Professional Documents

Culture Documents

Viscosity Thixotropic Index

Uploaded by

Jayesh2281Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Viscosity Thixotropic Index

Uploaded by

Jayesh2281Copyright:

Available Formats

Tech Tip # 3:

Viscosity and the

Thixotropic Index

Viscosity and the Thixotropic Index (T.I.) are two common components in an

epoxy that can have a great effect on how the product will work for a particular

application.

Viscosity is a measurement of a fluids resistance to flow. Viscosity is measured

in Poise, and the centipoise (cP) is the common unit used. One cP is defined as

the viscosity of water. From this base, all other viscosities are derived. A

product like honey would have a much higher viscosityaround 10,000 cPs

compared to water. Honey would flow much slower out of a tipped glass than

water would. Here is a list of common materials and their viscosities:

Approximate Viscosities of Common Materials (At Room Temperature-70F)

Material Viscosity in Centipoise

Water 1 cps

Milk 3 cps

SAE 10 Motor Oil 85-140 cps

SAE 20 Motor Oil 140-420 cps

SAE 30 Motor Oil 420-650 cps

SAE 40 Motor Oil 650-900 cps

Castrol Oil 1,000 cps

Karo Syrup 5,000 cps

Honey 10,000 cps

Chocolate 25,000 cps

Ketchup 50,000 cps

Mustard 70,000 cps

Sour Cream 100,000 cps

Peanut Butter 250,000 cps

Thixotropic Index is a ratio of a materials viscosity at two different speeds,

generally different by a factor of ten. A thixotropic materials viscosity will reduce

as agitation or pressure is increased. This index indicates the materials ability to

hold its shape. Mayonnaise is a great example of this. It holds its shape very

well, but when a shear stress is applied, the material easily spreads.

The viscosity of a material can be decreased with an increase in temperature in

order to better suit an application. The viscosity of most materials will drop in a

common fashion, exponential fashion. Below, the graph of 353ND shows how a

material will react to heat.

Temp Viscosity

353ND Mixed Viscosity versus Temp

(C) (cPs)

23 3153

4000

25 2252

Viscosity ( cps )

27 2147 3000

29 1728 2000 viscosity

31 785

1000

33 737

0

35 737

23 25 27 29 31 33 35 45 55 65 70

45 409

Temp ( C )

55 163

65 143

70 102

The viscosity of the 353ND drops very quickly, and then levels out at increased

temperature. This is a good method to use if an epoxy is very good for a certain

application, but the viscosity is slightly high. It must be noted that by heating up

the mixture, some of the pot life is used up during the heating, so it will gel faster

than if left at room temperature.

Still have questions?

Call Technical Services at 1-978-667-3805

Or

E-mail: techserv@epotek.com

You might also like

- Tech Tip 3 - Viscosity and TIDocument2 pagesTech Tip 3 - Viscosity and TIflavioferiNo ratings yet

- Tech Tip 3 Viscosity and Thixotropic IndexDocument2 pagesTech Tip 3 Viscosity and Thixotropic IndexnationNo ratings yet

- Liquid Epoxy Coating (3M)Document5 pagesLiquid Epoxy Coating (3M)Thamaraikani ManiNo ratings yet

- Effect of Ultrasonic Irradiation Treatment On Rheological BehaviourDocument17 pagesEffect of Ultrasonic Irradiation Treatment On Rheological BehaviourSOCRATESNo ratings yet

- 323+ Data SheetDocument5 pages323+ Data SheetSergioNo ratings yet

- Epoxy System LR625 VIP/Laminating: DescriptionDocument2 pagesEpoxy System LR625 VIP/Laminating: DescriptionjavadNo ratings yet

- Lubrication FundamentalsDocument152 pagesLubrication FundamentalsIbrahimAmroNo ratings yet

- DS - 1050 - 105XS(2)Document5 pagesDS - 1050 - 105XS(2)mandocraftingNo ratings yet

- 08 - Analisis Del Lugar Geometrico de La RaicesDocument1 page08 - Analisis Del Lugar Geometrico de La RaicesNorbert HernándezNo ratings yet

- Specifications & Properties for Motiva Base OilsDocument1 pageSpecifications & Properties for Motiva Base OilsMassimiliano VolaNo ratings yet

- Epolam2040 2042 2047 GBDocument6 pagesEpolam2040 2042 2047 GBEduardo JoseNo ratings yet

- Kaeser Sigma 8000 S 100 150 PDFDocument1 pageKaeser Sigma 8000 S 100 150 PDFJan HendriksNo ratings yet

- Acrolon 7300: Acrylic Urethane Gloss FinishDocument2 pagesAcrolon 7300: Acrylic Urethane Gloss FinishOswaldo SantoyoNo ratings yet

- Epoxy System LR620 Laminating: DescriptionDocument3 pagesEpoxy System LR620 Laminating: DescriptionFarzad LotfalipourNo ratings yet

- Zalac 002Document4 pagesZalac 002Stevie Herman TDNo ratings yet

- 95 517 Xiameter PMX 200 Si Fluid PDFDocument4 pages95 517 Xiameter PMX 200 Si Fluid PDFمحمد مقلدNo ratings yet

- Epilux 800Document2 pagesEpilux 800anandNo ratings yet

- High Solids Epoxy Zinc Rich Primer for Corrosion ProtectionDocument2 pagesHigh Solids Epoxy Zinc Rich Primer for Corrosion ProtectionmuthukumarNo ratings yet

- QALCO Syntholube GX 220Document1 pageQALCO Syntholube GX 220Deepak JoyNo ratings yet

- Reference Guide: Everyday Consumable Goods in Relation To General Product Viscosity in Centipoise (CPS)Document1 pageReference Guide: Everyday Consumable Goods in Relation To General Product Viscosity in Centipoise (CPS)Engg DesignNo ratings yet

- Lab 8Document8 pagesLab 8api-347340507No ratings yet

- ChevronTexaco Multigear LS SAE 80W 90Document2 pagesChevronTexaco Multigear LS SAE 80W 90Marcio AlexandreNo ratings yet

- Ceilcote 380 PrimerDocument4 pagesCeilcote 380 Primeryoonchankim0911No ratings yet

- 9 - Paul B AMS - Presentation - 1!4!2012Document50 pages9 - Paul B AMS - Presentation - 1!4!2012anhntran4850No ratings yet

- TDS 3M Scotch-Weld Epoxy Adhesive DP100 GENERALDocument8 pagesTDS 3M Scotch-Weld Epoxy Adhesive DP100 GENERALAkbar Perwira UtamaNo ratings yet

- Ceilcote 6650 Ceilcrete+ds+engDocument4 pagesCeilcote 6650 Ceilcrete+ds+engMohamed NouzerNo ratings yet

- Thermally Conductive Grease Comparison ChartDocument1 pageThermally Conductive Grease Comparison ChartrajivNo ratings yet

- Momentive RTV 630 TDS 2019Document7 pagesMomentive RTV 630 TDS 2019crushergaming1804No ratings yet

- 3M Fluorinert Liquids For Electronics ManufacturingDocument4 pages3M Fluorinert Liquids For Electronics ManufacturingIon ZabetNo ratings yet

- Ceilcote 6640 Ceilcrete+ds+engDocument4 pagesCeilcote 6640 Ceilcrete+ds+englivefreakNo ratings yet

- Determine Softening Point of Bitumen Using Ring and BallDocument5 pagesDetermine Softening Point of Bitumen Using Ring and BallamirafatinNo ratings yet

- Data Sheet Schott® Borofloat: Chemical PropertiesDocument2 pagesData Sheet Schott® Borofloat: Chemical PropertiesDiego SaenzNo ratings yet

- Viskositäts Standards 2018Document2 pagesViskositäts Standards 2018Omer MukhtarNo ratings yet

- World's Largest Science, Technology & Medicine Open Access Book PublisherDocument9 pagesWorld's Largest Science, Technology & Medicine Open Access Book PublisherWilder GanozaNo ratings yet

- Araldite CY 225 Hardener HY 925 Filler Silica Flour: Araldite Casting Resin SystemDocument8 pagesAraldite CY 225 Hardener HY 925 Filler Silica Flour: Araldite Casting Resin SystemZackNo ratings yet

- Syltherm XLT: Property SI Units English UnitsDocument3 pagesSyltherm XLT: Property SI Units English UnitsArifNo ratings yet

- Material Data Sheet SuperelasticDocument1 pageMaterial Data Sheet SuperelasticlarryNo ratings yet

- Marine Fuel OilDocument3 pagesMarine Fuel OiltasosNo ratings yet

- ISO 8217 marine fuel oil specificationsDocument4 pagesISO 8217 marine fuel oil specificationstasosNo ratings yet

- SR 1126 Fire Resistant Epoxy Laminating System: Systems Based On The Resin SR 1126Document5 pagesSR 1126 Fire Resistant Epoxy Laminating System: Systems Based On The Resin SR 1126McFlyNo ratings yet

- Zepoxy 350Document2 pagesZepoxy 350Aahsan Iqbal احسن اقبالNo ratings yet

- Marine Fuel Oil ISO 8217:2017: Information On Specifications and TestsDocument2 pagesMarine Fuel Oil ISO 8217:2017: Information On Specifications and TestsnarutorazNo ratings yet

- EPILUX 5 Coal Tar Epoxy Anti-Corrosion CoatingDocument2 pagesEPILUX 5 Coal Tar Epoxy Anti-Corrosion CoatingShyam ShrishNo ratings yet

- Sunmide X-2000-TDSDocument2 pagesSunmide X-2000-TDSTerrence LaiNo ratings yet

- Ksaeic Fisita00 A134Document5 pagesKsaeic Fisita00 A134Prihastya WishnutamaNo ratings yet

- Epofine 740 - Finehard 5200Document4 pagesEpofine 740 - Finehard 5200Karishma PrabhuNo ratings yet

- A 400HB E: Rchco PoxyDocument2 pagesA 400HB E: Rchco PoxyBenjamin AmezquitaNo ratings yet

- 1Document2 pages1Victor FirimaNo ratings yet

- NBR Catalogue Eng KKPCDocument2 pagesNBR Catalogue Eng KKPCChandrasekar KrishnamurthyNo ratings yet

- Exxonmobil Marine Fuel OilDocument1 pageExxonmobil Marine Fuel OilPrinceSadhotraNo ratings yet

- Brushable CeramicDocument2 pagesBrushable CeramicDivyanshu GuptaNo ratings yet

- Renolin ThermDocument1 pageRenolin ThermFarhan TamjidNo ratings yet

- Instrumental Analysis of Food: Faculty of Applied Science Lab ReportDocument8 pagesInstrumental Analysis of Food: Faculty of Applied Science Lab ReportnajwaNo ratings yet

- Gelshield 200 Eng A4 20190924Document2 pagesGelshield 200 Eng A4 20190924Lin LinNo ratings yet

- Data Sheet PF-5060Document4 pagesData Sheet PF-5060sshaffer_9No ratings yet

- High Performance: Wax AdditivesDocument36 pagesHigh Performance: Wax AdditivesAPEX SONNo ratings yet

- Fluid Analysis for Mobile Equipment: Condition Monitoring and MaintenanceFrom EverandFluid Analysis for Mobile Equipment: Condition Monitoring and MaintenanceNo ratings yet

- Introduction to Microsystem Technology: A Guide for StudentsFrom EverandIntroduction to Microsystem Technology: A Guide for StudentsRating: 5 out of 5 stars5/5 (1)

- Cellulose Nanocrystals: Properties, Production and ApplicationsFrom EverandCellulose Nanocrystals: Properties, Production and ApplicationsNo ratings yet

- Tips SizeDocument2 pagesTips SizeJayesh2281No ratings yet

- Airless Spray SafetyDocument1 pageAirless Spray SafetyJayesh2281No ratings yet

- Mesh To Micron Convertion TableDocument1 pageMesh To Micron Convertion TableJayesh2281No ratings yet

- Viscosity Thixotropic IndexDocument3 pagesViscosity Thixotropic IndexJayesh2281No ratings yet

- Permiability CoefficientDocument1 pagePermiability CoefficientJayesh2281No ratings yet

- Epoxy HandbookDocument80 pagesEpoxy HandbookJayesh2281100% (2)

- SSPC Paint System RecommendationsDocument3 pagesSSPC Paint System RecommendationsJayesh2281No ratings yet

- Viscosity Thixotropic IndexDocument3 pagesViscosity Thixotropic IndexJayesh2281No ratings yet

- Paint Processing ProcedureDocument1 pagePaint Processing ProcedureJayesh2281No ratings yet

- 4 Epoxy ResinsDocument12 pages4 Epoxy ResinsJayesh2281No ratings yet

- Electrical GlossaryDocument4 pagesElectrical GlossaryJayesh2281No ratings yet

- New Microsoft Office Excel WorksheetDocument2 pagesNew Microsoft Office Excel WorksheetJayesh2281No ratings yet

- Electrical GlossaryDocument4 pagesElectrical GlossaryJayesh2281No ratings yet

- System Three Epoxy BookDocument50 pagesSystem Three Epoxy Bookyunamierdapinchadaen100% (1)

- Viscosity Conversion Chart from Gardner to Stokes ScaleDocument8 pagesViscosity Conversion Chart from Gardner to Stokes ScaleJayesh2281100% (1)

- List of Veterinary Hospitals in IndiaDocument7 pagesList of Veterinary Hospitals in IndiaJayesh2281100% (2)

- Basic of PaintsDocument1 pageBasic of PaintsJayesh2281No ratings yet

- Lecture NotesDocument21 pagesLecture NotesMohamed Abdallah Elsheraiy Saad0% (1)

- CSP0000160-01 Accessory Equipment-Tab 1-14 PDFDocument531 pagesCSP0000160-01 Accessory Equipment-Tab 1-14 PDFDavid Saico CuracaNo ratings yet

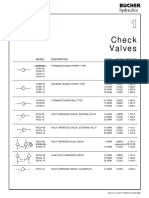

- 01 Check Valve Mini CatalogDocument50 pages01 Check Valve Mini Catalognemi90No ratings yet

- Hamdan - Sami Artifiscial Recharge of Groundwater With Stormwater As A New Water Resource - Case Study of The Gaza Strip PalestineDocument186 pagesHamdan - Sami Artifiscial Recharge of Groundwater With Stormwater As A New Water Resource - Case Study of The Gaza Strip PalestinePana EuNo ratings yet

- Venturi ScrubberDocument22 pagesVenturi ScrubberTanzeela RiazNo ratings yet

- USP Lab 4 SFEE Blower DuctDocument4 pagesUSP Lab 4 SFEE Blower DuctRoshiv Sharma0% (1)

- Total Solids Analysis in Water SamplesDocument10 pagesTotal Solids Analysis in Water SamplesSYaz WAniNo ratings yet

- Turbomachinery AnalysisDocument18 pagesTurbomachinery AnalysiskamalNo ratings yet

- Qiang Hydrostatic SpindleDocument14 pagesQiang Hydrostatic SpindleCamilla Gandine GoncalvesNo ratings yet

- ESP Design Calculation PDFDocument17 pagesESP Design Calculation PDFMohammed Abdul Moied100% (1)

- Suspension - Comparative Oil Weights Table-1Document8 pagesSuspension - Comparative Oil Weights Table-1Vennia PapadipoulouNo ratings yet

- Section 3 - Understanding & Analyzing Overpressure Scenarios Training 1.0.5.2 PDFDocument64 pagesSection 3 - Understanding & Analyzing Overpressure Scenarios Training 1.0.5.2 PDFFaiz Abdullah100% (1)

- HydraulicsDocument4 pagesHydraulicsyobroNo ratings yet

- 5-A (Fátima S)Document18 pages5-A (Fátima S)Fatima Sanchez LopezNo ratings yet

- Pump Performance Datasheet: Operating Conditions LiquidDocument4 pagesPump Performance Datasheet: Operating Conditions LiquidVaibhav SharmaNo ratings yet

- T-07 Retention PondDocument13 pagesT-07 Retention PondRirin UtariNo ratings yet

- Lecture-3-Fluid StaticsDocument48 pagesLecture-3-Fluid StaticsSyed WasimNo ratings yet

- NPSH Calculator Single Pump ApplicationDocument10 pagesNPSH Calculator Single Pump ApplicationKali Dass KMNo ratings yet

- Water Transmission and Distribution SystemsDocument71 pagesWater Transmission and Distribution SystemsDr. Akepati Sivarami Reddy100% (6)

- Drainage System: by Asst. Professor S.Kumar Budha College of ArchitectureDocument31 pagesDrainage System: by Asst. Professor S.Kumar Budha College of ArchitecturemimahmoudNo ratings yet

- Predicting The Performance of An Industrial Centrifugal Fan Incorporating Cambered Plate Impeller BladesDocument12 pagesPredicting The Performance of An Industrial Centrifugal Fan Incorporating Cambered Plate Impeller BladesEtvan TvanNo ratings yet

- Centrifugal PumpDocument44 pagesCentrifugal PumpAmishaan KharbandaNo ratings yet

- Flow Lab Experiments Boundary Layers & Pressure ProfilesDocument4 pagesFlow Lab Experiments Boundary Layers & Pressure ProfilesgetsweetNo ratings yet

- Failure of WeirsDocument2 pagesFailure of WeirsBernard PalmerNo ratings yet

- A Spherical Particle Is Falling Slowly. in A Viscous Liquid Such That Reynolds Number Is Less Than 1. Which Statement Is Correct For This Situation?Document6 pagesA Spherical Particle Is Falling Slowly. in A Viscous Liquid Such That Reynolds Number Is Less Than 1. Which Statement Is Correct For This Situation?Aduchelab AdamsonuniversityNo ratings yet

- Primary consolidation settlement calculations for varying liquid limitsDocument11 pagesPrimary consolidation settlement calculations for varying liquid limitsAnkush JainNo ratings yet

- 330B and 330B L Excavators Hydraulic System: 330B: 8SR1-UP 330B L: 8TR1-UP 1JS1-UP 1KS1-UPDocument2 pages330B and 330B L Excavators Hydraulic System: 330B: 8SR1-UP 330B L: 8TR1-UP 1JS1-UP 1KS1-UPsandrayaniNo ratings yet

- Amca 200-95 (R2011)Document59 pagesAmca 200-95 (R2011)johnb1978No ratings yet

- Lecture 4 Finite Difference PDFDocument96 pagesLecture 4 Finite Difference PDFMega GamesNo ratings yet

- ME8694 HydraulicsandPneumaticsQuestionBank PDFDocument15 pagesME8694 HydraulicsandPneumaticsQuestionBank PDFVikram mNo ratings yet