Downloads?Linktrack Footer:Support - DownloadsDocument1 pageLaptops/Y50 70 Notebook Lenovo/Downloads?Linktrack Footer:Support - Downloadsnil006No ratings yet

- Chiller Plant Efficiency ComputationDocument28 pagesChiller Plant Efficiency ComputationNeell RojasNo ratings yet

- Beam DiagramDocument1 pageBeam Diagramnil006No ratings yet

- 4 Points System:: Yards InspectionDocument1 page4 Points System:: Yards Inspectionnil006No ratings yet

- Sizing MachineDocument21 pagesSizing MachineKomol Kabir100% (2)

- Tencel Fiber Properties Under 40 CharactersDocument1 pageTencel Fiber Properties Under 40 Charactersnil006No ratings yet

- Chel QuafDocument1 pageChel Quafnil006No ratings yet

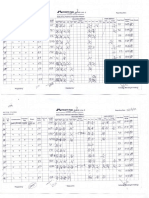

- Drop wire dimensions and weightDocument1 pageDrop wire dimensions and weightnil006No ratings yet

- Grey Inspection ReportDocument5 pagesGrey Inspection Reportnil006No ratings yet

- Fabric Inspection Four-PointDocument6 pagesFabric Inspection Four-Pointramf2000lkNo ratings yet

- Technology For Enzymatic Finishing of Fabrics Made of Tencel Fiber or Its Mixture With Other FibersDocument1 pageTechnology For Enzymatic Finishing of Fabrics Made of Tencel Fiber or Its Mixture With Other Fibersnil006No ratings yet

- 4 Point SystemDocument6 pages4 Point Systemapi-2649455589% (9)

- IRC FormDocument1 pageIRC Formnil006No ratings yet

- Polyester YarnDocument6 pagesPolyester Yarnnil006100% (1)

- M-RSLRSL Version 01 2017Document5 pagesM-RSLRSL Version 01 2017nil006No ratings yet

- Fleece FabricsDocument6 pagesFleece Fabricsnil006100% (11)

- Reasons of Slow Sizing Production & Production Loss Due To Yarn FaultDocument1 pageReasons of Slow Sizing Production & Production Loss Due To Yarn Faultnil006No ratings yet

- What is an Intrapreneur? Definition and Role of an Inside EntrepreneurDocument1 pageWhat is an Intrapreneur? Definition and Role of an Inside Entrepreneurnil006No ratings yet

- 08 Passage Rigid RapieDocument2 pages08 Passage Rigid Rapienil006No ratings yet

- 05 Passage AirjetDocument2 pages05 Passage Airjetnil006No ratings yet

- Medical Textile - BangladeshDocument16 pagesMedical Textile - Bangladeshnil00667% (3)

- 01 Cone Winding Study (Calculation)Document4 pages01 Cone Winding Study (Calculation)Hasan Istiaque Ahmed60% (5)

- Design of CPP Manufacturing Plant and Study Its DefectsDocument33 pagesDesign of CPP Manufacturing Plant and Study Its DefectsSid sidNo ratings yet

- LT4535 TT Aerospace Structural Products For Composite AssemblyDocument2 pagesLT4535 TT Aerospace Structural Products For Composite AssemblymoazshehabNo ratings yet

- Antisense Technology 7th SemDocument17 pagesAntisense Technology 7th SemSavita GoyalNo ratings yet

- HF-4760 (BL) : Product Data SheetDocument2 pagesHF-4760 (BL) : Product Data SheetCarito LopezNo ratings yet

- Basics of Hydroxyapatitedstructure, Synthesis, Properties, and Clinical ApplicationsDocument31 pagesBasics of Hydroxyapatitedstructure, Synthesis, Properties, and Clinical ApplicationsDaniel Martinez ParodisNo ratings yet

- Freudenberg - en - Technical Elastomers-Web PDFDocument37 pagesFreudenberg - en - Technical Elastomers-Web PDFdhowardjNo ratings yet

- Fonte Segura Aneis Novos CAT PEHJ0062-01 PDFDocument2 pagesFonte Segura Aneis Novos CAT PEHJ0062-01 PDFPedro Alberto BenitesNo ratings yet

- Emit Drugs of Abuse Cross Reactivity ListDocument52 pagesEmit Drugs of Abuse Cross Reactivity ListCharles AlmondNo ratings yet

- Cotton FibreDocument32 pagesCotton FibreSanjeev SinglaNo ratings yet

- BS en 124 - 2015 Part 5 Vat Lieu CompositeDocument38 pagesBS en 124 - 2015 Part 5 Vat Lieu CompositequochunguicNo ratings yet

- BiopolymersDocument17 pagesBiopolymersNAVEEN KUMAR KARRINo ratings yet

- Heptane Combustion and ReactionsDocument46 pagesHeptane Combustion and Reactions梁瀚允No ratings yet

- Chemical-Profiles by ICISDocument143 pagesChemical-Profiles by ICISk_paresh100% (2)

- Oligomer ProblemDocument4 pagesOligomer ProblemMonjur MorshedNo ratings yet

- Dermatological Pharmacology Topical AgentsDocument5 pagesDermatological Pharmacology Topical AgentsYilianeth Mena DazaNo ratings yet

- Guide RNA for Genome EditingDocument9 pagesGuide RNA for Genome EditinggiacummoNo ratings yet

- Propylene Glycol Industrial Grade: Technical DocumentationDocument12 pagesPropylene Glycol Industrial Grade: Technical DocumentationjohnNo ratings yet

- Lifting Supervisor and Engineer-Cranes SafetyDocument43 pagesLifting Supervisor and Engineer-Cranes SafetyLan Tian100% (7)

- IS 11521: Cargo Handling NetsDocument16 pagesIS 11521: Cargo Handling NetsGanesh ModiNo ratings yet

- GUR 022 BroucherDocument4 pagesGUR 022 BroucheryatheendravarmaNo ratings yet

- Lecture Notes - Polymer Reaction EngineeringDocument8 pagesLecture Notes - Polymer Reaction EngineeringTenson SichoneNo ratings yet

- KB HormonalDocument65 pagesKB Hormonaljessica_siahaan_1No ratings yet

- Aramid Dyeing CHT PDFDocument18 pagesAramid Dyeing CHT PDFno1gandhi9770No ratings yet

- Subject: Chemistry Class - 12: UT 1st (2021 - 2022)Document2 pagesSubject: Chemistry Class - 12: UT 1st (2021 - 2022)Tarun Pratap SinghNo ratings yet

- Tanatex - Green Solutions PDFDocument66 pagesTanatex - Green Solutions PDF郭哲宏No ratings yet

- Basement Waterproofing - Lecture 1Document41 pagesBasement Waterproofing - Lecture 1Taanaya100% (1)

- Agarose - and Alginate-Based Biopolymers For Sample Preparation PDFDocument9 pagesAgarose - and Alginate-Based Biopolymers For Sample Preparation PDFSofija NikolićNo ratings yet

- Fabricating MWCNT Composite Membrane for Water TreatmentDocument9 pagesFabricating MWCNT Composite Membrane for Water TreatmentSolehah OmarNo ratings yet

- Agribusiness Project Cargill Adhesive ApplicationDocument23 pagesAgribusiness Project Cargill Adhesive ApplicationFananh11No ratings yet

- Us5028366 PDFDocument7 pagesUs5028366 PDFEdgarNo ratings yet